3.

SAFETY INSTRUCTIONS

Prior

to

installation

• Ensure the entire contents

of

this instruction manual are read.

• Ensure the package contains all component parts listed in this instruction manual.

• Ensure the two check valves stored inside the rubberchamber

of

the

appliance are removed.

• Ensure all packaging material is removed and disposed

of

correctly.

Installation

• Electrical installation

of

the appliance mustonlybe carried

out

by

a qualified person.

• The appliance must be installed in accordance with the installation instructions specified in

this document.

• Always ensure the macerator is connected

to

mainspower before water enters the unit.

Priorto use

• Before using the macerator, clean water must be flushed through

the

appliance several

times.Thiswill ensure the macerator is correctly installed.

Dailyuse

• The appliance

is

suitable for domestic, indoor use only.

• The appliance

is

suitable for the discharge

of

domestic faecal matter, wastewater and

toilet paper only. Failure

to

complywith thiswill invalidate the warranty.

• Products not

to

be

discharged using the appliance include but are not exclusive to: kitchen

towels, wet wipes, cotton wool, condoms and sanitary towels.

Servicing and maintenance

• Before servicing the appliance, always ensure the electrical supply

is

fully disconnected.

• Troubleshooting, maintenance and servicing

of

the appliance must only be carried out by a

person who

is

competent to do so.

• To maintain optimum performance, it is recommended that the appliance is serviced and

cleaned at least once every 6 months.

•

For

hygiene reasons, rubbergloves should be worn at all times when servicing the

appliance.

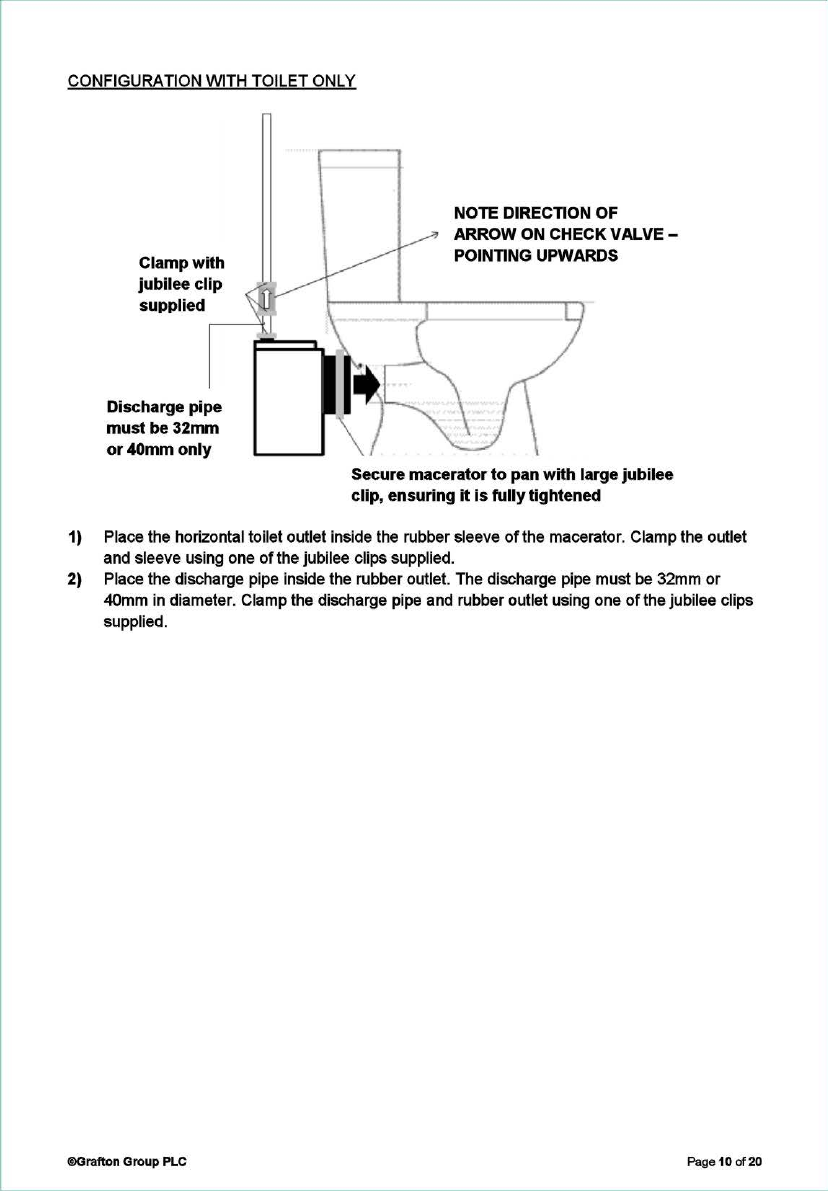

WARNING: This appliance must only be used with a 32mm

or

40mm waste pipe from the outlet to

the soil stack. It is not suitable for use with 22mm

or

25mm pipework. Using the maceratorwith an

incorrectly sized waste

may

result in a leaking unit.

C>Grafton

Group

PLC Page

5of20