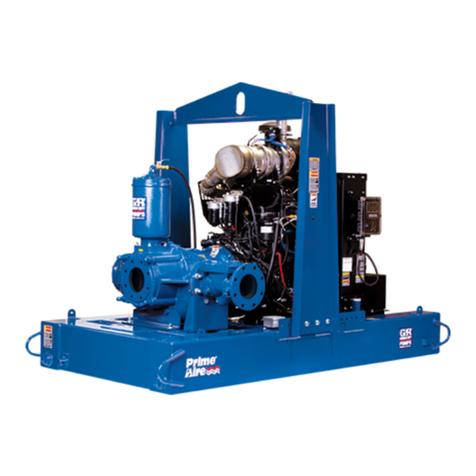

GORMAN-RUPP PUMPS PRIME-AIRE Series Operating instructions

Other GORMAN-RUPP PUMPS Water Pump manuals

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 16A2-F3L Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 03B51-B Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS SUPER T2C3SC-B Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA4A60-4045T User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 80 Series Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS ULTRA V3D60SC-B Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 80 Series User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 03H1-GR /S3 User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS T3A65S-B User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 811/4A3-B Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 10 Series User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA6D60-4045T FT4-ESP Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS GMS Series User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS SF6D User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 82D1-L70W FT4-X User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA Series User manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 10 Series Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 0 Series Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS D Series Application guide

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 02K3-E2 3P Application guide

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual