2Technical Information

Service Manual

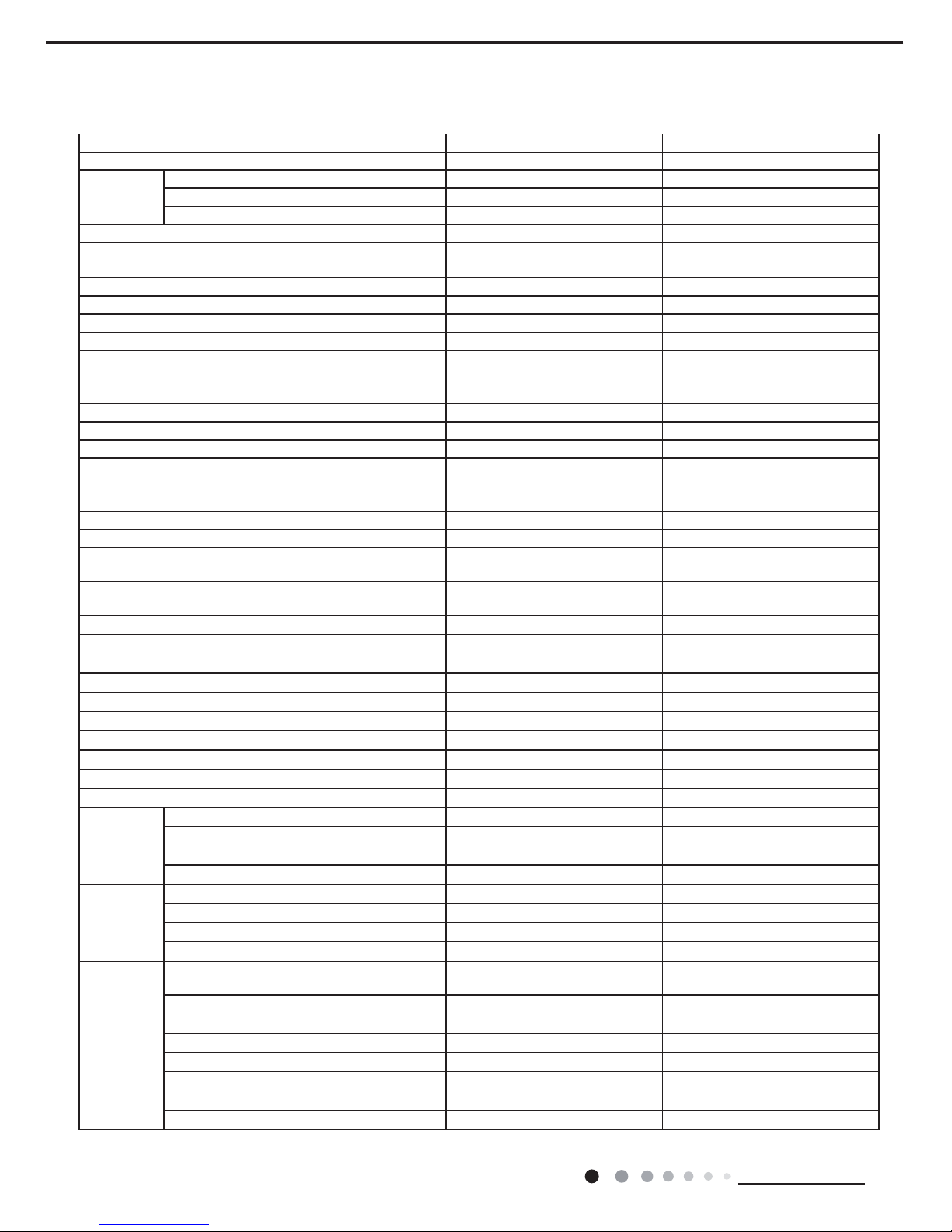

6SHFL¿FDWLRQV

Model GDN40AU-K3EBA1A GDN40AW-K3EBA1A

Product Code CK051024400 CK051024500

Power

Supply

Rated Voltage V Њ220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

5DWHG'HKXPLGL¿FDWLRQ&DSDFLW\ Pint/D 50 51

Power Input W 570 570

Current Input A 2.65 2.65

Set Humidity Range % 30/80 30/80

Air Flow Volume (H/M/L) m3/h 230/195/170 230/195/170

Fan Motor Speed (H/M/L) r/min 1260/1070/900 1260/1070/900

Fan Motor Power Output W 20 20

Fan Motor RLA A 0.35 0.35

Fan Motor Capacitor ȝ) 22

Fan Type Centrifugal Centrifugal

Fan Diameter Length (DXL) mm ĭ; ĭ;

Throttling Method Capillary Capillary

Fuse Current A 3.15 3.15

Sound Pressure Level (H/M/L) dB (A) 46/43/40 46/43/41

Sound Power Level (H/M/L) dB (A) 56/53/50 56/53/51

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating Pressure for the

Discharge Side MPa 4.3 4.3

Permissible Excessive Operating Pressure for the

Suction Side MPa 2.5 2.5

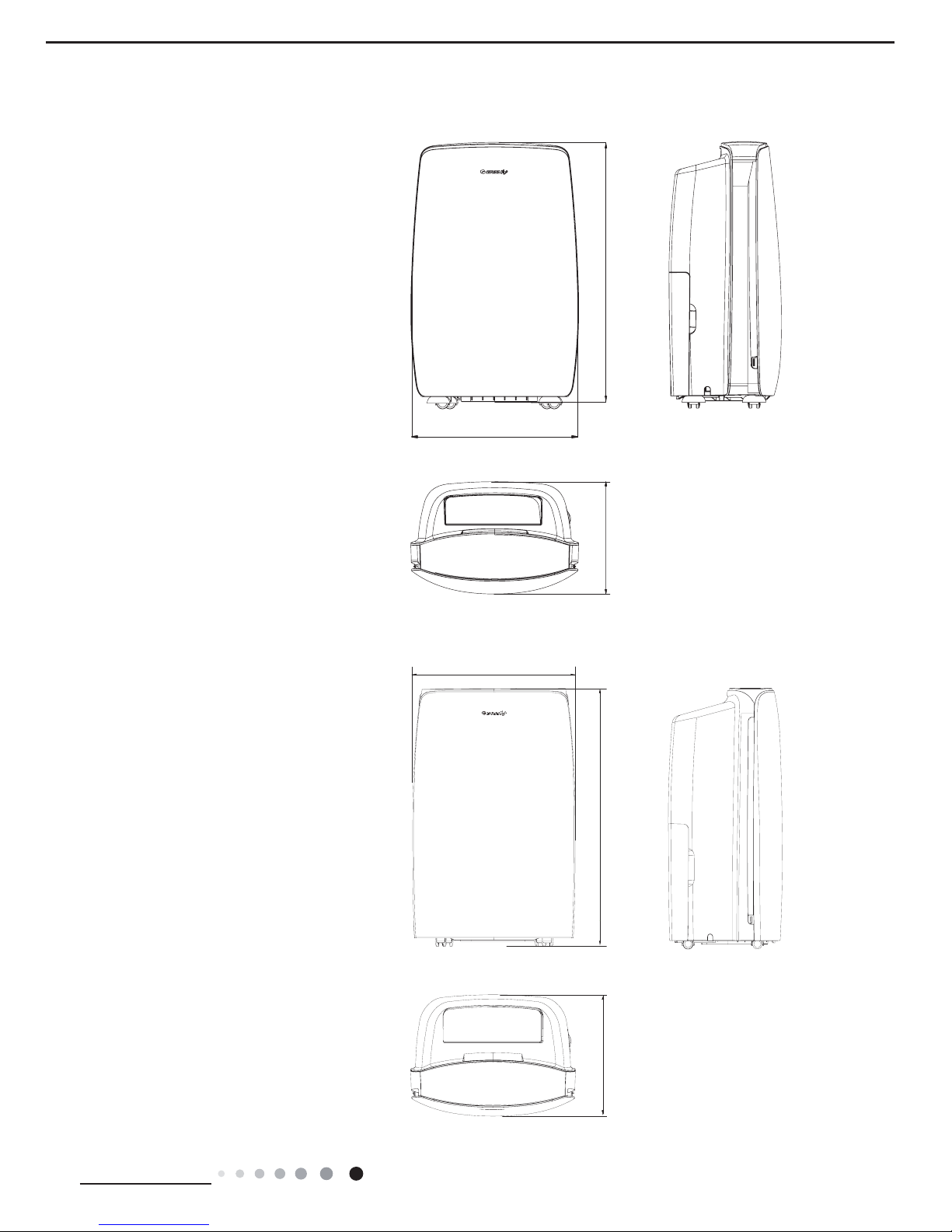

Dimension (WXHXD) mm 390X628X286 396X625X286

Dimension of Carton Box (LXWXH) mm 348X461X655 448X338X638

Dimension of Package (LXWXH) mm 351X464X670 451X341X653

Application Area m248 48

Net Weight kg 22 23

Gross Weight kg 23.5 24.5

Refrigerant R410A R410A

Refrigerant Charge kg 0.31 0.31

Bucket Capacity L 6.5/7 6.5/7

Control Type Electronic Electronic

Evaporator

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Evaporator Pipe Diameter mm ĭ ĭ

(YDSRUDWRU5RZ¿Q*DS mm 2-1.4 2-1.4

Evaporator Coil Length (LXDXW) mm 261X228.6X25.4 261X228.6X25.4

Condenser

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm ĭ ĭ

&RQGHQVHU5RZV¿Q*DS mm 3-1.4 3-1.4

Condenser Coil Length (LXDXW) mm 261X228.6X38.1 261X228.6X25.4

Compressor

Compressor Manufacturer ZHUHAI LANDA COMPRESSOR

CO., LTD.

ZHUHAI LANDA COMPRESSOR

CO., LTD.

Compressor Model QXA-A071L130C QXA-A071L130C

Compressor Type Rotary Rotary

Compressor Power Input W 630 630

Compressor Overload Protector UP3-B0 UP3-B0

Compressor Oil RB68EP RB68EP

Compressor LRA. A 15 15

Compressor RLA A 2.9 2.9

The above data is subject to change without notice; please refer to the nameplate of the unit.

6SHFL¿FDWLRQ6KHHW