The manufacture of this product will not be held responsible if someone is injured or

the unit is damaged, as a result of improper installation, debugging, unnecessary

maintenance which is not in line with this manual.

This manual includes all the necessary information about installation, debugging,

discharging and maintenance. Please read this manual carefully before you open or

maintain the unit.

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure the low

noise level with insulation.

5 Good heat exchange rate

The heat pump unit use special designed heat exchanger to enhance whole efficiency.

The unit must be installed by qualified personnel.

—The unit can only be opened or repaired by qualified installer or an authorised dealer.

—Use genuine standard spare parts only.

—Maintenance and operation must be carried out according to the recommended time and

frequency, as stated in this manual.

Failure to comply with these recommendations will invalidate the warranty.

2 Nice appearance

The heat pump is designed with beautiful looking. The monobloc one has the water

pump included which is very easy for installation.

3 Flexible installation

The unit has smart structure with compact body, just simple outdoor installation is needed.

This series of heat pump unit owns following features:

1 Advanced controlling

The PC microcomputer based controller is available for the users to review or set the

running parameters of the heat pump. Centralized controlling system can control several

units by PC.

It is vital that the below instructions are adhered to at all times to keep the warranty.

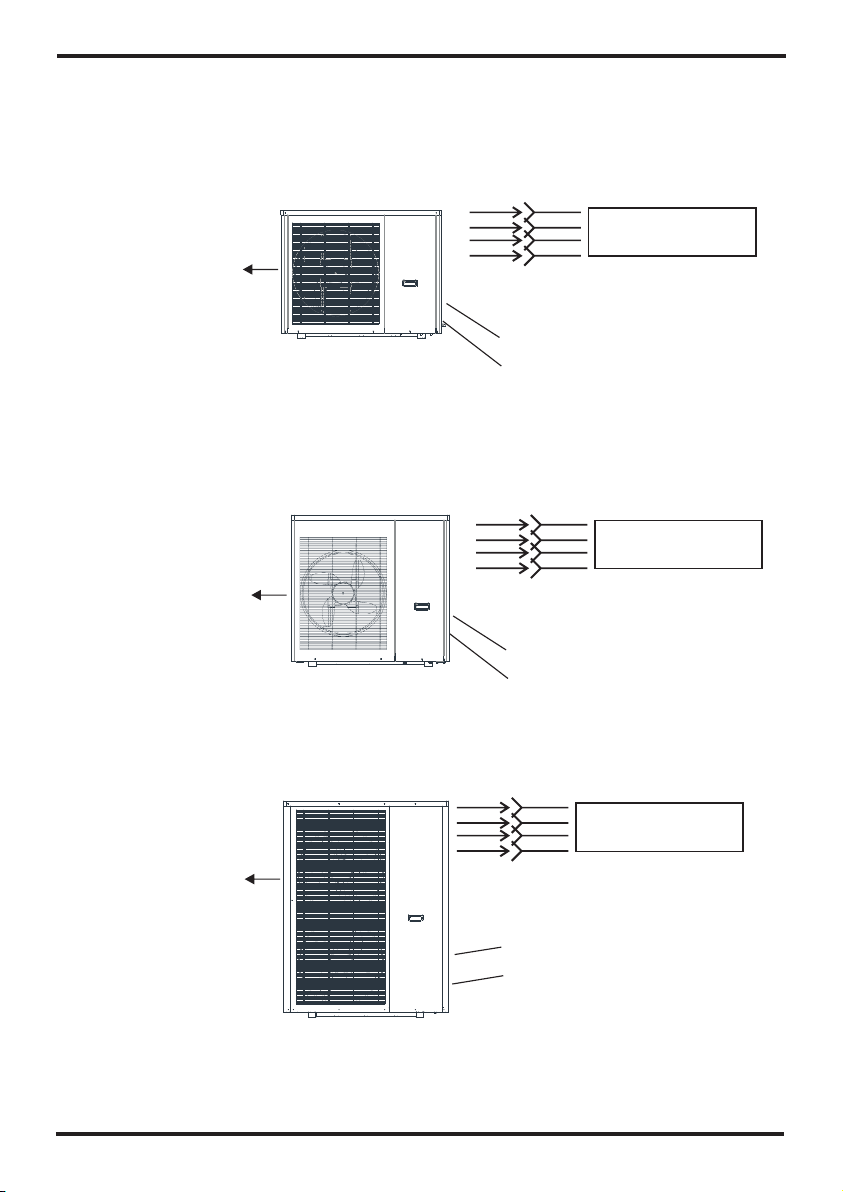

Inverter ir ource ater eat umpa s w h p is a kind of high efficiency, energy saving and

environment friendly equipment, which is mainly used for house warming. It can work with

any kind of indoor unit such fan coil, radiator, or floor heating pipe, by provide warm or hot

water. One unit of monobloc heat pump can also work with several indoor units.

The air source water heat pump unit is designed to have heat recovery by using super

heater which can provide hot water for sanitary purpose.

6 Large working range

This series of heat pump is designed to work under different working conditions as low

as -15 degrees for heating.

In order to provide the customers with high quality, strong reliability and good versatility

product, this heat pump is produced by strict design and manufacture standards.

Preface

1