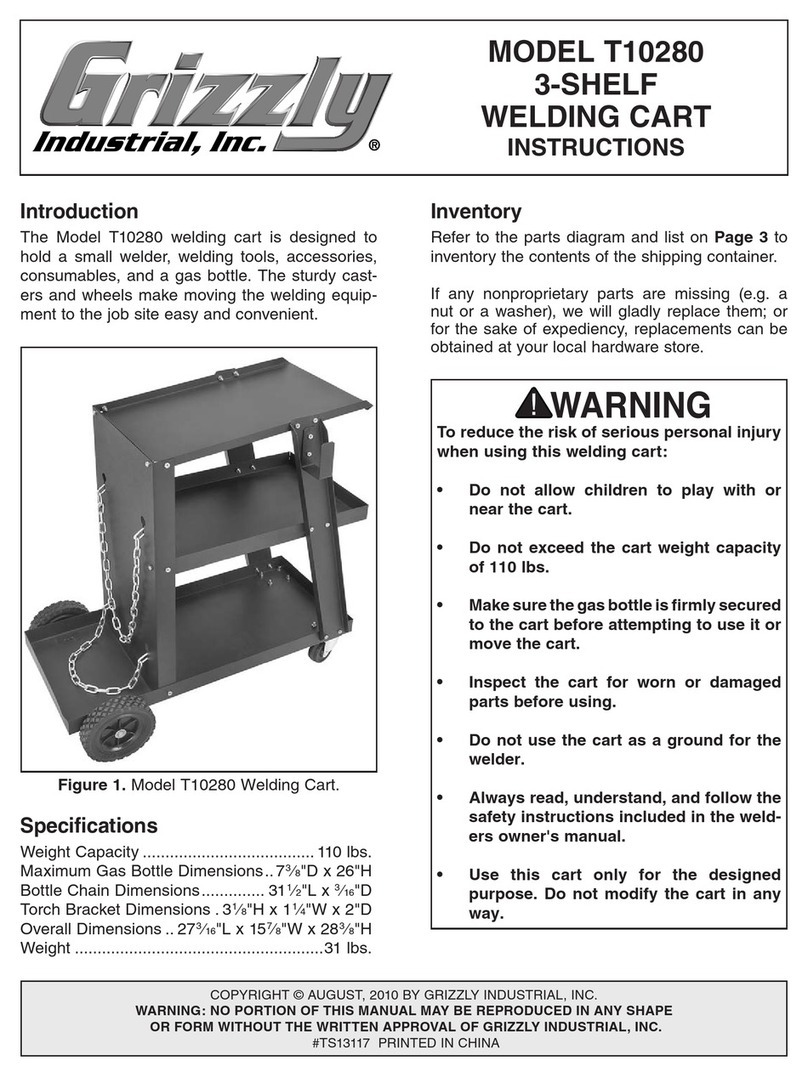

Introduction

This Welding Helmet features a view area of 11⁄4" x

31⁄4" and a weight of 19 oz., fully adjustable head-

gear with sweat band and is supplied with a #13

shade filter.

Inventory

A. Welding Hood ............................................. 1

Operation Safety

Welding produces ultraviolet and infrared rays

that are harmful if skin or eyes are left unpro-

tected. Please read and follow these important

safety guidelines.

• Use a welding helmet that is supplied with

the correct shade filter to protect your eyes

and face while welding or watching a welding

process.

Welding Helmet

MODEL H7787

INSTRUCTION SHEET

Welding helmets do not provide unlimited

protection for your eyes, ears and lungs.

Personal injury could result from using

this welding helmet without proper protec-

tive gear. Always wear safety glasses, an

approved respirator, and hearing protection

while welding.

COPYRIGHT © OCTOBER, 2005 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#DD7616 PRINTED IN CHINA

• Wear safety glasses with sides shields or

goggles under the welding helmet.

• Wear protective clothing that is fire resistant

like leather or wool. DO NOT wear tennis

shoes or street shoes while welding. Wear

leather boots that come up past the ankles

and have fire resitant soles.

• Protect those around you from welding

flash and fire by using protective barriers or

screens.

• Remove any flammable materials in the area

before you begin to weld.

• Have someone perform fire watch while you

are welding and for at least an hour after you

have finished welding, to guard against fire.

• DO NOT weld if the welding helmet is dam-

aged. Inspect it carefully and replace com-

ponents as needed. Make sure the clear

protective lense is not scratched or covered

with smoke as it may obstuct vision.

• Never use the welding helmet to look at the

sun. The welding helmet is designed for use

while welding, only.

• DO NOT grind while wearing the helmet. The

helmet and/or lense may become damaged

and malfunction or break.