8

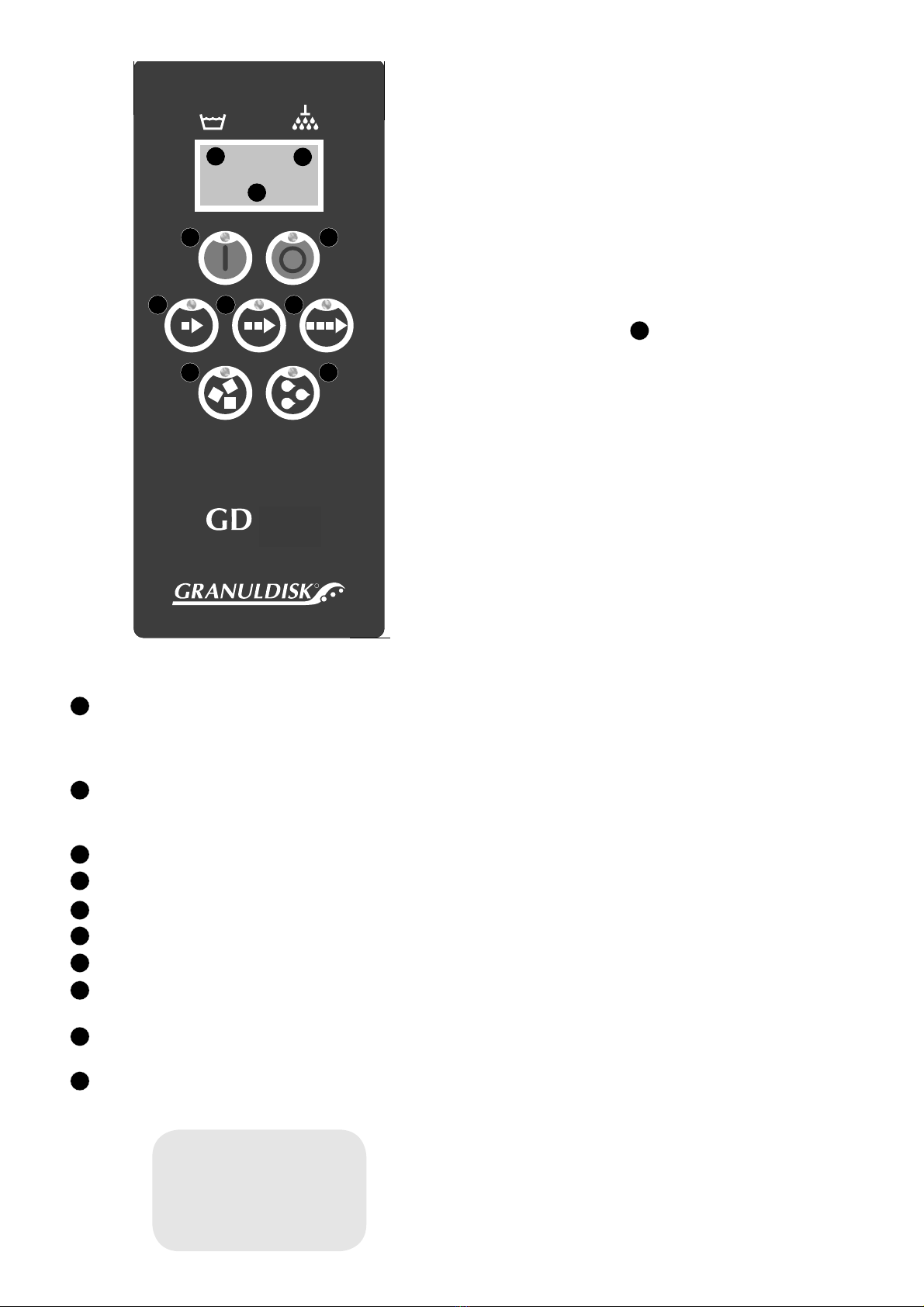

2. General description

The GD 600 potwashing system is designed to cope wth the

requirements of small to medium-size kitchens. The pots are

washed in the machine with a mixture of granules, water and

detergent. All the components are included in the system for effi

cient potwashing. From collection of pots through preparation

to putting the clean pots back on the shelf. The GD 600 is spe-

cially equipped for granule potwashing but also gives excellent

results without granules.

Design

The machine has a capacity for 4 gastronorm 200 mm deep 1/1

containers.There are various fi ttings available.These are designed

to accept the whole gastronorm range from 2/1 to 1/9 trays.

Other kitchenware from ladles and whisks to large saucepans can

also be washed by altering the fi ttings in a simple operation. The

machine is delivered as standard with two fittings.

3. Functional desciption

All operations described in this chapter may only be carried out by

qualified staff.

All electrical components described in this chapter apply to 400-

volt machines. Recalculated electrical values apply to other voltages

(see technical data).

Method of Operation

The machine comprises a wash tank containing water and gran-

ules. The wash pump sucks water and granules from the bottom

of the wash tank through a coarse grid, so preventing large objects

from being sucked into the pump. In the bottom of the tank is

a granule valve which controls whether washing is to take place

with or without granules. The mixture of water and granules is

distributed evenly over the items to be washed via spray pipes

and special nozzles. The water and granules re-circulate in the

system. There are heater elements in the wash and rinse tanks to

heat the water to operating temperature.

After the washing phase there is a separation phase with just

water to rinse away the remaining granules from the items being

washed. Finally the items being washed are rinsed with fresh

water pumped from the open rinse tank, which is entirely sepa-

rated from the water mains network by means of what is known

as a type AB airgap, in accordance with EN 1717, and the rinse

water is pumped out from this via separate final rinse pipes and

nozzles. The final rinse is to wash away any granule residue and

to increase the temperature of the items being washed to guar-

antee a disinfectant cleaning. During the final rinsing phase the

refilling of the machine with water will occur.

Wash programmes

There are three wash programmes to choose from: short,

normal or long programmes, plus these programmes with or

without granules. If other times or combinations are required,

these can be programmed by an authorised service engineer.

The granules are separated out from the wash water once the

granule cycle is complete. The wash pump stops after 1 minute

of washing without granulate, then the final rinse starts. The

final rinse is set to guarantee a water temperature of 85 °C for

30 seconds.

If the rinse water temperature is too low, the wash time is

extended until it is at 85 °C. The wash programmes without

granules are 1 minute shorter than those with. When the steam

reduction function is used, the hot steam is condensed for 1

minute at the end of every programme.

Wash water system

The wash tank is fitted with a 9 kW heater element to keep the

wash water at the right temperature. The wash tank is filled with

heated water from the rinse tank. A temperature sensor in the

wash tank ensures that the wash water is at the right temperature.

A level sensor at the back of the wash tank maintains a constant

water level. Wash water and granules are pumped through the

two spray pipes and sprayed at high pressure at the items to be

washed. Water and granules are re-circulated in a closed system.

The granules are gradually rinsed out of the items to be washed

during the separation phase and rinsed out of the wash water.

Rinse water system

The rinse tank has a capacity of some 12 litres and is entirely

separated from the water mains network by means of what is

known as a type AB airgap, in accordance with EN 1717. 8 litres

of water are used for every final rinse. The water in the tank is

heated by a 9 kW heater element. The final rinse starts once the

wash cycle is completed. The rinse water at 85 degrees is pumped

and distributed through the nozzles on the rinse pipe. This rinses

away chemical residue while at the same time killing bacteria.

The final rinse jets are divided up on a four pronged final

rinse arm located in the lid together with the wash arm. They

are located so that the rinse water is directed evenly over the

items being washed. The machine is also filled with water via

these nozzles.

Heater elements and temperature sensors

The GD 600 is fitted with one heater element for heating the

wash water and one heater element for heating the rinse water.

The water temperature is regulated by means of temperature sen-

sors, one in the wash tank and one in the rinse tank, and these

emit signals via the control card to the relay switches for the

respective heater elements. The heater elements in the wash tank

and rinse tank operate alternately with priority for the rinse tank

during washing and for the rinse tank in standby mode. In the

event of an error in any of the temperature sensors, the wash

cycle is interrupted and the machine is returned to stop mode.

An error code relating to the temperature sensor is shown in the

display: see Troubleshooting on page 20. There are overheating

protectors in both the wash tank and the rinse tank in order to

prevent damage due to overheating of the heater elements.

Drain valve

At the bottom of the machine, on the front, is a handle for the

wash tank drain valve. This valve is fitted with a sensor which

senses whether the valve is open or closed. If the machine is in an

active process and the valve is opened, the machine switches to

stop mode and an error message is shown in the display.

WARNING!

Only qualified electricians may work

with the electrical unit.

The main fuse shall always be removed

when working with the electrical

components.

Incorrect connections can cost lives.