5 | P a g e

NOVA/ G-2000/ G-1500 – BASIC ADJUSTMENTS

A. ADJUSTING MOTOR LIMIT SWITCHES

NOTE: The motor limit switches have been adjusted to the correct position at the

factory prior to shipment. The awning motor is set to stop the exact moment the

awning box closes. The fabric should be taut, the arms should be slightly bent,

exposing a 1/4” gap at the elbows.

Always check the motor limits after installation to ensure that the awning opens

and closes correctly. Awning fabric can stretch over time, this will require an

adjustment of the OUT limit switch.

IMPORTANT: EXTREME CARE SHOULD BE TAKEN TO ENSURE THAT THE MOTOR LIMIT

TURNS OFF AT THE EXACT MOMENT THE AWNING BOX CLOSES. FAILURE TO DO SO

WILL CAUSE THE MOTOR TO RUN WHEN THE AWNING IS CLOSED. THIS CAN

SUBSTANTIALLY REDUCE THE LIFE OF THE MOTOR.

1. The AC motors used in Girard Systems awnings are reversible. Any

reference made to the motor limit switches in these instructions are based

on the right-hand placement of the motor. For left hand placement,

simply reverse the instructions. (Figure 8)

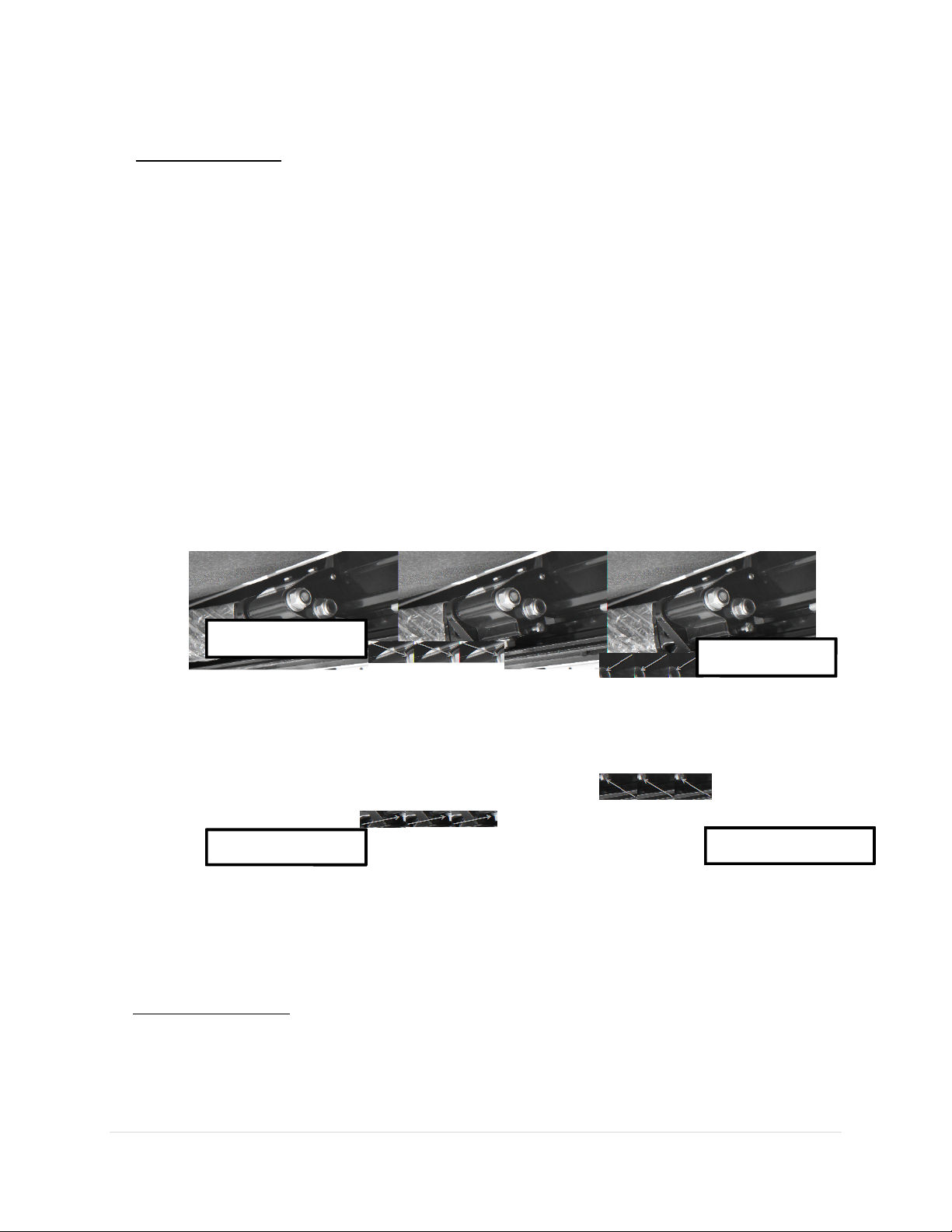

2. The motor has limit settings for both OUT (extension) and IN (retraction).

3. Adjust the limit switches with the black key provided with the awning, or

you may use a 4mm (5/32”) allen wrench.

4. Extend the awning a few feet to gain access to the motor. Locate the

motor (standard installation is on the right hand side of the awning). The

limit adjustment holes are located on the head of the motor. Using the

symbols printed next to the adjustment holes, turn the black key (or 4mm

allen wrench) to make the necessary adjustments. Typically, the motors

are labeled with a (+) or a (-). (Figure 9)