Table of Contents

EQ-77X LDLS® Operation Manual 3of31

Contents

Contents.................................................................................................................................................................. 3

Chapter 1. Introduction ........................................................................................................................................... 5

Chapter 2. Safety and Compliance ........................................................................................................................... 6

2.1 General Precautions ..................................................................................................................................... 6

2.2 Definition of Equipment and Document Symbols and Designations .............................................................. 7

2.3 Laser Information ......................................................................................................................................... 8

2.4 EMC Compliance Standards .......................................................................................................................... 9

2.5 Labels and Safety Notification....................................................................................................................... 9

2.6 Safety Interlocks ......................................................................................................................................... 10

2.7 External Interlocks ...................................................................................................................................... 11

2.8 Correct Disposal of the Unit........................................................................................................................ 11

Chapter 3. Preparation of System .......................................................................................................................... 12

3.1 Unpacking Guide ........................................................................................................................................ 12

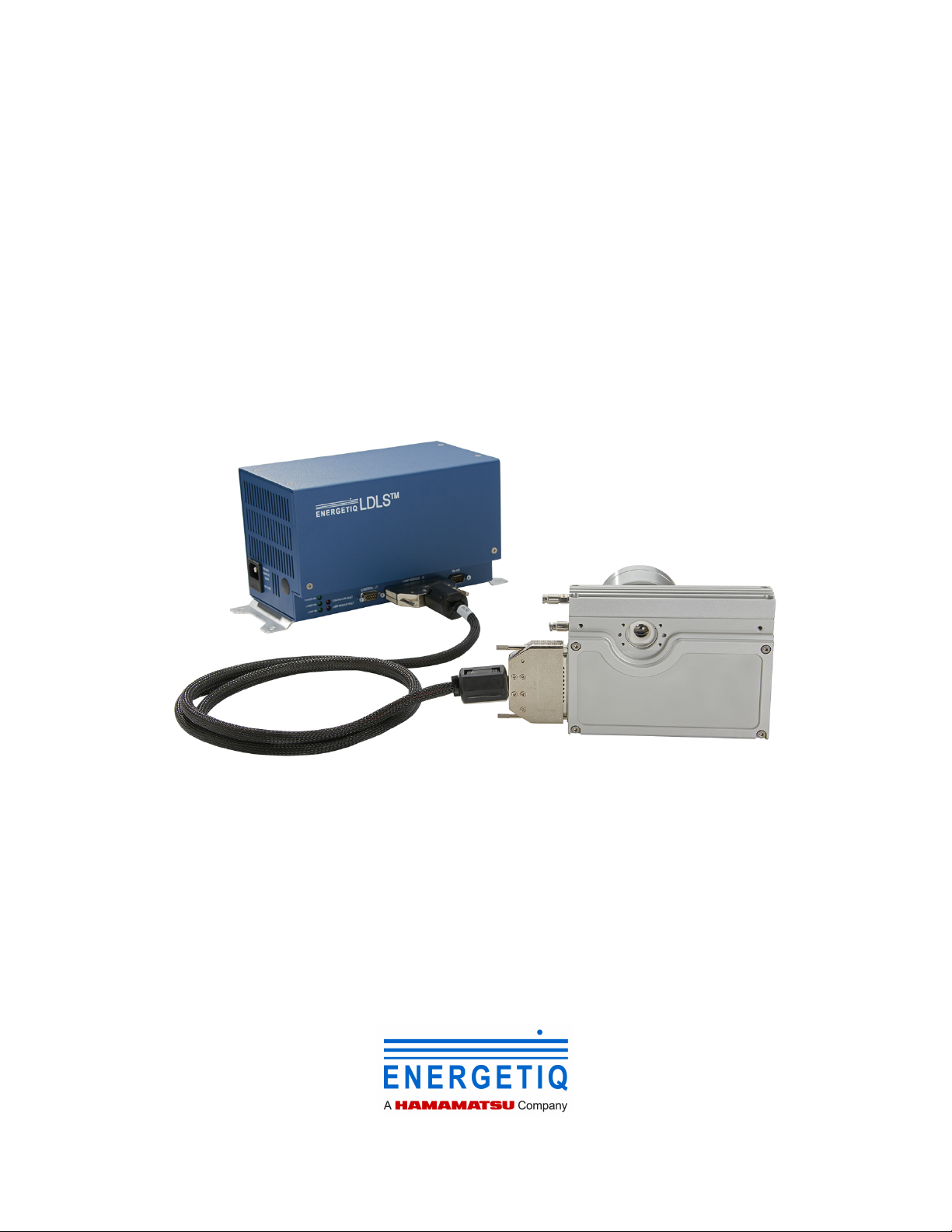

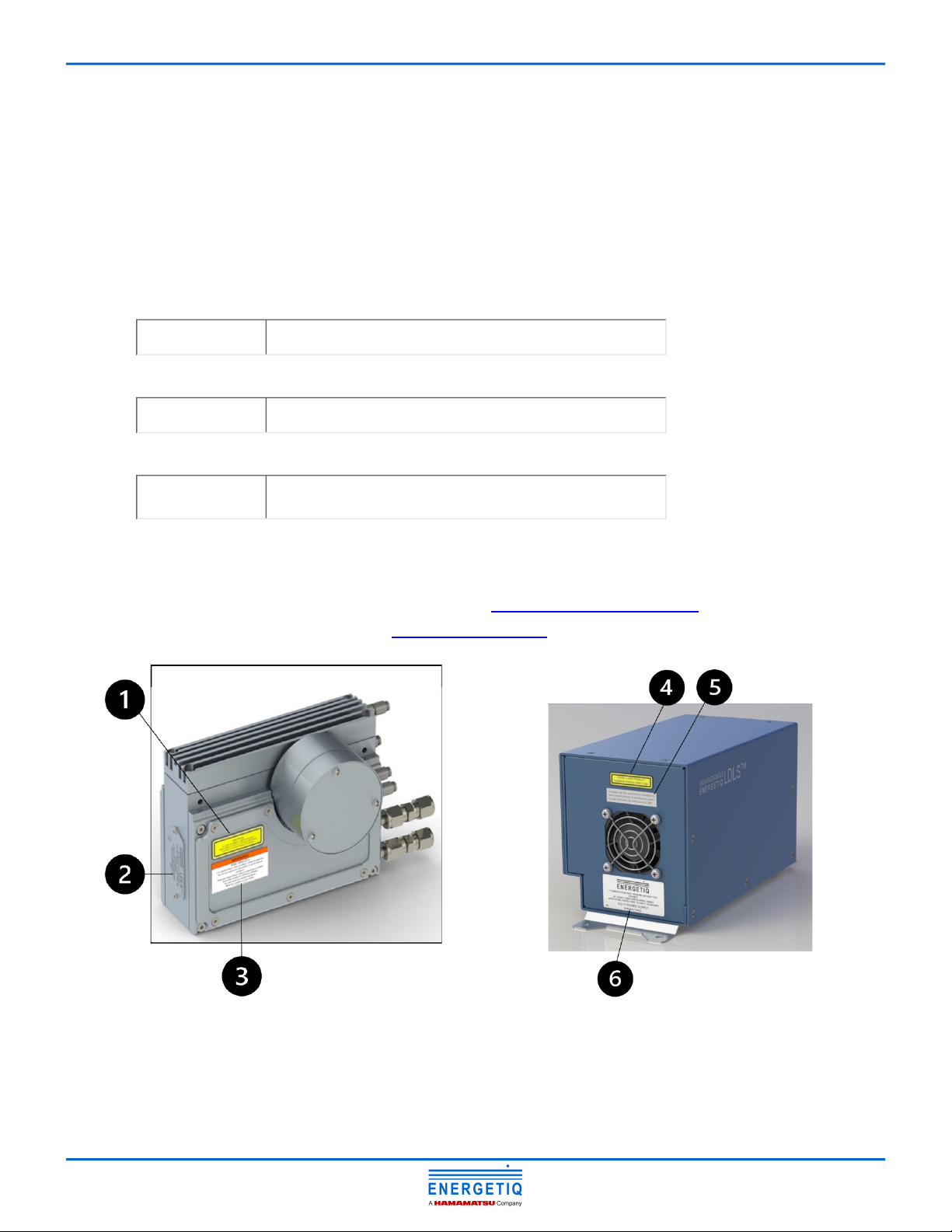

3.2 System Description ..................................................................................................................................... 12

3.3 Physical Specifications ................................................................................................................................ 15

3.4 Utility Requirements................................................................................................................................... 15

3.5 Environmental Requirements ..................................................................................................................... 15

3.6 Remote Interface ........................................................................................................................................ 15

3.7 External Interlock Connection..................................................................................................................... 16

Chapter 4. EQ-77X Setup........................................................................................................................................ 17

4.1 Connections................................................................................................................................................ 17

4.1.1 Electrical Power ........................................................................................................................................... 17

4.1.2 Purge Gas..................................................................................................................................................... 17

4.1.3 Cooling Fluid ................................................................................................................................................ 17

4.1.4 Optical Interface .......................................................................................................................................... 18

4.1.5 Signal Connections ...................................................................................................................................... 18

4.1.6 Lamp House I/O........................................................................................................................................... 19

4.1.7 RS-485 Interface .......................................................................................................................................... 19

4.2 Installation Procedure................................................................................................................................. 19

4.3 Chiller Information ..................................................................................................................................... 20

Chapter 5. EQ-77X Operation................................................................................................................................. 21

5.1 Startup ....................................................................................................................................................... 21

5.2 Stopping ..................................................................................................................................................... 21