Bizon Pumps BPN-330C User manual

BISON DEEP WELL HAND PUMP

INSTALLATION INSTRUCTIONS

Inspect the contents of the box to be sure everything you ordered has been received. Be sure to check

the serial number on the pump head assembly to verify it matches the serial number on your

invoice/packing list.

Read All Instructions Before Beginning the Actual Pump Installation

DO'S & DON'TS FOR PUMP INSTALLATION

DO NOT begin the installation without first reading the entire instruction booklet, studying and

understanding the diagrams.

DO NOT attempt the installation by yourself.

DO NOT begin the installation of the pump without first checking the water level in your well to be

sure you have enough pipe and rod to install the pump cylinder at least 20’ below the static water

level.

DO NOT over tighten the 1 ¼” pvc piping into the pvc female pipe thread bell end of the sch. 120

plastic pipe. The pipe can be threaded with a pair of pliers or a 12” pipe wrench.

DO NOT use large pipe wrenches for the assembly of the pvc piping.

DO NOT install the pump during a thunder and lightning storm. Be aware of any overhead power

lines.

DO NOT hurry the installation of your pump. Think before you act.

DO NOT screw multiple lengths of pipe and rod together, laid out on the ground, and then try to lift

all the pipe and rod to a vertical position to lower it into the well.

DO NOT lower the pump and pipe sections into the well by the safety rope. Grab the pipe securely

with both hands and lower the pipe, cylinder and safety rope into the well 8’ at a time, using the

paddle as a stop. The safety rope should be tied off to a secure object, i.e. the well casing so that it

can be lowered slowly and safely.

If you are going down more than 14 lengths of pipe and rod, mechanical means of

lowering them into the well is recommended along with the Bison lifting tool and

adjustable rod. Gloves are recommended when handling rope.

WARNING: All pumps are shipped with a stainless steel male pipe thread hose adaptor. You may

want to check local codes to see if a hose Bibb backflow preventer should be used when

connecting a hose to the hose adaptor on the pump. CONSULT YOUR LOCAL PLUMBING CODE!!

DO read the installation instructions and study all diagrams. Begin the installation when you are

confident you understand the instructions completely.

DO have another person help you with the installation. If you are not comfortable with the

mechanics of the installation, we suggest you hire the services of a licensed plumber, pump installer

or well driller.

DO install the pipe and rod’s 8’ sections one at a time until the entire pipe and rod is installed.

DO make sure one end of the safety rope is securely tied to the cylinder and the other end to a

secure object such as the well casing.

DO turn the electricity off to the electric submersible pump before beginning the installation if you

are installing the hand pump in the same well as the electric submersible.

DO use the paddle provided to aid in the installation of your pump.

DO thread the ends of the rods together so they butt up against each other then tighten the lock nuts

with ½” & 9/16” open end wrenches.

DO use Teflon tape on any male pipe threads which are not already taped before you screw them

together.

Note: Bison Pumps and any of its affiliates will not be held responsible for defects or damage to

this product due to inexperienced or negligent workmanship during installation of the pump and

associated parts.

INSTALLATION INSTRUCTIONS

(Bison Pumps recommend two people be involved for ease of installation.)

REQUIRED TOOLS: ½” and 9/16” open end wrenches, pliers, vice grips

STEP #1 - Make sure you have read and understand the installation instructions.

STEP #2 - If you are installing the pump in a well casing specifically dedicated to a hand pump, go

to STEP #6.

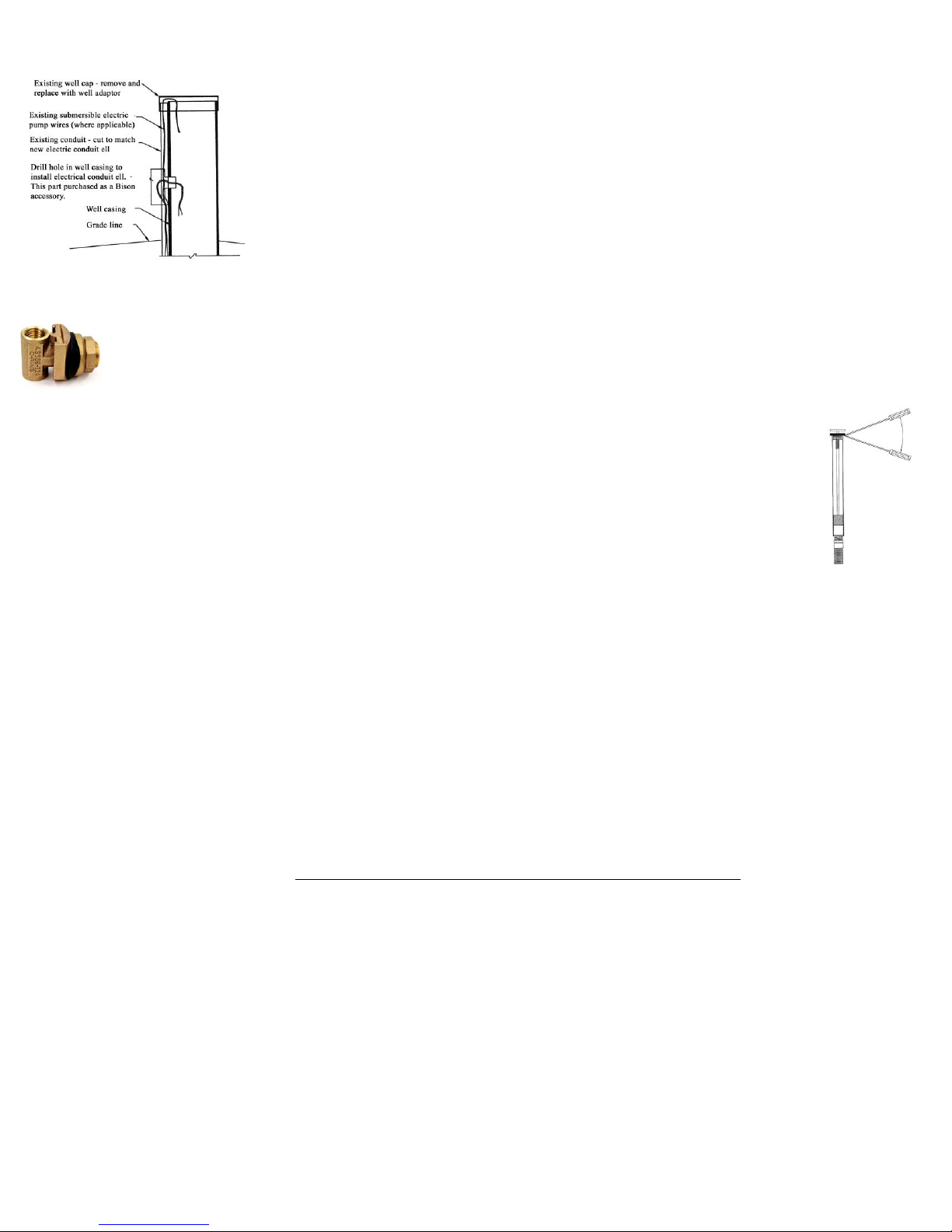

STEP #3 - If you are installing your Bison Deep Well Hand Pump in the same casing as an electric

submersible pump or piping which connects to a jet pump, proceed as follows:

STEP #4 - Remove the existing well cover or well seal, whichever you may have and set it aside. *If

you have a submersible pump, be sure to shut the electricity off to the pump before beginning the

installation of the Bison Hand Pump*

If you are installing in the same casing as an electric submersible pump, in most

cases the electrical wires exit the top of the casing then run back down to the ground

with a piece of conduit. Using a bi-metal hole saw, drill a hole through the side of the

well casing 3-4” below the top of the casing then install the electrical conduit ell

(pictured –offered as an accessory by Bison Pumps).

This will allow you to pass the wire from outside the casing through the

conduit ell to the inside of the casing where you can re-connect the wires

to the submersible pump.

STEP #5 - You may need to lift your submersible pump or deep well jet assembly and

foot valve in order to pass the Bison Pump Cylinder by the Pitless adaptor (pictured) in

your well casing. To avoid this step, you may want to select a smaller Bison Pump

cylinder.

STEP #6 - Remove the Bison Pump Cylinder from the box. Remove the red plastic

plug from the pump cylinder and discard. Raise the PVC t-handle to loosen the

piston seal. Once you have released the piston seal, pump the t-handle up and down

a few times to loosen the seal. As you pump the piston, you will hear the check

valves "burp". This indicates that the check valves are functioning properly. The

plastic t-handle can be discarded at this point.

STEP #7 - Start the assembly of your Bison Pump. If you have purchased a complete kit, you will

notice the safety rope has been securely tied to the pump cylinder when you received your pump. Tie

the other end of the rope to a secure object, i.e. the well casing, temporarily. The safety rope will be

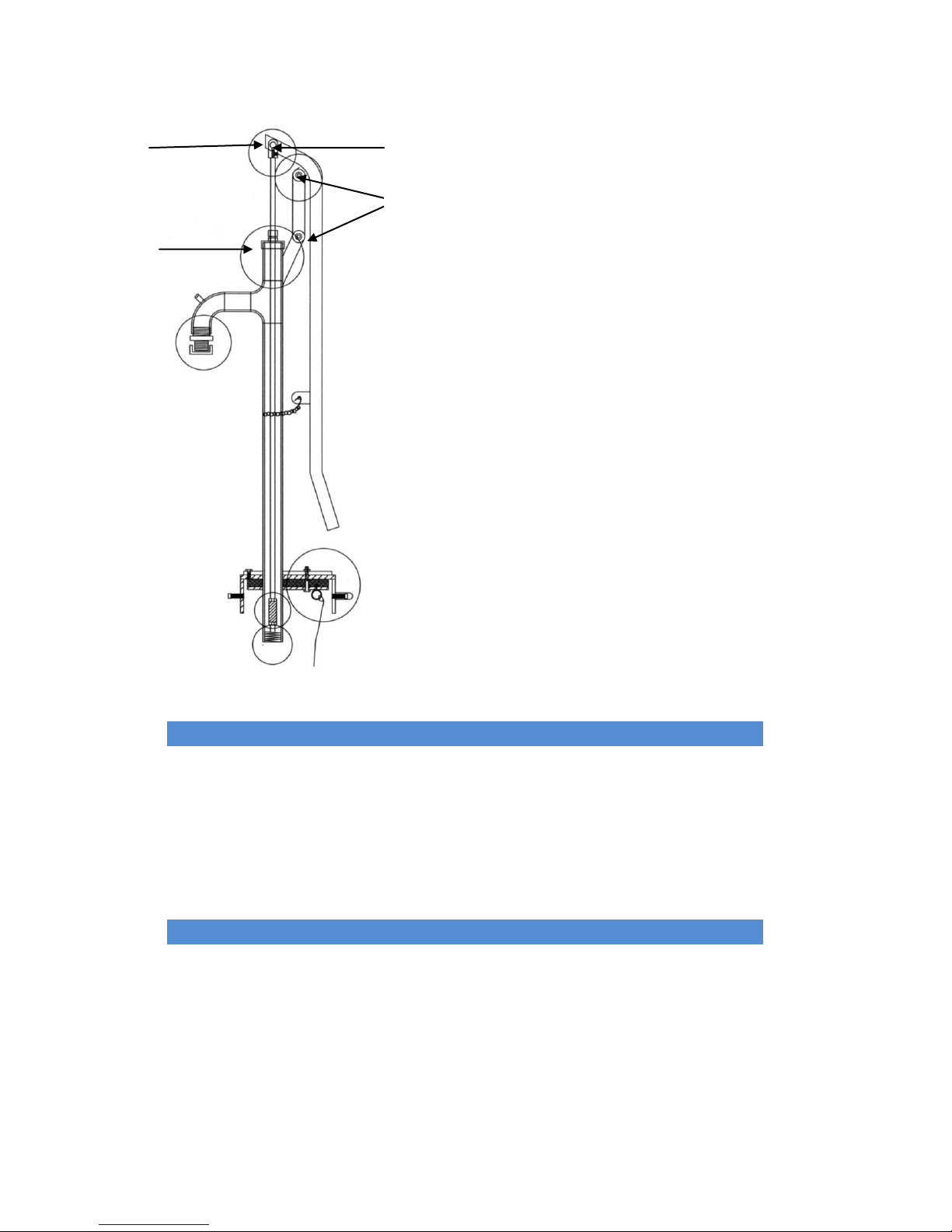

tied to the 1/4" eye bolt on the bottom of the well adaptor in step #13. (See Detail "A").

STEP #8 –Note: when you receive your rod, one of the lock nuts will already be tightened

securely. Assemble your first piece of 3/8" stainless steel rod to the rod protruding from the cylinder.

Pull the rod in the Bison Pump Cylinder all the way to the top to connect the first rod. As you

assemble the stainless steel rod, screw the rod into the coupling until the two rod ends butt up against

each other. Use pliers to lock the rods together. Be sure to tighten the 3/8" stainless steel jam nuts on

both sides of the rod coupling. We recommend as you connect each rod thereafter, thread on the Rod

Retrieval Tool to pull rod up as far as you can and connect a pair of vice grips to hold the rod in place

while you secure the coupling and tighten the lock nuts. This should be done each time. You will

notice as you assemble the rod and piping in the well, the weight of the rod may push the piston in the

pump cylinder down so the rod lowers inside the 1 1/4" PVC pipe to a point where you can't reach it

to connect the next rod coupling.

STEP #9 - Screw the PVC male end of the first 8' section of pipe into the female thread in the head of

the pump cylinder. Use Teflon tape or pipe dope compound on all pipe threads.

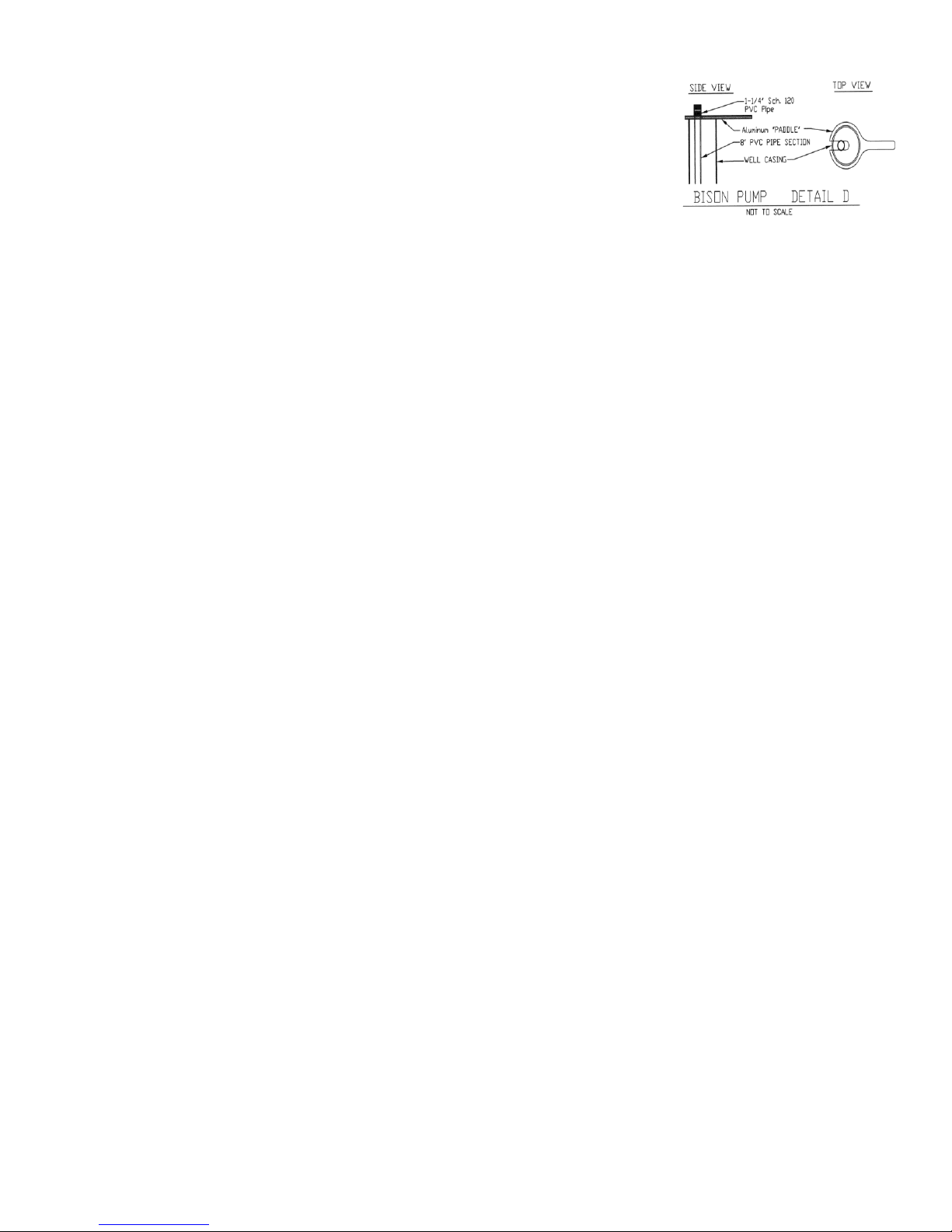

STEP #10 - Lower the cylinder and the first 8' section of piping into the

well. Using the slotted aluminum paddle you received with your pump,

slide it under the PVC bell end of the pipe and rest the paddle on top of

the well casing. This will hold the pipe in place while you assemble the

rod and pipe. Continue to connect the 3/8" rod sections and PVC pipe

until you have lowered all of the pipe into the well.

STEP #11 –Attach the rod retrieval tool to the last section of rod and pull all the way up. Attach vice

grips to hold the rod up from the pipe. Remove the 3/8" Allen head shoulder bolt at the top of the

handle connection to the lift rod (See Detail "A").

STEP #12 - Screw the 3/8" rod that is protruding from the bottom of the well head into the last rod

sticking out of the PVC pipe. Tighten these rods together using plier or vice grips and a 9/16”

wrench. Thread the jam nut up against the lift rod and tighten. Screw the Well Head into the PVC bell

end of the pipe. (This step is performed more easily with two people.)

STEP #13 - Tie the end of the safety rope to the 1/4" eye bolt on the underside of the well adaptor

(See Detail "A"). Set the well adaptor and pump head onto the casing, squarely and straight; then

evenly tighten the (4) stainless steel nuts on top of the well adaptor. Tighten the (4) allen head set

screws on the well adaptor to secure it to the casing. Check to make sure the pump head is square and

straight on the well casing; making sure all the bolts are tight. Place the (4) rubber boots on the allen

head set screws of the well adaptor. Reconnect the pump handle to the lift rod with the 3/8" Allen

head shoulder bolt. Ensure the set screw in the eyelet at the top of the handle is facing back towards

the handle. Do not over tighten the shoulder bolt as this will cause the pump handle to pump

hard.

STEP #14 - Pump the handle on your Bison Deep Well Hand Pump and enjoy a cold glass of water

directly from your well.

If you are currently treating the water in your home, remember that the water you pump directly

from your well is untreated water. Bison Pumps recommends that you have your water tested to be

sure that it is good quality potable drinking water.

Additional Installation Tips:

1. If you live in an area that experiences freezing temperatures, be sure to drill an 1/8" hole in the

1 1/4" PVC pipe approximately 6' to 7' below the well adaptor. If you experience freezing

temperatures that could have a frost penetration deeper than 7', drill the hole lower on the 1

1/4" PVC pipe. (See Detail "A")

2. If you experience any deficiencies or malfunction of your Bison Deep Well Hand Pump, please

call 1-800-339-2601 for assistance and answers to your specific questions or concerns.

3. Be sure to check local plumbing codes in your area to be verify that your installation

meets all code requirements.

4. You will notice a handle locking loop is attached to your pump handle along with a stainless

steel chain and hook. If you choose, you can use either a paddle lock or a cable lock to secure

the handle to the pump when not in use. Locking the handle is totally optional.

5. You will also notice that a brass hose bibb cap is shipped with the hose bibb adaptor. This cap

can be tightened to the hose bibb to keep insects out when the pump is not in use. Caution: In

the winter months, be sure to let the pump drain back completely before securing the

brass cap. You may not want to use the cap during the winter.

6. Thank you for investing in a Bison Deep Well Hand Pump.

BISON DEEPWELL HAND PUMP PARTS BREAKDOWN

BPN-RPK

Repair Kit DW Hand Pump

BPN-006

Wash Flat Nylon 3/8" x1-1/16

BP-GN

Gland Nut

BPN-012

Bush Brz 3/8"x1/2"x3/4" -Hdl

BPN-069

Nut Ny-locknut 316 3/8"-16

BPN-018

scr Cup P.Set 316 1/4"x1/4"

BPN-121

Cup Seals Buna 3" Cyl

Part Numbers

Options DW Hand Pump

BPN-330C

Check Valve for Pressurizing Tanks

BPN-375C

Conduit Ell

BPN-012

BPN-018

BP-GN

BPN-006

BPN-069

Bison Pumps Cylinder General Performance Chart

Cylinder

Size

Pipe

Size

Static Water

Level (Feet)

Oz/Stroke

Output

Approximate

GPM

Lbs

Pressure

Exerted

on

Handle

3”

1-1/4”

0’ - 30’

20

4-1/2 –5 gpm

15

3”

1-1/4”

31’ - 75’

17

4 gpm

50

3”

1-1/4”

76’ - 100’

14

3 gpm

80

2 ½”

1-1/4”

0’ – 30’

14

4 gpm

15

2”

1-1/4”

0’ – 10’

11

5 gpm

5

2”

1-1/4”

11’ – 125’

7

3gpm

40

2”

1-1/4”

126’ - 150’

5

2-1/2 gpm

50

2”

1-1/4”

151’ - 200’

5

2-1/2 gpm

60

1-1/2”

1”

0’ – 10’

6

3 gpm

Effortless

1-1/2”

1”

11’ - 50’

4

2 gpm

10

1-1/2”

1”

51’ - 100’

4

2 pgm

15

1-1/2”

1”

101’–150’

3

1-1/2 pgm

35

1-1/2”

1”

151’ - 200’

3

1-1/2 pgm

40

Maximum static levels depths for the practical use of a hand pump are as

follows:

1-1/2” Cylinder; up to a 200’ static water level

2” Cylinder; up to a 200’ static water level

2 ½” Cylinder; performance equal to the 3” cylinder at the same levels

3” Cylinder; up to a 100’ static water level

1. The information in the chart is based on actual field tests and is intended as a general guide.

2. The gallons per minute (gpm) output on each cylinder size is based on the Bison Pump being

operated by a 200 lb. male, 6’ tall, stroking the handle sixty times in one minute. Over time, the

gallons-per-minute output is directly related to the physical condition of the operator.

3. The highlighted lines in the chart are approximate limits to each size cylinder (+/- 10%).

4. On static water levels 100’ and greater, the pump should be installed using mechanical lifting and

lowering devices (i.e. electric winch, manual hoist, etc.). This should be done by experienced

installers with appropriate equipment.

5. Always install the pump with safety rope properly tied off and secured. Two people are required

for most installations.

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Raider

Raider RD-GWP04 user manual

Zoeller

Zoeller QWIK JON ULTIMA 203 installation instructions

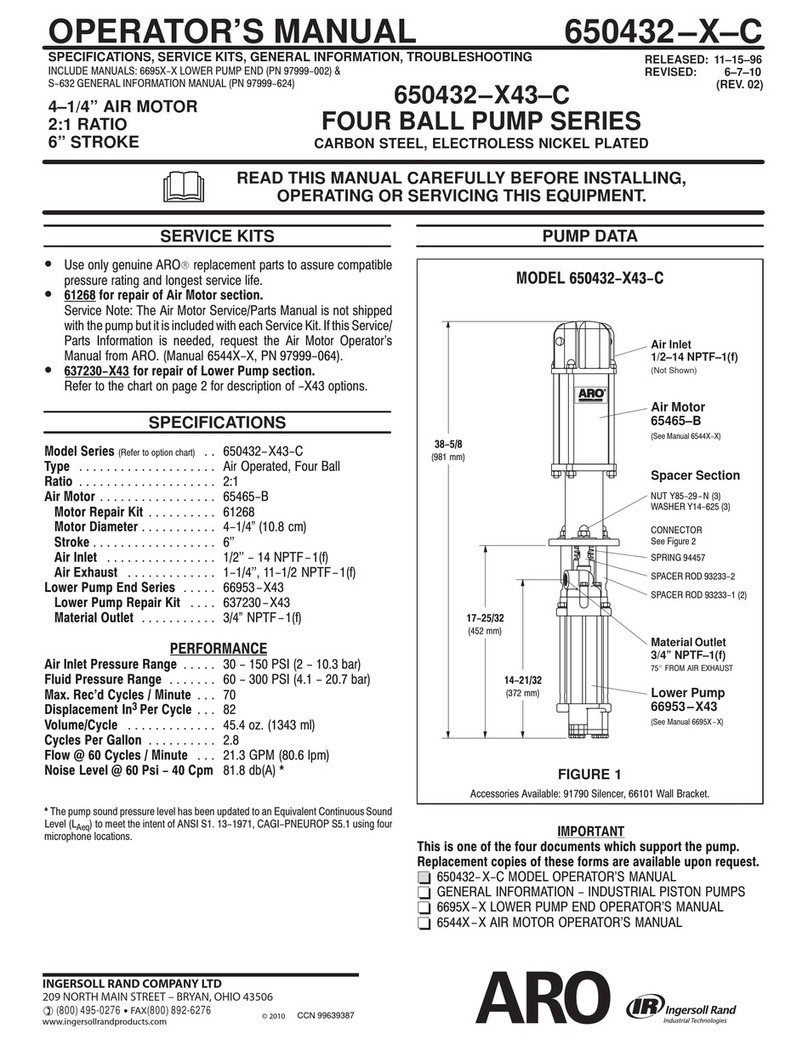

Ingersoll-Rand

Ingersoll-Rand ARO 650432-X43-C Series Operator's manual

Xylem

Xylem GOULDS LNE Series Installation, operation and maintenance manual

Gormann-Rupp Pumps

Gormann-Rupp Pumps SUPER T Series Installation, operation, and maintenance manual with parts list

Espa

Espa DRAIN instruction manual