Warnings

43A6623C

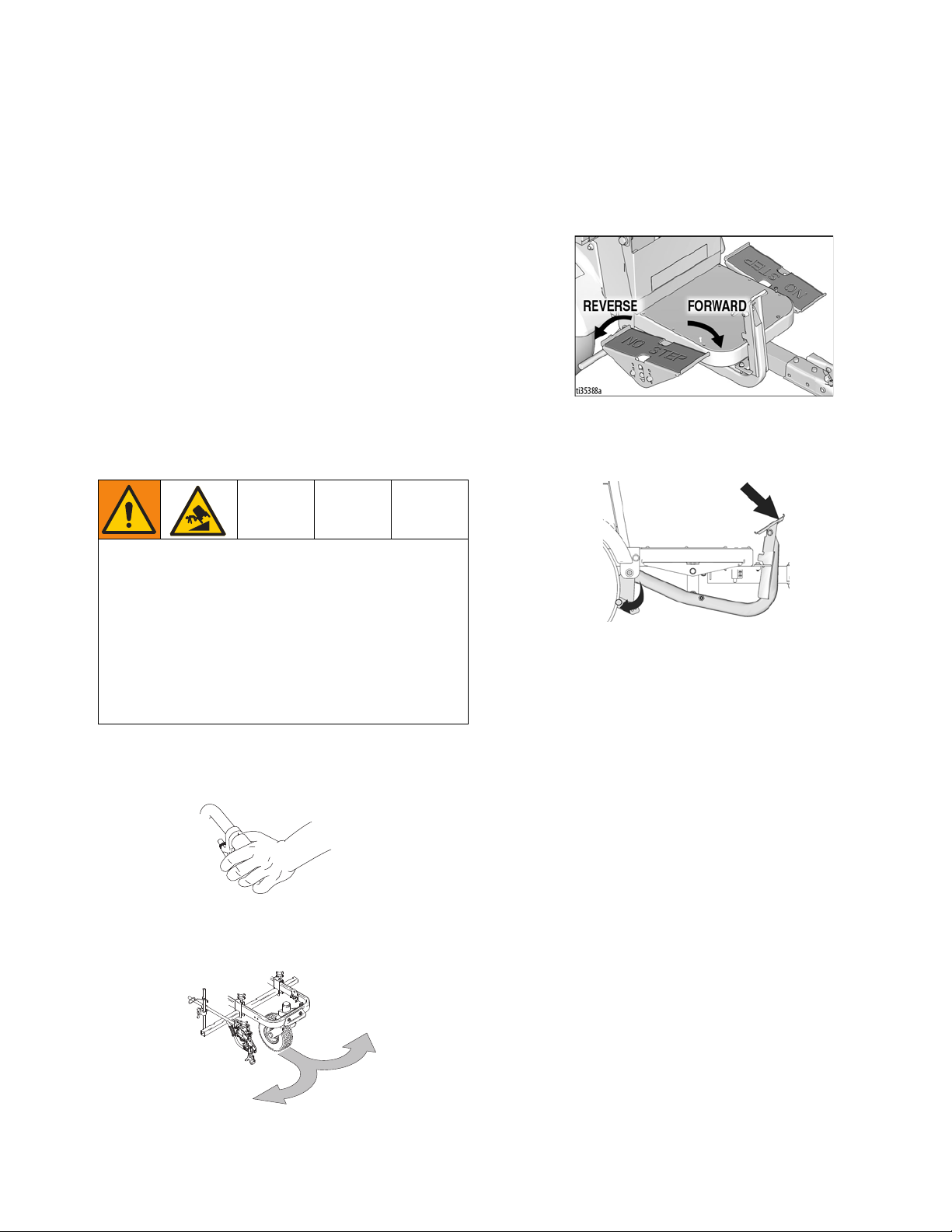

MOVING VEHICLE HAZARD

Careless and reckless behavior causes accidents. Falling from vehicle, running into people or object, or being

struck by other vehicles may result in serious injury or death.

•

Do not operate unless attached to line striping or line removal equipment.

•

Do not step on forward/reverse pedals.

•

Make turns slowly. Do not make turns greater than 45°.

•

Loss of traction may occur going downhill.

•

Do not operate on slopes greater than 7.5°.

•

Do not carry passengers.

•

Do not tow.

•

Use with line striping or line removal equipment only.

•

Use appropriate traffic control in all traffic areas. Refer to manual on Uniform Traffic Control Devices (MUTCD), U.S.

Department of Transportation, Federal Highway Administration or local highway and transportation regulations.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

BATTERY HAZARD

Lead-acid batteries produce explosive gases and contain sulfuric acid that can cause severe burns. To avoid

sparks and injury when handling or working with a lead-acid battery:

• Only use the battery type specified for use with the equipment. See Technical Data.

• Read and follow the battery manufacturer’s warnings.

• Exercise caution when working with metallic tools or conductors to prevent short circuits and sparks.

• Keep all sparks, flames, and cigarettes away from batteries.

• Always wear protective eyewear and protective equipment for face, hands, and body.

• If you have direct contact with battery fluid, flush with water and consult a physician immediately.

• Installation and maintenance must be performed by knowledgeable personnel only.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.