English (US)

2

English (US) Installation and operating instructions

Original installation and operating instructions

CONTENTS

Page

1. Limited warranty

Products manufactured by GRUNDFOS PUMPS CORPORATION

(Grundfos) are warranted to the original user only to be free of

defects in material and workmanship for a period of 24 months

from date of installation, but not more than 30 months from date

of manufacture. Grundfos' liability under this warranty shall be

limited to repairing or replacing at Grundfos' option, without

charge, FOB Grundfos' factory or authorized service station, any

product of Grundfos' manufacture. Grundfos will not be liable for

any costs of removal, installation, transportation, or any other

charges which may arise in connection with a warranty claim.

Products which are sold but not manufactured by Grundfos are

subject to the warranty provided by the manufacturer of said

products and not by Grundfos' warranty. Grundfos will not be

liable for damage or wear to products caused by abnormal

operating conditions, accident, abuse, misuse, unauthorized

alteration or repair, or if the product was not installed in

accordance with Grundfos' printed installation and operating

instructions.

To obtain service under this warranty, the defective product must

be returned to the distributor or dealer of Grundfos' products from

which it was purchased together with proof of purchase and

installation date, failure date, and supporting installation data.

Unless otherwise provided, the distributor or dealer will contact

Grundfos or an authorized service station for instructions. Any

defective product to be returned to Grundfos or a service station

must be sent freight prepaid; documentation supporting the

warranty claim and/or a Return Material Authorization must be

included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES

ARISING FROM INSTALLATION, USE, OR ANY OTHER

CAUSES. THERE ARE NO EXPRESS OR IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND

THOSE WARRANTIES DESCRIBED OR REFERRED TO

ABOVE.

Some jurisdictions do not allow the exclusion or limitation of

incidental or consequential damages and some jurisdictions do

not allow limit actions on how long implied warranties may last.

Therefore, the above limitations or exclusions may not apply to

you. This warranty gives you specific legal rights and you may

also have other rights which vary from jurisdiction to jurisdiction.

2. General information

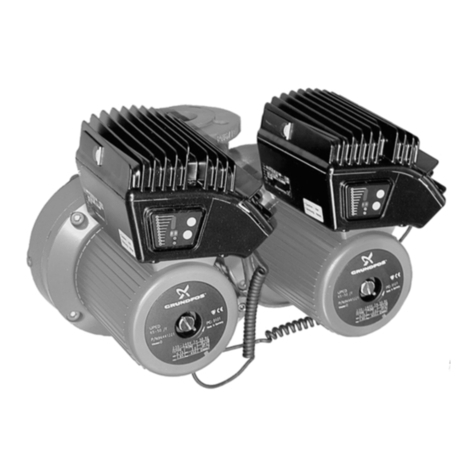

These installation and operating instructions apply to Grundfos

DSS (dosing skid station) systems equipped with Grundfos

dosing pumps.

The proper functioning of a DSS system depends on the following

points:

• correct operation

• regular maintenance

• calibration of the pump after installing the service kit and

periodic re-calibration of the pump

• installation of service kit as recommended by individual DSS

component manuals, ie manuals for dosing pumps, back

pressure and pressure relief valves.

1. Limited warranty 2

2. General information 2

2.1 Type key 3

3. Safety information 4

3.1 Target group 4

3.2 Symbols used in this document 4

3.3 Safety-related symbols on the product 4

3.4 Safety instructions for the user 4

3.5 Unauthorized changes 4

3.6 Safety of the system in the event of product failure 4

3.7 Working with chemicals 5

4. Product introduction 5

4.1 Certificates 5

4.2 Intended use 5

4.3 Improper use 5

4.4 Product overview and dimensions 5

4.5 Standard DSS pipe and instrumentation diagram for 1-,

2- and 3-pump systems 7

5. Technical data 8

6. Transport and storage 8

7. Installation 9

7.1 Electrical connection 9

8. Startup 12

8.1 Calibration 12

9. Operation 12

10. Maintenance 12

10.1 Safety instructions 12

10.2 Maintenance intervals 13

11. Long-term shutdown 13

12. Disposal 13

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

Read the installation and operating instructions of

the DSS components (dosing pumps, back pressure

and pressure relief valves, pulsation dampers,

calibration columns and control panels)