Hansin Special Equipment HS Series User manual

Instruction Manual & Repairing Guide

MODEL : HS2750 SMART

HANSIN SPECIAL EQUIPMENT CO.

- 1 -

Contents

1. Introduction --------------------------------- 2

2. General Precautions when using the equipment ----- 3

3. Composition and Specifications

A. Main composition and functions ---------------------- 4~5

B. Features of HS 2750 SMART--------------------------- 6

C. Diagram of Equipment Composition --------------------7~8

D. Working Radius Diagram ----------------------------- 9

E. Hyd' Component & Circuit -----------------------------10

F. Connective Diagram of Electricity -----------------------11~12

4. Safety Rules

A. Precaution before Operation ------------------------ 13

B. Precaution of Outrigger Operation -------------------- 13

C. Precaution of Operator ------------------------------ 14

D. Precaution During Equipment operation ---------------- 14~15

5. Operation and Usage of HS 2750 SMART

A. Operation preparation ------------------------------ 16

B. Equipment preparation in hard winter ------------------ 16

C. Equipment Operation of Function Section --------------- 16~23

6. Repair Precaution & Examination

A. Check Points before Operation ----------------------- 24

B. Check Points during the Operation -------------------- 24

C. Check Points after Operation ------------------------- 24

D. Check Points after 1month Operation ------------------- 25

E. Check Points after 6months Operation ------------------ 25

F. Lubrication ---------------------------------------- 26

G. Examination & Exchange of the Hydraulic pressure oil ----- 26

H. Exchange & Examination of Filter ---------------------- 27

I. Cylinder Exchange -------------------------------- 28~29

7. Malfunction & Measurement ----------------------30~31

- 2 -

1. Introduction

Thank you for buying Hansin HS series!

This guide is all about HS 2750 SMART, it helps you to provide all

necessary materials to be used effectively and safely for users.

This also gives you the summary, description of data, equipment

repair information and preparation which explained the procedure

operation for management of equipment designed for Aerial Lift

Truck.

However, If you want your equipment last, you should follow this

guide to prevent failure. So, apparently HS2750 SMART operate to

secure lifetime use.

Prior HS2750 SMART, you must follow all the guides for your safety.

If you find any difficulties while using this guide or if you have any

questions, feel free to contact the dealer.

In addition, if you want to request some parts you are required to

find the Part Number and Description from the components list.

Please let us know.

- 3 -

2. General Precautions when using the equipment

a. Before using the equipment, be sure to read the user manual and

basic principles, usage and safety precautions for your awareness.

b. When not in use, pull the parking break so that vehicle may not

move. Connect the gear to neutral and place wedges so that the

tires may not move.

c. When you move the P.T.O, you should definitely press the clutch

fully. If you hear sound from the Transmission, please check and

request it to the dealer. If the sound occurred and you use it

continually it might break the P.T.O and Transmission.

d. Before you operate the Equipment, always get out the Beam of the

outrigger and get down the outrigger cylinder. In particularly, you

must check it to the ground surface outrigger cylinder very well.

e. During the operation of Equipment, expert operator is only allowed

to the operation limits.

f. Do not operate equipment around the high tension as this is so

dangerous.

g. Prior rotating the Boom, make sure that there is no dangerous

things beside it when you rotate it. (Especially building, signboard,

high tension, peoples etc...)

h. People should not pass around the equipment. Follow the

instructions as prescribed.

i. When you're driving the Aerial lift Truck, you should duly reach

the Boom Rest and the Boom should always fold.

j. Never use the Boom from pulling something.

k. Please do not operate the Equipment from the front of the Truck

CAB.

- 4 -

3. Composition and Specifications

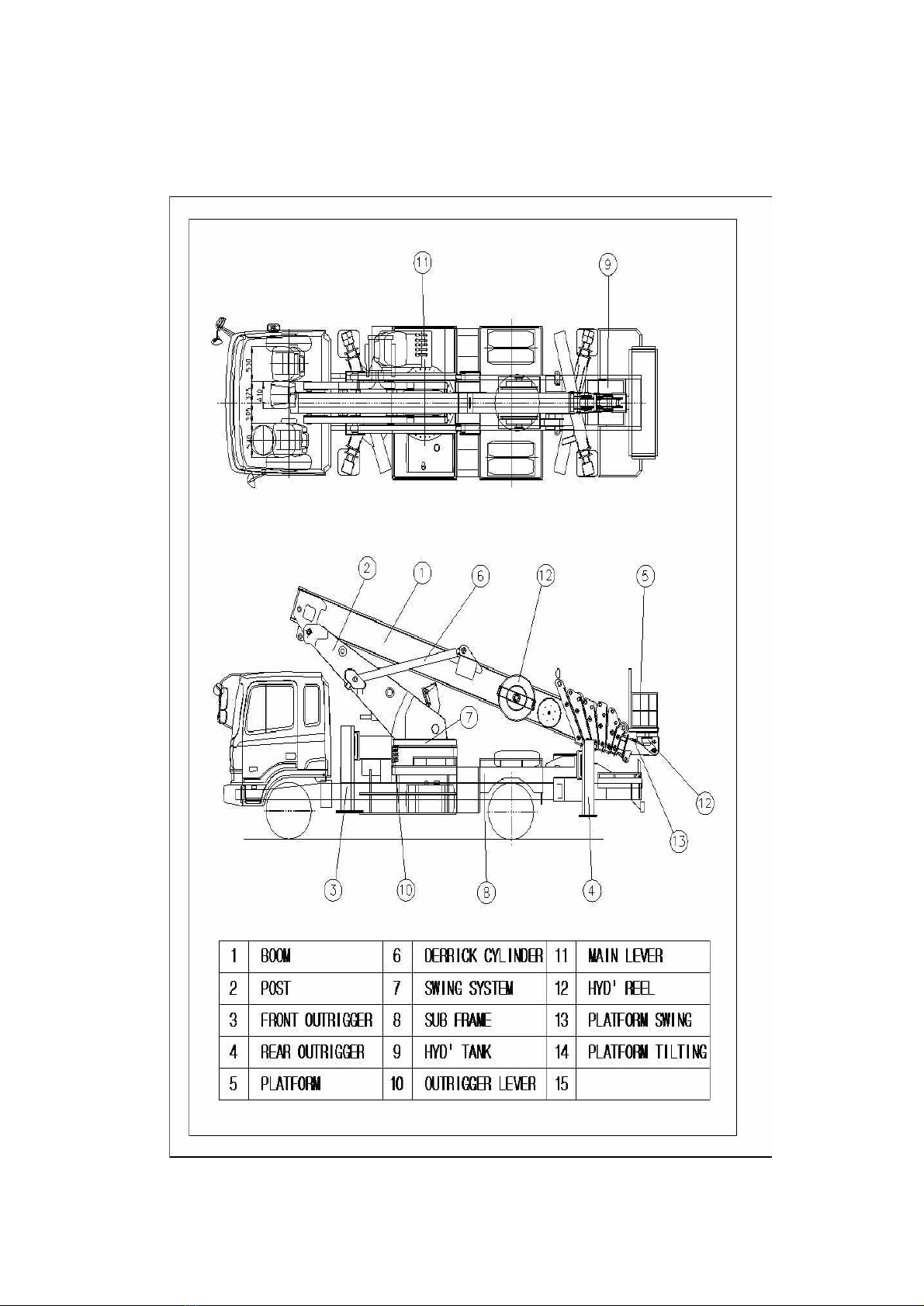

A. Main composition and functions

1) This Aerial lift Truck composed of basic parts like middle frame, X-type

front outrigger, rear outrigger, turn table, 5 stages boom & one

boarding platform, all these parts should have a proper installation for

maintenance level.

2) Main composition has various functions, the left-right 350° operation

(boom rotation), withdrawal operation & leading in operation. These

functions deals with the producer of Oil pressure power which have the

Oil pressure pump and Oil pressure system. This handling operation

refer to outrigger self examination and Usage of Wireless Remote

Controller.

- 5 -

<Diagram of Equipment Composition>

- 6 -

B. Features of HS 2750 SMART

ITEM UNIT HS 2750 SMART

Vehicle on board HYUNDAI 3.5ton LONG

Features

Height ㎜ 2895

Width ㎜ 2130

Length ㎜ 7385

Gross

Weight ㎏ 8075

Boom

Stage 5 Stages

Shape Octagon

Withdrawal

Type Extension at the same time

Quality of

the material High tensile structural steel (ATOS80)

Outrigger

Type X TYPE, Device Hydraulic

Withdrawal

Width ㎜ 5960(Front), 5960(Rear)

Work scope

Withdrawal

Height m 27

Withdrawal

Weight 2 persons or 300㎏

Turning

gear

Type Hydraulic Motor (Mechanical reduction gear - Double

decelerator) TYPE

Turning

angle Left and Right 180°

Boarding

Platform

Size 3000 X 1100

Turning Type Hydraulic Motor Type (Mechanical reduction gear)

Turning

angle Left and Right 2 rotations

Controlling

device

Outrigger Lever Type, Left and Right Type

Boom Wireless Remote controller

Convenience Device

Night Search Light, Remote Starting On/Off,

Electronic Type Axel,

Automatic Oil Cooler, Toolbox

Safety Device Rollover Caution Safety, Over Center Valve,

Pilot Check Valve, AML Safety

Options

- 7 -

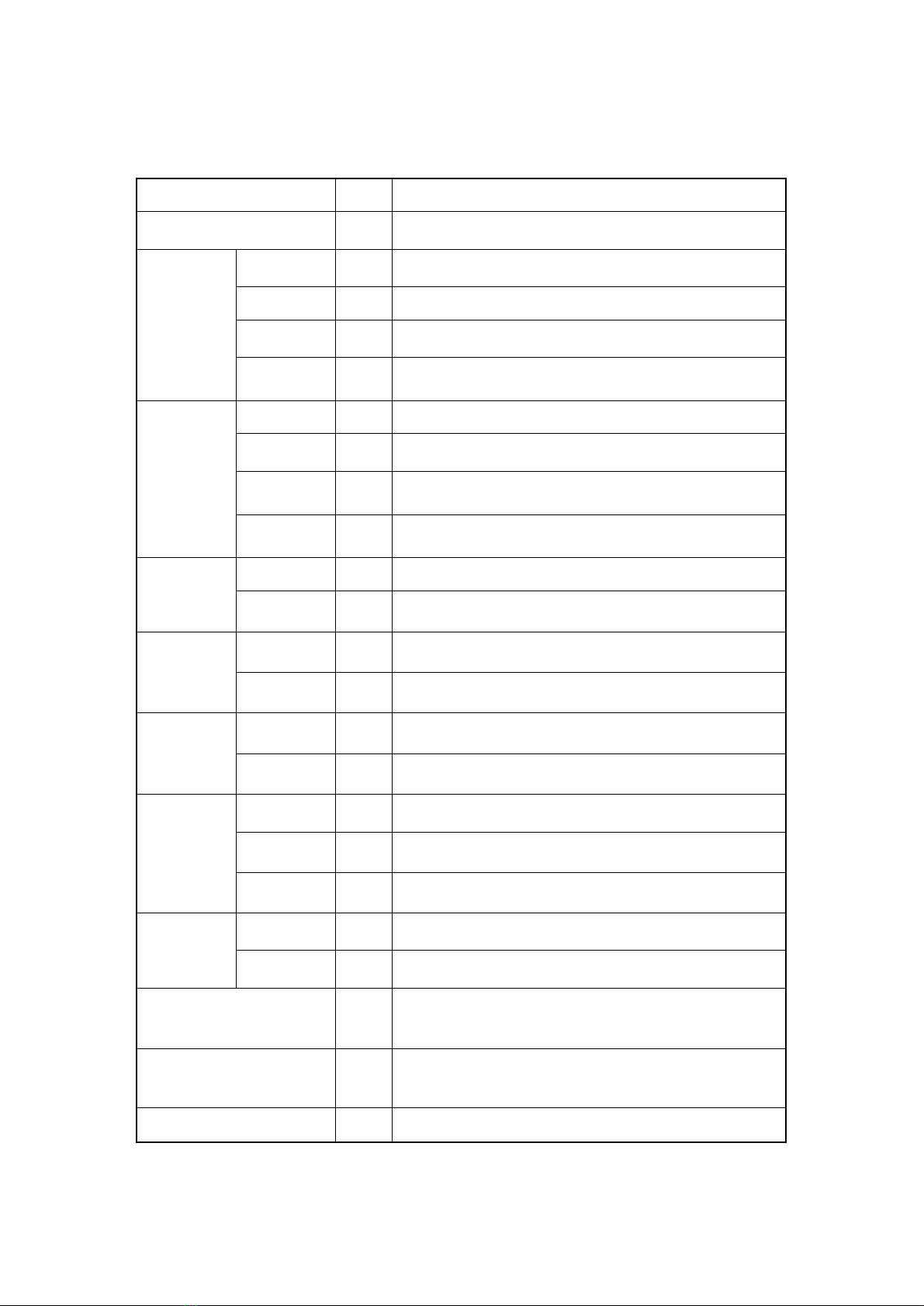

C. Diagram of Equipment Composition

The size and shape of the Equipment content details basically refer to 3.5 ton

Truck.

While the driver still moving, make sure you fully understand the correct maximum

height before and after the operation.

In particular, the driver operation will be determined after verifying that it is safe

to pass for below overpass, telephone pole side, inside storage, tunnels or

obstructions such as large construction sites prior entering the height and width.

Names and functions of equipment for each area described in the following, please

refer to equipment configurations.

- 8 -

<Diagram of Equipment Appearance>

- 9 -

<Working Radius Diagram>

- 10 -

<Hyd' Component & Circuit>

- 11 -

<Connective Diagram of Electricity>

- 12 -

리모콘 송신기

메인 밸브

<Connective Diagram of Electricity>

- 13 -

Safety Rules

This Equipment will have a good performance, if you do it right.

During the equipment operation, in order to prevent safety accident, be sure to

follow the basic rules and regulation.

So, the operator takes all the responsibilities to follow the basic safety regulation

for people and equipment.

The operator should have no doubt in concerned to warning device and safety

device of equipment.

Not following the safety regulation may resulted to safety accident.

You either required to master the operation sense too.

The operator need to follow the safety regulation as well as duty to forestall the

safety accident while doing the equipment operation.

A. Precaution before Operation

1) Always park in a flat and solid or paved road place where you can pull the

parking break.

2) Without interfering obstructions in the working area go to a near place where

you can find easy access.

3) Without moving the vehicle, it is possible to perform many task at any route.

4) Put a wedge under the wheels of the vehicle to prevent accidents while

working in a sloppy areas.

B. Precaution of Outrigger Operation

1) Properly install the outrigger on the floor.

2) To ensure stability, spread the outrigger beams as much as possible.

3) The installation should be firmed to get in touch with the outrigger cylinder

support.

4) Within the inclined position of the truck, put down the lower end outrigger

following the higher outrigger to ensure vehicle horizontality.

5) If the area to be used anywhere is uneven or soft ground you should have

competent support.

6) Due to slippy situation while the vehicle shaking, put the wedges carefuly to

prevent from falling down.

7) When operating in a soft ground, put down the outrigger and place a wedges.

then check the condition of ground.

- 14 -

C. Precaution of Operator

1) Read the instructional manual and maintenance instructions, to familiarize

yourself with the operation.

2) Operator must have a proper training to build enough experience prior

operation of the equipment. to prevent harmful illness such epilepsy or seizure

you should take early medication, any physical disabilities may damage the

operation. It is your responsibility to perform self examinations to maintain

calmness and good health.

3) Be safe in you working area before operation, the road should be safe either,

you should check it from time to time.

4) Check the initial operation of all equipment devices as well as the driver brakes

properly.

5) Check the equipment condition with your naked eye everytime if the equipment

have damage condition, whether its from the structural part of the conclusion

or whether there are oil leakages and looses of bolts or pins, make sure to

take immediate action.

6) Seat belts and straps must be checked before the operation as per safety rules.

7) Equipment preventive maintenance must be checked daily, however the

lubrication should be conducted regularly prior defect of the equipment. If

damage occur, stop the operation.

8) Do not operate the equipment when the there's a bad weather condition such as

severe wind or heavy fog.

9)People are not allow around th workplace, building, etc. as they were

surrounded by some ground or objects which cause unsafe condition so always

put barricade caution when start the operation.

10) Please be reminded, to check the warning devices at all times, neglect to pay

attention should be involved in any safety violation which may cause people

and equipment accident.

11) Daily checking of controls must be check for any abnormality condition, do not

step on boarding platform before using the equipment.

12) There will be no assurance for modifications of equipment that can cause

people damage and structural defect

13) Stay away from any electrical wires and secure a safety distance when

operating the equipment.

- 15 -

D. Precaution of Equipment Operation

1) Only certified operator must operate the equipment.

2) While working on board platform, seat belt and belt strap must properly wear.

3) When heavy item is loaded on the boom and boarding platform, be careful not

to exceed. (2 persons or 300 Kg) Do not load that exceeds the limit.

Excessive weight may cause deterioration of the equipment function or safety accident.

Please comply with the standards.

4) If the boom remote control have electrical jamming or any disconnection, switch

on the emergency power of the transmitter. You must take this action the

problem will no longer occurs.

5) Stop and prohibit the operation if you experience bad weather conditions. Below

were as follows.

- During heavy rain

- During heavy snow.

- During thunder and lightning storm

- By ambient conditions such as fog, when the visually impaired

- When the wind speed exceeds 10m/sec

6) Check the passenger's safety prior operation of the equipment.

7) Avoid passing on the boom, and do not come in and out on the boarding

platform.

8) When operator comes in the boarding platform, the boom should reach the

bottom of the ground so that the boarding platform will also reach the ground

floor, through that, the operator must be able to go on boarding.

9) When you ride down on a boarding platform into the ground, you must be

specially careful on the lever operation

10) The equipment operator access all the action as possible

11) Do not change the boom speed randomly.

12) Do not exceeds the limits of the operation.

13) Operator should maintain stable condition to operate the operation. Do not use

ladder, planks or other tools to reach the location.

14) Movement of vehicle or outrigger manipulation where there are people on the

board should absolutely prohibited as the boom spread.

15) Prohibit the booms or boarding platform by pushing or pulling objects.

16) Workers inside the boarding platform including stuff aboard must be careful

from falling down.

17) Be careful from moving the boom around the person or obstacles.

- 16 -

5. Operation and Usage of HS 2750 SMART

A. Operation preparation

1) Hold the hand brake of the car.

2) Check the proper amount of oil tank. (prudent hydraulic pressure oil))

3) Press the clutch of the vehicle and connect to the PTO gear. ( the gear should

be in a nuetral position)

4) While the PTO is rotating, check for any noise condition.

B. Equipment preparation in hard winter

During winter time, the hydraulic pressure oil gets lower that's why viscosity

temperature gets lower as well, continuing the operation may damage the

hydraulic component.

1) Turn on the gear of PTO engine. As the engine rotates slowly, do not press

the AXEL.

2) Turn on the engine for about 10 minutes, however do not operate the control

lever.

3) 3-WAY V / V lever to move toward the outrigger position.

4) Push the two sides of front outrigger levers within 4-5 minutes.

5) Check the hydraulic oil tank with your hand, the temperature should be in

lukewarm condition when operating the boom.

C. Equipment Operation of Function Section

1) PTO method operation.

a) Press the clutch if the gear in neutral standing position. Press "ON" the PTO

switch and make sure dashboard light is turn on.

b) If you hear some noise. Press the PTO switch "OFF" and then PTO switch

"ON". If the noise still occurs, please contact the dealer and the A/S. Use it

after solving the problem.

2) Outrigger method operation.

Outrigger have two configuration , the 2 front outrigger and the 2 rear outrigger

control valve formation is composed by the terminals.

- 17 -

A) Step by step procedure during the installation.

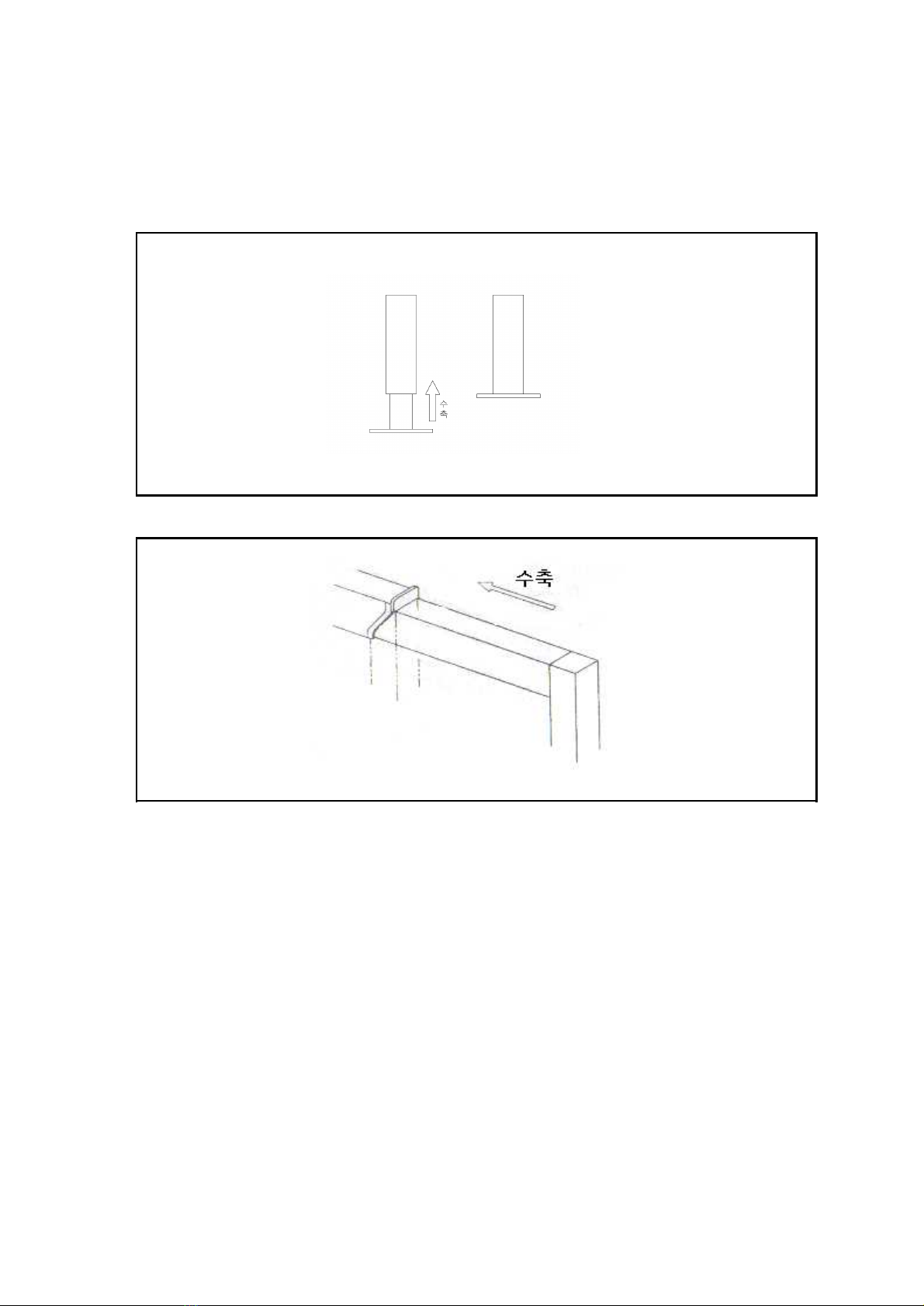

ㄱ) Withdrawal of outrigger INNER BEAM.

b) Please keep the vehicle horizontally while the outrigger levers direction moves

decrease.

* Caution

- Check the ground condition avoid slope areas and soft ground before installing

the outrigger

- Move out the inner beam outrigger to the maximum level to guarantee stability.

- To obtain horizontality of vehicle control lever, manipulate the outrigger cylinder

properly.

- Outrigger cylinder withdrawal should prohibit the vehicle wheels from moving

out. except from special circumstances. (Board spring power lift height is

adequate)

- 18 -

B) Installation evacuation order of operation

ㄱ)Outrigger cylinder by operating the lever side operation to fully rise to

contraction

ㄴ) Check whether your withdrawal Inner Beam attached by the inlet.

* Caution

- When moving from the vehicle and the cylinder is not completely shrink, it may

cause damage, because of the presence of the bumps and smooth stone figure

together with other object. Please go after fully contracted.

- 19 -

3) Switching direction valve (3-WAY V / V) method of operation

3 -Way valve supply direction of the hydraulic flow to the outrigger and boom.

A) The operation sequence

a) When operating the outrigger, the lever to locate the "Outrigger" in the

indicated direction.

b) When operating the Boom, the lever to locate the "BOOM" in the indicated

direction.

B) Caution

a) When spreading or operating the boom, the transition valve prohibit towards

Outrigger as this is extremely dangerous.

b) Entirely up to the point where you operate exactly.

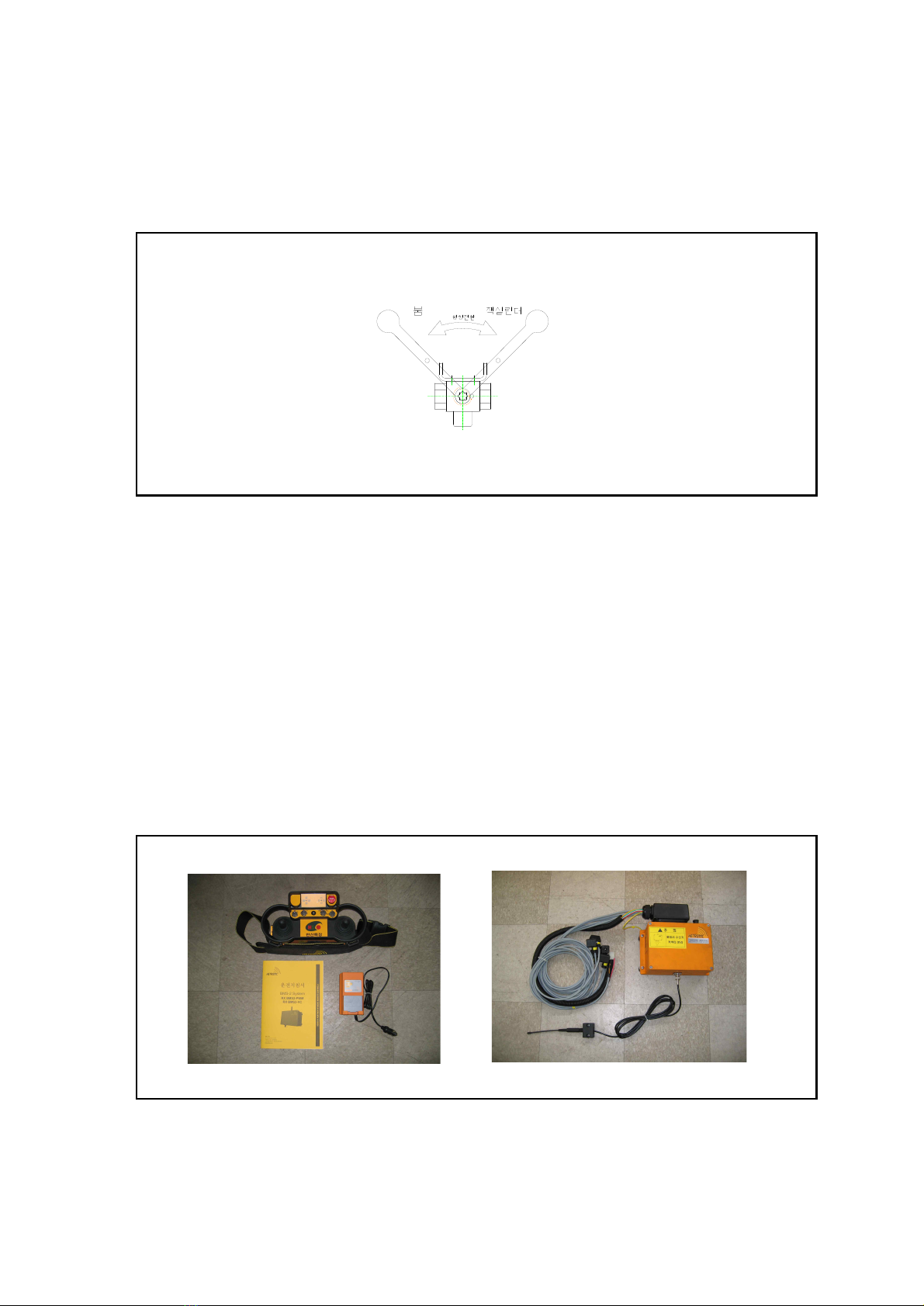

4) Manipulating remote control to boom

A) Overview

Equipment operated by a wired and wireless remote control equipment.

B) Diagram composition of component

This manual suits for next models

1

Table of contents