Page 8

DESIGN

SYSTEM DESIGN

General

• All Torrent HP models covered by this manual, are only suitable for open vented

primary (heat pump and space heating) circuits. Therefore the pressure in the

primary circuit depends upon the height of the feed and expansion cistern and

could be as low as 0.20 bar. Therefore ensure that the heat pump selected will

operate at primary circuit pressures e.g. it is not fitted with a non-adjustable low

system pressure switch.

• The heat pumps normally operate at lower temperature difference (5-10°C)

betweenflowandreturnthanthatforagasboilers(10-20°C)resultinginhigherflow

rates in the heat pump primary circuit. Therefore it is important that the primary

pipeworkconnectingtheheatpumptothethermalstoreandthecirculatingpump

are sized to achieve flow rates recommended by the heat pump manufacturer.

• The efficiency (i.e. coefficient of performance, COP) of a heat pump depends

upontheprimaryflowandreturntemperaturesanditisgenerallyhigheratlower

primarycircuittemperatures.Alsotheheatpumpsnormallyoperateatlowerflow

temperatures;typically45-55°Ccomparedwith75-80°Cforgasboilers.Thereforeif

traditionalradiators areusedthen, theseshouldbe oversizedinaccordance with

the heat pump manufacturers recommendations.

• For optimum operational efficiency and hence lower running costs, a low

temperaturespaceheating(e.g.under-floorheating)systemshouldbeusedwhere

feasible.

Heat Pump Sizing

• The efficiency (i.e. coefficient of performance, COP) of an air source heat pump

and hence its heat output generally decreases as the ambient air temperature

decreases. Therefore, this factor should be taken into account when sizing and

selecting the heat pump.

• The design space heating load of a dwelling should be calculated in accordance

with BS 5449. The allowance for domestic hot water heating (shown in table

below),dependsupontheoperatingmode.Forexample,ifthesystemisdesigned

to operate with priority for domestic hot water, then no additional allowance for

hot water is required for sizing the heat pump.

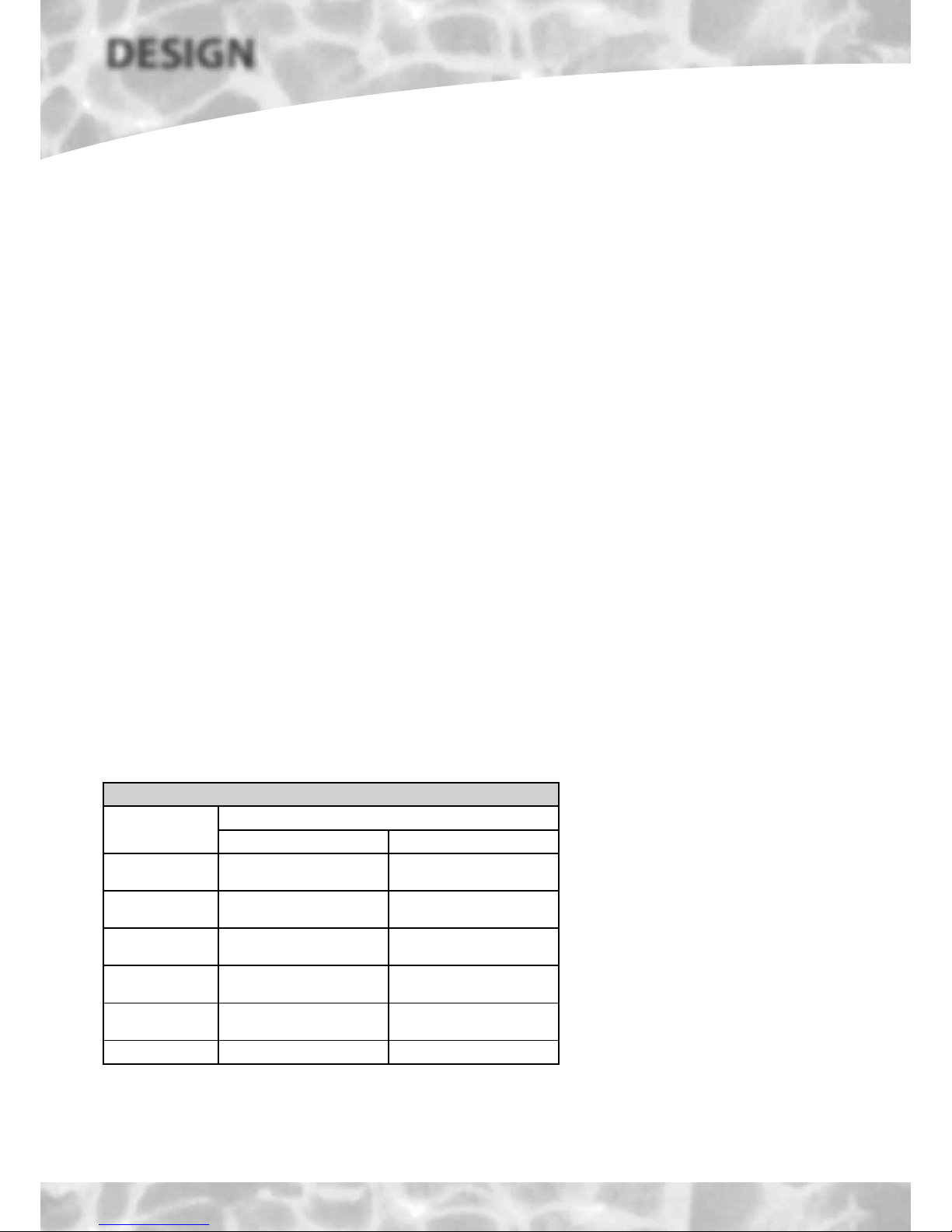

Allowance for Domestic HotWater Heating

Model Allowance for Domestic HotWater

HotWater Priority Mode Flow Share Mode

THP150

THP180-SOL 0kW 1.5kW

THP180

THP210-SOL 0kW 2.5kW

THP210

THP250-SOL 0kW 3.0kW

THP250

THP300-SOL 0kW 3.5kW

THP300

THP450-SOL 0kW 4.0kW

THP450-SOL 0kW 5.0kW

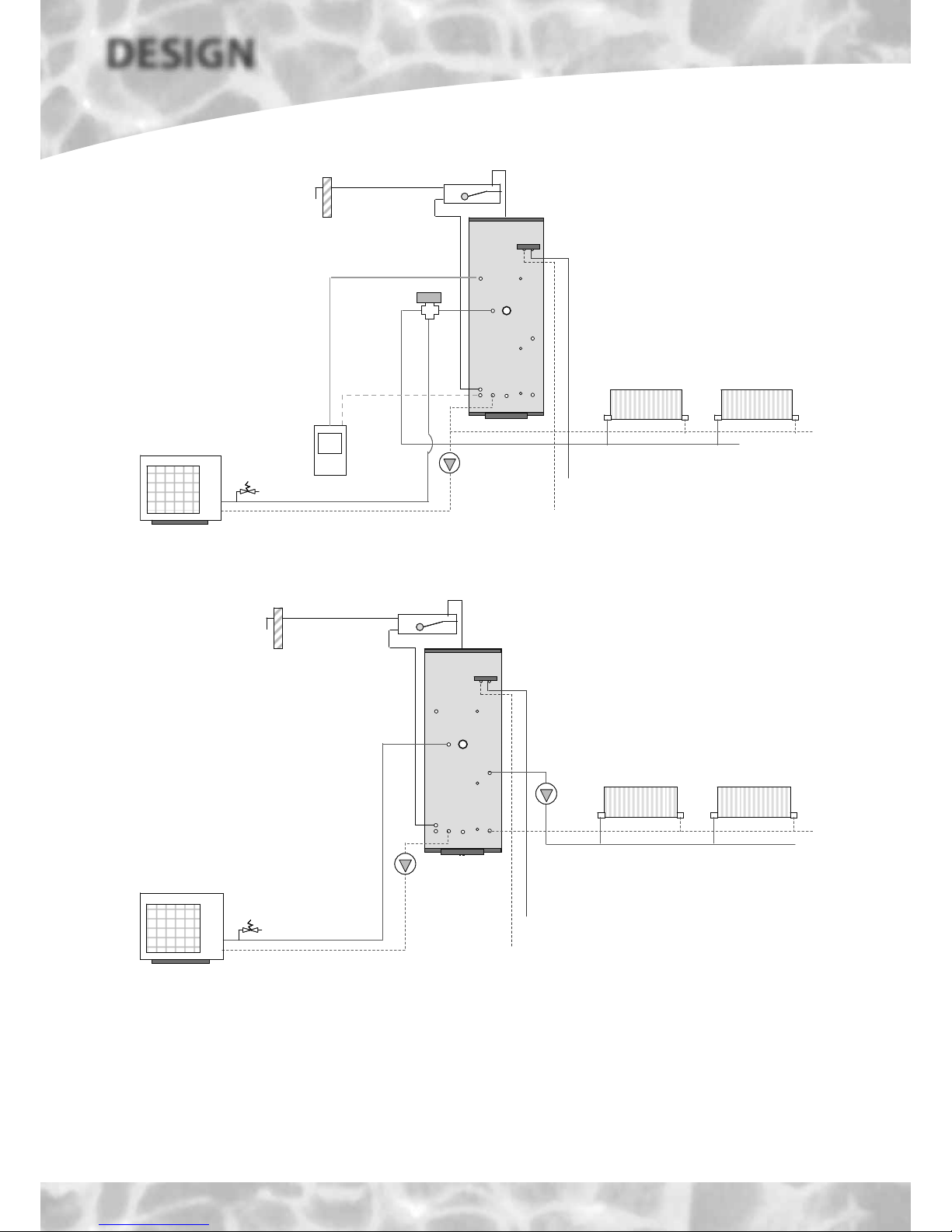

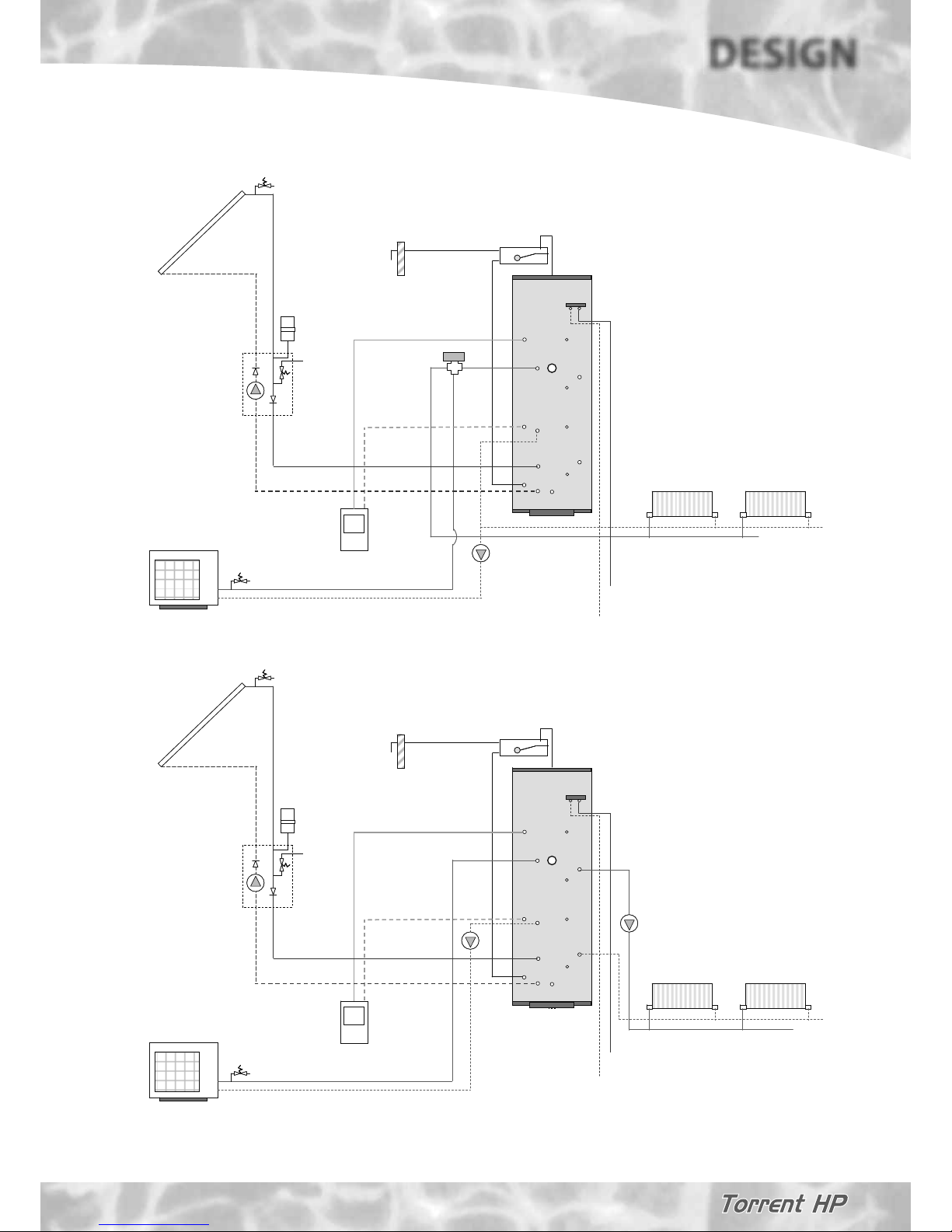

Heating System Arrangement

The Torrent HP models are designed to be

heated directly by an air or a ground source

heat pump and the space heating can be

supplied directly from the heat pump circuit

asshowninfigures6and8orfromthethermal

storeasshowninfigures7and9.Theselection

betweenthetwooptionswilldependuponthe

operating characteristics of the heat pump,

type of heating system and control strategy.

For general guidance: -

• If the heat pump requires a buffer for

operation; for example to reduce rapid

cycling etc, then the system would benefit

if the heating system is supplied from

the thermal store (figures 7 and 9). In

this configuration, the operation of the

heat pump Is only controlled by the store

thermostat(s).

• Iftheheatpumpismulti-stageormodulating

typeorhasweathercompensatingcontrols,

then the space heating circuit should be

supplied directly from the heat pump as

shown in figures 6 and 8. In this system

configuration,thethermalstoreisonlyused

for producing hot water.

• A hybrid system arrangement can also

be used (not shown). For example; a low

temperatureweathercompensatedheating

circuit e.g. under floor heating can be

supplieddirectlyfromtheheatpumpcircuit

andconstanttemperaturee.g.towelrailscan

be supplied from the thermal store.

Ballvalve/overflow - All Models

Where the whole of the heating system is

supplied from the thermal store,figures 7 and

9,thenaballvalveandoverflowshouldbefitted

in the feed and expansion tank.

Where the heat pump supplies the heating

circuit directly, figures 6 and 8, then fitting a

ballvalveandoverflowisoptionalifitispractical

onoccasionstomanuallyfillthestore.However,

fittingaballvalveandoverflowwilleliminatethe

needforthehouseholdertoundertakethistask

and is therefore preferable.If the siting of the

Torrent HP makes it difficult to fit an overflow

then the‘manual fill’option can be used.In all

cases,if a ballvalve is fitted,then an overflow/

warning pipe must always be fitted.