3.

4.

5.6.7.

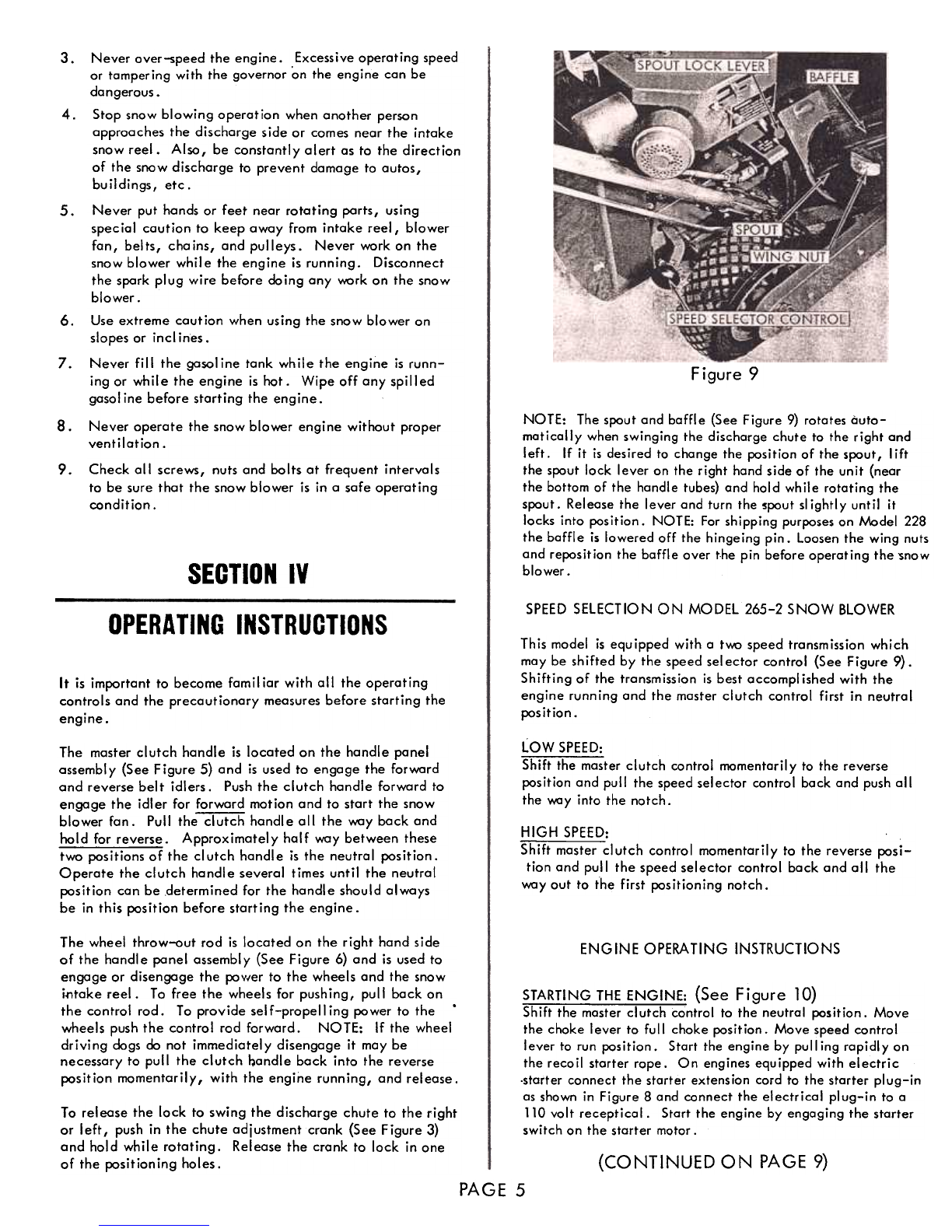

Figure 9

8.

NOTE: The spout and baffle (See Figure 9) rotates auto-

motically when swinging the dischorge chute to the right ond

left. If it is desired to change the position of the spout I lift

the spout lock lever on the right hand side of the unit (near

the bottom of the handle tubes) and hold while rotating thespout.

Reieose the Iever and turn the spout slightl y until it

locks into position. NOTE: For shipping purposes on ,'.;.odel 228

the baffle is lowered off the hingeing pin. Loosen the wing nutsand

reposition the baffle over the pin before operating the ~now

blower.

9.

Never over-speed the engine. Excessive operoting speed

or tompering with the governor on the engine con be

dangerous.

Stop snow blowing operation when onother person

opproaches the discharge side or comes near the intake

snow reel. Also, be constantly alert as to the direction

of the snow discharge to prevent damage to autos,

buildings, etc.

Never put hands or feet near rotating parts, using

special caution to keep away from intake reel, blower

fan, belts, chains, and pulleys. Never work on the

snow blower while the engine is running. Disconnect

the spark plug wire before doing ony work on the snow

blower.

Use extreme coution when using the snow blower on

slopes or inclines.

Never fill the gasoline tank while the engine is runn-

ing or while the engine is hot. Wipe off any spilled

gasoline before starting the engine.

Never operate the snow blower engine without proper

ventilation.

Check all screws, nuts and bolts at frequent intervals

to be sure thot the snow blower is in a safe operating

condition.

SECTIONIV

SPEED

SELECTION ON MODEL 265-2 SNOW BLOWER

OPERATING

INSTRUCTIONS This model is equipped with a tv.\:>speed transmission which

moy be shifted by the speed selector control (See Figure 9).

Shifting of the tronsmission is best accompl ished with the

engine running and the master clutch control first in neutral

position.

It is important to became familiar with all the operating

controls and the precautionary measures before starting the

engine.

The master clutch handle is located on the handle panel

assembly (See Figure 5) and is used to engage the forward

and reverse belt idlers. Push the clutch handle forward to

engage the idl er for forward motion and to start the snow

blower fan. Pull the clutch handle all the way back and

hold for reverse. Approximately half way between these

twa positions of the clutch handle is the neutral position.

Operate the clutch handle several times until the neutral

position can be determined for the handle should always

be in this position before starting the engine.

LOW SPEED:

Shift the master clutch control momentarily to the reverse

position ond pull the speed selector control bock and push all

the way into the notch.

HIGH SPEED:

Shift master clutch control momentarily to the reverse posi-

tion and pull the speed selector control back and all the

way out to the first positioning notch.

The wheel throw-out rod is located on the right hand side

of the handl e panel assembl y (See Figure 6) and is used to

engage or disengage the pav{er to the wheels and the snow

i~take reel. To free the wheels for pushing, pull back on

the control rod. To provide self-propelling pawer to the'

wheels push the control rod forward. NOTE: If the wheel

driving dogs do not immediately disengage it may be

necessary to pull the clutch ~andle back into the reverse

position momentarily, with the engine running, and release.

ENGINE OPERATING INSTRUCTIONS

STARTINGTHEENGINE: (See Figure 10)

To release the lock to swing the discharge chute to the right

or left, push in the chute adjustment crank (See Figure 3)

and hold while rotating. Release the crank to lock in one

of the positioning holes. (CONTINUED ON PAGE 9)

PAGE 5

Shift the master clutch control to the neutral position. Move

the choke lever to full choke position. Move speed control

lever to run position. Start the engine by pull ing rapidly on

the recoil starter rope. On engines equipped with electric

-starter connect the starter extens ion cord to the starter pi ug-in

as shown in Figure 8 and connect the electrical plug-in to a

110 volt receptical. Start the engine by engaging the starter

switch on the starter motor.