Subject to change without notice 5

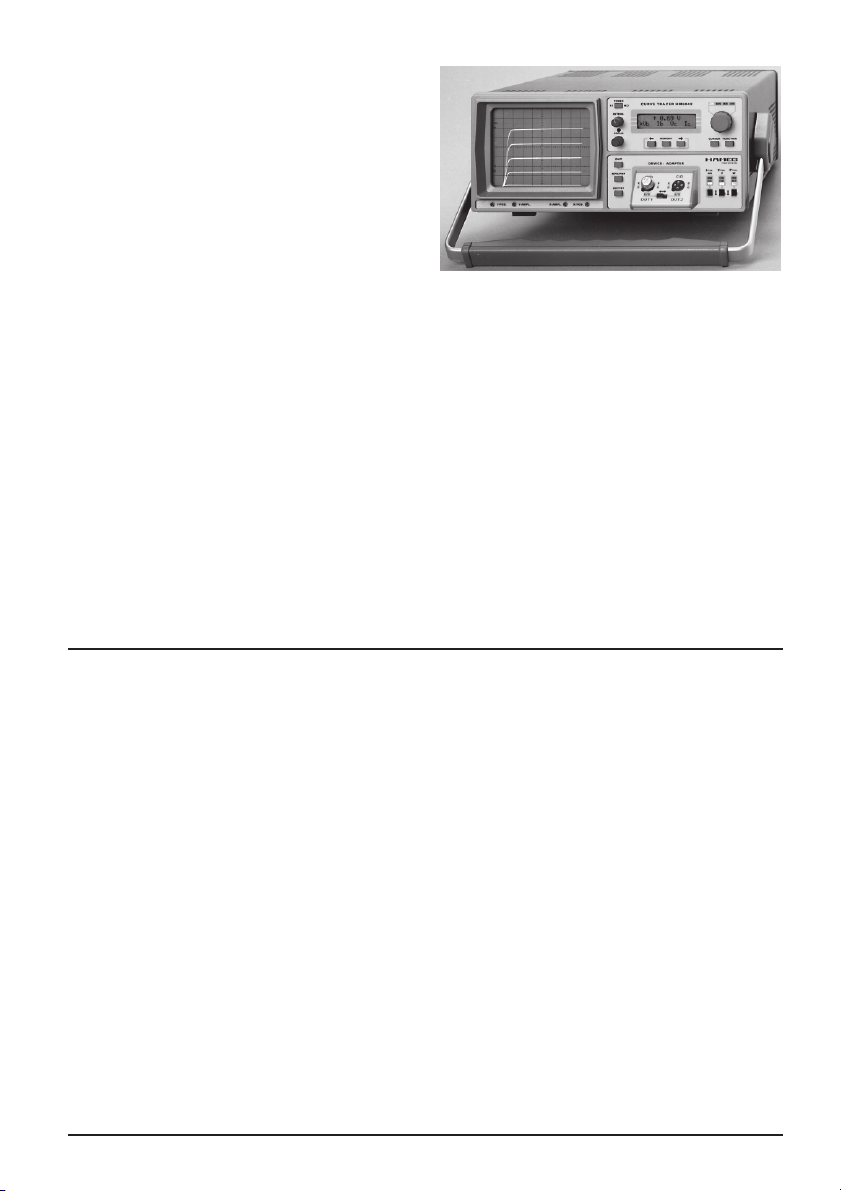

Curve Tracer HM6042

■■

■■

■Ease of Operatio

■Characterisatio a d Test of

Semico ductor Devices

■Accurate Cursor Measureme ts

■Quick a d easy Compariso

of Semico ductors

■Refere ce Data Memory

■O -Scree Display of 5 Curves

■Low Power Co sumptio

The HM6042 Curve Tracer is used to accurately display the characteristics of two and three terminal

semiconductor devices. The instrument combines ease of operation and versatile features at an

affordable price. Unlike its counterpart, the HM8042 plug-in unit, it uses a built-in CRT and an LCD to

display the characteristics of the device under test.

The HM6042 displays a set of 5 curves at a time. All numeric values and parametric data can be

read out on a 2x16 digit LCD. Device type and all relevant parameters are selected and modified by a

simple front-panel keypad entry. Collector voltage and current parameters are easily changed. A 3-

step power limiter avoids damage of the Device Under Test by excessive power.

One set of parameters can be stored in memory for comparison of one device to another or a

reference device. This feature gives substantial enhancements in productivity when matching

semiconductors. Two cursors can be moved along the displayed curves. X and Y position of the cursor

will be displayed on the screen. Basic accuracy is 2% of the measurement value. Measured parameters

are: base voltage, base current, collector current, collector voltage and Beta. The dynamic parameters

h11, h21, and h22 are calculated by the i ter al processor.

A device adapter socket with side-by-side terminals for two devices for the comparison of two

semiconductors is supplied with the instrument.

The HM6042 is remarkably easy to operate. This makes the instrument also ideally suited for

educational use.

Specificatio s

(Reference Temperature 23°C ± 1°C)

Measureme t Ra ges

3 Voltage Ra ges:

Collector/Drain Voltages ≤2V, 10V, 40V ±5%

3 Curre t ra ges:

Collector/Drain Currents ≤ 2mA, 20mA, 200mA ±5%

3 Power Ra ges:

Output Power ≤0.04W, 0.4W, 4W ±10%

Base-/Gate-Voltages a d Curre ts:

Ib1µA to 10mA Vbto 2V ±5% Vgto 10V ±5%

Accuracy

Accuracy of Static Values:

Vc/d ± (2% o.v.1) + 3 Dig.) Ic/d ± (2% o.v. + 3 Dig.)

Ib± (2% o.v. + 3 Dig.) Vb± (2% o.v. + 3 Dig.)

Vg± (3% o.v. + 3 Dig.)

ββ

ββ

βto 1000: ± (5 % o.v. + 3 Dig.)

to 100000: ± [(6 + 0.001 x β) % o.v. + 3 Dig.]

Accuracy of Dy amic Values:

h11 ≤1000Ω± (12% o.v. + 3 Dig.)

≥ 1000Ω

± [(12 + 0.001 meas. value) % o.v.+ 3 Dig.]

h21 ≤1000 ± (12% o.v. + 3 Dig.)

≥ 1000

± [(12 + 0.001 meas. value) % o.v.+ 3 Dig.]

y21 ≤1000mS ± (12% o.v.. + 3 Dig.)

h/y22 ≤1000mS ± (12% o.v.. + 3 Dig.)

Miscella eous

Reference measurement values can be stored for component

selection.

Cursor Measureme ts:

Si gle mode: The Cursor marks the position from which the

measurement value is calculated.

Tracki g mode: Two Cursors mark the positions, from hich

the h/y-Parameter measurement values are calculated.

Evaluatio of curves from

Diodes, Zener Diodes, NPN/PNP-Transistors,

FET/MOS-FET (N/P-Channel), Thyristors

Display: 2x16-Digit, LCD

Presentation of measurement values from a set of 5 curves

on CRT.

Ge eral I formatio

CRT: D14-364GY/123 or ER151-GH/-,

6" rectangular screen (8x10cm) internal graticule

Acceleratio voltage: approx. 2000V

Trace rotatio : adjustable on front panel

Line voltage: 100-240V AC ±10%, 50/60Hz

Power co sumptio : approx. 36 Watt at 50Hz.

Min./Max. ambient temperature: 0°C...+40°C

Protective system: Safety class I (IEC 1010-1)

Weight: approx. 5.6kg, color: techno-brown

Cabinet: W 285, H125, D380 mm

1) o.v. = of value