READ BEFORE INSTALLING

AND OPERATING PUMP

Inspection – Check pump for shortage and damage immediately upon arrival. Note

damage or shortage on freight bill (bill of lading); immediately le claim with carrier. Notify

the A-C Pump sales ofce.

Handling – Handle with care. Dropping or jarring can seriously damage or break parts.

WARNING: WHEN UNLOADING HORIZONTAL PUMPS, LIFT EQUALLY AT FOUR OR

MORE POINTS ON THE BASEPLATE. DO NOT LIFT ON THE DRIVER OR PUMP. DO NOT

LIFT BY FLANGES OR BY THE EYEBOLTS FOUND ON THE MOTOR. BE VERY CARE-

FUL NOT TO DAMAGE ANY AUXILIARY PIPING OR CONTROLS WHEN MOVING

PUMPS. FOR FURTHER DETAILS, SEE LIFTING INSTRUCTIONS ATTACHED TO PUMP.

Exterior – Pay particular attention to external hardware, drive motor conduit box (if

drive motor included) and accessories. Touch up abrasions or scratches with approved

paint. By hand, test that shaft rotates freely. Check coupling for damage.

Interior – If external damage is noted, or impeller is damaged (look in ports), or shaft

binds or sticks, disassemble as required to permit internal inspection. Refer to applicable

pump and driver maintenance manuals for procedures.

TEMPORARY STORAGE:

If the pump is not to be installed and operated soon after arrival, store it in a clean, dry

place having slow, moderate changes in ambient temperature. Route the shaft periodically

to coat the bearings with lubricant and to retard oxidation, corrosion, and to reduce the

possibility of false brinelling of the bearings. Refer to pump instruction book for temporary

storage instructions. For storage of three months or longer, ask for bulletin 52-113-268.

INSTALLATION:

Pump location should provide the following:

1. Proximity as close to suction supply as possible.

2. Shortest and most direct suction pipe practical. Suction lift must not exceed

limit for pump. NPSH available must equal or exceed pump requirement.

3. Suction port below pumping level to provide priming.

4. Plenty of room for inspection and maintenance.

5. Protection from freezing when idle in cold weather.

6. Correct power supply for electric motor driver; ample ventilation for internal

combustion motor driver..

7. If outdoors, protection from elements.

8. Access to water supply when stufng box lubrication or ushing is required.

BASEPLATE SETTING, HORIZONTAL UNITS ONLY:

NOTE: This procedure assumes that a concrete sub-foundation has been prepared

with anchor or hold down studs extending up ready to receive unit.

Initial Alignment:

1. Use blocks and shims under base for support at anchor studs and midway be-

tween studs, to position base approximately 2” above the concrete sub-foundation

with studs extending through holes in the baseplate.

2. Level unit by adding or removing shims under base until pump shaft and anges

are level or plumb.

3. If customer drills the base and mounts his own motor A-C Pump can assume no

responsibility for alignment. If customer mounts his own motor on predrilled base,

the motor must be centered in its mounting holes and remain that way during initial

alignment. Pump should be moved in its mounting holes to align. If the pump and

motor were factory mounted, the motor was centered in its mounting holes and

initial alignment veried at the factory.

4. Draw anchor nuts tight against base, and observe pump and motor shafts or coupling

hubs for alignment. (Temporarily remove coupling guard for checking alignment.)

5. If alignment needs improvement, add shims or wedges at appropriate positions

under base so that re-tightening of anchor nuts will shift shafts into closer align-

ment. Repeat this procedure until proper alignment is reached. For single element

couplings, proper initial alignment is dened as .020” TIR parallel alignment and

.009” TIR per inch of radius (R) angular alignment. For double element couplings,

the initial alignment tolerance is .020” TIR parallel and .006” TIR angular per inch

of radius (R). If the motor has been centered in its mounting holes and proper initial

alignment has been achieved, then nal alignment after grouting will be achievable.

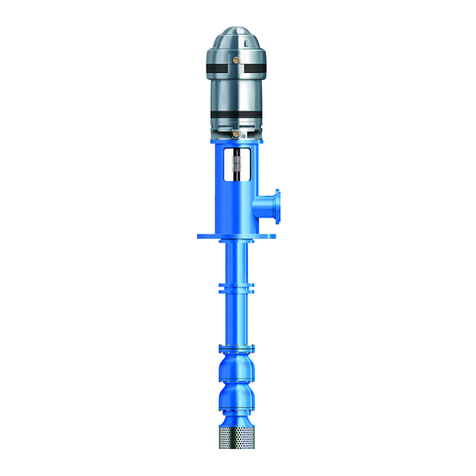

BASEPLATE SETTING, VERTICAL UNITS:

1. For vertical pumps where machined ts have been provided for the drive, proper

alignment has been designed into the unit. Where no locating t is provided for the

drive, the nal alignment procedure must be followed. For vertical pumps with line

shafts, consult line shaft manufacturer’s instructions.

GROUTING PROCEDURES

Grout compensates for uneven foundation, distributes weight of unit, and prevents

shifting. Use an approved, non-shrinking grout (such as Embeco 636 by Master Builders,

Cleveland, Ohio or equivalent) as follows, after setting and leveling unit.

1. Build strong form around the foundation to contain grout.

2. Soak top of concrete thoroughly, then remove surface water.

3. Flow grout to ll cavities and prevent air pockets. Temporarily use air-relief tubing if

necessary, to remove trapped air.

4. Grout should be 1 inch minimum under baseplate and lled-in at least 4 inches

from all four edges.

5. Grout baseplate in completely and allow grout to dry thoroughly before attaching

piping to pump (24 hours is sufcient time with approved grouting procedure.)

FINAL COUPLING ALIGNMENT:

NOTE: A exible coupling will only compensate for small amounts of misalignment.

Permissible misalignment will vary with the make of coupling. The tolerances listed

below are recommended for satisfactory pump operation. Consult coupling manu-

facturer’s data when in doubt.

A. For single element couplings

NOTE: Proper alignment is essential for correct pump operation. This should be per-

formed after baseplate has been properly set and grout has dried thoroughly accord-

ing to instruction. Final alignment should be made by shimming driver only. If align-

ment is critical, it should be made at operating temperatures.

1. Coupling hubs are usually mounted on the shaft, if not, install them at this time.

2. Mount dial indicator on one hub as shown in illustration for parallel alignment. Set

dial to zero.

3. Scribe index lines on coupling halves as shown.

4. Turn both coupling halves so that index lines match. Observe dial reading to see

whether pump or driver needs adjustment. Total indicator reading for one complete

turn should not exceed 0.004 inch.

5. Mount indicator as shown for angular alignment. Set dial to zero.

6. Turn both coupling halves so index lines match. Observe dial reading to see whether

driver needs adjustment. Total indicator reading of 0.004 inch per inch of radius (R)

is satisfactory for angular alignment.

7. Assemble coupling. Tighten all bolts and set screws. It may be necessary to repeat

#2 and #4 for a nal check.

B. For double element oating shaft spacer coupling.

Parallel misalignment for double element or two plane oating shaft coupling should

not exceed 1/16 inch per foot of plane separation. Angular misalignment should be .002”

per inch of radius (R). It is recommended to offset universal joint coupling alignment by

1/8” to 1/4” for best operation. Consult coupling manufacturer’s data if in doubt.

PIPING

Suction and discharge gages are useful to check pump operation and are excellent trouble

indicators. Install gages in lines if pump nozzles do not have gage taps. Observe these

precautions when installing piping.

1. Support piping close to, but independently of pump.

2. Keep piping as straight as possible, with few or no bends and ttings.

3. Remove burrs, sharp edges, ream pipe cuts, and make joints air tight.

4. Do not “spring” pipes to make connection. Strain must not be transmitted to pump.

5. Allow for pump expansion with hot uids. If rubber expansion joints, or exible pipe

connectors are to be used, they should be installed in accordance with the instal-

lation and maintenance section of the Technical Handbook for Rubber Expansion

Joints and Flexible Pipe Connectors, published by the Fluid Sealing Association.

Pipe anchors should be adjustable to avoid undue strains on pump anges.

6. Do not move pump to pipe. This could make nal coupling alignment impossible.

Note that piping should not be connected to pump until unit has been set per instruc-

tions and grouted in.

Suction – Size and install piping to keep pressure loss at minimum and to provide

correct NPSH.

1 Suction piping should be as short and direct as possible.

2. Size must never be smaller than suction port; for long runs, use 1 or 2 sizes larger.

3. Pipe should slope upward to pump, even for horizontal runs.

4. Use eccentric reducer at pump, eccentric side down.

5. Use 45 degree or long sweep 90 degree elbows.

6. Use apper type foot valve, but only when necessary to hold prime. Sudden

closing upon reversal of ow may cause serious damage to pump and other

equipment..

7. Use gate valves only for parallel connection and for isolating pump when shut

down. Stem must be horizontal or slope down. Never use globe valves in suc-

tion line, particularly where NPSH is critical. Never throttle pump by use of

suction valve.

8. Use increasing suction nozzle or “drop-out” pipe section to permit cleaning pump.

Discharge – Some end suction pumps permit discharge port location at a number

of positions. If discharge positions must be changed, consult instruction book. Be sure

there is adequate clearance with selected position for lubrication and service of both

driver and pump.

1. If discharge line is short, size may be same as discharge port; if long, use 1 or

2 sizes larger.

2. For long horizontal runs, keep grade as even as possible, avoid high spots and

loops. Trapped air may throttle ow and can result in erratic pumping.

3. Install check and gate valves in discharge line near to pump. Check valve (if

used) should be installed between pump and gate valve.

Stufng Box – For packed pumps the stufng box must have clean, clear liquid

to ush and lubricate packing. For packed stuff boxes, the seal water quality should be

1000 ppm or better with the maximum particle size being 44 microns. For mechanical

seals, the seal water quality should be 1000 ppm or better with the maximum particle

size being 15 microns. Determine stuff box pressure by using a pressure gauge. Provide

seal water pressure at 5 to 10 psi above maximum box operating pressure. For double

mechanical seals, seal water pressure should be 10 to 20 psi above stuff box pressure.

Consult instruction book or factory.

External Seal Flushing Liquid – If pumped liquid will damage or deteriorate seal

material, suitable clean liquid must be supplied to the seal from an outside source.

Install valves in ushing supply piping to regulate ow and pressure to the box. This is

extremely important and must be given careful, engineered planning. Refer to separate

maintenance manual.

OPERATION

Pre-Start – Before initial start of pump check as follows:

1. With coupling disconnected be sure pump operates in direction indicated by

arrow on pump casing. If electric motor drive is used, check rotation each time

motor leads have been disconnected.

2. Check driver for proper operation.

3. Check suction and discharge piping pressure gages, and all other cooling, drain

lines, etc. for proper operation.

4. Turn rotating element by hand to assure free rotation.

5. Check impeller adjustment. Refer to pump maintenance manual.

6. Check stufng box adjustment, lubrication and piping.

7. Assure that all bearings are properly lubricated. Oil lubricated pumps are

shipped without oil. Fill to line in sight gage with oil of the proper viscosity.

See pump instruction book. Grease lubricated pumps are pre-greased at the

factory. Just prior to starting, add one (1) ounce of lithium based NLGI-2 grade

grease at each bearing. Remove vent plug (where provided) for rst half hour

of operation.

8. Assure that pump is full of liquid (primed).

Priming – If pump is installed with a positive head on the suction, prime by opening

suction valve and allowing liquid to enter casing, at the same time venting all air out of

casing.

If pump is installed with a suction lift, priming must be done by other methods,

such as foot valves, ejectors or by manually lling casing and suction line..

CAUTION: UNDER EITHER CONDITION, THE PUMP MUST BE COMPLETELY

FILLED WITH LIQUID BEFORE STARTING. DO NOT RUN THE PUMP IN

THE HOPE IT WILL PRIME ITSELF. IF THIS CONDITION IS NOT SATISFIED

SERIOUS DAMAGE TO THE PUMP WILL RESULT.