3

• Always check for damaged or loose

hoses and fittings.

12. Workplace Hazards

• The use of the tool can expose the

operator's hands to hazards including

crushing, impacts, cuts and abrasions

and heat. Wear suitable gloves to

protect hands.

• Operators and maintenance personnel

should be physically able to handle the

bulk, weight and power of the tool.

• Hold the tool correctly; operator

should be ready to counteract normal

or sudden movements and have both

hands available.

• Maintain a balanced body position and

secure footing.

• It is recommended to use a suspension

arm/spring balancer whenever

possible.

• The working places shall be kept

ventilated, clean and illuminated.

• It is recommended to use means to

absorb the reaction torque above 4

Nm for straight tools, above 10 Nm for

pistol-grip tools.

• Release the trigger in the case of an

interruption of the energy supply.

• Do not use in confined spaces and

beware of crushing hands between

tool and work piece, especially when

unscrewing

• The Pneumatic tool is not intended

for use in potentially explosive

atmospheres and is not insulated

against electric power.

• Make sure there are no electrical

cables, gas pipes, etc., that can cause

a hazard if damaged by use of the tool

13. Additional Safety Topics

• If the operator experiences symptoms

such as persistent or recurring

discomfort, pain, throbbing, aching,

tingling, numbness, burning sensations

or stiness, these warning signs

should not be ignored. The operator

should tell the employer and consult a

qualified health professional.

• If you experience numbness, tingling,

pain or whitening of the skin in your

fingers or hands, stop using the

Pneumatic tool for threaded fasteners,

tell your employer and consult a

physician.

• Appropriate controls to reduce the risk

may include actions such as damping

materials to prevent work pieces from

“ringing”.

• Exposure to vibration can cause

disabling damage to the nerves and

blood supply of the hands and arms.

• Do not use worn or ill-fitting sockets or

extensions, as this is likely to cause a

substantial increase in vibration.

• Support the weight of the tool in a

stand, tensioner or balancer, if possible.

• Hold the tool with a light but safe grip,

taking account of the required hand

reaction forces, because the risk from

vibration is generally greater when the

grip force is higher

• Use hearing protection in accordance

with employer's instructions and

as required by occupational health

and safety regulations. Unprotected

exposure to high noise levels can cause

permanent, disabling, hearing loss

and other problems, such as tinnitus

(ringing, buzzing, whistling or humming

in the ears).

• Dust and fumes generated when

using Pneumatic tools can cause ill

health (for example, cancer, birth

defects, asthma and/or dermatitis);

risk assessment and implementation of

appropriate controls for these hazards

are essential.

• Use respiratory protection in

accordance with employer's

instructions and as required by

occupational health and safety

regulations.

INSTALLATION

Air Pressure

Always use clean and dry air at 90 PSI

(6.2 bar) to operate the Pneumatic tools

Do not operate Pneumatic tools beyond the

maximum working air pressure of 90 PSI

(6.2 bar).

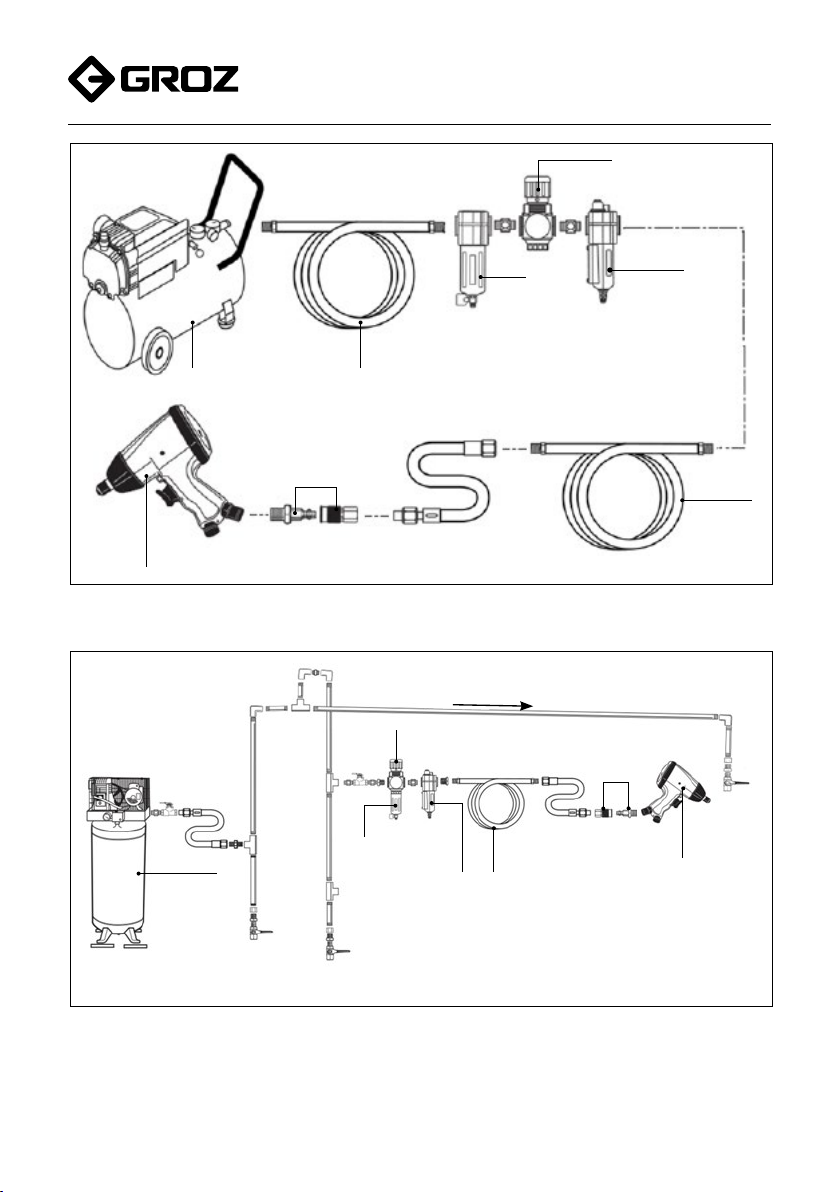

Air Line

For using pneumatic tools eciently, connect

air hose to the air inlet. Compressed air

has traces of moisture (water droplets)

in it and this moisture may permeate into

the pneumatic tools and cause mechanical

failure, therefore It is strongly recommended

to install an air filter, moisture separator,

regulator and lubricator in the air supply line.

Typical air supply setups are shown in the

following figures.