Harbour HBRCGG905W User manual

90cm Glass Gas

Cooktop

INSTRUCTION MANUAL

IM VERSION V1.3 |MODEL HBRCGG905W |PRODUCT CODE 706143 |ISSUE DATE 09/2021

SUPPORT: 1300 11 4357 |WWW.HARBOUR-APPLIANCES.COM.AU

02

Congratulations on purchasing your new Glass Gas Cooktop.

All products brought to you by Harbour are manufactured to the highest standards

of performance and safety and, as part of our philosophy of customer service and

satisfaction, are backed by our comprehensive 3 Year In Home Warranty.

We hope you will enjoy using your purchase for many years to come.

Welcome

03

Contents

2 Welcome

4 Warranty Details

5 General Safety Instructions

9 Product Overview

10 Installation Instructions

18 Operation Instructions

20 Maintenance and Cleaning

22 Troubleshooting

24 Specifications

26 Repair and Refurbished Goods or Parts Notice

27 Warranty Returns

04

The product is guaranteed to be free from defects in workmanship and parts for a period

of 36 months from the date of purchase. Defects that occur within this warranty period,

under normal use and care, will be repaired, replaced or refunded at our discretion. The

benets conferred by this warranty are in addition to all rights and remedies in respect of

the product that the consumer has under the Competition and Consumer Act 2010 and

similar state and territory laws.

Our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and for compensation

for any other reasonably foreseeable loss or damage. You are also entitled to have the

goods repaired or replaced if the goods fail to be of acceptable quality and the failure does

not amount to a major failure.

90cm Glass Gas Cooktop

Congratulations!

REGISTER YOUR PURCHASE AT www.aldi.com.au/en/about-aldi/product-registration/ TO KEEP UP-TO-DATE WITH IMPORTANT PRODUCT INFORMATION

You have made an excellent choice of this quality product. Our commitment to quality also includes our service. Should you, contrary to

expectations, experience defects due to manufacturing faults, ALDI will provide you with a warranty against defects as follows:

Warranty

The product is guaranteed to be free from defects in workmanship and parts for a period of 36 months from the date of purchase. Defects that occur within this

warranty period, under normal use and care, will be repaired, replaced or refunded at our discretion. The benefits conferred by this warranty are in addition to

all rights and remedies in respect of the product that the consumer has under the Competition and Consumer Act 2010 and similar state and territory laws.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure

and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure.

Proof of Purchase

This warranty is valid for the original purchase and is not transferable. Please keep your purchase docket, tax invoice or receipt as the best proof of purchase, and

as proof of date on which the purchase was made.

Extent of Warranty

This warranty is limited to defects in workmanship or parts. All defective products or parts will be repaired or replaced.

Normal Wear and Tear

This warranty does not cover normal wear and tear to the products or parts.

118 Campbell Street, Collingwood, VIC 3066

Exclusions

This warranty does not cover:

• Any defects caused by an accident, misuse, abuse, improper installation or operation, lack of reasonable care, unauthorised modification, loss of parts,

tampering or attempted repair by a person not authorised by the distributor.

• Any product that has not been installed, operated or maintained in accordance with the manufacturer’s operating instructions provided with the product.

• Any product that has been used for purposes other than domestic use.

• Any damage caused by improper power input or improper cable connection.

To Make a Claim

This warranty against defects is provided by ALDI Stores, Locked Bag 56, St Marys Delivery Centre, NSW 2760, Phone (02) 9675 9000. If a defect in the goods

appears within 36 months, you are entitled to claim a warranty, please contact or send all warranty claims to:

When making a return, please ensure the product is properly packaged so as to ensure that no damage occurs to the product during transit.

Please provide the original or a copy of the proof of purchase. Also please make sure you have included an explanation of the problem.

Please note that the costs of making a warranty claim, including any return postage, will be covered by the supplier identified above.

Please note upon receiving your warranty claim, the supplier will send, via the post or email, a repair and refurbished goods

or parts notice.

Please provide your email address and advise the supplier, if you wish to obtain a repair and refurbished goods or

parts notice via email.

AFTER SALES SUPPORT:

1300 11 4357

AUS

3

Hotline number: 1300 11 4357

Residentia Group Pty Ltd

MODEL: SUC54EEW PRODUCT CODE: 62878 11/2018

IN HOME

05

General Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

READ CAREFULLY AND KEEP FOR FUTURE REFERENCE

Read this manual thoroughly before first use, even if you are familiar with this type of product. The safety

precautions enclosed in here reduce the risk of electric shock and injury when correctly adhered to.

Make sure you understand all instructions and warnings.

Keep this user manual in a safe place for future reference, along with the completed warranty card and

purchase receipt. If you sell or transfer ownership of this unit, pass on these instructions to the new owner.

Always follow basic safety precautions and accident prevention measures when using an electrical

appliance, including the following:

IMPORTANT: Pay particular attention to messages that contain the words DANGER, WARNING or

CAUTION. These words are used to alert you to a potential hazard that can seriously injure you and others.

The instructions will tell you how to reduce the chance of injury and let you know what can happen if the

instructions are not followed.

IMPORTANT: This appliance should be installed by a qualified technician or installer.

BEFORE FIRST USE

Prior to using your Gas on Glass Cooktop, please read all safety and operating instructions thoroughly.

Please ensure you follow the steps below before using this product:

•Unpack the appliance but keep all packaging materials until you have made sure the new Gas on Glass

Cooktop is undamaged and in good working order. We recommend you keep the original packaging for

storing your Gas on Glass Cooktop when not in use or transporting.

WARNING: Plastic wrapping can be a suffocation hazard for babies and children, so ensure all

packaging materials are out of their reach.

•Inspect the power cord and plug for any damage or defects. In case of damage, do not use this product

and contact the Residentia Group support team on 1300 11 HELP (4357) for further advice.

USAGE CONDITIONS AND RESTRICTIONS

• Domestic use only: This appliance is intended for indoor household use only. It is not intended for

commercial, industrial or outdoor use. It is not intended for use in a recreational vehicle.

• Purpose: Do not use this appliance for anything other than its intended purpose. Other uses are not

recommended and may cause fire, electric shock or personal injury.

• Attachments: The use of attachments is not recommended by the appliance manufacturer and

distributor as they may be hazardous.

• Improper use: Damage due to improper use, or repairs made by unqualified personnel will void your

warranty. We assume no liability for any eventual damages caused by misuse of the product or

noncompliance with these instructions.

This appliance is not intended for use by persons including children with reduced physical, sensory or

mental capabilities or lack of experience and knowledge unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

•Children should be supervised to ensure that they do not play with the appliance.

•If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

•The new hose-sets supplied with the appliance should be used and old hose-sets should not be reused.

•The openings must not be obstructed by a carpet.

•This appliance is intended for indoor domestic or household use only, and is not intended for

commercial, trade or industrial use.

•Do not repair or replace any part of the appliance unless specifically recommended in the manual. All

other servicing should be done by a qualified technician.

06

GENERAL SAFETY INSTRUCTIONS CONT.

DANGER: GAS LEAKS

If gas seems to leak,take the actions as follow:

•Do not turn on the light.

•Do not switch on/off any electrical appliance and do not touch any electric plug. - Do not use a

telephone.

1. Stop using the product and close the middle valve.

2. Open the window to ventilate.

3. Contact our service center by using a phone outside.

NOTE: The fuel gas contains mercaptan, so that you can smell the gas leak (smell of rotten garlic or egg)

even where only 1/1000 of the gas is in the air.

WARNING INSTALLATION

•This appliance shall be installed in accordance with regulations in force and only used in a well ventilated

space.

•Prior to installation, ensure that the gas and electrical supply complies with the type stated on the rating

plate.

•Where this appliance is installed in marine craft or in caravans, it should not be used as a space heater.

•The gas pipe and electrical cable must be installed in such a way that they do not touch any parts or the

appliance.

CAUTION INSTALLATION

•This appliance should be installed by a qualified technician or installer.

•The adjustment conditions for this appliance are stated on the label or date plate.

•Remove all packaging before using the appliance.

•After unpacking the appliance, make sure the product is not damaged and that the connection cord is in

perfect condition. Otherwise, contact the dealer before installing the appliance.

•The adjacent furniture and all materials used in the installation must be able to withstand a minimum

temperature of 85ºC above the ambient temperature of the room it is located in while it is in use.

•In the event of one of the burner flames being accidentally extinguished, turn off the burner control and

do not attempt to re-ignite the burner for at least one minute.

•The use of a gas cooking appliance results in the production of heat and moisture in the room in which

it is installed. Ensure that the kitchen is well ventilated: keep natural ventilation holes open or install a

mechanical ventilation device (mechanical extractor hood).

•Prolonged intensive use of the appliance may call for additional ventilation, for example opening of a

window, or more effective ventilation, for example increasing the level of mechanical ventilation where

present.

CAUTION SAFETY AROUND CHILDREN

•Do not allow children to play near or with the appliance.

•The appliance gets hot when it is in use.

•Children should be kept away until it has cooled.

•.This appliance is designed to be operated by adults.

•Children can also injure themselves by pulling pans or pots off the appliance.

•This appliance is not intended for use by children or other persons whose physical, sensory or mental

capabilities or lack of experience and knowledge prevents them from using the appliance safely without

supervision or instruction by a responsible person to ensure that they can use the appliance safely.

07

GENERAL SAFETY INSTRUCTIONS CONT.

WARNING OPERATING THE APPLIANCE

•The appliance and its accessible parts become hot during use.

•Care should be taken to avoid touching heating elements.

•Only use the appliance for preparing food.

•Do not modify this appliance. Burner panel is not designed to operate from an external timer or separate

remote control system.

•The use of a gas cooking appliance results in the production of heat and moisture in the room in which

it is installed. Ensure that the kitchen is well ventilated : keep natural ventilation holes open or install a

mechanical ventilation device mechanical extractor hood.

•Do not use the appliance if it comes in contact with water. Do not operate this appliance with wet hands.

•The heating and cooking surface of the appliance become hot when they are in use, take all due

precautions.

•Do not use large cloths, tea towels or similar as the ends could touch the flames and catch fire.

•Never leave the appliance unattended when cooking.

•Unstable or misshapen pans should not be used on the appliance as they can cause an accident by

tipping or spillage.

•Do not store or use flammable materials in a storage drawer near the appliance.

•Perishable food ,plastic items and aerosols may be affected by heat and should not be stored above or

below the appliance.

•Do not spray aerosols in the vicinity of the appliance while it is in operation.

•Ensure the control knobs are facing upwards in the off position when not in use.

CAUTION OPERATING THE APPLIANCE

•The appliance is intended for domestic cooking only. It is not designed for commercial or industrial

purposes

•Prolonged intensive use of the appliance may call for additional ventilation, for example opening a

window or increasing the level of mechanical ventilation where present.

•Use heat resistant pot holders or gloves when handling pots and pans.

•Do not let pot holders come near open flames when lifting cookware.

•Take care not to let pot holders or gloves get damp or wet, as this causes heat to transfer through the

material quicker with the risk of burning yourself.

•Only ever use the burners after placing pots or pans on them. Do not heat up empty pots or pans.

•Never use plastic or aluminium foil dishes on the appliance.

•If you have any mechanical parts in your body please consult a doctor before using the appliance.

•Do not sure a tea towel or similar materials in place of a pot holder. Such cloths can catch fire on a hot

burner.

•When using glass cookware, make sure it is designed for top plate cooking. If the surface that is made of

glass cracks, switch off the appliance to avoid defeat electrocution.

•To minimise the possibility of burns, ignition of flammable materials and spillage, turn cookware handles

toward the side or center of the top plate without extending over adjacent burners.

•Always turn burner controls off before removing cookware.

•Carefully watch food being fried at a high flame setting.

•Always heat fat slowly and watch as it heats.

•Food for frying should be as dry as possible. Frost on frozen foods or moisture on fresh foods can cause

hot fat to bubble up and over the sides of the pan.

•Never try to move a pan of hot fat, especially a deep fryer. Wait until the fat is completely cool.

08

RESPONSIBLE DISPOSAL

The symbol on the product, or in its packaging, indicates that this product may not

be treated as household wasted, Instead, it should be taken to the appropriate waste

collection point for the recycling of electrical and electronic equipment. By ensuring this

product is disposed of correctly, you will help prevent potential negative consequences

for the environment and human health, which could otherwise be caused by the

inappropriate waste handling of this product. For more detailed information about

the recycling of this product, please contact your local council, your household waste

disposal service, or the shop where you purchased the product.

GENERAL SAFETY INSTRUCTIONS CONT.

WARNING CLEANING AND MAINTENANCE

•Never use abrasive or caustic cleaning agents.

•This appliance should only be repaired or serviced by an authorised service agent and only genuine

spare parts should be used.

•Before attempting to clean the appliance it should be disconnected from the mains and cooled.

•You should not use a steam jet or any other high pressure cleaning equipment to clean the appliance.

ENVIRONMENTAL INFORMATION

•After installation, please dispose of the packaging with due regard for safety and the environment.

•When disposing of an old appliance, make it unusable by cutting off the cable.

09

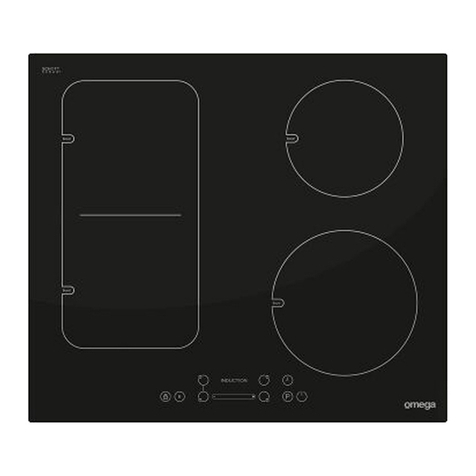

Product Overview

YOUR 90CM GLASS GAS COOKTOP

1. Semi-rapid Burner

2. Triple-crown Wok Burner

3. Auxilary Burner

4. Rapid Burner

5. Semi-rapid Burner

6. Knob Controls

Key:

1

3

2

4

5

6

A

How to Use the appliance

ccessories

Description of the appliance

Black circle: gas off

Large flame: maximum setting

Small flame: minimum setting

Automatic ignition with flame failure safety device

10

Bracket (4) Sponge (4)

Screw

(4)

Elbow

(1) Auxiliary pan support (1)

(5)

Instruction

Manual (1)

Voltage regulator valve (1)

Pressure joint(1)

The appliance is fitted with a flame failure safety device on each burner, which

is designed to stop the flow of gas to the burner head in the event of the flame

going out.

Injector

The minimum setting is at the end of the anti-clockwise rotation of the control handle.

All operation positions must be selected between the maximum and minimum position.

The symbol on the control panel,next to the control handle will indicate which burner it

operates.

7KHIROORZLQJV\PEROVZLOODSSHDURQWKHFRQWUROSDQHOQH[WWRHDFKFRQWUROKDQGOH

Accessories:

10

Installation Instructions

INSTALLATION WARNINGS

•Do not modify this appliance.

• This appliance must be installed by an authorised technician or installer.

•Prior to installation, ensure that the local distribution conditions nature of the gas and gas pressure and

the adjustment of the appliance are compatible.

•The adjustment conditions for this appliance are stated on the label or data plate

•This appliance is not connected to a combustion products evacuation device. It should be installed and

connected in accordance with current installation regulations. Particular attention should be given to the

relevant requirements regarding ventilation.

•Before installing, turn off the gas and electricity supply to the appliance.

•All appliances containing any electrical components must be earthed.

•Ensure that the gas pipe and electrical cable are installed in such a way that they do not touch any parts

of the appliance which may become hot.

•Gas pipe or connector shouldn’t be bent or blocked by any other appliances.

•Check the dimensions of the appliance as well as the dimensions of the gap to be cut in the kitchen unit.

•The panels located above the work surface, directly next to the appliance, must be made of non-

flammable material. Both the stratified surfacing and the glue used to secure it should be heat resistant,

to prevent deterioration.

•Turn on appliance tap and light each burner. Check for a clear blue flame without yellow tipping and if

burners show any abnormalities check the following;

- Burner lid is on correctly

- Flame spreader is positioned correctly

- Burner vertically aligned with injector end

•A full operational test and test for possible leakages must be carried out by the installer after installation.

•The flexible hose shall be fitted in such a way that it cannot come into contact with a movable part of the

housing unit and does not pass through any space susceptible of becoming congested.

•Grease cranes produced at the factory to meet the requirement of all life hob.

11

INSTALLATION INSTRUCTIONS CONT.

POSITIONING

•Clearances required when fitting the cooktop with a cooker hood above.

•This appliance is to be built into a kitchen unit or 600mm worktop,providing the following minimum

distances are allowed;

•The edges of the hob must be a minimum distance of 60mm from a side or rear wall.

•700 mm between the highest point of the hob surface including the burners and the underside of any

horizontal surface directly above it.

•400 mm between the hob surfaces, providing that the underside of the horizontal surface is in line with

the outer edge of the hob. If the underside of the horizontal surface is lower than 400 mm, then it must

be at least 50 mm away from the outer edges of the hob.

•50 mm clearance around the appliance and between the hob surface and any combustible materials.

•You must have a gap of at least 25 mm and at most 74 mm between the underneath of the appliance

and any surface that is below it.

•An oven must have forced ventilation to install a hob above it.

•Check the dimensions of the oven in the installation manual.

•The cut out size must obey the indication.

Positioning

The edges of the hob must be a minimum distance of mm from a side or

rear wall.

700 mm between the highest point of the hob surface (including the burners)

and the underside of any horizontal surface directly above it.

400 mm between the hob surfaces, providing that the underside of the

horizontal surface is in line with the outer edge of the hob. If the underside of

the horizontal surface is lower than 400 mm, then it must be at least 50 mm

away from the outer edges of the hob.

50 mm clearance around the appliance and between the hob surface and any

combustible materials.

45 mm

60

You must have a gap of at least 25 mm and at most 74 mm between

the underneath of the appliance and any surface that is below it.

16

o

o

o

o

o

CLEARANCES REQUIRED

WHEN FITTING THE HOB

WITH A COOKER HOOD ABOVE

900mm

700mm

400mm

400mm

FO 0813

60mm

480mm

in

0

.

0mm

M

2

This appliance is to be built into a kitchen unit or 600mm worktop,providing

the following minium distances are allowed;

- An oven must have forced ventilation to install a hob above it.

- Check the dimensions of the oven in the installation manual.

- The cut out size must obey the indication.

830mm

Positioning

The edges of the hob must be a minimum distance of mm from a side or

rear wall.

700 mm between the highest point of the hob surface (including the burners)

and the underside of any horizontal surface directly above it.

400 mm between the hob surfaces, providing that the underside of the

horizontal surface is in line with the outer edge of the hob. If the underside of

the horizontal surface is lower than 400 mm, then it must be at least 50 mm

away from the outer edges of the hob.

50 mm clearance around the appliance and between the hob surface and any

combustible materials.

45 mm

60

You must have a gap of at least 25 mm and at most 74 mm between

the underneath of the appliance and any surface that is below it.

16

o

o

o

o

o

CLEARANCES REQUIRED

WHEN FITTING THE HOB

WITH A COOKER HOOD ABOVE

900mm

700mm

400mm

400mm

FO 0813

60mm

480mm

in

0

.

0mm

M

2

This appliance is to be built into a kitchen unit or 600mm worktop,providing

the following minium distances are allowed;

- An oven must have forced ventilation to install a hob above it.

- Check the dimensions of the oven in the installation manual.

- The cut out size must obey the indication.

830mm

12

INSTALLATION INSTRUCTIONS CONT.

INSTALLING THE APPLIANCE

•Remove the pan supports, the burner lid and

flame spreader and carefully turn the appliance

upside down and place it on a cushioned mat.

Take care that the Ignition devices and flame

supervision devices are not damaged in this

operation.

•Apply the sponge provided around the edge of

the appliance.

•Do not leave a gap in the sealing agent or

overlap the thickness.

WARNING!

DO NOT use a silicon sealant to seal the appliance

to the bench top.

This will make it difficult to remove the appliance

from the aperture in future, particularly if it needs to

be serviced.

1. Place the bracket B over the holes that match

the size of the screws. There are one set of screw

holes in each corner of the cooktop.

2. Slightly tighten a screw C through the bracket

B so that the bracket is attached to the hob, but

so that you can still adjust the position. Carefully

turn the hob back over and then gently lower it

into the aperture hole that you have cut out.

3. On the underneath of the hob, adjust the

brackets into a position that is suitable for

your worktop.

Then fully tighten the screws C to secure the hob

into position.

Installing the appliance

Bottom view

of the screws.There are one set of screw holes in each

corner of the hob (H) .

Slightly tighten a screw (C) through the bracket (B) so

that the bracket is attached to the hob, but so that you

can still adjust the position

.

.2 Carefully turn the hob back over and then gently lower

it into the aperture hole that you have cut out.

.3 On the underneath of the hob, adjust the brackets into

a position that is suitable for your worktop.

Then fully tighten the screws (C) to secure the hob into

position.

(A) SEALING STRIP

(C) SCREW (B) BRACKET

17

Remove the pan supports, the burner lid

and flame spreader and carefully turn the

appliance upside down and place it on a

cushioned mat.

Take care that the Ignition devices and

flame supervision devices are not damaged

in this operation.

2. Apply the sponge provided around the

edge of the appliance.

3.

1.

Do not leave a gap in the sealing agent or

overlap the thickness.

3ODFHWKHEUDFNHW %RYHUWKHKROHVWKDWPDWFKWKHVL]H

7KLVZLOOPDNHLWGLI¿FXOWWRUHPRYHWKH

DSSOLDQFHIURPWKHDSHUWXUHLQIXWXUH

SDUWLFXODUO\LILWQHHGVWREHVHUYLFHG

Do not use a silicon sealant to seal the

appliance against the aperture.

Installing the appliance

Bottom view

of the screws.There are one set of screw holes in each

corner of the hob (H) .

Slightly tighten a screw (C) through the bracket (B) so

that the bracket is attached to the hob, but so that you

can still adjust the position

.

.2 Carefully turn the hob back over and then gently lower

it into the aperture hole that you have cut out.

.3 On the underneath of the hob, adjust the brackets into

a position that is suitable for your worktop.

Then fully tighten the screws (C) to secure the hob into

position.

(A) SEALING STRIP

(C) SCREW (B) BRACKET

17

Remove the pan supports, the burner lid

and flame spreader and carefully turn the

appliance upside down and place it on a

cushioned mat.

Take care that the Ignition devices and

flame supervision devices are not damaged

in this operation.

2. Apply the sponge provided around the

edge of the appliance.

3.

1.

Do not leave a gap in the sealing agent or

overlap the thickness.

3ODFHWKHEUDFNHW %RYHUWKHKROHVWKDWPDWFKWKHVL]H

7KLVZLOOPDNHLWGLI¿FXOWWRUHPRYHWKH

DSSOLDQFHIURPWKHDSHUWXUHLQIXWXUH

SDUWLFXODUO\LILWQHHGVWREHVHUYLFHG

Do not use a silicon sealant to seal the

appliance against the aperture.

13

INSTALLATION INSTRUCTIONS CONT.

GAS CONNECTION

WARNING!

•This appliance must be installed and connected in accordance with installation regulations in force in the

county in which the appliance is to be used.

•This appliance is supplied to run on natural gas only and cannot be used on any other type of gas without

modification. Conversion for use on LPG and other gases must be undertaken by a qualified person.

•Turn off the power for safety and appliance protection. Close middle valve to prevent gas leakage.

•Keep flammable materials away from the appliance.

•Before work put on gloves.

CAUTION!

•Cool off the appliance for a while right after using appliance for your safety, burners can reach a high

temperature during use.

Most of the tools required are shown below. Some are optional.

REPLACEMENT OF GASTYPE FITTING

Tool: Open-end wrench

Steps for operation:

1. Disassemble with a wrench the gas-type fittings from main gas tube.

When you disassemble/assemble gas connection, use 2 spanners. One for fixing gas connection

elbow, the other for tightening gas hose.

2. Look tightly a replaceable gas-type fitting onto the main gas tube.

STATUTORY REQUIREMENTS

•This installation must conform with the following:

•Manufacturer’s Installation instructions

•Local Gas Fitting Regulations

•Municipal Building Codes

Gas Connection

18

Keep away from inflammable materials around appliance.

Before work, put on gloves.

CAUTION

Cool off the appliance for a while right after using appliance for your safety

because you can get burners by high temperature from the appliances.

B: Look tightly a replaceable gas-type fitting onto the main gas tube.

Turn off power for safety and appliance protection. Close middle valve to

prevent gas leakage.

Most of the tools that you might need are shown below. Some are optional.

Replacement of gas-type fitting

Tool: Open-end wrench

Steps for operation:

A: Disassemble with a wrench the gas-type fittings from main gas tube.

When you disassemble/assemble gas connection, use 2 spanners. One for fixing gas

connection elbow, the other for tightening gas hose.

Ŷ7KLVDSSOLDQFHPXVWEHLQVWDOOHGDQGFRQQHFWHGLQDFFRUGDQFHZLWKLQVWDOOD

WLRQUHJXODWLRQVLQIRUFHLQWKHFRXQWU\LQZKLFKWKHDSSOLDQFHLVWREHXVHG

Ŷ7KLVDSSOLDQFHLVVXSSOLHGWRUXQRQQDWXUDOJDVRQO\DQGFDQQRWEHXVHGRQ

DQ\RWKHUW\SHRIJDVZLWKRXWPRGL¿FDWLRQ&RQYHUVLRQIRUXVHRQ/3*DQG

RWKHUJDVHVPXVWRQO\EHXQGHUWDNHQE\DTXDOL¿HGSHUVRQ

1

2

Gas Connection

18

Keep away from inflammable materials around appliance.

Before work, put on gloves.

CAUTION

Cool off the appliance for a while right after using appliance for your safety

because you can get burners by high temperature from the appliances.

B: Look tightly a replaceable gas-type fitting onto the main gas tube.

Turn off power for safety and appliance protection. Close middle valve to

prevent gas leakage.

Most of the tools that you might need are shown below. Some are optional.

Replacement of gas-type fitting

Tool: Open-end wrench

Steps for operation:

A: Disassemble with a wrench the gas-type fittings from main gas tube.

When you disassemble/assemble gas connection, use 2 spanners. One for fixing gas

connection elbow, the other for tightening gas hose.

Ŷ7KLVDSSOLDQFHPXVWEHLQVWDOOHGDQGFRQQHFWHGLQDFFRUGDQFHZLWKLQVWDOOD

WLRQUHJXODWLRQVLQIRUFHLQWKHFRXQWU\LQZKLFKWKHDSSOLDQFHLVWREHXVHG

Ŷ7KLVDSSOLDQFHLVVXSSOLHGWRUXQRQQDWXUDOJDVRQO\DQGFDQQRWEHXVHGRQ

DQ\RWKHUW\SHRIJDVZLWKRXWPRGL¿FDWLRQ&RQYHUVLRQIRUXVHRQ/3*DQG

RWKHUJDVHVPXVWRQO\EHXQGHUWDNHQE\DTXDOL¿HGSHUVRQ

1

2

•Refer to AS/NZS 5601.1 for Gas Installations

•S.A.A. Wiring Code

•Local Electrical Regulations

•Any other statutory regulations

14

PREPARING TO INSTALL

•Refer to AS/NZS 5601.1 for piping size details. These built-in cooktops are intended to be inserted in a

benchtop cutout. Only an officially authorised technician should connect the appliance. Before you

begin, turn off the gas and electricity supply.

WARNING!

•A full operational test and a test for possible leakages must be carried out by the fitter after installation.

•Access to the whole length of the connection hose must be possible and the gas hose must be replaced

before its use before the end of service life indicated on the hose.

•Before Leaving-Check all connections for gas leaks with soap and water.

•DO NOT use a naked flame for detecting leaks. Ignite all burners both individually and concurrently to

ensure correct operation of gas valves, burners and ignition. Turn gas taps to low flame position and

observe stability of the flame for each burner individually and all together. Adhere the duplicate data

plate to an accessible location near the hotplate. When satisfied with the hotplate, please instruct the

user on the correct method of operation. In case the appliance fails to operate correctly after all checks

have been carried out, refer to the authorised service provider in your area.

GAS CONNECTION

•Flexible Hose: If installing with a hose assembly, it must comply with AS/NZS 1869, 10mmID,class B or D,no

more than 1.2m long and installed in accordance with AS/NZS 5601.1.

•Ensure that the hose does not contact the hot surfaces of the hotplate,oven,dishwasher or any other

appliance that may be installed underneath or next to the hotplate. The hose should not be subjected to

abrasion, kinking or permanent deformation and should be able to be inspected along its entire length

with the cooktop in the installed position. Unions compatible with the hose fittings must be used and

all connections tested for gas leaks. The supply connection point shall be accessible with the appliance

installed.

• WARNING! Ensure that the hose assembly is restrained from accidental contact with the flue outlet of an

under bench oven.

Install in accordance with relevant gas standards and/or codes of practice applicable. Connect the elbow

fitting to the appliance gas manifold connection, and check that seals between the elbow and manifold

connection are in place and in good condition.

•For Natural gas: connect the natural gas appliance regulator pictured opposite with integral test point

using approved gas thread tape or compound to the elbow fitting.

•For Universal LPG: connect the brass test point adapter pictured opposite using approved gas thread

tape or compound to the elbow fitting.

•Ensure the supply connection point, test point and natural gas regulator adjustment screw for Natural

gas installation are accessible for testing and/or adjustment with the hotplate in the installed position.

INSTALLATION INSTRUCTIONS CONT.

Gas Connection

Statutory requirements

This installation must conform with the following:

■Manufacturer’s Installation instructions

■Local Gas Fitting Regulations

■Municipal Building Codes

■Refer to AS/NZS 5601.1 for Gas Installations

■S.A.A. Wiring Code

■Local Electrical Regulations

■Any other statutory regulations

Preparing to install

Refer to AS/NZS 5601.1 for piping size details. These built-in cooktops are intended to

be inserted in a benchtop cutout. Only an officially authorised technician should

connect the appliance. Before you begin, turn off the gas and electricity supply.

19

A full operational test and a test for possible leakages must be

carried out by the fitter after installation.

Access to the whole length of the connection hose must be possible

and the gas hose must be replaced before its use before the end of

service life (indicated on the hose.)

Before Leaving-Check all connections for gas leaks with soap and

water.

DO NOT use a naked flame for detecting leaks. Ignite all burners both

individually and concurrently to ensure correct operation of gas

valves, burners and ignition. Turn gas taps to low flame position and

observe stability of the flame for each burner individually and all

together. Adhere the duplicate data plate to an accessible location

near the hotplate. When satisfied with the hotplate, please instruct

the user on the correct method of operation. In case the appliance

fails to operate correctly after all checks have been carried out, refer

to the auth orised service provider in your area.

Natural gas connection

95

115

LPG gas connection

pressure test point

pressure test point

15

INSTALLATION INSTRUCTIONS CONT.

GAS CONNECTION CONT.

Where a flexible hose assembly is used, ensure it is approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with the flue outlet of an under bench oven. This hose

assembly shall be suitable for connection to a fixed consumer piping outlet located as follows: Hotplates

at a point 800 mm to 850 mm above the floor and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy solution, never a naked flame

GAS SPECIFICATION

Where a flexible hose assembly is used, ensure it is

approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with

the flue outlet of an under bench oven.

This hose assembly shall be suitable for connection to a

fixed consumer piping outlet located as follows:

Hotplates at a point 800 mm to 850 mm above the floor

and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy

solution, never a naked flame. Inlet connection region for flexible hose

Gas Connection

Install in accordance with relevant gas standards and/or codes of

practice applicable.

Connect the elbow fitting to the appliance gas manifold

connection, and check that seals between the elbow and

manifold connection are in place and in good condition.

For Natural gas: connect the natural gas appliance

regulator (pictured opposite) with integral test point using

approved gas thread tape or compound to the elbow

fitting.

For Universal LPG: connect the brass test point adaptor

(pictured opposite) using approved gas thread tape or

compound to the elbow fitting.

Ensure the supply connection point, test point and natural gas

regulator adjustment screw (for Natural gas installation) are

accessible for testing and/or adjustment with the hotplate in

the installed position.

20

■

■

■

Flexible Hose: If installing with a hose assembly, it must comply with AS/NZS

accordance with AS/NZS 5601.1.

Ensure that the hose does not contact the hot surfaces of the

hotplate,oven,dishwasher or any other appliance that may be installed

underneath or next to the hotplate.The hose should not be subjected to abrasion,

kinking or permanent deformation and should be able to be inspected along its

entire length with the cooktop in the installed position. Unions compatible with

the hose fittings must be used and all connections tested for gas leaks.The

supply connection point shall be accessible with the appliance installed.

WARNING: Ensure that the hose assembly is restrained from accidental contact

with the flue outlet of an underbench oven.

Gas Connection

1869,10mmID,class B or D,no more than 1.2m long and installed in

Where a flexible hose assembly is used, ensure it is

approved to AS/NZS 1869, Class B. Any hose assembly

used must be restrained from accidental contact with

the flue outlet of an under bench oven.

This hose assembly shall be suitable for connection to a

fixed consumer piping outlet located as follows:

Hotplates at a point 800 mm to 850 mm above the floor

and in the region outside the width of the appliance to a

distance of 250 mm.

After connecting to gas, check for leaks using soapy

solution, never a naked flame. Inlet connection region for flexible hose

Gas Connection

Install in accordance with relevant gas standards and/or codes of

practice applicable.

Connect the elbow fitting to the appliance gas manifold

connection, and check that seals between the elbow and

manifold connection are in place and in good condition.

For Natural gas: connect the natural gas appliance

regulator (pictured opposite) with integral test point using

approved gas thread tape or compound to the elbow

fitting.

For Universal LPG: connect the brass test point adaptor

(pictured opposite) using approved gas thread tape or

compound to the elbow fitting.

Ensure the supply connection point, test point and natural gas

regulator adjustment screw (for Natural gas installation) are

accessible for testing and/or adjustment with the hotplate in

the installed position.

20

■

■

■

Flexible Hose: If installing with a hose assembly, it must comply with AS/NZS

accordance with AS/NZS 5601.1.

Ensure that the hose does not contact the hot surfaces of the

hotplate,oven,dishwasher or any other appliance that may be installed

underneath or next to the hotplate.The hose should not be subjected to abrasion,

kinking or permanent deformation and should be able to be inspected along its

entire length with the cooktop in the installed position. Unions compatible with

the hose fittings must be used and all connections tested for gas leaks.The

supply connection point shall be accessible with the appliance installed.

WARNING: Ensure that the hose assembly is restrained from accidental contact

with the flue outlet of an underbench oven.

Gas Connection

1869,10mmID,class B or D,no more than 1.2m long and installed in

Gas Specification

21

13.5MJ/h 4.3MJ/h

0.58

1.72 0.93

Universal

LP Gas

2.75kPa

Wok burner Rapid burner Semi-rapid Auxiliary

Heat input and orifice size marked(mm)

Gas type &

pressure

Natural Gas

1.0kPa

10.8MJ/h 6.3MJ/h

0.68

1.15

1.00 0.90

1.50

16

INSTALLATION INSTRUCTIONS CONT.

ELECTRICAL CONNECTION

• This appliance must be earthed

• This appliance is designed to be connected to a 220-240V, 50Hz-60Hz AC electricity supply

• The wires in the mains leads are coloured in accordance with the following code.

Green/yellow = Earth

Blue = Neutral

Brown = Live

WARNING! The wire which is coloured green/yellow must be connected to the terminal which is marked with

the letter E or by the earth symbol.

WIRING DIAGRAM

When the power cord is damaged it must be replaced by the manufacturer to produce, customer service

agent or similarly qualified personnel.

Electrical Connection

- Green/yellow = Earth

- Blue = Neutral

- Brown = Live

22

■ This appliance is designed to be connected to a 220-240V, 50Hz-60Hz AC electricity supply.

Ŷ7KHZLUHZKLFKLVFRORXUHGJUHHQDQG\HOORZPXVWEHFRQQHFWHG

WRWKHWHUPLQDOZKLFKLVPDUNHGZLWKWKHOHWWHU(RUE\WKHHDUWK

V\PERO

ʄ:,5

When the power cord is damaged it must be replaced by the manufacturer to produce,

customer service agent or similarly qualified personnel.

,1*',$*5$0

Ŷ7KLVDSSOLDQFHPXVWEHHDUWKHG

Ŷ7KHZLUHVLQWKHPDLQVOHDGDUHFRORXUHGLQDFFRUGDQFHZLWKWKHIROORZLQJFRGH

Switch 1

Switch 2

AC INPUT

Switch 3

Switch 4

IGNITION

L

E

N

Switch 5

17

INSTALLATION INSTRUCTIONS CONT.

GAS ADJUSTMENT

•Take precautions on the operations and adjustments to be carried out when converting from one gas to

another.

•All work must be carried out by a qualified technician

• Before you begin, turn off the gas and electricity supply to the appliance.

1. Change the injector of the burners

Remove the pan support, Burner lid and Flame spreader. Unscrew the injector using a 7mm box

spanner and replace it with the stipulated injector for new gas supply. Carefully reassemble the all

components. After injectors are replaced, it is advisable to strongly tighten the injector in place.

2. Adjustment of minimum level of the flame

•Turn the taps down to minimum.

•Remove the knob from the tap and place a small bladed screwdriver in the center of the tap shaft.

•The correct adjustment is obtained when the flame has a length of about 3-4mm.

- For butane / propane gas, the adjusting screw must - be tightly screwed in.

- Refit the control knob.

Make sure that the flame does not go out by quickly turning from maximum flow to minimum flow. If it

does then remove the control knob and make further adjustments to the gas flow, testing it again once

the adjustment has been made.

•Repeat this process for each one of the gas taps.

•5 Attach the ULPG sticker to the cooker, near the gas supply inlet. Cover the Natural label that is factory

fitted.

Gas adjustment

1

Injector

23

Remove the pan support, Burner lid and Flame spreader.

Unscrew the injector using a 7mm box spanner and

replace it with the stipulated injector for new gas

supply. Carefully reassemble the all components.

After injectors are replaced, it is advisable to strongly

tighten the injector in place.

Ŷ7DNHSUHFDXWLRQVRQWKHRSHUDWLRQVDQGDGMXVWPHQWVWREHFDUULHGRXWZKHQ

FRQYHUWLQJIURPRQHJDVWRDQRWKHU

Ŷ$OOZRUNPXVWEHFDUULHGRXWE\DTXDOL¿HGWHFKQLFLDQ

Ŷ%HIRUH\RXEHJLQWXUQRIIWKHJDVDQGHOHFWULFLW\VXSSO\WRWKHDSSOLDQFH

Change the injector of the burners.

2

Control handle

Tap

Sealing ring

Adjustment of minimum level of the flame.

Turn the taps down to minimum.

-

Remove the knob from the tap and place a small

bladed screwdriver in the centre of the tap shaft.

The correct adjustment is obtained when the flame

has a length of about 3 - 4 mm.

-

For butane

/ propane gas, the adjusting screw must

Make sure that the flame does not go out by

quickly turning from maximum flow to minimum

flow. If it does then remove the control knob and

make further adjustments to the gas flow, testing it

again once the adjustment has been made.

Repeat this process for each one of the gas taps.

be tightly screwed in.

Refit the control knob.

-

Ŷ

%HIRUHSODFLQJWKHEXUQHUV

EDFNRQWKHWRSSODFHPDNHVXUH

WKDWWKHLQMHFWRULV

QRWEORFNHG

FDUULHGRXWDIWHUJDVFRQYHUVLRQ

VXFKDVVRDSZDWHURUJDV

DTXDOL¿HGWHFKQLFLDQRULQVWDOOHU

KDVWRPDUN³9´RQWKHULJKWJDV

FDWHJRU\

WRPDWFKZLWKWKH

VHWWLQJ

LQUDWLQJSODWH

5HPRYHWKHSUHYLRXV

VHWWLQJ³9´PDUN

LQWKHHYHQWRIDPDOIXQFWLRQ

FKDQJHWKHZKROHWDS

Ŷ

$IXOORSHUDWLRQDOWHVWDQGDWHVW

IRUSRVVLEOHOHDNDJHVPXVWEH

Ŷ

$IWHUFRPSOHWLQJFRQYHUVLRQ

GHWHFWRU

ŶDo not dismantle the tap shaft:

Attach the ULPG sticker to the cooker, near the gas

supply inlet. Cover the Natural label that is factory

fitted.

5

Gas adjustment

1

Injector

23

Remove the pan support, Burner lid and Flame spreader.

Unscrew the injector using a 7mm box spanner and

replace it with the stipulated injector for new gas

supply. Carefully reassemble the all components.

After injectors are replaced, it is advisable to strongly

tighten the injector in place.

Ŷ7DNHSUHFDXWLRQVRQWKHRSHUDWLRQVDQGDGMXVWPHQWVWREHFDUULHGRXWZKHQ

FRQYHUWLQJIURPRQHJDVWRDQRWKHU

Ŷ$OOZRUNPXVWEHFDUULHGRXWE\DTXDOL¿HGWHFKQLFLDQ

Ŷ%HIRUH\RXEHJLQWXUQRIIWKHJDVDQGHOHFWULFLW\VXSSO\WRWKHDSSOLDQFH

Change the injector of the burners.

2

Control handle

Tap

Sealing ring

Adjustment of minimum level of the flame.

Turn the taps down to minimum.

-

Remove the knob from the tap and place a small

bladed screwdriver in the centre of the tap shaft.

The correct adjustment is obtained when the flame

has a length of about 3 - 4 mm.

-

For butane

/ propane gas, the adjusting screw must

Make sure that the flame does not go out by

quickly turning from maximum flow to minimum

flow. If it does then remove the control knob and

make further adjustments to the gas flow, testing it

again once the adjustment has been made.

Repeat this process for each one of the gas taps.

be tightly screwed in.

Refit the control knob.

-

Ŷ

%HIRUHSODFLQJWKHEXUQHUV

EDFNRQWKHWRSSODFHPDNHVXUH

WKDWWKHLQMHFWRULV QRWEORFNHG

FDUULHGRXWDIWHUJDVFRQYHUVLRQ

VXFKDVVRDSZDWHURUJDV

DTXDOL¿HGWHFKQLFLDQRULQVWDOOHU

KDVWRPDUN³9´RQWKHULJKWJDV

FDWHJRU\

WRPDWFKZLWKWKH

VHWWLQJLQUDWLQJSODWH

5HPRYHWKHSUHYLRXV

VHWWLQJ³9´PDUN

LQWKHHYHQWRIDPDOIXQFWLRQ

FKDQJHWKHZKROHWDS

Ŷ

$IXOORSHUDWLRQDOWHVWDQGDWHVW

IRUSRVVLEOHOHDNDJHVPXVWEH

Ŷ

$IWHUFRPSOHWLQJFRQYHUVLRQ

GHWHFWRU

ŶDo not dismantle the tap shaft:

Attach the ULPG sticker to the cooker, near the gas

supply inlet. Cover the Natural label that is factory

fitted.

5

Gas adjustment

1

Injector

23

Remove the pan support, Burner lid and Flame spreader.

Unscrew the injector using a 7mm box spanner and

replace it with the stipulated injector for new gas

supply. Carefully reassemble the all components.

After injectors are replaced, it is advisable to strongly

tighten the injector in place.

Ŷ7DNHSUHFDXWLRQVRQWKHRSHUDWLRQVDQGDGMXVWPHQWVWREHFDUULHGRXWZKHQ

FRQYHUWLQJIURPRQHJDVWRDQRWKHU

Ŷ$OOZRUNPXVWEHFDUULHGRXWE\DTXDOL¿HGWHFKQLFLDQ

Ŷ%HIRUH\RXEHJLQWXUQRIIWKHJDVDQGHOHFWULFLW\VXSSO\WRWKHDSSOLDQFH

Change the injector of the burners.

2

Control handle

Tap

Sealing ring

Adjustment of minimum level of the flame.

Turn the taps down to minimum.

-

Remove the knob from the tap and place a small

bladed screwdriver in the centre of the tap shaft.

The correct adjustment is obtained when the flame

has a length of about 3 - 4 mm.

-

For butane

/ propane gas, the adjusting screw must

Make sure that the flame does not go out by

quickly turning from maximum flow to minimum

flow. If it does then remove the control knob and

make further adjustments to the gas flow, testing it

again once the adjustment has been made.

Repeat this process for each one of the gas taps.

be tightly screwed in.

Refit the control knob.

-

Ŷ

%HIRUHSODFLQJWKHEXUQHUV

EDFNRQWKHWRSSODFHPDNHVXUH

WKDWWKHLQMHFWRULV

QRWEORFNHG

FDUULHGRXWDIWHUJDVFRQYHUVLRQ

VXFKDVVRDSZDWHURUJDV

DTXDOL¿HGWHFKQLFLDQRULQVWDOOHU

KDVWRPDUN³9´RQWKHULJKWJDV

FDWHJRU\

WRPDWFKZLWKWKH

VHWWLQJ

LQUDWLQJSODWH

5HPRYHWKHSUHYLRXV

VHWWLQJ³9´PDUN

LQWKHHYHQWRIDPDOIXQFWLRQ

FKDQJHWKHZKROHWDS

Ŷ

$IXOORSHUDWLRQDOWHVWDQGDWHVW

IRUSRVVLEOHOHDNDJHVPXVWEH

Ŷ

$IWHUFRPSOHWLQJFRQYHUVLRQ

GHWHFWRU

ŶDo not dismantle the tap shaft:

Attach the ULPG sticker to the cooker, near the gas

supply inlet. Cover the Natural label that is factory

fitted.

5

Gas adjustment

1

Injector

23

Remove the pan support, Burner lid and Flame spreader.

Unscrew the injector using a 7mm box spanner and

replace it with the stipulated injector for new gas

supply. Carefully reassemble the all components.

After injectors are replaced, it is advisable to strongly

tighten the injector in place.

Ŷ7DNHSUHFDXWLRQVRQWKHRSHUDWLRQVDQGDGMXVWPHQWVWREHFDUULHGRXWZKHQ

FRQYHUWLQJIURPRQHJDVWRDQRWKHU

Ŷ$OOZRUNPXVWEHFDUULHGRXWE\DTXDOL¿HGWHFKQLFLDQ

Ŷ%HIRUH\RXEHJLQWXUQRIIWKHJDVDQGHOHFWULFLW\VXSSO\WRWKHDSSOLDQFH

Change the injector of the burners.

2

Control handle

Tap

Sealing ring

Adjustment of minimum level of the flame.

Turn the taps down to minimum.

-

Remove the knob from the tap and place a small

bladed screwdriver in the centre of the tap shaft.

The correct adjustment is obtained when the flame

has a length of about 3 - 4 mm.

-

For butane

/ propane gas, the adjusting screw must

Make sure that the flame does not go out by

quickly turning from maximum flow to minimum

flow. If it does then remove the control knob and

make further adjustments to the gas flow, testing it

again once the adjustment has been made.

Repeat this process for each one of the gas taps.

be tightly screwed in.

Refit the control knob.

-

Ŷ

%HIRUHSODFLQJWKHEXUQHUV

EDFNRQWKHWRSSODFHPDNHVXUH

WKDWWKHLQMHFWRULV

QRWEORFNHG

FDUULHGRXWDIWHUJDVFRQYHUVLRQ

VXFKDVVRDSZDWHURUJDV

DTXDOL¿HGWHFKQLFLDQRULQVWDOOHU

KDVWRPDUN³9´RQWKHULJKWJDV

FDWHJRU\

WRPDWFKZLWKWKH

VHWWLQJ

LQUDWLQJSODWH

5HPRYHWKHSUHYLRXV

VHWWLQJ³9´PDUN

LQWKHHYHQWRIDPDOIXQFWLRQ

FKDQJHWKHZKROHWDS

Ŷ

$IXOORSHUDWLRQDOWHVWDQGDWHVW

IRUSRVVLEOHOHDNDJHVPXVWEH

Ŷ

$IWHUFRPSOHWLQJFRQYHUVLRQ

GHWHFWRU

ŶDo not dismantle the tap shaft:

Attach the ULPG sticker to the cooker, near the gas

supply inlet. Cover the Natural label that is factory

fitted.

5

18

OPERATION OF YOUR GLASS GAS COOKTOP

KNOB CONTROLS

•The following symbols will appear on the control panel, next to each control knob.

GAS OFF

MAX.

BURNER

INDICATOR

•The minimum setting is at the end of the anti-clockwise rotation of the control handle.

•All operation positions must be selected between the maximum and minimum position.

•The symbol on the control panel, next to the control handle will indicate which burner it operates.

AUTOMATIC IGNITION WITH FLAME FAILURE SAFETY DEVICE

•The appliance is fitted with a flame failure safety device on each burner, which is designed to stop the

flow of gas to the burner head in the event of the flame going out.

HOW TO IGNITE A BURNER

•Press in the control knob of the burner that you wish to light and turn it anti-clockwise to the maximum

position.

•If you keep the control knob depressed, the automatic ignition for the burner will operate.

•You should hold down the control knob for 15 seconds after the flame on the burner has lit. If after 15s the

burner has not lit, stop operating the device and open the compartment door and/or wait at least 1 min

before attempting a further ignition of the burner.

•After this 15-second interval, to regulate the flame you should continue turning the control knob anti-

clockwise until the flame is at a suitable level.

•The operating position MUST be at a position between the maximum and minimum position.

•To switch the burner off, turn the control knob fully clockwise to the gas Off position.

•In case of power failure, the burners can be lit by carefully using a match.

Operation Instructions

MIN.

19

MIN.

OPERATION INSTRUCTIONS CONT.

SAFETY AND ENERGY SAVING ADVICE

•The diameter of the bottom of the pan should correspond to that of the burner

• CAUTION Do not use cookware that overlaps the edge of the burner.

CAUTION

•It is not recommended to use roasting pans,frying pans or grill stones heated simultaneously on several

burners because the resulting heat build-up may damage the appliance.

•Do not touch the top plate and trivet whilst in use for a certain period after use.

•As soon as a liquid starts boiling,turn down the flame so that it will barely keep the liquid simmering.

Safety and Energy saving advice

- The diameter of the bottom of the pan should correspond to that of the burner.

BURNERS

200mm 240mm

200mm 240mm

160mm

NO YES

120mm 160mm

180mm

12

Triple-Crown

Rapid

Semi-Rapid

Auxiliary

PANS

min. max.

Do not use small diameter cookware on large

burners.

The flame should never come up the sides of

the cookware.

Avoid cooking without a lid or with the

lid half off

-as this wastes energy

Do not use a pan with a convex or

concave bottom.

Do not place cookware on one side of a

burner,as it could tip over.

Do not use cookware with a large diameter

on the burners near the controls,which when

placed on the middle of the burner may

touch the controls or be so close to them

that they increase the temperature in this

area and may cause damage.

Never place cookware directly on top of the

burner.

Do not place anything,eg.flame

tamer,asbestos mat,between pan and pan

support as serious damage to the appliance

may result.

Do not use excessive weight and do not

hit the cooktop with heavy objects.

Always use cookware that is

suitable for each burner, to avoid

wasting gas and discolouring the

cookware.

Place a lid on the cookware.

Only use pots,saucepans and

frying pans with a thick,flat

bottom.

Always place the cookware right

over the burners,not to one

side.

Place the cookware on top of

the trivet.

Handle cookware carefully when

they are on the burner.

Ŷ'RQRWXVHFRRNZDUH

WKDW

RYHUODSVWKHHGJH of the

burner.

It is not recommended to use roasting pans,frying pans or grill stones

heated simultaneously on several burners because the resulting heat

build-up may damage the appliance.

Do not touch the top plate and trivet whilst in use for a certain period

after use.

As soon as a liquid starts boiling,turn down the flame so that it will

barely keep the liquid simmering.

20

Maintenance and Cleaning

CAUTION

•Cleaning operations must only be carried out when the appliance is completely cool

•The appliance should be disconnected from your mains supply before commencing any cleaning

process.

•Clean the appliance regularly preferably after each use.

•Abrasive cleaners or sharp objects will damage the appliance surface; you should clean it using water

and a little washing up liquid.

PAN SUPPORTS AND CONTROL KNOBS

•Take off the pan support

•Clean these and the control knobs with a damp cloth, washing up liquid and warm water. For stubborn

soiling soak beforehand.

•Dry everything with a clean soft cloth.

TOP PLATE

•Regularly wipe over the top plate using a soft cloth well wrung out in warm water to which a little

washing up liquid has been added.

•Dry the top plate thoroughly after cleaning.

•Thoroughly remove salty foods or liquids from the hob as soon as possible to avoid the risk of corrosion.

•Stainless steel parts of the appliance may become discoloured over time. This is normal because of the

high temperatures. Each time the appliance is used these parts should be cleaned with a product that is

suitable for stainless steel.

BURNERS

•Remove the burner lids and flame spreaders by pulling them upwards and away from the top plate.

•Soak them in hot water and a little detergent or washing up liquid.

•After cleaning and washing them, wipe and dry them carefully. Make sure that the flame holes are clean

and completely dry.

•Wipe the fixed parts of the burner cap with a damp cloth and dry afterwards.

•Gently wipe the ignition device and flame suspension device with a well wrung out cloth and wipe dry

with a clean cloth.

•Before placing the burners back on the top plate, make sure the injector is not blocked.

This manual suits for next models

1

Table of contents

Other Harbour Cooktop manuals

Popular Cooktop manuals by other brands

Kenmore

Kenmore ELITE 790.3322 Series Use & care guide

Everdure

Everdure CBGS711 Installation, operation & maintenance instructions

Frigidaire

Frigidaire FGC6X7XESD installation instructions

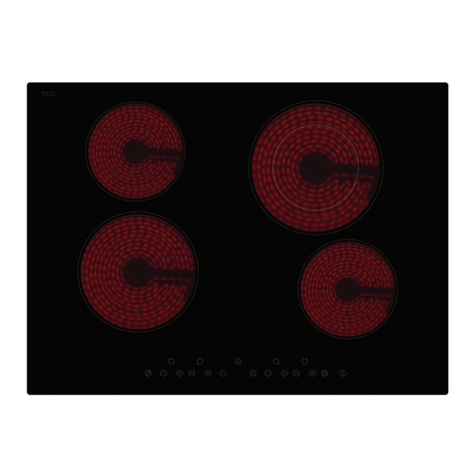

Stirling

Stirling SCC7T instruction manual

KitchenAid

KitchenAid KECD806RSS04 parts list

Frigidaire

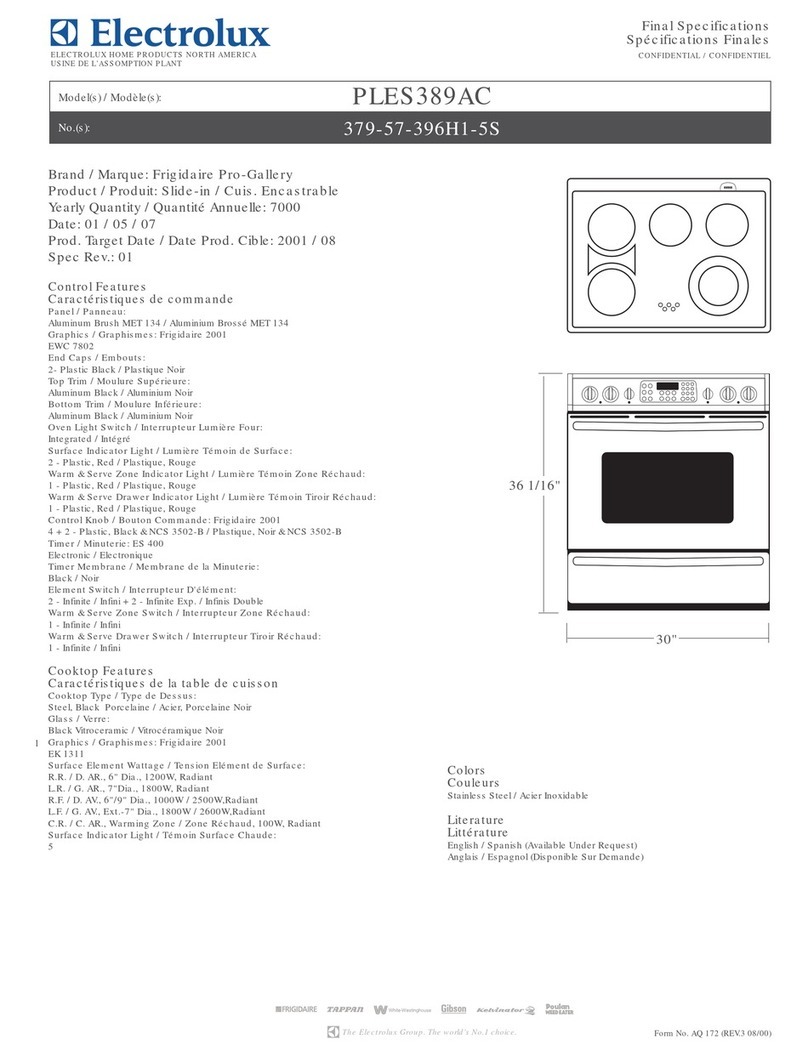

Frigidaire PLES389A Specifications