..........................................................................................................................................................

......................

...............................................

.........................................................................................................................

PEC 0205 Issue 1

As part of our poli y of ontinuous produ t improvement, we reserve the right to hange spe ifi ations at any time.

May 201

Page

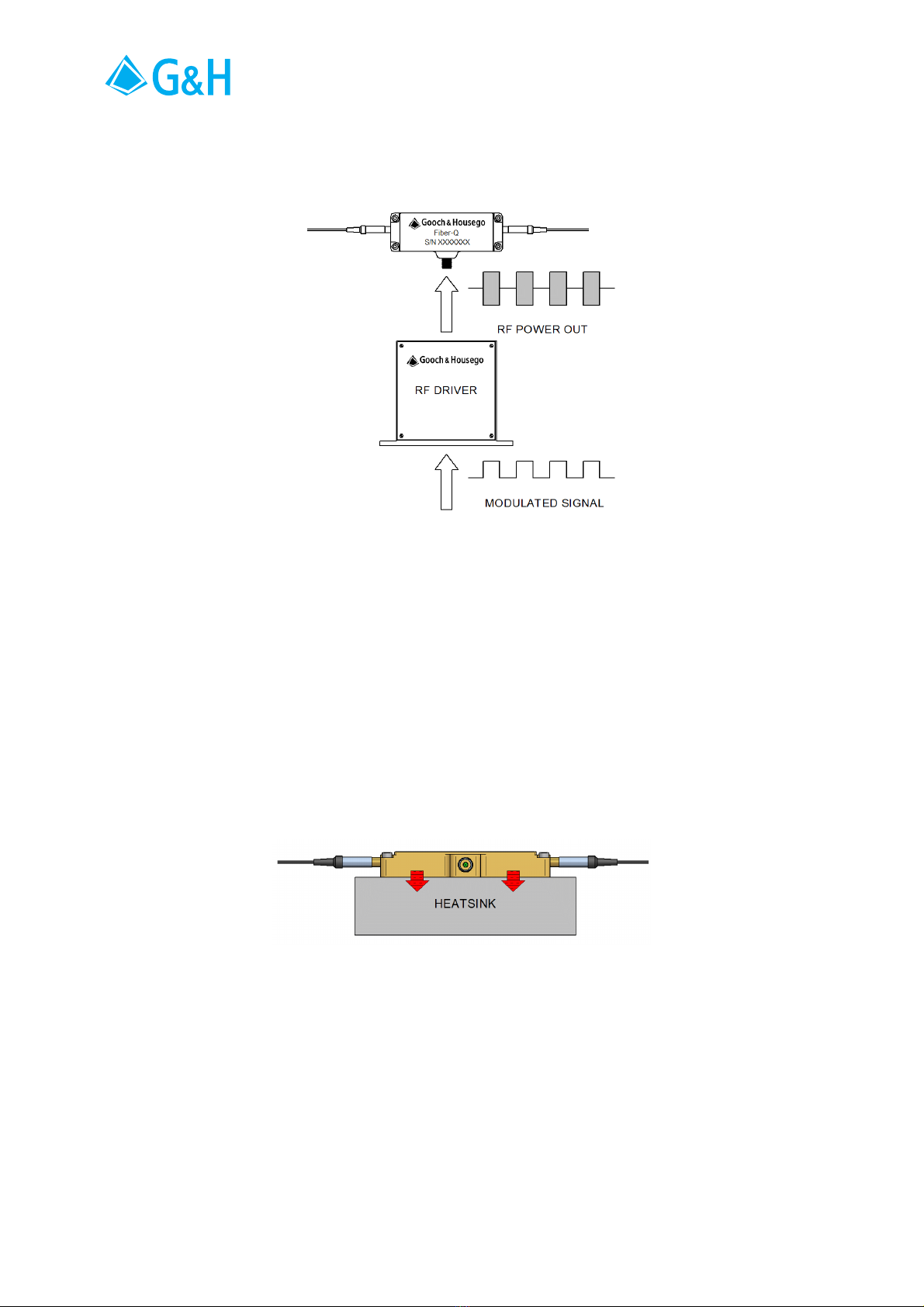

Operation Scheme:

To use a fiber oupled a ousto-opti modulator (AOM), onne t the two fiber ports (re ipro al)

into the light path, then onne t the driver to the AOM SMA onne tor using a suitable RF able.

Adjust the RF power level to optimise throughput (minimise insertion loss), taking great are not

to ex eed the maximum re ommended RF power (as indi ated in the spe ifi ations).

The diffra ted light may be modulated via the analogue or digital modulation input on the RF

driver.

Heat Sinking Fiber Coupled AOM

The stability of our fiber oupled AOM depends on effi ient internal heat ondu tion. For long

term use we re ommend heat sinking the base of Fiber-Q® pa kage housing as des ribed in the

figure below.

In order to aid thermal ondu tion, it is ne essary that thermal onta t is ensured at the onta t

surfa e between Fiber-Q® housing and the heat sink. To a hieve this please;

•

Use a thermally ondu tive interfa e layer; su h as paste tape, or other interfa e

materials (there are an extensive range of ommer ially available produ ts).

•

Bolt down the devi e to the heat sink through the four fixing holes on the pa kage. M2 x

10 so ket head ap s rews are re ommended for fixing the hermeti Fiber-Q®,

re ommended torque for fixing to a steel surfa e is 0.1 Nm.