10

GB

General Safety

WARNING Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, re and/or serious injury.

WARNING: This appliance is not intended for use by persons (including children) with reduced, physical

or mental capabilities or lack of experience or knowledge unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children must be

supervised to ensure that they do not play with the appliance.

Save all warnings and instructions for future reference.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids,

gases or dust.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

2) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

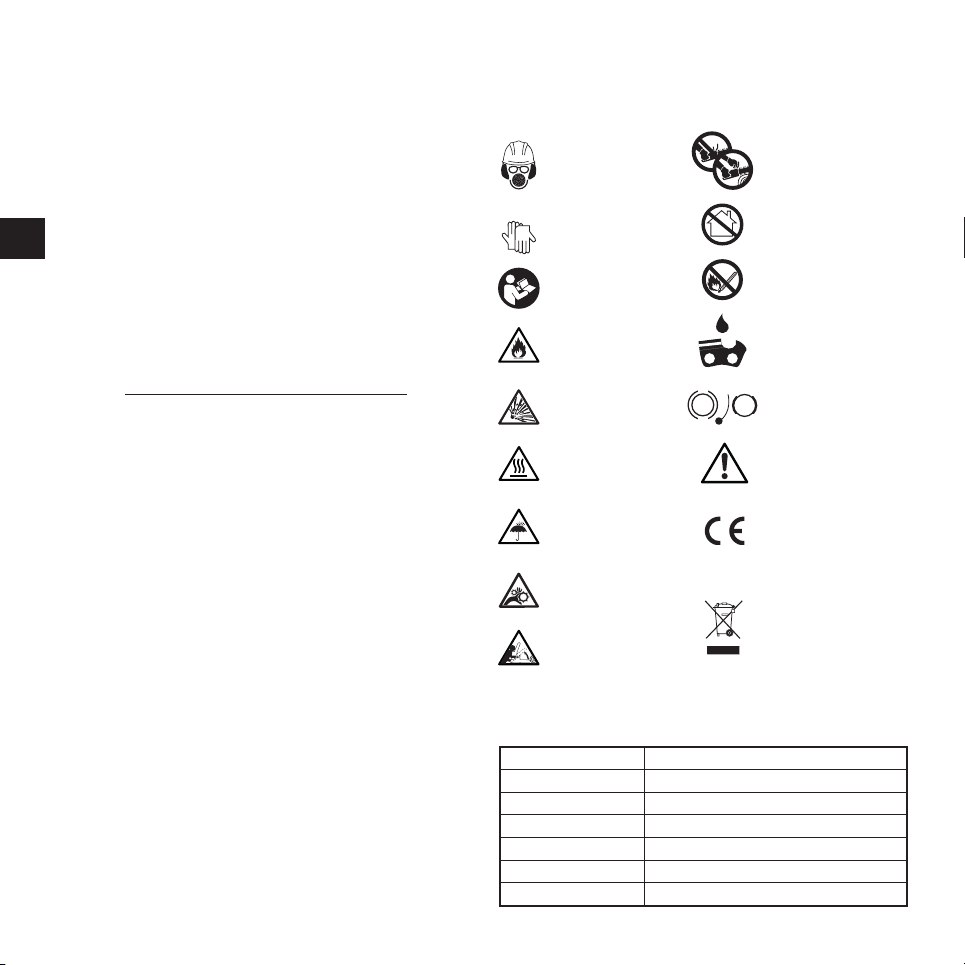

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position when not operating the tool and

make use of other safety features which prevent unintentional starting

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

WARNING: User exposure to tool vibration can result in loss of sense of touch, numbness, tingling and reduced

ability to grip. Long term exposure can lead to a chronic condition. If necessary limit the length of time exposed

to vibration. Use the gures provided in the specication relating to vibration if provided to calculate the duration

and frequency of operating the tool. The 2002/44/EC directive relating to vibration in the workplace may provide

useful information even for domestic use of tools. In the rst instance of feeling uncomfortable due to vibration

STOP using the tool immediately.

WARNING: Always wear ear protection where the sound level exceeds 85dB(A) and limit the time of exposure

if necessary. If sound levels are uncomfortable even with ear protection stop using the tool immediately and

check the ear protection is correctly tted and provides the right level of sound attenuation for the level of sound

produced by your tool.

3) Use and care

a) Maintain tools. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the tool’s operation. If damaged, have the tool repaired before use. Many

accidents are caused by poorly maintained tools.

b) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

c) Use the tool’s accessories and tool bits etc. in accordance with these instructions, taking into

account the working conditions and the work to be performed. Use of the tool for operations different

from those intended could result in a hazardous situation.

4) Service

a) Have your tool serviced by a qualied repair person using only identical replacement parts. This will

ensure that the safety of the tool is maintained.

Internal Combustion Engine Safety

Dangerous environment

• DO NOT use petrol tools in damp or wet conditions, or expose them to rain. Provide adequate surrounding

work space and keep area well lit.

• DO NOT use petrol tools where there is a risk of explosion or re from combustible material, ammable

liquids, ammable gases, or dust of an explosive nature

Switch off

• Ensure that the engine has stopped before attaching any accessories to the tool

• If the tool stops unexpectedly ensure that the power is switched off and the engine is not running before

attempting to check the tool

Running-in the engine

• New tools should be used at moderate speed

• DO NOT maintain high engine speed until the engine is completely run-in

• The engine will not be capable of developing maximum power until the end of the running-in period

• When rst using the tool, periodically stop and check that all nuts and screws are securely fastened and

tighten them as necessary

• DO NOT use fuels containing methanol or ethanol, as these may cause internal damage to the fuel tank

and fuel lines

Warning

• NEVER leave the tool running unattended

• NEVER leave the machine unattended when parts are still hot

Servicing

• We recommended that your tool is serviced shortly after its rst use

• In normal use, have the tool serviced regularly

• DO NOT modify any of the components of this tool. To do so would invalidate your guarantee, and could

result in injury to yourself or others around you

• ALWAYS have your tool serviced at an authorized service centre

Storage

• Clean the tool completely after use

• Be careful not to damage the fuel tank, or fuel lines, when it is placed on the ground

• Ensure that the tool will not be subject to impact damage; any damage could cause the tool to become

unsafe

• Store the tool away from direct sunlight

• Ensure that fuel and oil is stored in a safe place, away from heat, direct sunlight or any source of ignition

• Whenever the machine is likely to be out of use for an extended period of time, proceed as follows:

• Empty the fuel tank completely

• Protect all metal engine parts from corrosion by coating them with oil

• Remove the spark plug, put a few drops of oil into the cylinder and then pull the recoil starter 2 to 3 times in

order to distribute the oil evenly

• Replace the spark plug

• Never store the machine where children may gain access to it

Chain Saw Safety

WARNING: Chainsaws are potentially dangerous machines which can cause major injury if used by untrained

people

• DO NOT allow children or pets near the work area

• Check that other people are a safe distance away from your work area before starting to cut. When tree

felling, all other people should be a minimum distance equal to twice the height of the tree away

• DO NOT work alone. Always ensure that there is someone nearby to help in an emergency

• DO NOT use this product in wet conditions. Ensure that material to be cut is dry before starting work

• Use of this tool requires the use of gloves, eye/face protection, dust mask, ear defenders, hard hat, and

sturdy clothing

698995_Z1MANPRO1.indd 10 19/12/2014 10:28