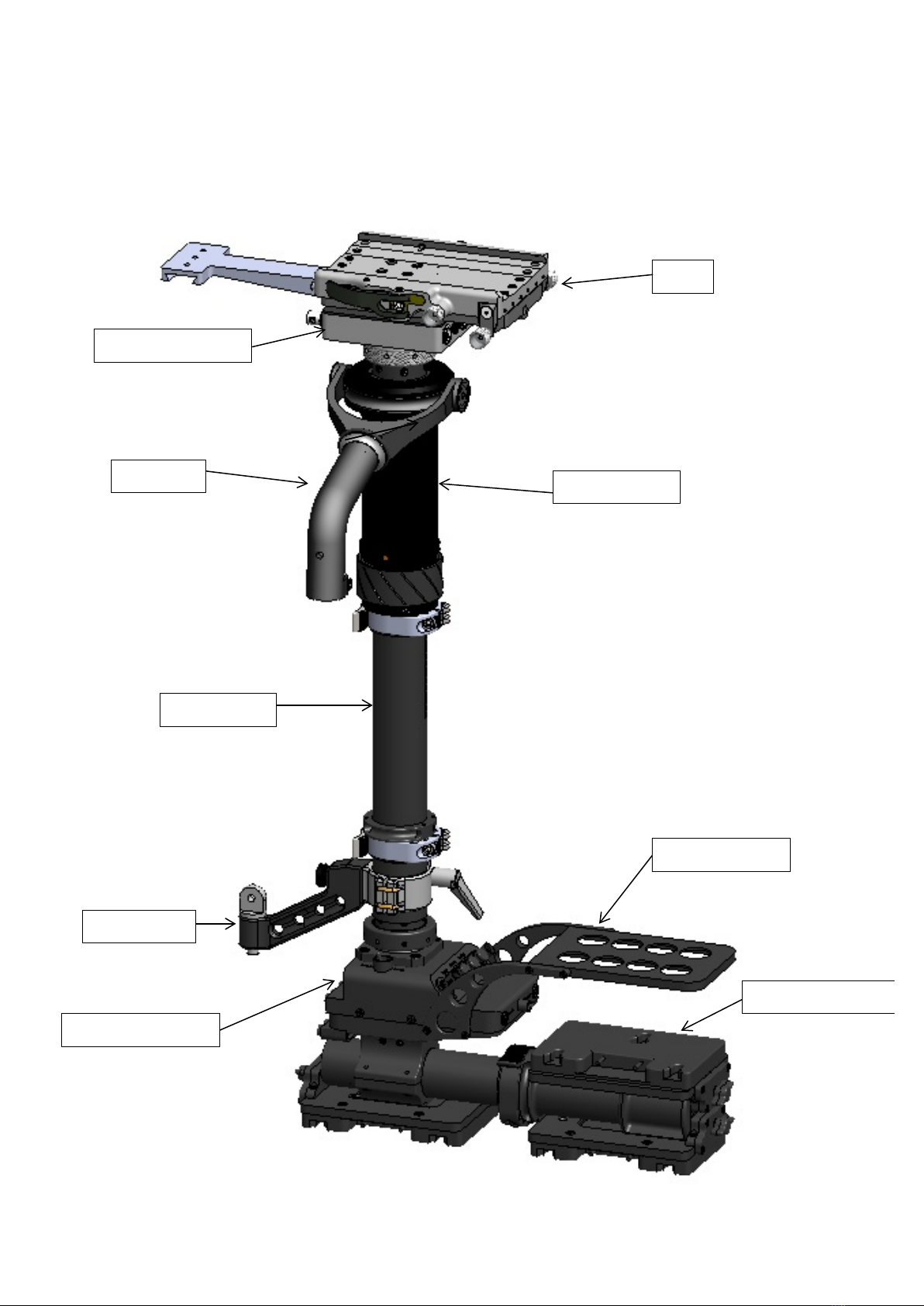

FIGURE 2:

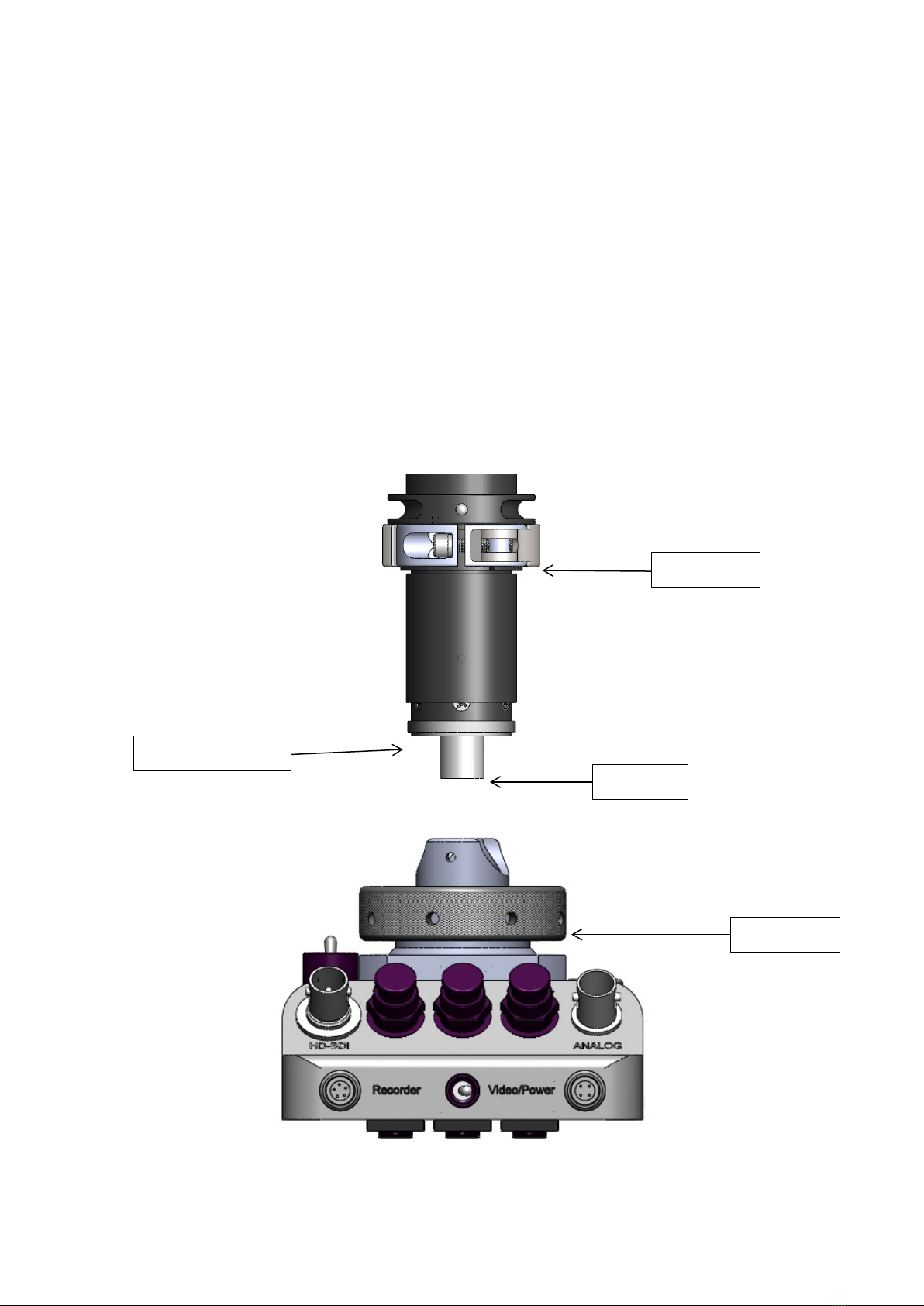

This third generation camera-mounting platform offers the following:

“Cross Roller Bearings” which, by their line contact, as opposed to the point contact of ball

bearings, and their increased length of engagement, multiply the stiffness of the D-Box III, and

allow smooth easy movement fore/aft and side/side.

Access to each of the four mounting screws at once, without the need to adjust the fore/aft or

side/side controls.

A “drop in/out” feature and an independent safety mechanism, so that in the event of a failure in

the locking mechanism, the camera is still secure when the safety lever is in place.

Tool-less rough adjustment of the camera, via the clamp lever located on the right side.

Quick change from hi to lo-mode.

Side/side and fore/aft controls on both the right and left side, for easy access regardless of the

mode you are operating in; high or low, or the side from which you operate; left or right.

Fine thread lead screws and captured lead nuts enable the operator to make small, accurate

adjustments.

Once the camera has been placed in the Donkey Box, lock the safety lever in place. Then,

ensuring that the clamp lever is in the up and locked position, tighten the locking screw, if this

screw is over-tightened the rough adjustment via the clamp lever will be defeated. For rough

adjustments to the camera’s fore/aft position first turn the clamp lever down (clockwise) then

push or pull to slide the camera into the desired position. Return the clamp lever to it’s locked

position and then use the controls on either side of the Donkey Box for final adjustments, fore

and aft and side to side.