Contents

SECTION 4 OPERATION INSTRUCTION ..............................................................................

4.1 General ......................................................................................................................................

4.2 Machine Operation....................................................................................................................

4.2.1 Drive operation........................................................................................................

4.2.2 Platform leveling.....................................................................................................

4.2.3 Platform rotating .....................................................................................................

4.2.4 Turntable slewing ....................................................................................................

4.2.5 Raise and lowering the upper boom........................................................................

4.2.6 Telescoping the upper boom....................................................................................

4.2.7 Raising and lowering the tower boom.....................................................................

4.2.8 Raising and lowering the jib....................................................................................

4.2.9 Emergency stop.......................................................................................................

4.2.10 Manual Emergency Lowering System (GB version) ............................................

4.2.11 Auxiliary Power (CE version) ...............................................................................

4.2.12 Shut down and park...............................................................................................

4.3 Transport and Lifting.................................................................................................................4

4.3.1 Release the brake while towing...............................................................................4

4.3.2 Lifting......................................................................................................................4

4.3.3 Securing the chassis ................................................................................................4

4.3.4 Securing the platform..............................................................................................4

SECTION 5 MAINTENANCE ....................................................................................................

5.1 General ......................................................................................................................................

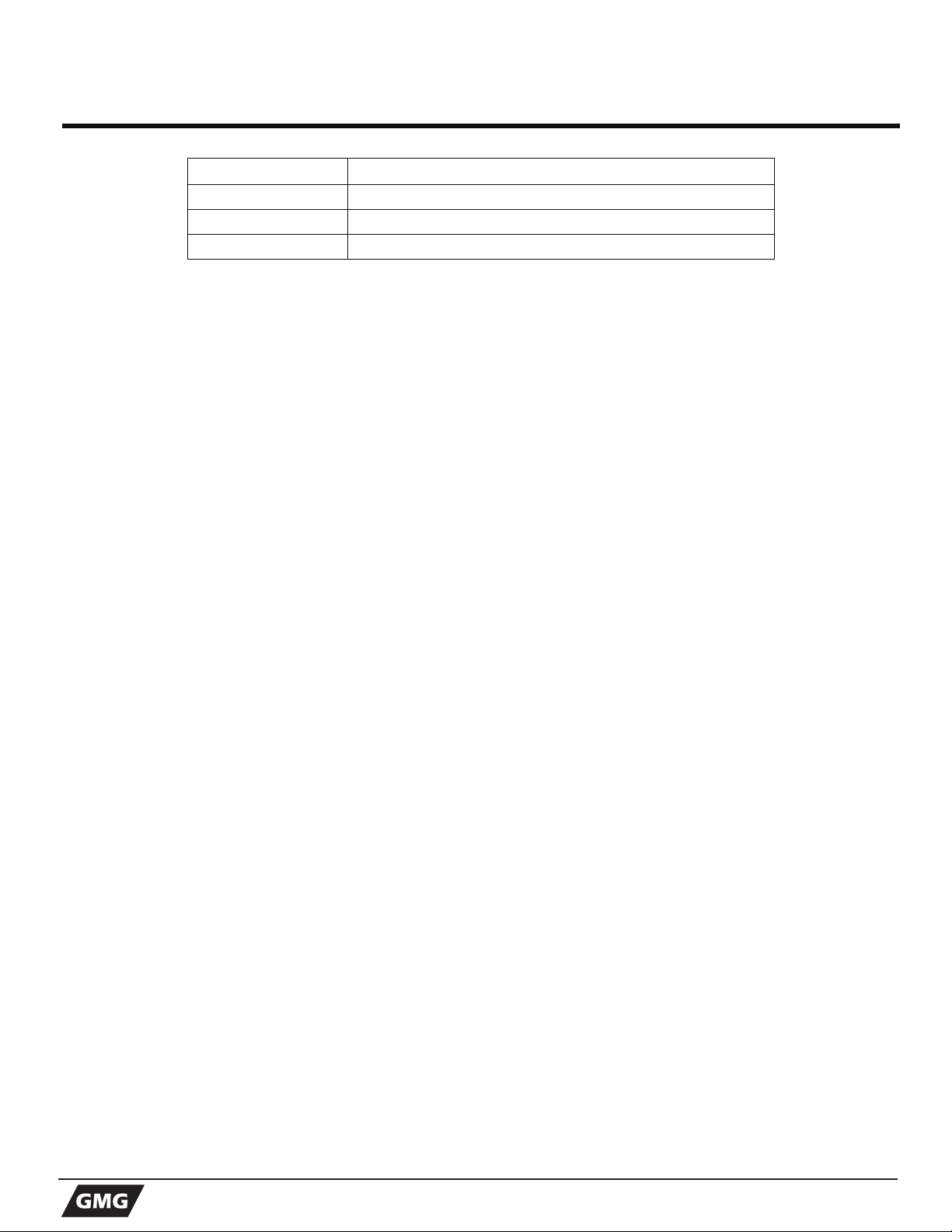

5.1.1 Maintenance symbols legend ..................................................................................

5.1.2 Pre-start inspection..................................................................................................

5.1.3 Maintenance hazards...............................................................................................

5.1.4 Body injury hazard..................................................................................................

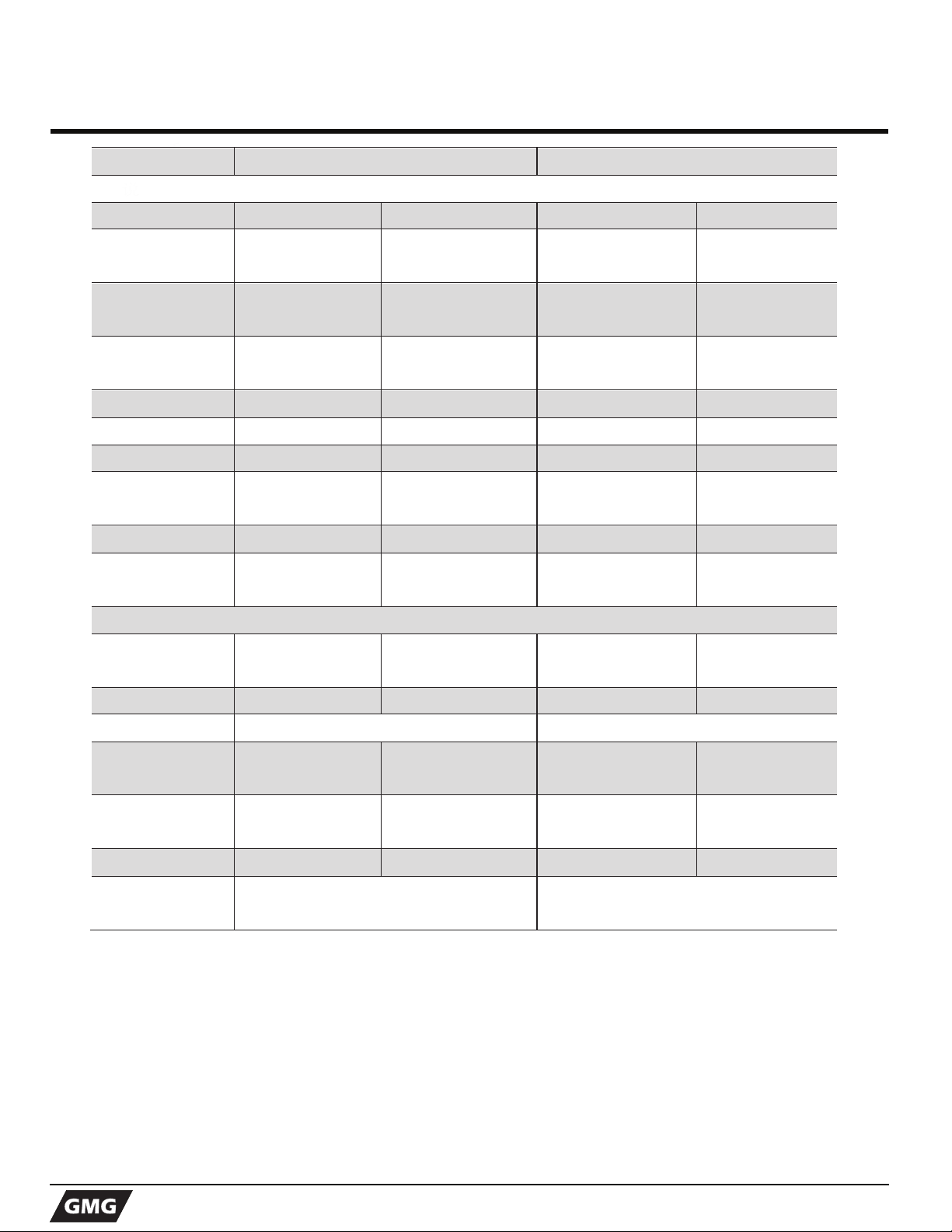

5.2 Power and Hydraulic system maintenance................................................................................

5.2.1 Check hydraulic oil .................................................................................................

5.3 Battery Maintenance..................................................................................................................

5.4 Regular Maintenance.................................................................................................................

5.5 Tire and Wheel ........................................................................................................................

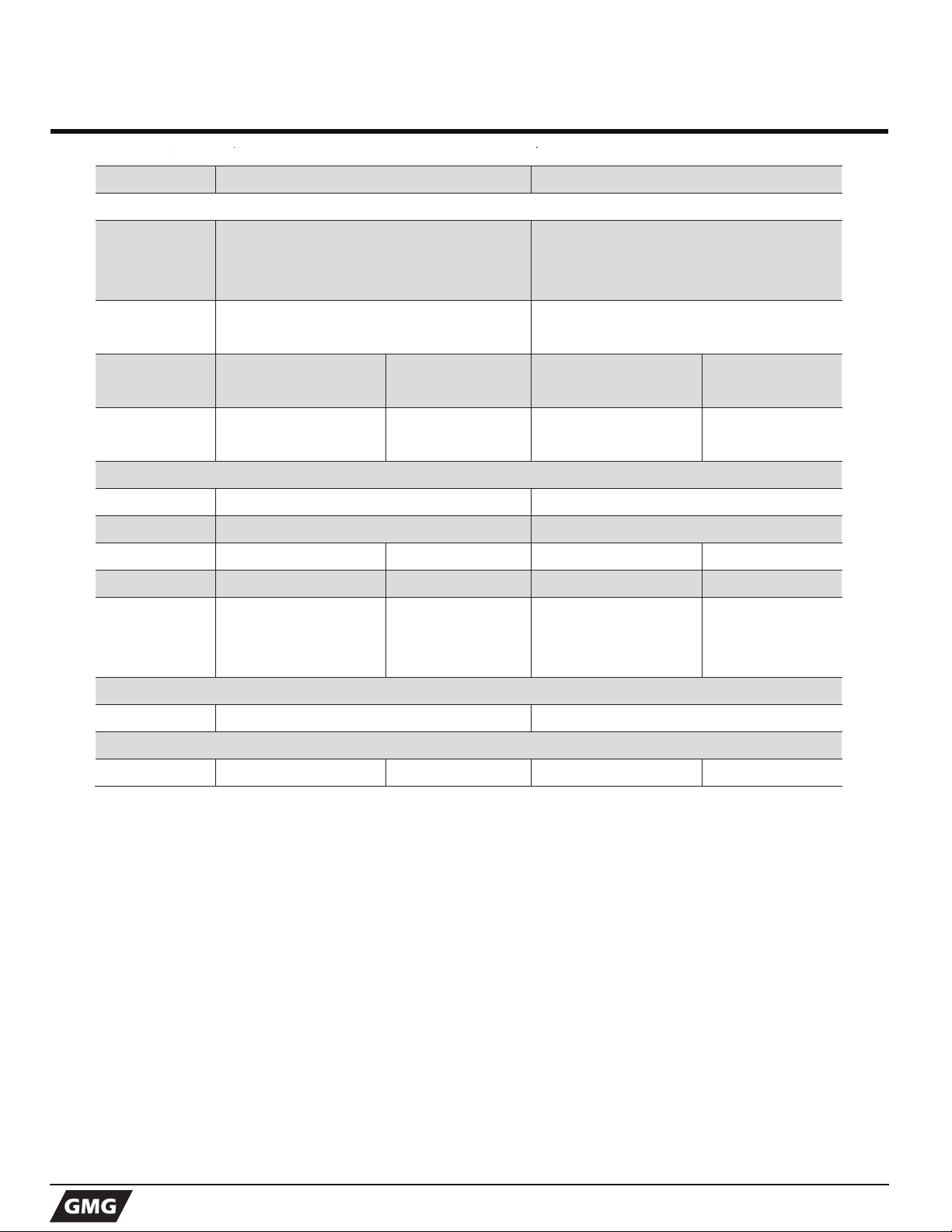

SECTION 6 0DFKLQH)DXOW&RGH5HIUHQFH ..............................................................

6.1 )DXOW&RGH/LVW ....................................................................................................................

$-(%RRP/LIW2SHUDWRU¶V0DQXDO

.1 Storage Conditions ....................................................................................................................

%RRP/LIW$QQXDO,QVSHFWLRQ............................................................................................................

SECTION STORAGE AND EX-FACTORY TEST ................................................................6