Installation

Installation

Genera Information

The Typical Installation shown is only a guide for

selecting and installing system components. Contact

your Graco distributor for assistance in planning a

system to suit your needs. Always use Genuine

Graco Parts and accessories. Be sure all accessories

are adequately sized and pressure rated to meet the

system’s requirements.

Reference letters in the text, for example (A), refer to

the callouts in the figures.

Variations in color between the plastic components

of this pump are normal. Color variation does not

affect the performance of the pump.

Tighten Fasteners

Before mounting and using the pump for the first time,

check and retorque all external fasteners. Follow

Torque Instructions, page 16, or see the torque

tag on your pump. After the first day of operation,

retorque the fasteners.

Tips to Reduce Cavitation

Cavitation in an AODD pump is the formation and

collapse of bubbles in the pumped liquid. Frequent

or excessive cavitation can cause serious damage,

including pitting and early wear of fluid chambers,

balls, and seats. It may result in reduced efficiency of

the pump. Cavitation damage and reduced efficiency

both result in increased operating costs.

Cavitation depends on the vapor pressure of the

pumped liquid, the system suction pressure, and the

velocity pressure. It can be reduced by changing any

of these factors.

1. Reduce vapor pressure: Decrease the

temperature of the pumped liquid.

2. Increase suction pressure:

a. Lower the installed position of the pump

relative to the liquid level in the supply.

b. Reduce the friction length of the suction

piping. Remember that fittings add friction

length to the piping. Reduce the number of

fittings to reduce the friction length.

c. Increase the size of the suction piping.

NOTE:

Be sure the inlet fluid pressure does not

exceed 25 % of the outlet working pressure.

3. Reduce liquid velocity: Slow the cyclic rate of

the pump.

Pumped liquid viscosity is also very important but

normally is controlled by factors that are process

dependent and cannot be changed to reduce

cavitation. Viscous liquids are more difficult to pump

and more prone to cavitation.

Graco recommends taking all the above factors

into account in system design. To maintain pump

efficiency, supply only enough air pressure to the

pump to achieve the required flow.

Graco distributors can supply site specific

suggestions to improve pump performance and

reduce operating costs.

Mount The Pump

To avoid serious injury or death from toxic fluid or

fumes:

• Ventilatetoaremotearea. Thepump

exhaust air may contain contaminants. See

Air Exhaust Ventilation, page 11.

• ever move or lift a pump under pressure. If

dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure, page 14,

before moving or lifting the pump.

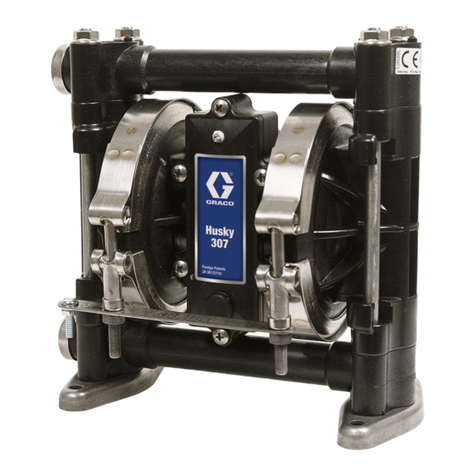

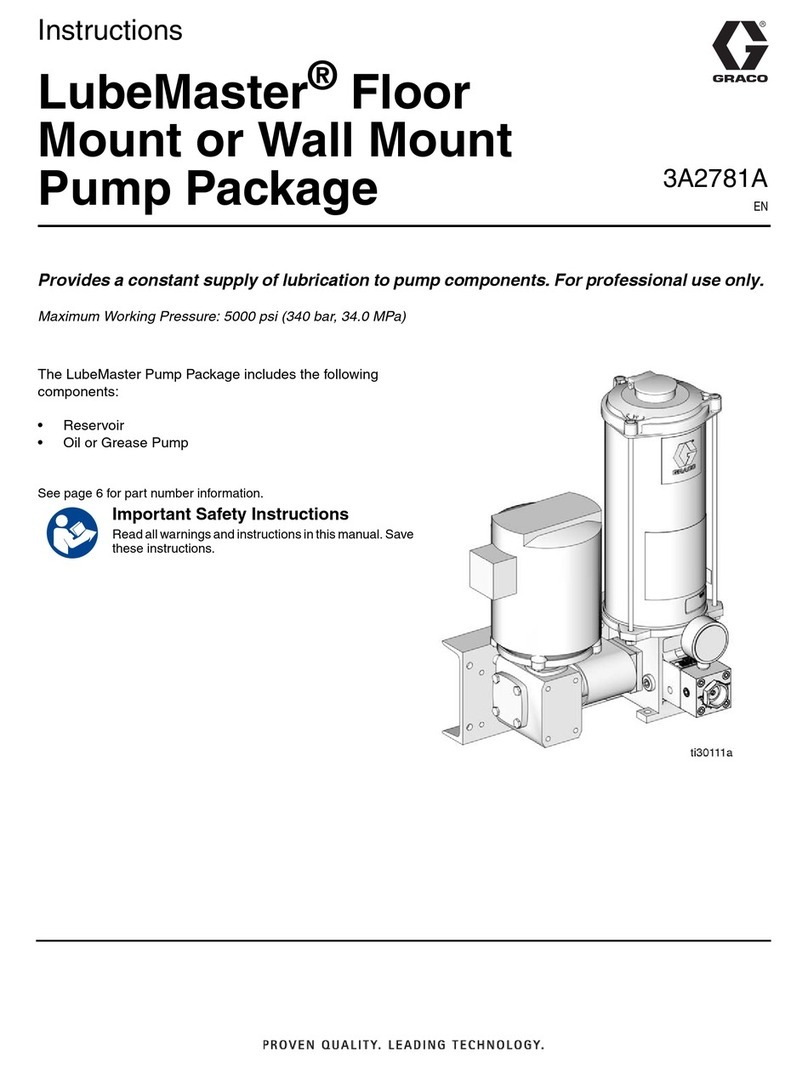

1. Be sure the mounting surface can support the

weight of the pump, hoses, and accessories, as

well as the stress caused during operation.

2. For all mountings, be sure the pump is secured

with screws through the mounting feet.

3. Make sure the surface is flat and that the pump

doesn’t wobble.

4. For ease of operation and service, mount the

pump so air valve, air inlet, fluid inlet and fluid

outlet ports are easily accessible.

83A2578