Greenlee Textron / Subsidiary of Textron Inc. 4

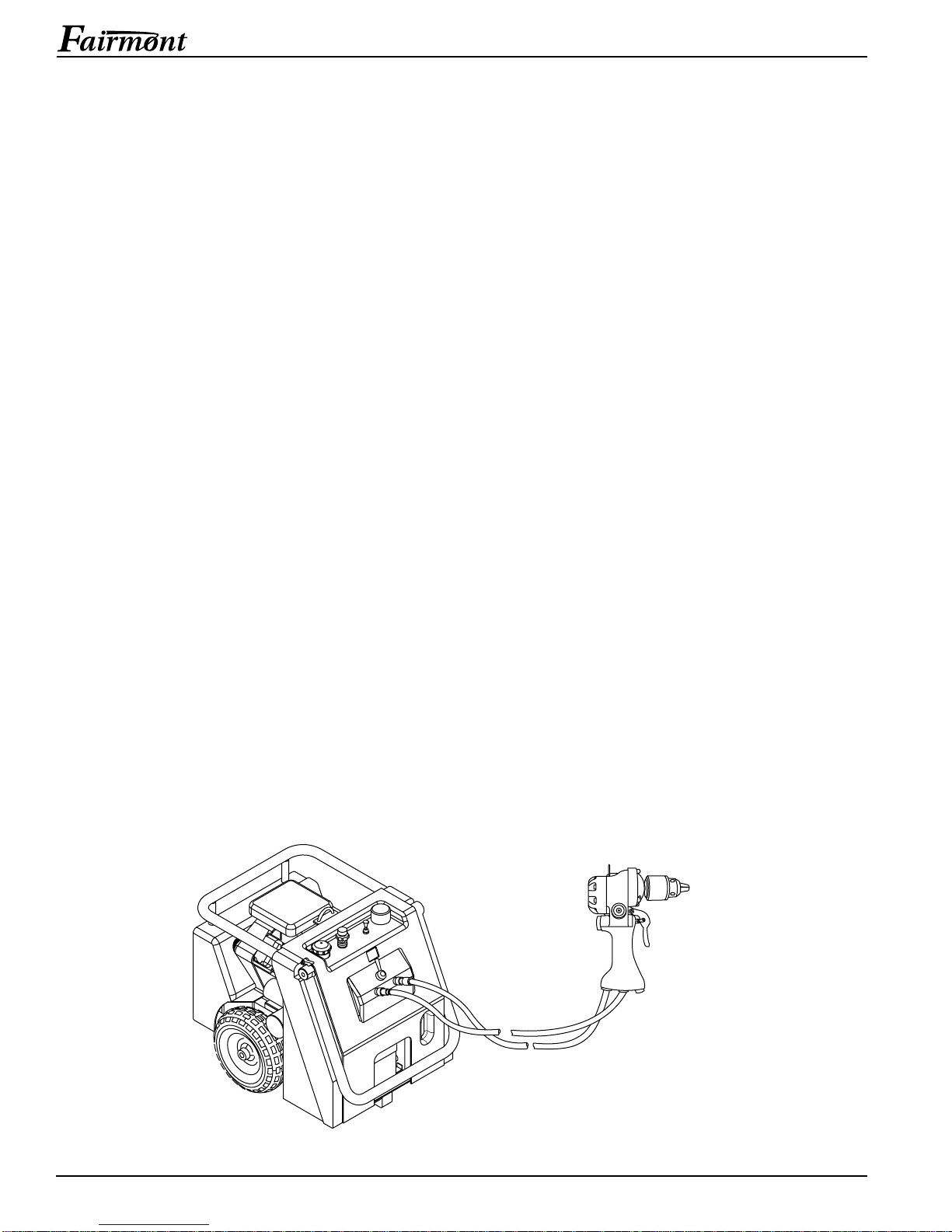

Reversible Drills

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

IMPORTANT SAFETY INFORMATION

Do not reverse hydraulic flow. Operation with

hydraulic flow reversed can cause tool malfunc-

tion. Connect the pressure (supply) hose and tank

(return) hose to the proper tool ports.

Failure to observe this warning can result in

severe injury or death.

• Remove the chuck key from the chuck before

drilling. Operation with the key in the chuck can

result in severe injury.

• Inspect accessories before use. Discard acces-

sories that have cracks, chips or gouges.

• Keep all parts of the body away from rotating

parts when the tool is in operation. Contact with

moving parts can result in severe injury.

• Do not change accessories, inspect, adjust or

clean tool when it is connected to a power

source. Accidental start-up can result in serious

injury.

• Maintain a firm grip on tool, using both hands at

all times. Serious injury can result if the operator

does not control the tool.

• Do not lock the trigger in the power-ON position.

The operator cannot stop the tool when the

trigger is locked.

Failure to observe these warnings can result in

severe injury or death.

Tool and accessory may be hot

during and after operation. Allow to

cool before handling, or handle with

heat-resistant gloves.

Failure to observe this warning

could result in severe injury.

Do not exceed the maximum hydraulic flow, pres-

sure relief or back pressure listed in the Specifica-

tions and Parts manual.

Failure to observe this warning can result in severe

injury or death.

Do not disconnect tool, hoses or fittings while the

power source is running or if the hydraulic fluid is

hot. Hot hydraulic fluid can cause serious burns.

• Wear protective gloves when handling, remov-

ing and installing drill bits. Drill bits can cut even

when stationary.

• Inspect tool before use. Replace any worn,

damaged or missing parts with Fairmont re-

placement parts. An improperly assembled tool

can malfunction, injuring nearby personnel.

• Inspect the hydraulic hoses and couplings every

operating day. Repair or replace if leakage,

cracking, wear or damage is evident. Damaged

hoses or couplings can fail, resulting in injury or

property damage.

• Use this tool for the manufacturer’s intended

purpose only. Use other than that which is

described in this manual can result in injury or

property damage.

• Ensure that all bystanders are clear of the work

area when handling, starting, and operating the

tool. Nearby personnel can be injured by flying

debris or by flying parts in the event of a tool

malfunction.