~

}R,

Table

of

Contents

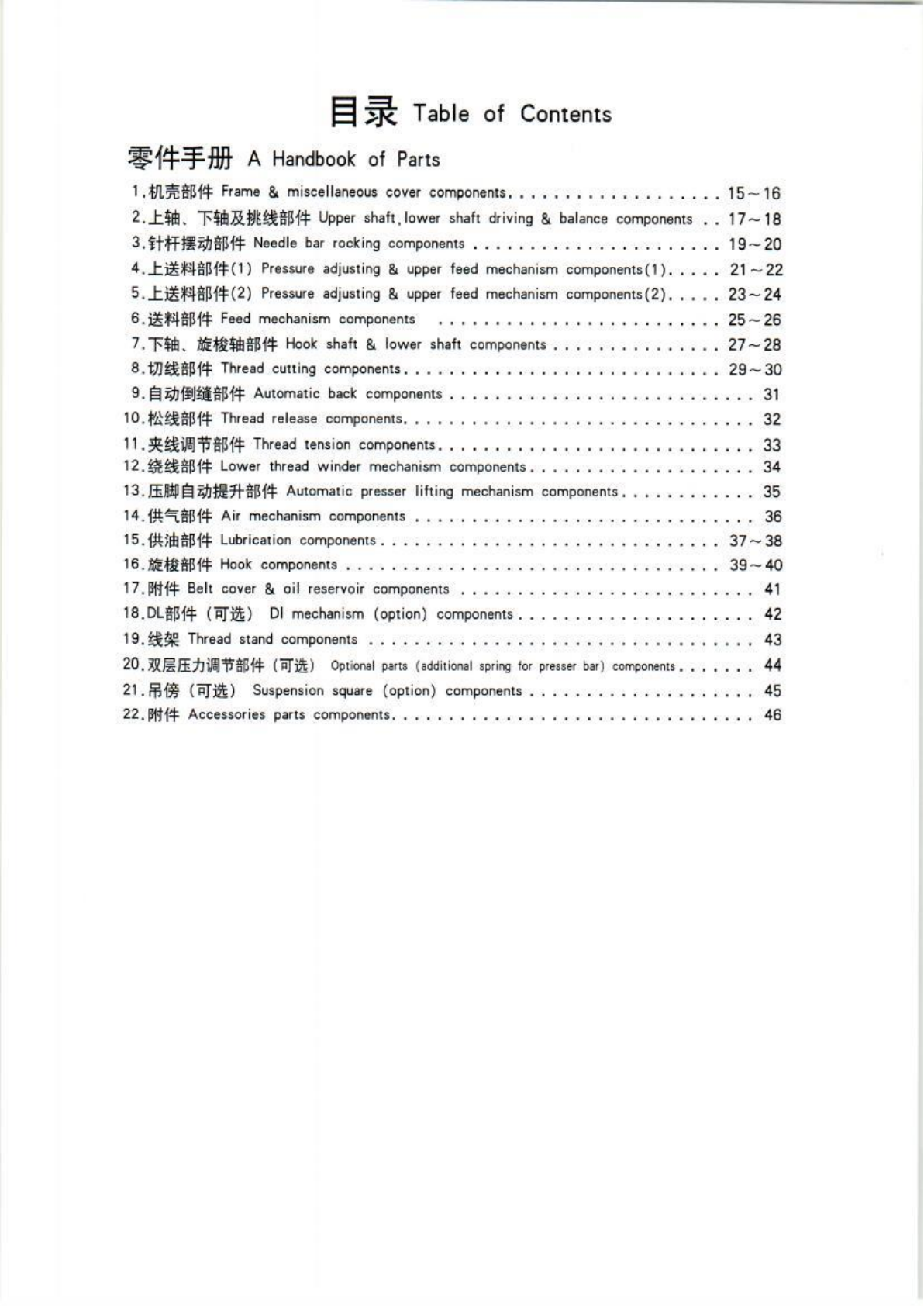

~14:~HJ}

A Handbook

of

Parts

1

.m~ll1lf!f:

Frame & mi

sce

ll

aneous cover components, , , , , , ,

..

, ,

....

..

•.

15-16

2.

..t*III-

7'$1b&#t~Uaf!f:

Upper shaft

.l

ower shalt drivi

ng

& balance components

..

1

7-18

3,

Hfflli;IJf!Bflf Needle bar rocking components .

...........

, , , . , , . . . .

19

-

20

4 .

..ti3JlilHIBflf(1)

Pressure adjusting & upper feed mechanism components

(!)

.....

21-22

5.

..tiisJ!illf!Bf!f:(2)

Pressure adjusting & upper feed mechan

ism

components

(2)

..•.

,

23-

24

6.

iliifllfillf/j:

F

ee

d m

ec

hanism components , ,

.....

, ,

...

, . ,

......

.. ..

25-

26

7.

"f$i!i.

~~$$$#

Hook

shaft & lower shaft components

......

•

........

27-

28

8.

tJJ!iilBf!f:

Thread cutti

ng

components. . . . . . . . . . . . . . . . . . . • . . . . . . . .

29-

30

9.

ia'll

i;IJ1JIJ!jf

ftl!f/j:

Automatic back components . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

10.

fl!i

li

llf!

!' Thread release components

.................

.

.........

.

...

32

11.*ti!t

iJll'i,i!IJ

flj:

Thread tension components

.........

, . ,

..

, , . , , , , , , , . . . .

33

12.

~!<!!HfBf!j:

Lower thr

ea

d winder mechanism components

..................

. .

34

13.

ffi.1!!11

la'll

i;li:!ift-ll1lf!f:

Automatic presser lifti

ng

mechani

sm

components. . . . . . . . . . . .

35

1

4.

f~~l!Bflf

Air

mechanism components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

15.

fjtilhl!Bflf

Lu

brication components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

-

38

16.;!ri~$f!j:

Hook

components . .

...

.

......

.

.....

.......

.

..

...

. .

39-40

17.

~H!f:

Be

lt

cover &

oi

l reser

voir

components . . . . . • . . . . . . . . . . • . . . . . . . . .

41

18.DLl!B

flf

(ia]"il\;)

DI mechanism (option) components

.•......

, , , . ,

...

.....

42

19.

ii~

Thread

sta

nd

components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

20.~~.ffifl/M,;aflft

(j;j'~)

Optional part• (additional spring for presser bar)

components,,

, , , , ,

44

21.

/iH~

(ia]"~) Suspension

sq

uare (option) components

..........

.

.........

45

22.

~tf'f Accessories parts components. . . . . . . . . . . . . . . • . . . . . . •

....

,

...

,

46

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com