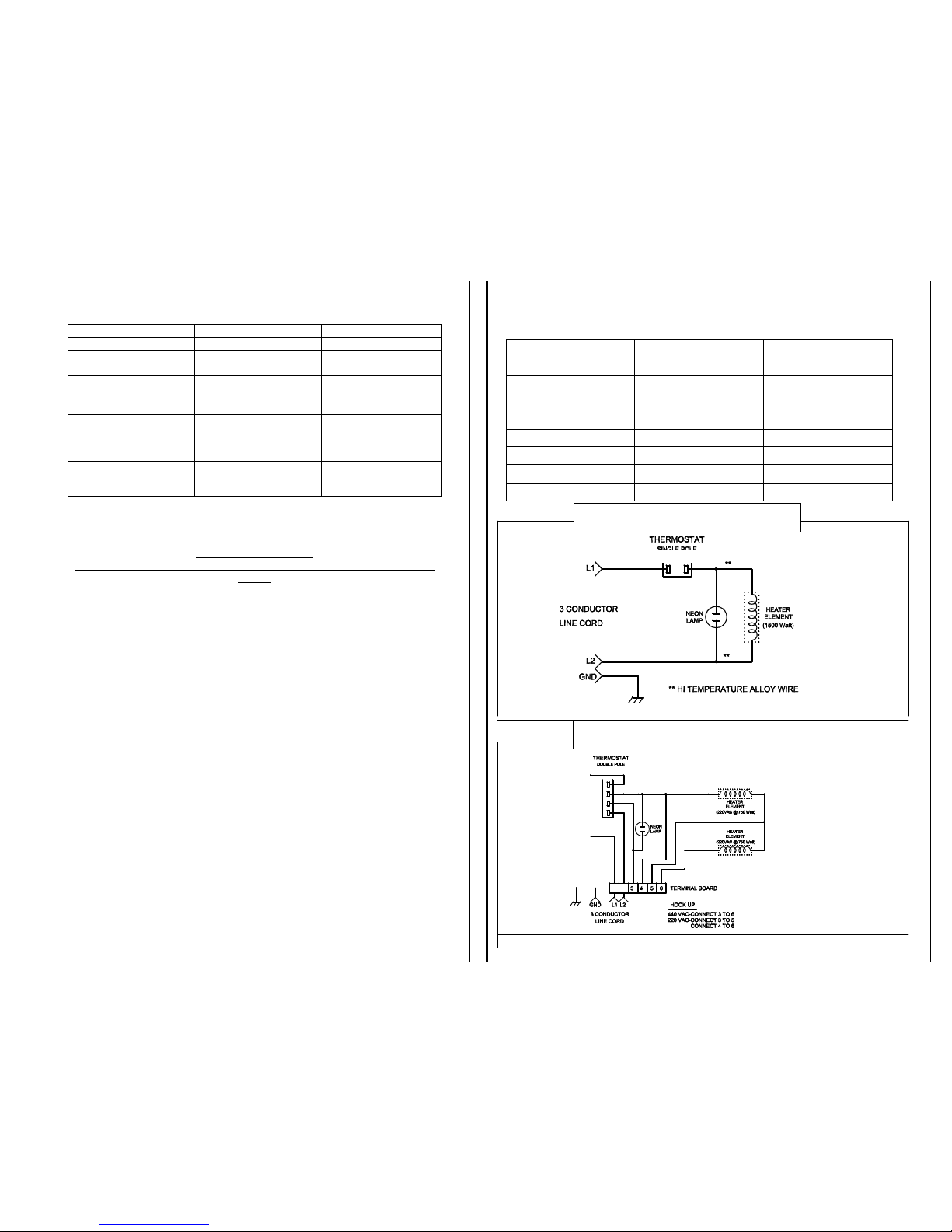

SPECIFICATIONS

THE FOLLOWING INSTRUCTIONS AND SAFTEY WARNINGS MUST BE READ

BEFORE THIS EQUIPMENT IS CONNECTED AND PLACED INTO SERVICE

BEFORE CONNECTION:

ENSURE THAT SUPPLY VOLTAGE MATCHES THAT SHOWN ON RATING

PLATE

The Model 350 and the Model 350A are 350 Lbs. (159 kg) capacity electrode

stabilizing ovens used to maintain welding electrodes in their dry state or to dry

electrode which have absorbed moisture. The Model 350 operated on single phase

power with heat being supplied by a single element. The Model 350A connects to three

phase power with heat being supplied by two elements. The ovens are normally located

in a central storage area. They are complete with recessed controls, removable shelves,

full insulation pilot light and a heating system incorporating low watt density elements.

Temperature is thermostatically controlled. Nesting feet and sockets ensure safe, easy

stacking of up to four ovens.

Ensure adequate free space is provided around the ovens for safe loading and

unloading of the electrodes. Users should exercise caution when loading and unloading

the oven. Certain parts of the oven and the electrodes may reach temperatures

exceeding 550º F (288°C). All exposed body parts must be protected against accidental

contact with hot materials. Safety glasses, gloves, overalls, and protective footwear

must be worn when using the over. Hot electrodes must be unloaded into a suitable

container capable of withstanding the heat and of containing the load safely.

To minimize the risk of electrical shock the Model 350 and Model 350A

should not be exposed to rain or placed in a wet location. Liquids should not be placed

in the oven. The oven should be connected to a suitable, fused power supply using a

recognised connector. The oven must be properly earth grounded. Before performing

ensure it cannot be restored. To minimise the risk of fire do not place food, beverages

or other combustible items in the oven.

USING THE OVEN

The oven is loaded and unloaded via the front door. Avoid contact with hot

surfaces during this operating. The load should be distributing securely and evenly

within the oven to ensure even heating. The shelves may be removed to accommodate

larger loads if required.

PARTS LIST