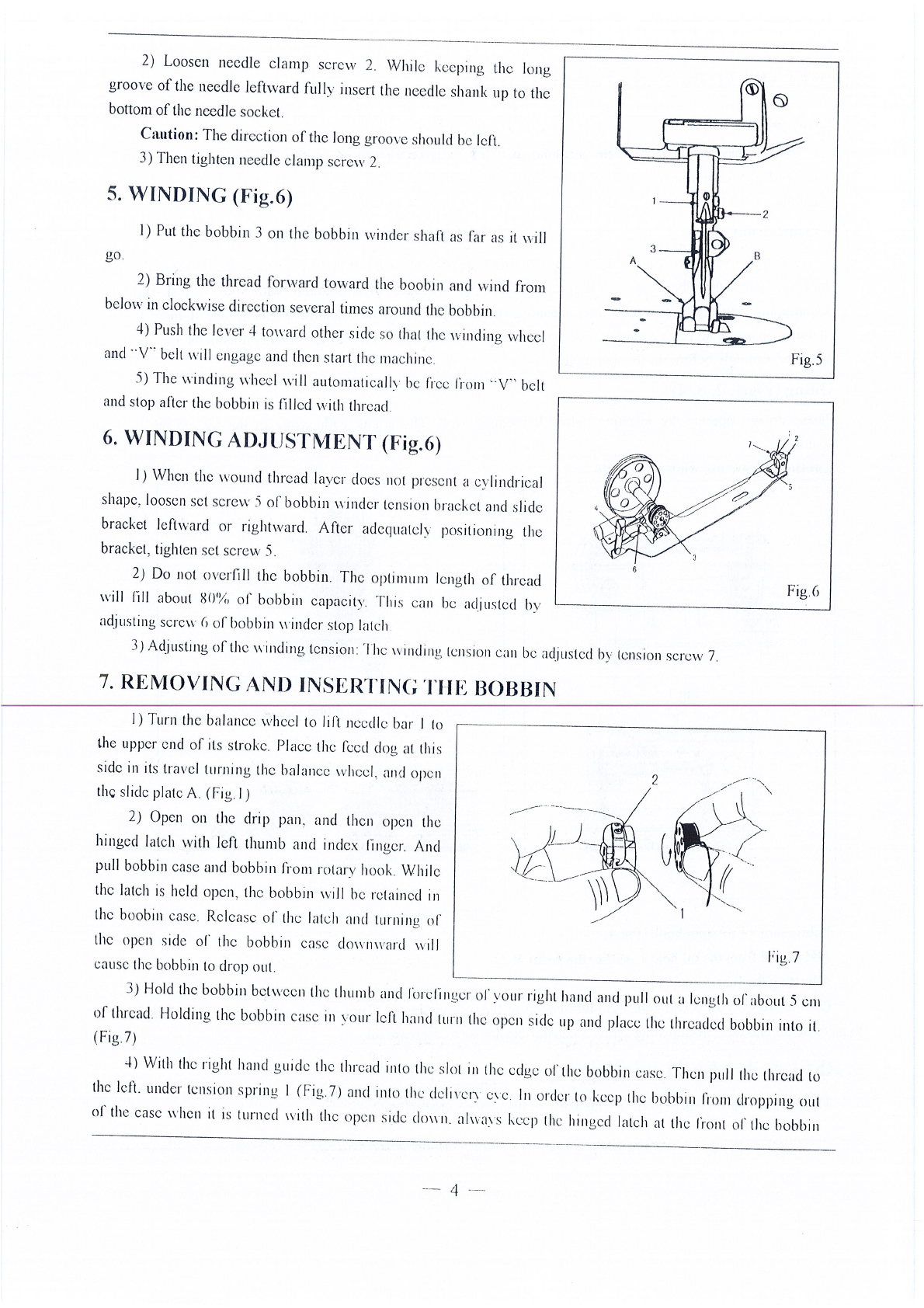

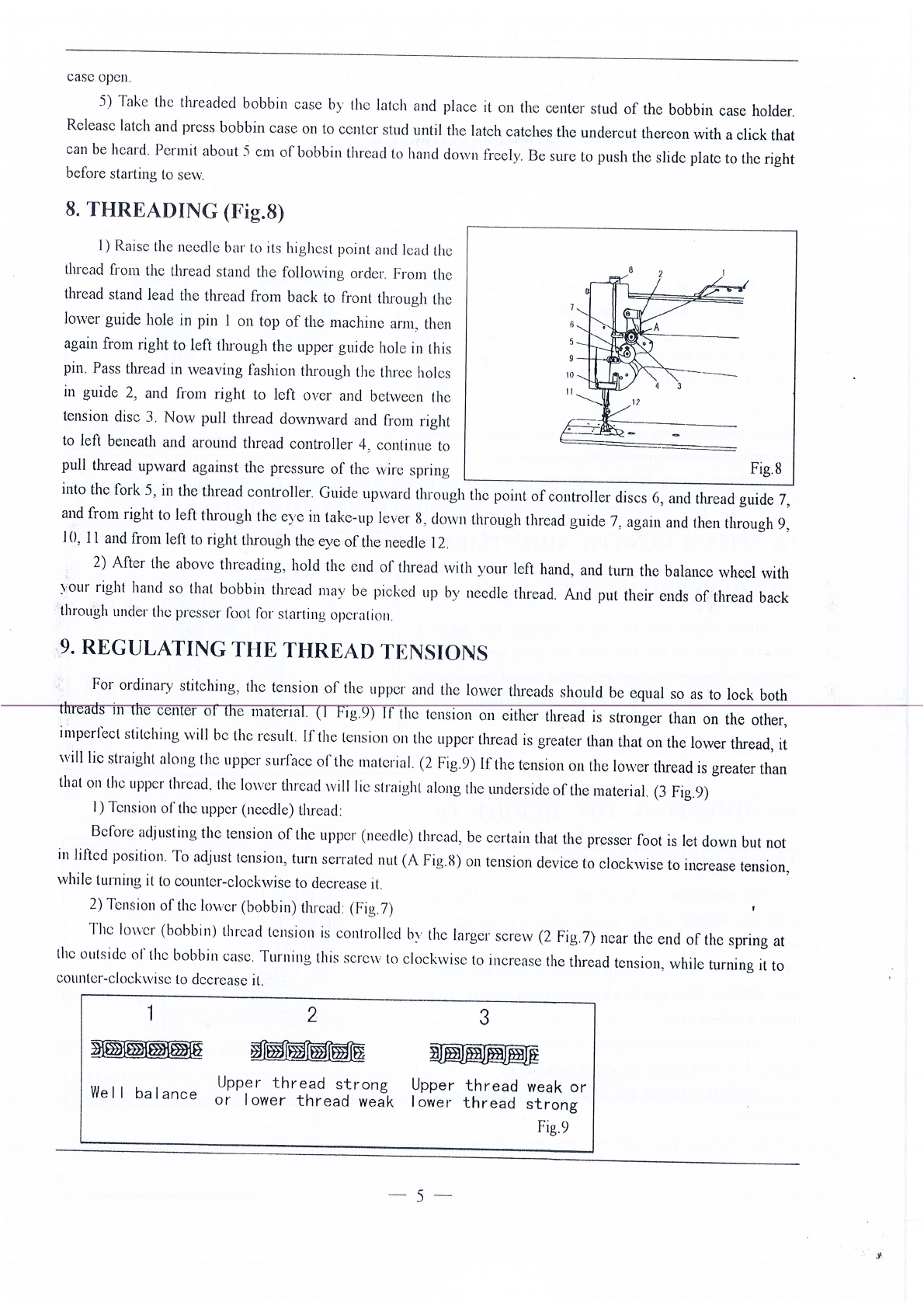

17.

ADJUSTING THE HEIGHT

OF

THE

NEEDLE

BAR

(Fig.17)

When

the needle bar

is

at its highest point, normally the measurement between the smface of the needle

plate

and

the

upper

end

of

th

e needle eye

is

22

.3

mm.

You

can also adjust

thi

s

at

it

s lowest point. I

11

thi

s case, normally

the

measureme

nt

betv,ecn the surface of

the

needle plate and the upper end

of

the needle eye

is

11

mm.

To

adjust this, loosen the screw

J

(Fig.3) and raise

or lower the needle bar

as

may be required. Then, tighten the screw upon completion

of

adjustment.

NOTE: These measurements are approximate standard, accordingly, following final adjustments "TIMING

BETWEEN THE HOOK AND THE NEEDLE" are

reco1m11ended.

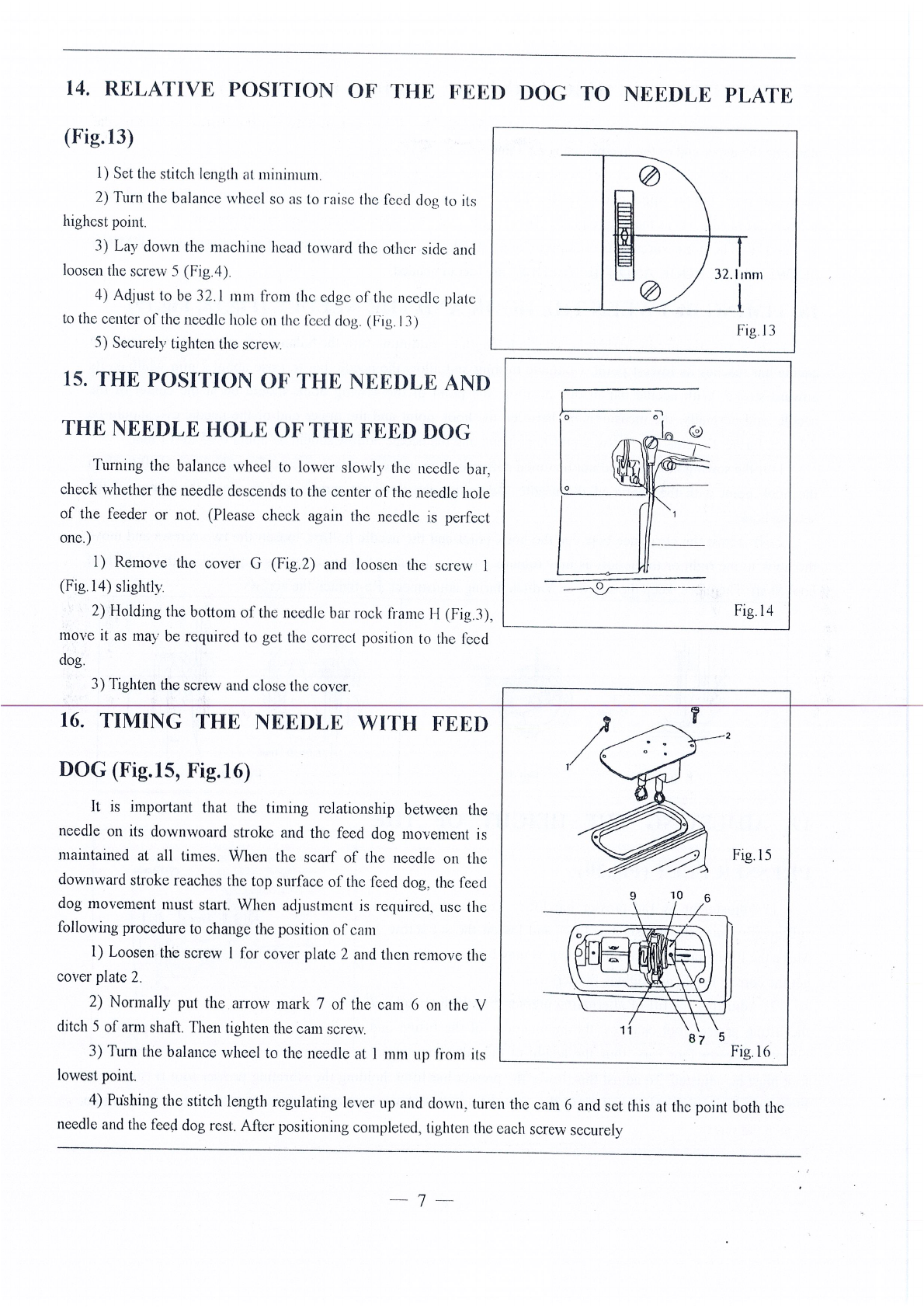

18.

TIMING BETWEEN THE HOOK

AND

THE

NEEDLE (Fig.18, Fig.19)

After setting the needle barheight, set stitch length lo minimum, turn the balance ,vheel toward you

until

the

needle bar reaches

its

lowest point. Continue tnrning and allow the needle bar

to

raise about 2 mm while on its

upward stroke. With needle bar

in

thi

s

p1.,

,

,1lion

,

the

point

of

the sewing hook should be

at

the center

of

the

needle,

and

normally, the measurement bet\veen

th

e hook point and the upper end

of

the needle eye should be

2.4

mm,

further the clearance betwe

en

the

hook

point

and

the needle hollow should be about

(l.05

to

OI

nun.

1)

If

the sewing hook should not be timed correctly, loosen the three set screws. Tum the hook shaft

to

align

the

hook

point with the center

of

the needle. Re-tighten the three set screws and re-check the timing

of

the

se\.ving

hook

.

2)

To

adjust the clearance between the hook point and the needle hollow, loosen the two screws

and

move

the

hook

to

the right or

to

the left

as

may

require. Please note one

of

the

two screws

is

placed on the V ditch

of

hook

shaft. Therefore, keep the screw

on

V ditch during adjustment. Re-tighten the acrews.

22

1rrm

===~=_l

Fig.17

Fig

18

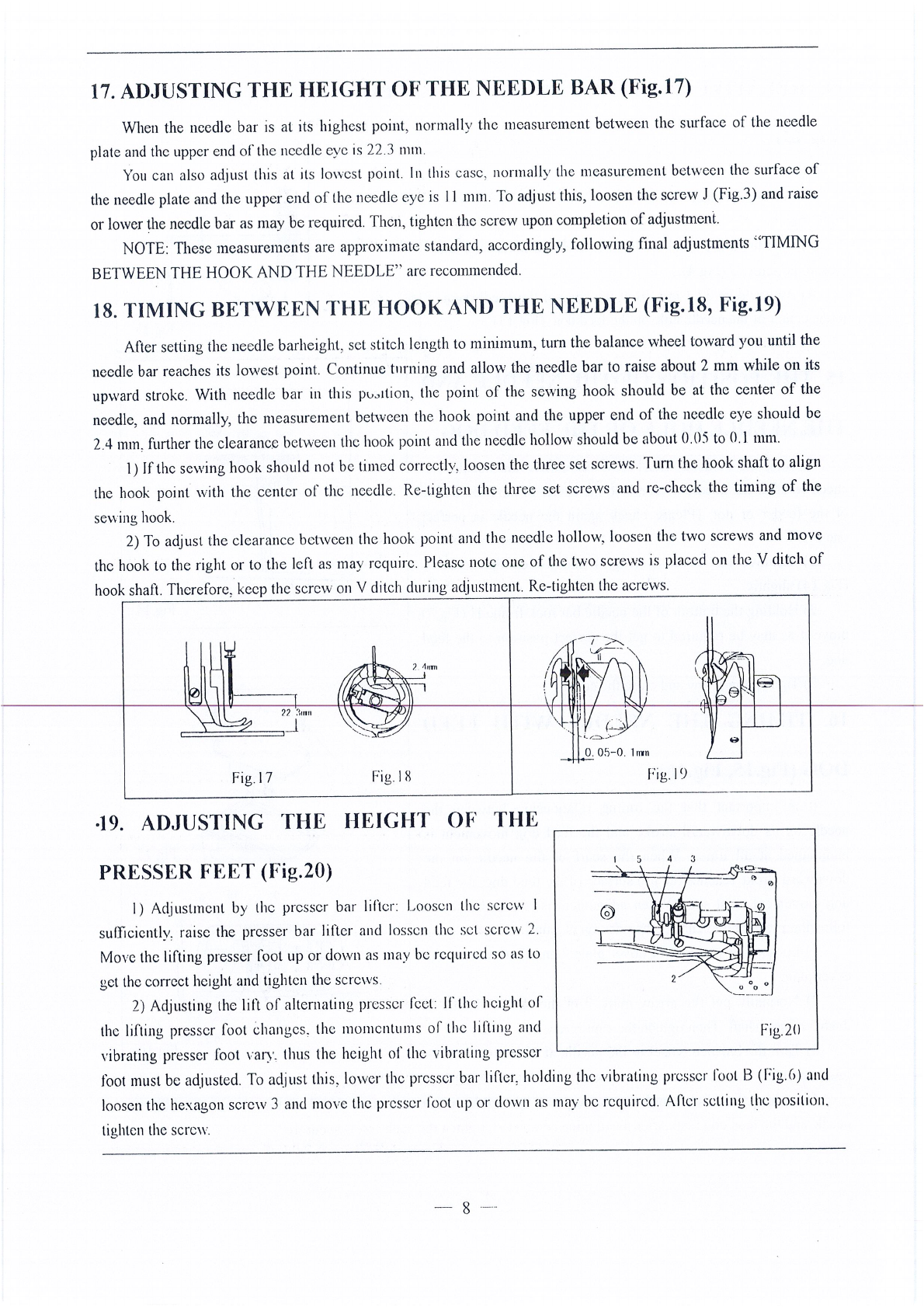

-19.

ADJUSTING THE HEIGHT

OF

THE

PRESSER

FEET

(Fig.20)

1)

Adjustmcnl

by

the presser

bc1r

lifter:

Loo

s

en

the screw I

sufficiently, raise the presser

bc1r

lifter and lossen the set screw 2.

Move

the lifting presser foot

up

or down

els

mc1y

be

required so

as

to

get

the

co1Tect

height and tighten the screws.

2) Adjusting

the

lift

of

allernating

pre

sser

fe

el If

th

e height

of

the

lifting presser foot changes, the momentums

of

the lifting

and

vibrating presser foot vary, thus the height of

th

e vibrating presser

Fig

.

19

5 4 3

Fig.20

foot

must be adjusted.

To

adjust this, lower the presser bar lifter, holding the vibrating presser

l'ool

B

(Fig.(>)

and

loosen the

hexc1gon

screw 3 and move the presser

foot

up

or down

as

nwy

be

required. After selling the position.

lighten

the

screw.

--

8 - -

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com