Contents

10.04.17 Working instructions WIDOS RSR 630 Page 4 of 28

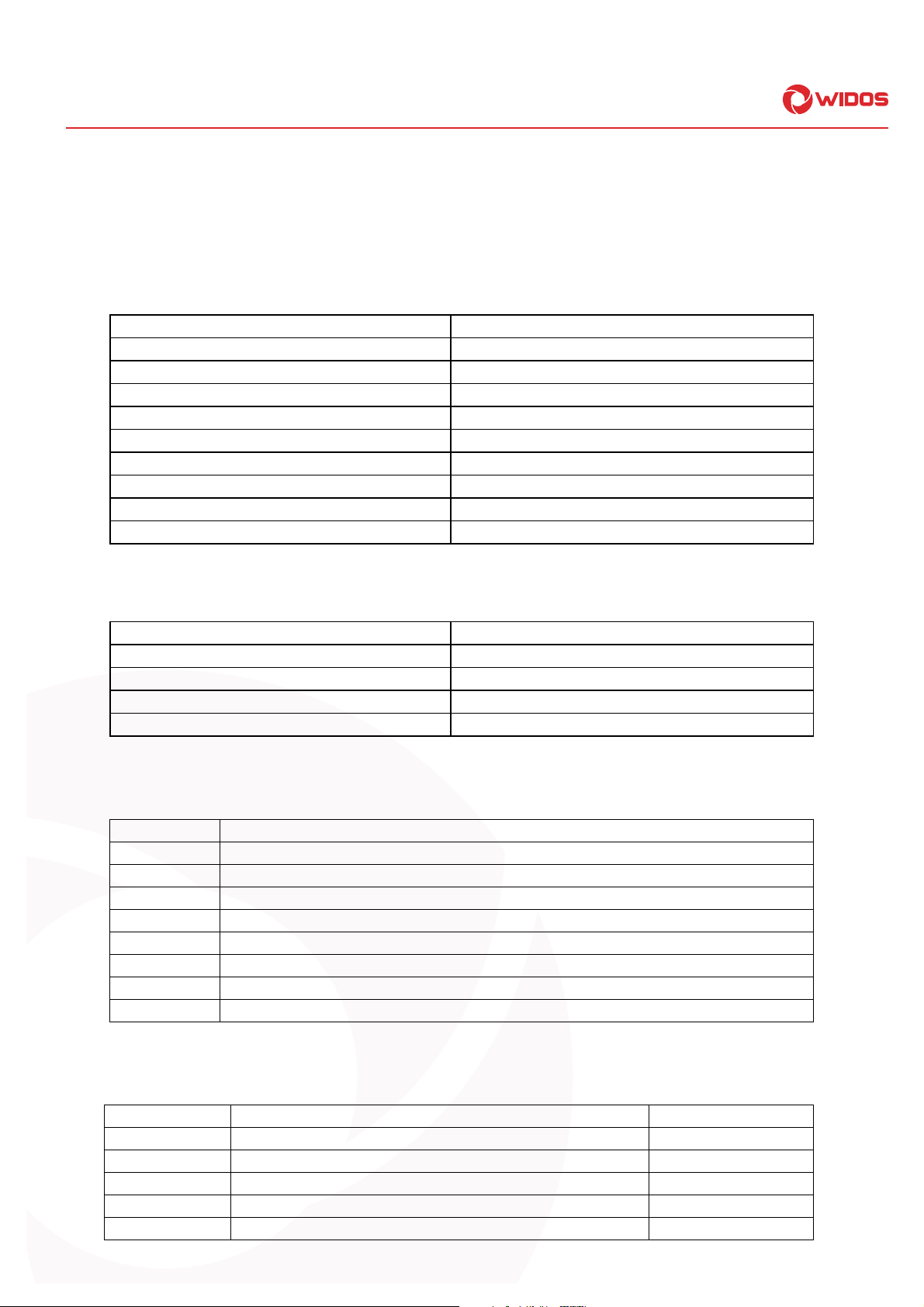

1.PRODUCT DESCRIPTION .................................................................................................... 6

1.1.Usage and purpose-oriented use......................................................................................................6

1.1.Safety measures ..............................................................................................................................6

1.1.Conformity........................................................................................................................................6

1.2.Designation of the product ...............................................................................................................7

1.2.1.Technical data ............................................................................................................................7

1.2.2.Electrical data.............................................................................................................................7

1.3.Equipment and accessories..............................................................................................................7

1.4.List of wear parts .............................................................................................................................7

2.SAFETY RULES................................................................................................................... 8

2.1.Explanation of symbols and indications ............................................................................................8

2.2.Obligations of the owner ..................................................................................................................9

2.3.Obligations of the worker .................................................................................................................9

2.4.Measures of organization.................................................................................................................9

2.5.Information about safety precautions ...............................................................................................9

2.6.Instructions for the staff...................................................................................................................9

2.7.Dangers while handling the machine............................................................................................. 10

2.8.General safety indications............................................................................................................. 10

2.9.Specific dangers ........................................................................................................................... 11

2.9.1.Danger of cutting or catching clothes......................................................................................... 11

2.9.2.Danger of stumbling over electric wire ....................................................................................... 11

2.9.3.Danger of being injured by chips / oddments............................................................................... 11

2.9.4.Risk of injury of noise ................................................................................................................ 11

2.10.Maintenance and inspection, repair ............................................................................................ 11

2.11.Remaining risks ........................................................................................................................... 11

2.12.Warranty and liability .................................................................................................................. 12

3.FUNCTIONAL DESCRIPTION............................................................................................. 13

4.OPERATING AND INDICATING ELEMENTS ....................................................................... 14

4.1.Machine overview......................................................................................................................... 14

4.1.1.Fuse ..................................................................................................................................... 15

4.2.Saw blade guiding and saw blade cover........................................................................................ 15

4.3.Adjust the cutting radius ............................................................................................................... 16

4.4.Vacuum device.............................................................................................................................. 17

5.STARTING AND OPERATING ............................................................................................ 18

5.1.Starting ......................................................................................................................................... 18

5.2.Clamp the pipes............................................................................................................................. 19