GMT 050 User manual

2

Contents

1. General ............................................................................................................................................................ 3

1.1 Use of this manual .................................................................................................................................. 3

1.2 Warnings and warning pictograms ......................................................................................................... 3

2. Safety guidelines ............................................................................................................................................. 4

3. Serial plate / Carrying vehicle .......................................................................................................................... 6

3.1 Serial plate .............................................................................................................................................. 6

3.2 Carrying vehicle ...................................................................................................................................... 6

4. Preparation for use ......................................................................................................................................... 7

4.1 Transport ................................................................................................................................................ 7

4.2 Mounting the felling grapple .................................................................................................................. 8

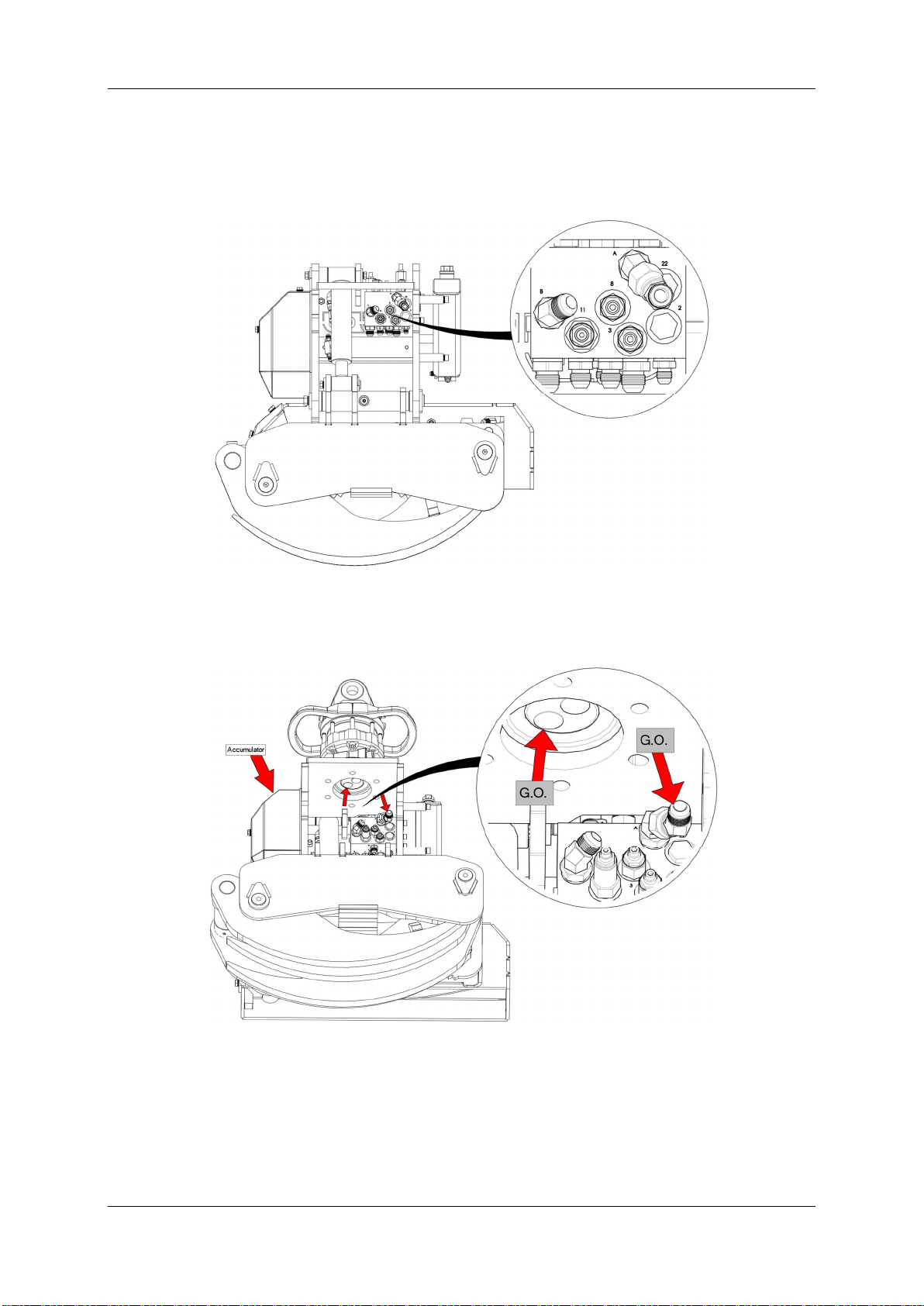

4.3 Connecting the GMT050 TTC .................................................................................................................. 9

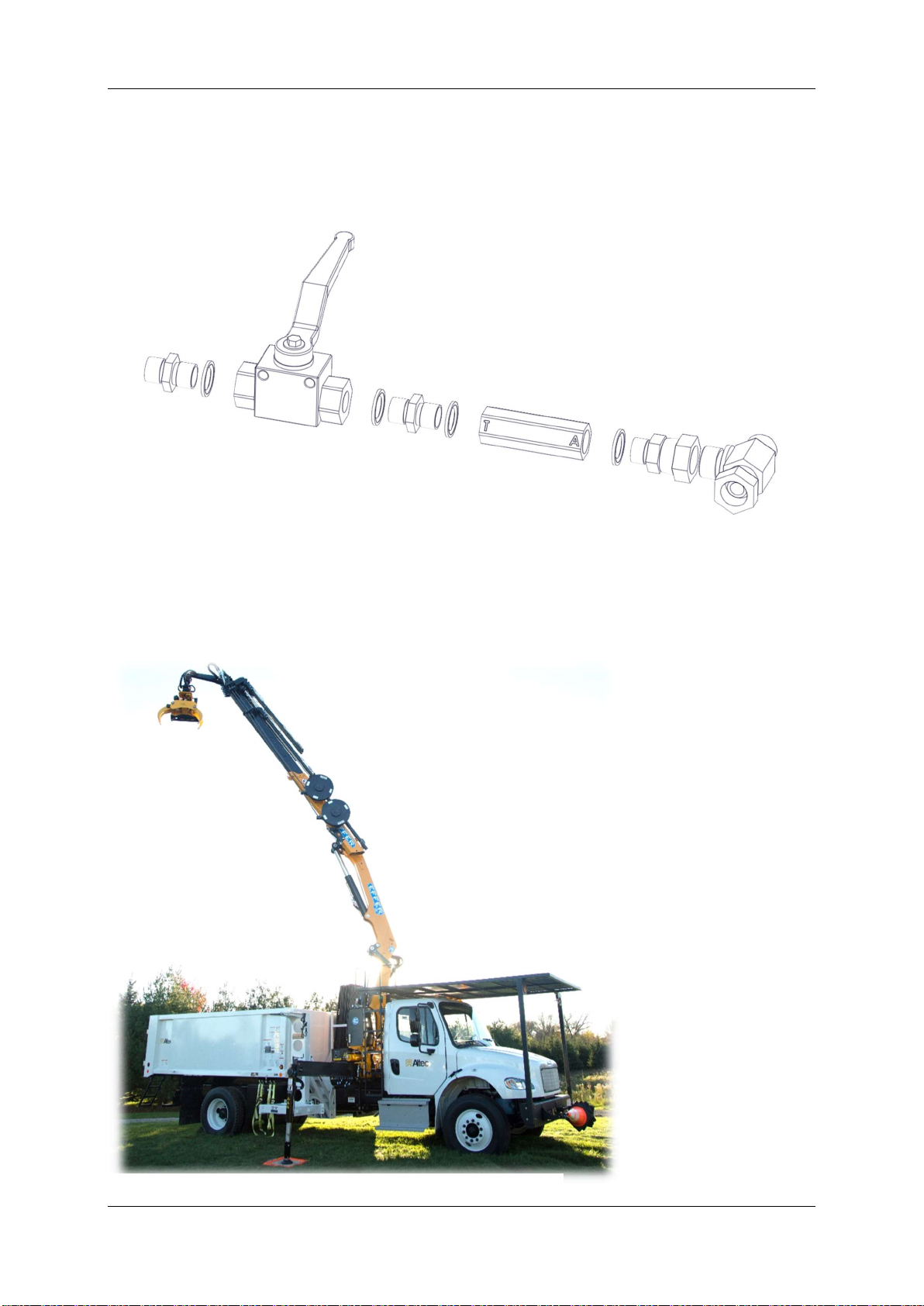

4.4 Installing the drain valve....................................................................................................................... 10

4.5 Installation on Telehandler ................................................................................................................... 11

4.6 Operating pressure ............................................................................................................................... 12

4.6.1 Hydraulic schematic for mounting ............................................................................................... 12

4.6.2 Hydraulic schematic for mounting GMT050 TTC ......................................................................... 13

4.6.3 Hydraulic schematic ..................................................................................................................... 14

5. Application .................................................................................................................................................... 15

5.1 Application GMT050 ............................................................................................................................. 15

5.2 Application GMT050 TTC ...................................................................................................................... 16

5.3 Operation of the felling grapple ........................................................................................................... 17

5.3.1 Felling a tree or branch ................................................................................................................ 18

5.3.2 Felling a tree or branch with TTC ................................................................................................. 20

5.4 Supplied tools ....................................................................................................................................... 22

4.3 Lifting reference for sawing at height .................................................................................................. 22

6. Maintenance ................................................................................................................................................. 24

6.1 Safety recommendations ..................................................................................................................... 24

6.2 Daily maintenance ................................................................................................................................ 24

6.3 Maintenance schedule ......................................................................................................................... 25

6.4 Repairs / Welding ................................................................................................................................. 25

6.5 Replacement of saw bar and chain ...................................................................................................... 26

6.6 Lubricants ............................................................................................................................................. 27

6.7 Hydraulic fluid ....................................................................................................................................... 28

6.8 Chain oil ................................................................................................................................................ 28

6.9 Handle the chainsaw ............................................................................................................................ 29

7. Adjusting the felling grapple ......................................................................................................................... 30

7.1 Pressure adjustments ........................................................................................................................... 30

7.1.1 Adjusting the valve block ............................................................................................................. 30

7.1.2 Pressurizing the accumulator ...................................................................................................... 35

7.1.3 Saw blade speed .......................................................................................................................... 37

7.1.4 Braking force of the TTC .............................................................................................................. 37

7.2 Saw safety guidelines ........................................................................................................................... 38

8. Removal of grapple ....................................................................................................................................... 38

9. Troubleshooting guide .................................................................................................................................. 39

9.1 General ................................................................................................................................................. 39

9.2 Checklist................................................................................................................................................ 39

9.3 Common malfunctions ......................................................................................................................... 39

9.3.1 Sawing problems .......................................................................................................................... 39

9.3.2 Problems with tilt up, placing grapple in horizontal position ...................................................... 40

9.3.3 Problems with tilt down, placing grapple in default position ...................................................... 40

10. Technical specifications ................................................................................................................................. 41

10.1 GMT050 ................................................................................................................................................ 41

10.2 GMT050 TTC ......................................................................................................................................... 42