INTRODUCTIONINTRODUCTION

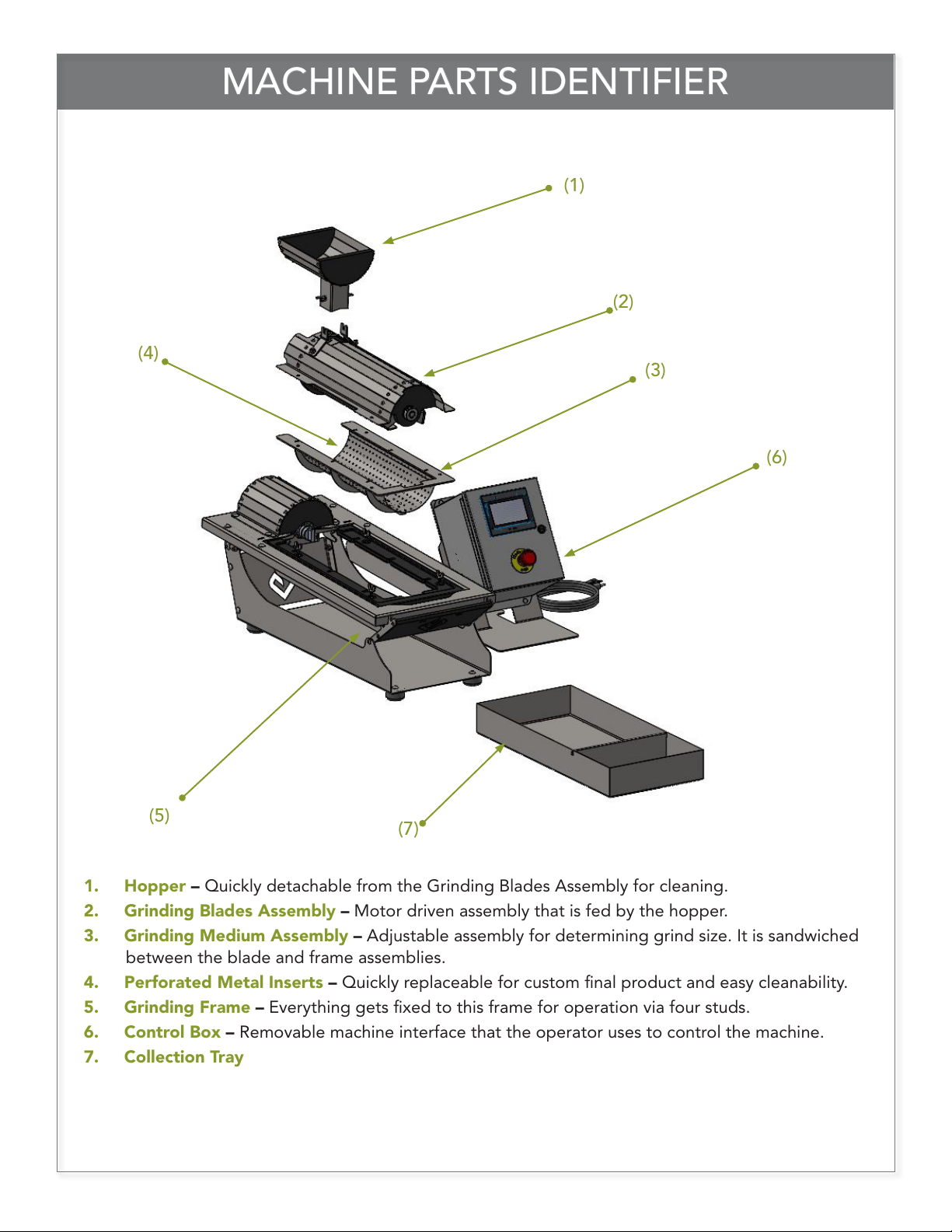

The G Lite Tabletop Cannabis Grinder is utilized in your post-harvest processing of hemp and

cannabis. The G Lite destems and grinds, it is the first machine of its kind that gives users

complete control of their finished product with perfect consistency. The G’s low RPM grinding

preserves trichomes and separates stems from material simultaneously.

The G Lite is consists mainly of a grinding assembly. It includes speed controls which allow users

to customize the size of the grind, get a consistent mill, and speed up downstream processes.

The assembly comes with the 1/8” screen size. The other screen sizes -- 5/32” and 3/16”-- are

available for purchase. Functions can be manipulated and adapted further by utilizing the

machine’s angle control.

The G Lite’s surgical stainless-steel construction discourages microbial growth and makes it easy

for users to break down and pressure wash the entire unit, minimizing downtime. The machine

has the smallest footprint of any grinder in its class. It can easily be transported to wherever it’s

needed.

Variable Effects Option #1 Option #2

Speed of the

blades:

Machine

Torque

RPMs

Number of

stems in your

biomass

Throughput

per hour

The SLOWER the grinding equates

to higher torque and increased stem

removal. Slower RPMs allow buds

more time to align with the face

of the blade, keeping them intact.

HOWEVER, there would be less

throughput.

The FASTER the grinder rotates, the

less torque it has, and the more often

it will cease (keep in mind, ceasing is

not an issue as long as the machine is

not ceased up for an extended period).

The higher RPM gives the buds less

time to align with the grinding blades

and, in turn, will break more stems,

putting them into the final product.

Humidity level

of material

Number of

stems in your

biomass

Grind

consistency

INCREASING the humidity level of

your biomass will DECREASE the

number of stems in the final output.

This is because dry stems snap and

fall apart instead of bending and

staying intact.

DECREASING the humidity level will

INCREASE the number of stems in the

final output. If your material turns into

a paste, instead of being ground, it is

too wet.

Angle of the

grinding

volume

Number of

stems in your

biomass

Throughput

per hour

INCREASING the angle of the

machine (1, 3, 6 options) will

DECREASE the number of stems in

your final output. This is because the

material will be ground for a smaller

amount of time.

DECREASING the angle of the

machine (1, 3, 6 options) will

INCREASE the amount of stems in

your final output. This is because the

material will be ground for a longer

period of time.

844.DRY.TRIM info@greenbroz.com greenbroz.com

4