3

PRE-STARTING CHECKS

Note: For units shipped with motor and drives separate, refer to the Motor Mounting Instructions included in the

hardware bag.

★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★

WARNING

DISCONNECT AND SECURE TO THE “OFF” POSITION ALL ELECTRICAL POWER TO THE FAN PRIOR TO INSPECTION OR

SERVICING. FAILURE TO COMPLY WITH THIS SAFETY PRECAUTION COULD RESULT IN SERIOUS INJURY OR DEATH.

★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★★

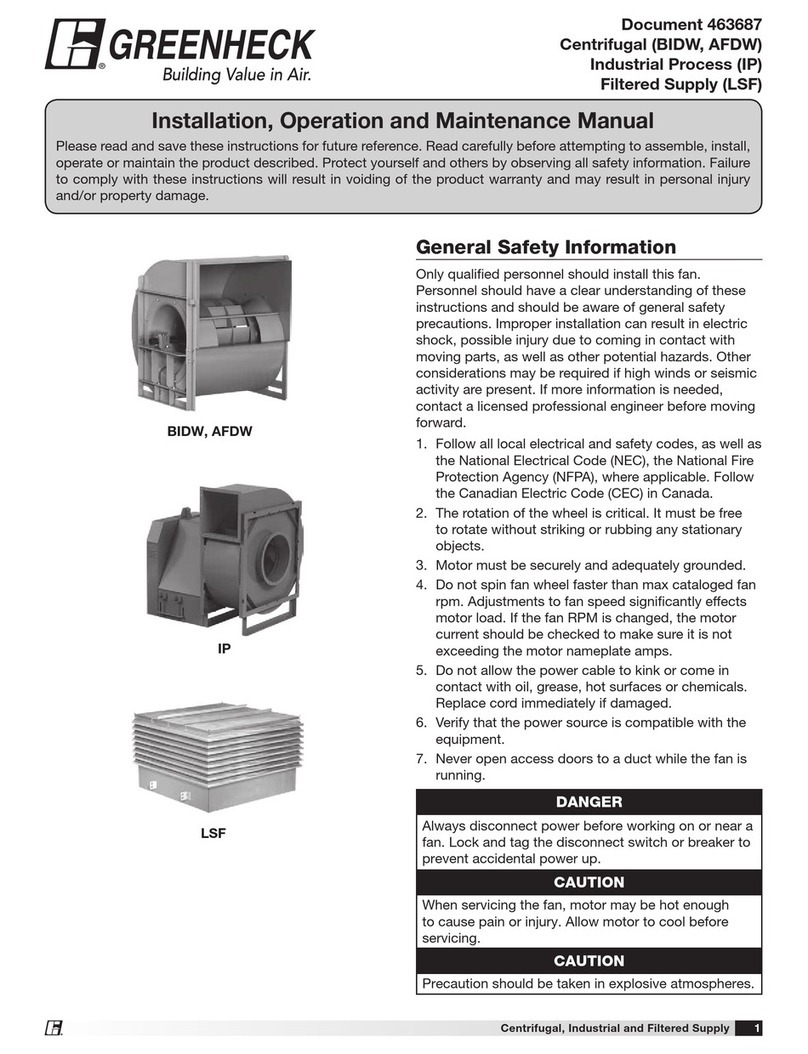

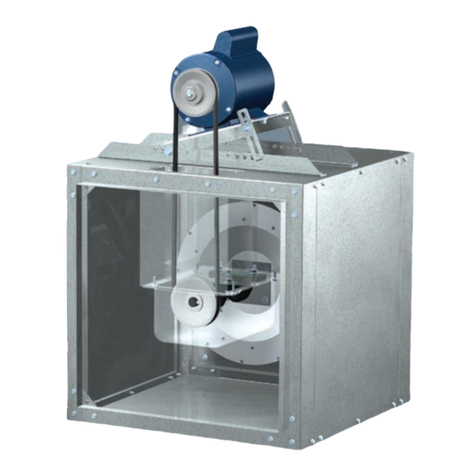

Check all fasteners and set screws for tightness.

Rotate the fan wheel by hand to assure it turns freely

and is centered between the inlets. Check pulleys and

belts for proper alignment to avoid premature belt wear,

noise, vibration and power loss. Motor and fan pulleys

must be parallel and in line as shown in Figure 2.

The adjustable motor pulley is set at the factory for

the fan RPM specified. Fan speed can be increased by

closing or decreased by opening the adjustable motor

pulley. Two groove variable pitch pulleys must be

adjusted an equal number of turns open. Any increase

in fan speed results in an increase in horsepower

required for the motor. Motor load amperes should

always be checked and compared to nameplate rating

when changing fan speed.

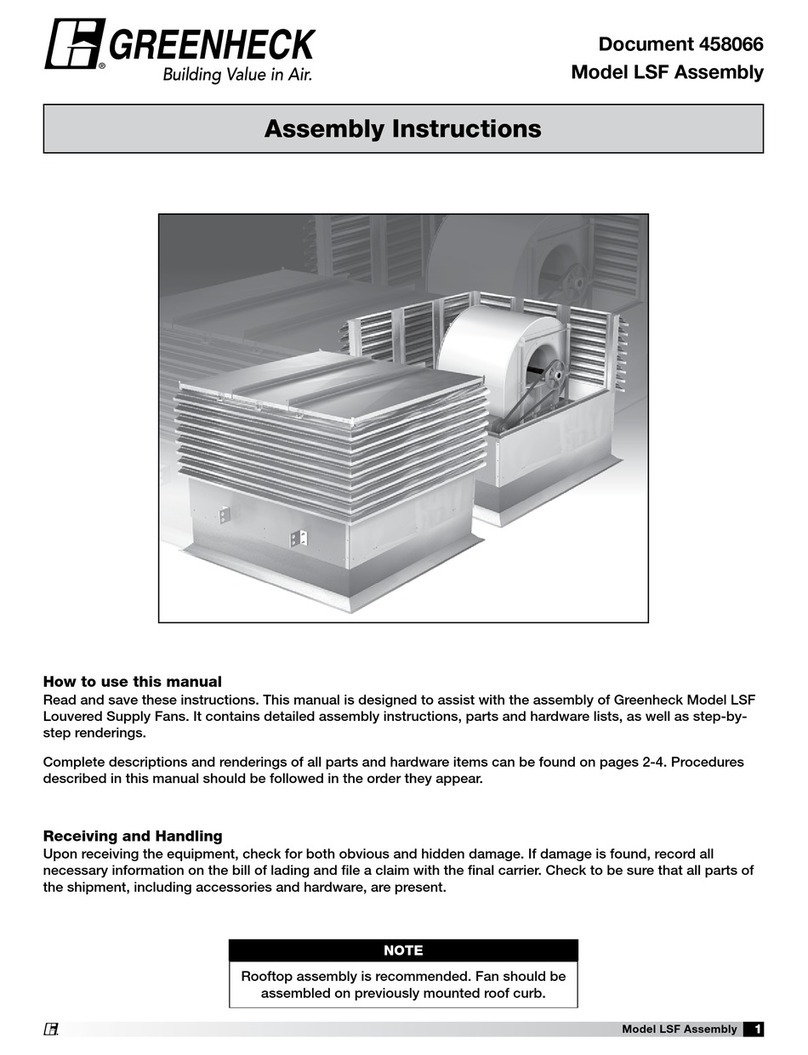

Direction of fan wheel rotation is critical. A fan wheel

rotating in the wrong direction will result in reduced

airflow, motor overloading and possible burn-out. Check

wheel rotation by momentarily turning the fan on.

Rotation should be in the same direction as airflow at

the outlet. See housing and wheel examples in Figure 3.

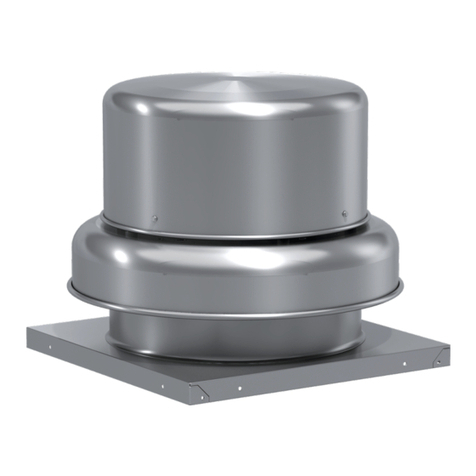

IMPORTANT NOTE: RSF/RSFP fans should be operated

only when attached to the completed system. Without

proper static pressure loading, the motor may be

overloaded and burnout occur.

ROUTINE MAINTENANCE

See WARNING above

To preserve the reliability and performance designed into the fan, regularly scheduled maintenance should be

performed. Items to be checked at each maintenance interval are filters, belts, bearings, fasteners, lubrication and

removal of dust and dirt.

FILTERS

1" washable aluminum mesh filters are standard on Model RSF and RSFP fans. (Optional 2" filters may be supplied

on some fans). Filters should be cleaned on a regular basis for optimum efficiency.

To remove the filters, first remove the fan cover by releasing the four latches. (Place the cover in an area where

wind will not blow it off the roof). The filters can be lifted out and washed in a mild detergent solution. If desired, an

adhesive spray available at most filter distributors can be applied to increase filter efficiency.

BELTS

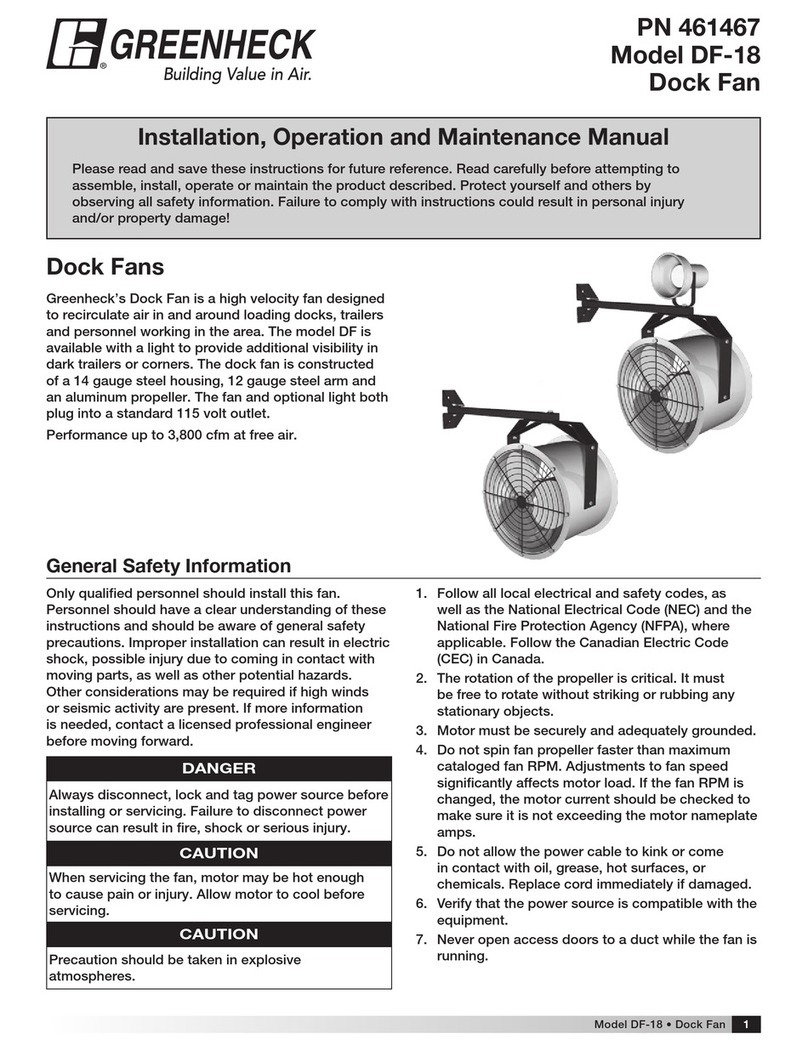

Belt tension should be checked two times during the first 24 hours of operation and during each scheduled

maintenance thereafter. Premature belt failures are frequently caused by improper belt tension, either too tight or loose.

The proper belt tension for operating a V-belt is the lowest tension at which the belt will not slip at peak load

conditions. For initial tensioning, belt deflection should be 1/64" for each inch of belt span, determined by using

moderate thumb pressure half way between pulley centers. For example, the belt deflection should be 1/2 inch if the belt

span is 32 inches (Figure 4).