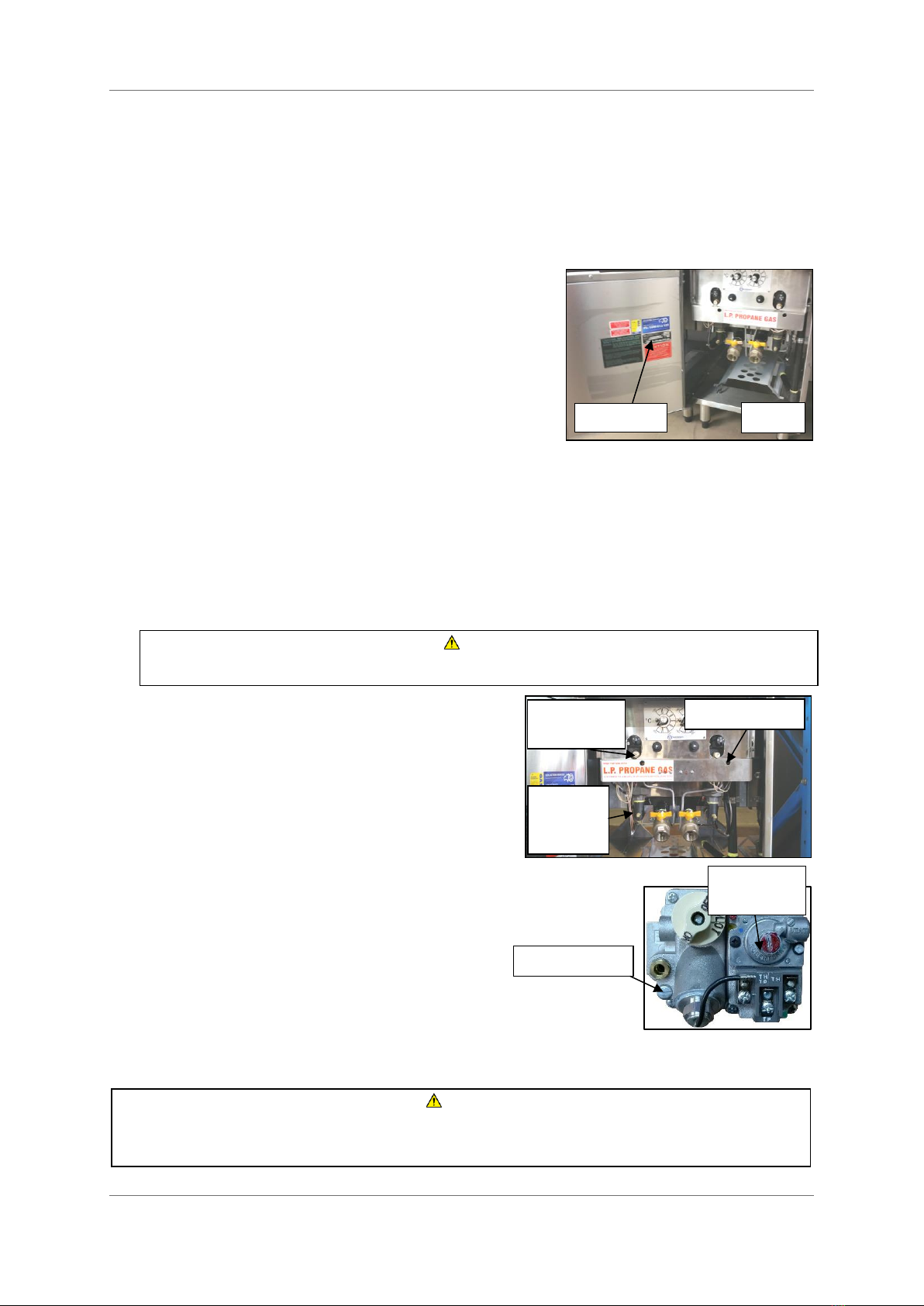

5.4 Gas Connection

This appliance has been tested and pre-set before leaving the factory, however minor adjustments

may be necessary to suit the gas supply pressure. Correct operation of the appliance must be tested

as part of the installation procedure.

Note: Gas fitting must only be carried out by an authorised and qualified person.

1. Have a licensed gas fitter or your gas supply company

connect & check that the gas supply line pressure and

volume are adequate for the appliance being installed.

The required pressure and input rating is shown on the

rating plate behind the door.

2. Install the appliance in accordance with AS5601 &

AS/NZS5601. Ensure that the appliance gas type

corresponds with the gas supply. Different gas types

are NOT compatible; however, the appliance can be converted from one gas type to

another. Please see conversion instructions for more details and contact the dealer for any

necessary components.

3. Fit an individual manual isolating valve to the appliance gas supply.

4. Connect the appliance to the gas supply. Location of the connection is shown in Dimensions

section 3 and is at the rear of the appliance with a ¾” B.S.P male fitting.

5. Ensure all gas connections are tight and free of leaks using appropriate gas detecting

equipment.

6. Bleed out any air in the lines.

7. Fill the tank and then measure the appliance

operating pressure at the manifold test point

with the appliance running. If required, adjust

the pressure at the gas valve to the value shown

in Specifications section 3.3- Gas Supply

Requirements.

8. Although the pilot is set in the factory, check that

the pilot flame does not interrupt the main burner and ensure it

lights quickly. Final adjustments can be made through the pilot

adjustment hole.