the outlet grills of the air conditioner are opened, and

the unit goes on working under the condition before the

grille will close automatically.

Notice:

Cannot pull direct the outlet grille by hand. Otherwise, the

grille will run incorrectly. If the grille is not run correctly,

stop for a minute and then start, adjusting by remote

controller.

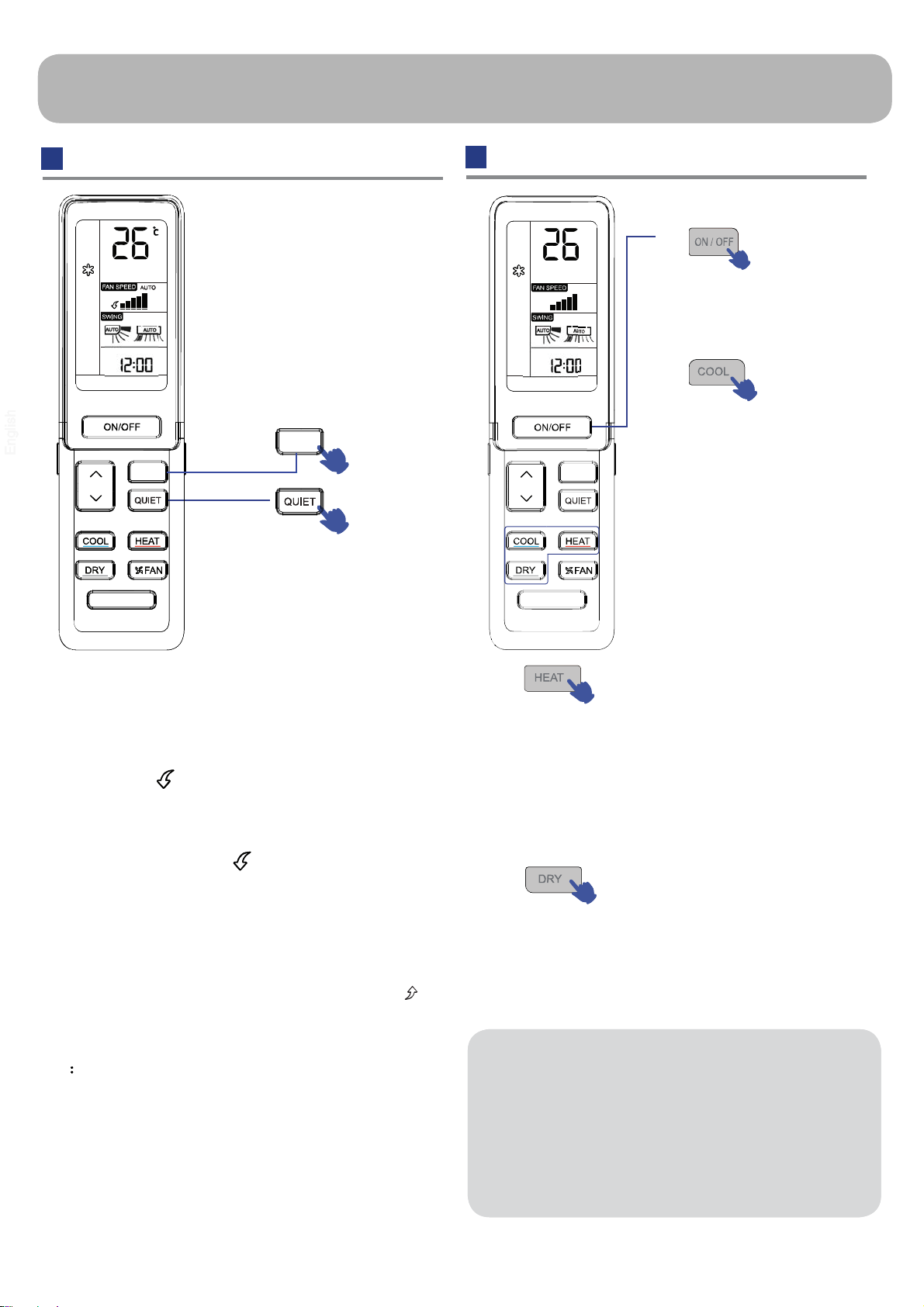

Remote controller can memorize each operation status.

when starting it next time, just press ON/OFF button and

unit will run in previous status.

The setting of

function

The cancel of

function

Operation

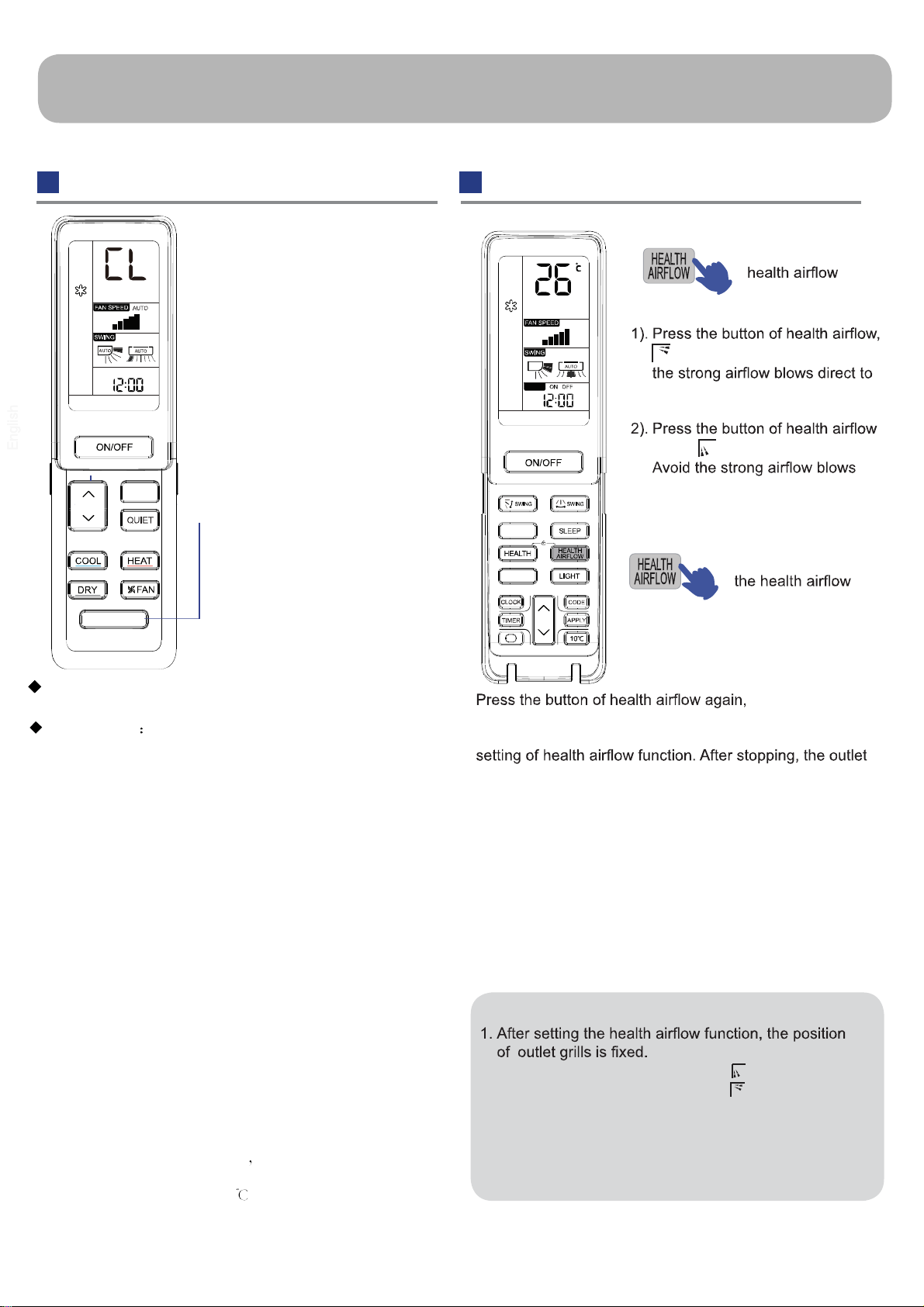

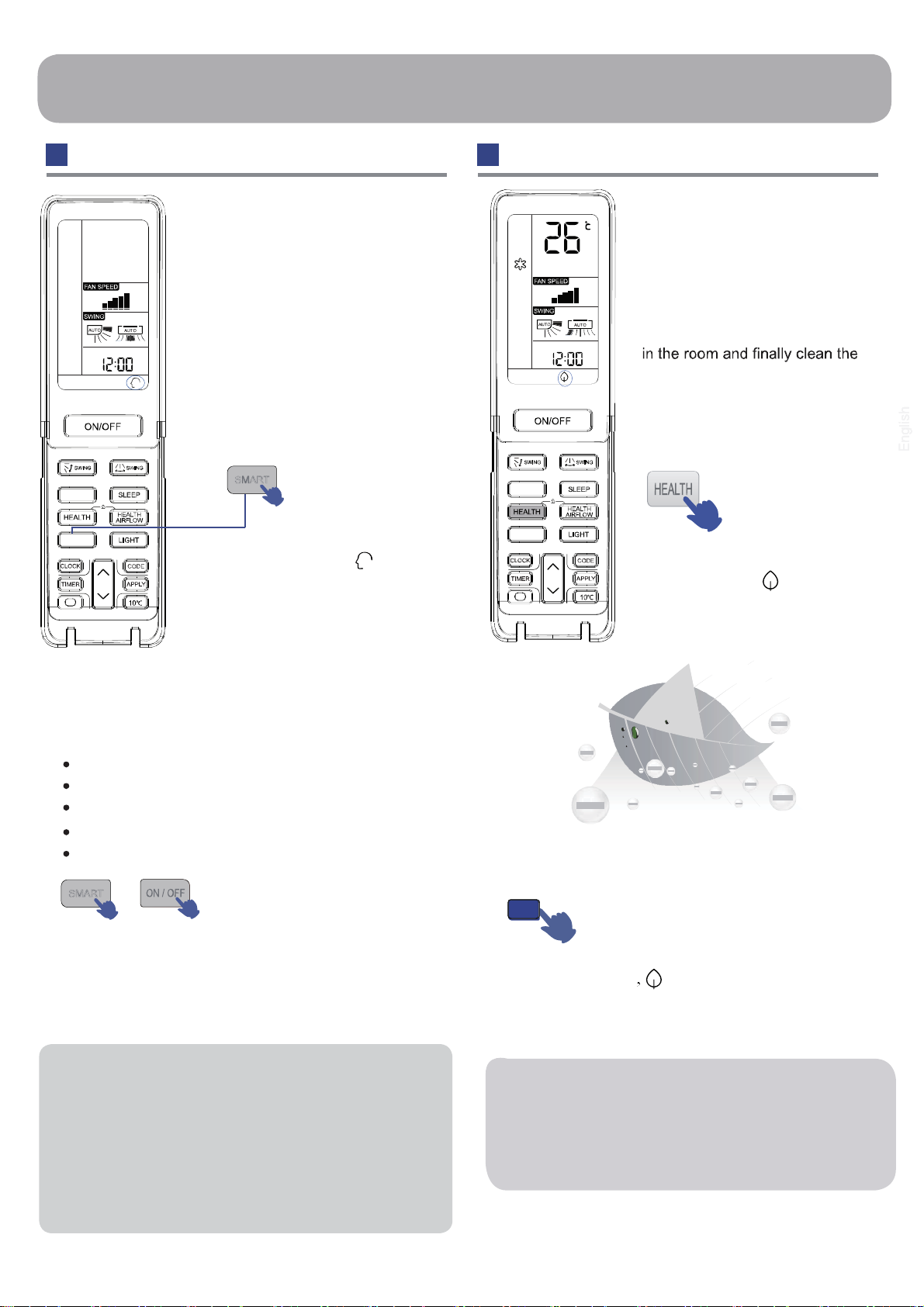

HEALTH AIRFLOW OperationSELF CLEAN Operation

appears on the display. Avoid

the body.

again, appears on the display.

direct to the body.

Note:

2. In heating, it is better to select the mode.

3. In cooling, it is better to select the mode.

4. In cooling and dry, using the air conditioner for a

long time under the high air humidity, a phenomenon

falling drips of water occurs at the outlet grille.

5. Select the appropriate fan direction according to the

actual conditions.

TIMER

FAN MODE

SMART

TURBO

SELF CLEAN

SELF CLEAN Operation

Functional description: the purpose of this function is to

clean the evaporator and the condenser.

Entry and exit Press self clean button to enter this

function, then it will display "CL" on the panel of the indoor

unit and also on the remote controller. After running 20-30

minutes, this function will exit automatically with the " Pi "

sound is heard twice, then the unit return to original state.

Under operation process of self clean, press the button

repeatedly has no effect and cannot exit, but the power off

button and other mode button can make it exit.

Note

1.It has no effect under the mode of timer/sleep.

2.After this mode starts, the air volume may reduce or

even have no airflow.

3.It is normal if the unit make some sound like expand with

heat and contract with cold

4. The “CL” display time may last differently on the remote

controller and panel.

5

5. During the self clean process of the outdoor unit, in order to

dry the evaporator, it’s normal the air conditioner would blow

out hot air occasionally.

6. The self clean effect would be affected by the using environ-

ment. If the cleaning effect is not achieved, please restart the

function after the interval of time.

7. When exit the self clean mode the water vapor would

accoured occasionally.

8. If the temperature is below 5 outside, the unit would only

do the indoor self clean.