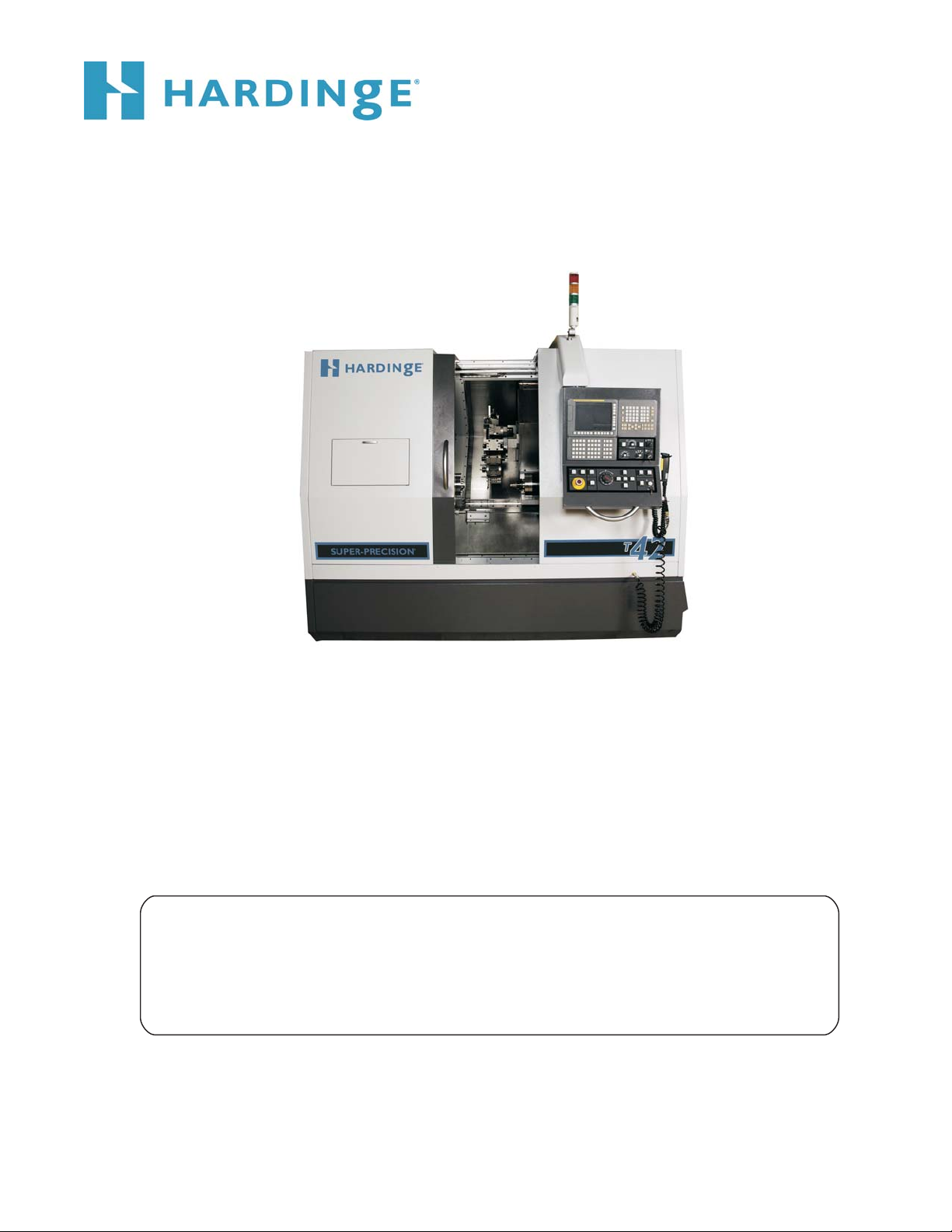

Hardinge T-51 Service manual

INSTALLATION AND

EXTENDED STORAGE INSTRUCTIONS

T-42

T-51

T-65

Multi-Tasking CNC Lathes

ATTENTION

READ THE ENCLOSED INFORMATION BEFORE

REMOVING THE MACHINE FROM THE SKID.

Revised: July 25, 2012

Original Instructions

Manual No. M-507C Litho in U.S.A.

Part No. M C-0009500-0507 April, 2012

TI7878A

- NOTICE -

Damage resulting from misuse, negligence, or accident is not covered by the

Hardinge Machine Warranty.

Information in this manual is subject to change without notice.

This manual covers the installation and extended storage of Hardinge

T-42, T-51, and T-65 Multi-Tasking CNC lathes.

In no event will Hardinge Inc. be responsible for indirect or consequential

damage resulting from the use or application of the information in this man-

ual.

Reproduction of this manual in whole or in part, without written permission

of Hardinge Inc., is prohibited.

CONVENTIONS USED IN THESE INSTRUCTIONS

- WARNINGS -

Warnings must be followed carefully to avoid the possibility of personal injury or

damage to the machine, machine attachments, tooling, or workpiece.

- CAUTIONS -

Cautions must be followed carefully to avoid the possibility of damage to the ma-

chine, machine attachments, tooling, or workpiece.

- NOTES -

Notes contain supplemental information.

© 2012, Hardinge Inc. M-507C

Table of Contents

Offices ........................................... iii

Machine Description and Intended Use .......................... iv

Warnings .......................................... v

CHAPTER 1 - INSTALLATION

Machine Installation Requirements ............................ 1-1

Foundation Requirements............................... 1-1

Approximate Weight.................................. 1-1

Machine Dimensions ................................... 1-2

T-42 and T-42 Big-Bore Lathes ............................ 1-2

T-51 and T-65 Lathes ................................. 1-3

Setting the Machine ................................... 1-5

Securing the Machine to the Floor ............................ 1-6

Shipping Brackets .................................... 1-8

Shipping Bracket Locations .............................. 1-8

Removing the Pendant Shipping Bracket ....................... 1-9

Removing the Guard Door Shipping Bracket (T-51 and T-65 Lathes) ........1-9

Removing the Guard Support Brackets (T-51 and T-65 Lathes)...........1-10

Removing the Platform and Carriage Shipping Brackets ..............1-11

Installing the Interlock Switch on the Rear Access Door ................1-12

Power Case Platform .................................. 1-13

Mounting the Control Pendant in Operating Position ..................1-15

Cleaning the Machine .................................. 1-18

Air Connection...................................... 1-19

Connecting the Air Supply .............................. 1-19

Setting the Machine Air Pressure .......................... 1-19

Spindle Chiller Installation................................ 1-20

Coolant Tank Installation ................................ 1-24

Coolant Chiller Installation................................ 1-28

Installing the Chiller Unit Fuses ............................. 1-31

Coolant ......................................... 1-33

Water-Based Coolants................................ 1-33

Filling the Coolant Tank ............................... 1-33

Grounding the Machine ................................. 1-34

Supplemental Earth Ground ............................. 1-34

System Ground ................................... 1-35

Electrical Power Connection .............................. 1-35

Electrical Requirements ............................... 1-35

Line Configuration for European Machine Installation ................1-36

Connect the Electrical Supply ............................ 1-37

Electrical Phase ................................... 1-38

Checking the Electrical Phase .......................... 1-38

Changing the Electrical Phase .......................... 1-38

M-507C i

Hydraulic System .................................... 1-39

Hydraulic Tank Fluid Capacity ............................ 1-39

Filling the Hydraulic Tank .............................. 1-39

Foot Switch Installation ................................. 1-40

Option Interface Receptacles .............................. 1-41

Non-Metallic Materials Typically Found in Hardinge Machine Construction.......1-41

CHAPTER 2 - EXTENDED STORAGE

Battery Maintenance ................................... 2-1

Control Battery .................................... 2-1

Axis Drive Batteries .................................. 2-3

Lubrication ........................................ 2-5

Lubrication Procedure................................. 2-6

Apply Rust Inhibitor .................................... 2-8

Clean the Spindle(s) ................................... 2-8

Clean the Air Filter Bowls ................................ 2-11

Coolant System ..................................... 2-12

Clean the Coolant Filter ............................... 2-12

Clean the Coolant Tank ............................... 2-13

Clean the Main Spindle Coolant Catcher ...................... 2-20

Hydraulic System .................................... 2-21

Spindle Chiller ...................................... 2-23

Coolant Chiller...................................... 2-25

Removing the Machine Hold-Down Brackets ......................2-26

Shipping Restraints ................................... 2-27

Install the Shipping Tubes .............................. 2-27

Install the Shipping Brackets............................. 2-29

Electrical and Air Supplies................................ 2-33

Electrical Lockout .................................. 2-33

Air Lockout...................................... 2-33

DOCUMENT REVISION RECORD

ii M-507C

OFFICES

Global Headquarters

United States Hardinge Inc.

One Hardinge Drive

Elmira, NY 14902-1507 USA

Telephone: 607-734-2281

web site: www.hardinge.com

Hardinge Subsidiaries

England Bridgeport

Hardinge Machine Tools, Ltd.

Whiteacres

Cambridge Road

Whetstone

Leicester

LE8 6BD England

Telephone: +44 (0)116 2869900

web site: www.bpt.com

email: [email protected]

Germany Hardinge GmbH

Saalestrasse 20

47800 Krefeld

Germany

Telephone: (49) 2151 496490

China Hardinge Machine (Shanghai) Co. Ltd.

Hardinge China Limited

No.1388 East Kang Qiao Road

Pudong , Shanghai 201319

Telephone : 0086 21 38108686

web site: www.hardinge.com.cn

Taiwan Hardinge Taiwan Precision Machinery Ltd.

4 Tzu Chiang 3rd Road

Nan Tou City

540 Taiwan, R.O.C.

Telephone: 886-49-226-0536

Distributor

France Delta Machines

3 Rue du Docteur Charcot

F-91422 Morangis Cedex

France

Telephone: +33 (0)1 60 49 09 74

web site: www.delta-machines.fr

email: [email protected]

M-507C iii

MACHINE DESCRIPTION

AND INTENDED USE

Applicable Machines: T-42, T-51, and T-65 Lathes

These lathes are numerically controlled machine tools designed to shape cold metal by the appli-

cation of a cutting tool and rotating workpiece capable of performing two or more machining pro-

cesses (e.g. turning, facing, drilling, grooving and boring) at one set-up of a workpiece and

incorporating the following features:

•Select and change tools from a turret.

•Change the position of the turret relative to the spindle clamped workpiece.

•Select and apply spindle speeds and axis feeds.

•Control auxiliary services.

•Tailstock provides added support when machining long parts and reduces part deflec-

tion.

•Optional sub-spindle provides capability of back side tuning.

•Optional live tooling provide milling capabilities.

These lathes are designed to machine non-hazardous metals only.

Non-hazardous materials such as Tools Steels, Aluminum, and Brass may be machined.

DO NOT machine any flammable, explosive, toxic, or radioactive material.

DO NOT machine any material that produces a hazardous residue, dust, or gas.

DO NOT use any flammable, explosive, or toxic cutting fluids.

In all cases, if in doubt about the content of the material that you wish to machine, contact the mate-

rial supplier.

iv M-507C

WARNINGS

CHEMICAL WARNING:

Current laws and regulations require that information regarding chemicals used

with this equipment be supplied to you. Refer to the applicable section of the

Material Safety Data Sheets supplied with your machine when handling, storing, or

disposing of chemicals.

BAR FEED WARNING:

Machine should only be used with a bar feed approved by Hardinge Inc.

SPINDLE TOOLING WARNING:

Hardinge HQC (Quick-Change) collets MUST NOT be used in applications where

the spindle is rotating without a bar or workpiece in the collet.

Rotating the spindle without a bar or workpiece in the collet can result in the collet

head being expelled from the spindle.

Failure to comply with this warning can result in serious injury or death.

ENTRAPMENT WARNING:

DO NOT climb into the machine guard! You may become entrapped.

Due to the compact size of the Hardinge lathes and the provision of side access

doors to allow servicing of the machine, it is not necessary to climb into the

machine guard.

In the unlikely event that this warning is ignored and the main access door is

closed, the door will latch shut and cannot be opened from the inside. Another

person must release the door lock. Refer to the Operator's Manual (M-505) for

information on releasing the door lock.

MAIN COOLANT GUARD:

The guards provided with the machine are intended to minimize the risks of

workpiece ejection and not to eliminate them completely.

M-507C v

- NOTES -

vi M-507C

CHAPTER 1 - INSTALLATION

MACHINE INSTALLATION REQUIREMENTS

T-42, T-51, and T-65 lathes require a substantial foundation. Do not locate the machine near equip-

ment that causes vibration. Poor surface finishes or damage to the control may result from vibration

transmitted to the machine.

FOUNDATION REQUIREMENTS

Refer to Figure 1.1, 1.2, or 1.3 to locate the feet in the machine base. Use the dimensions to size the

machine footprint and locate the concrete pads.

The soil under the pads or floor for the machine must be compacted to a safe bearing capacity of 4

tons per square foot [0.38 MPa].

The pads must be level with each other within ±.13 inch [±3.3 mm] or the floor must be level within

±.13 inch in 5 feet [±3.3 mm in 1524 mm] and be constructed of 3000 psi [207 bars] concrete or better.

Avoid placing the machine over floor expansion joints.

RECOMMENDED 6 inch [152 mm] thick concrete floor as large as the machine footprint.

The machine footprint is the overall dimensions, length and width, of the

machine.

ACCEPTABLE Concrete pads 14 x 14 x 6 inches [356 x 356 x 152 mm] centered under

each of the machine feet.

MINIMUM 4 inch [102 mm] thick concrete floor as large as the machine footprint or

concrete pads 14 x 14 x 4 inches [356 x 356 x 102 mm] centered under

each of the machine feet.

APPROXIMATE WEIGHT

- NOTE -

The machine weight and shipping weight will vary, depending on the configuration

of the machine.

Machine Model Machine Weight

lb [Kg]

Shipping Weight

lb [Kg]

T-42 Lathe 12,600 [5,715] 13,200 [5,988]

T-51 and T-65 Lathes 17,900 [8,165] 18,800 [8,528]

Refer to the machine weight tag mounted on the power case door.

M-507C 1-1

MACHINE DIMENSIONS

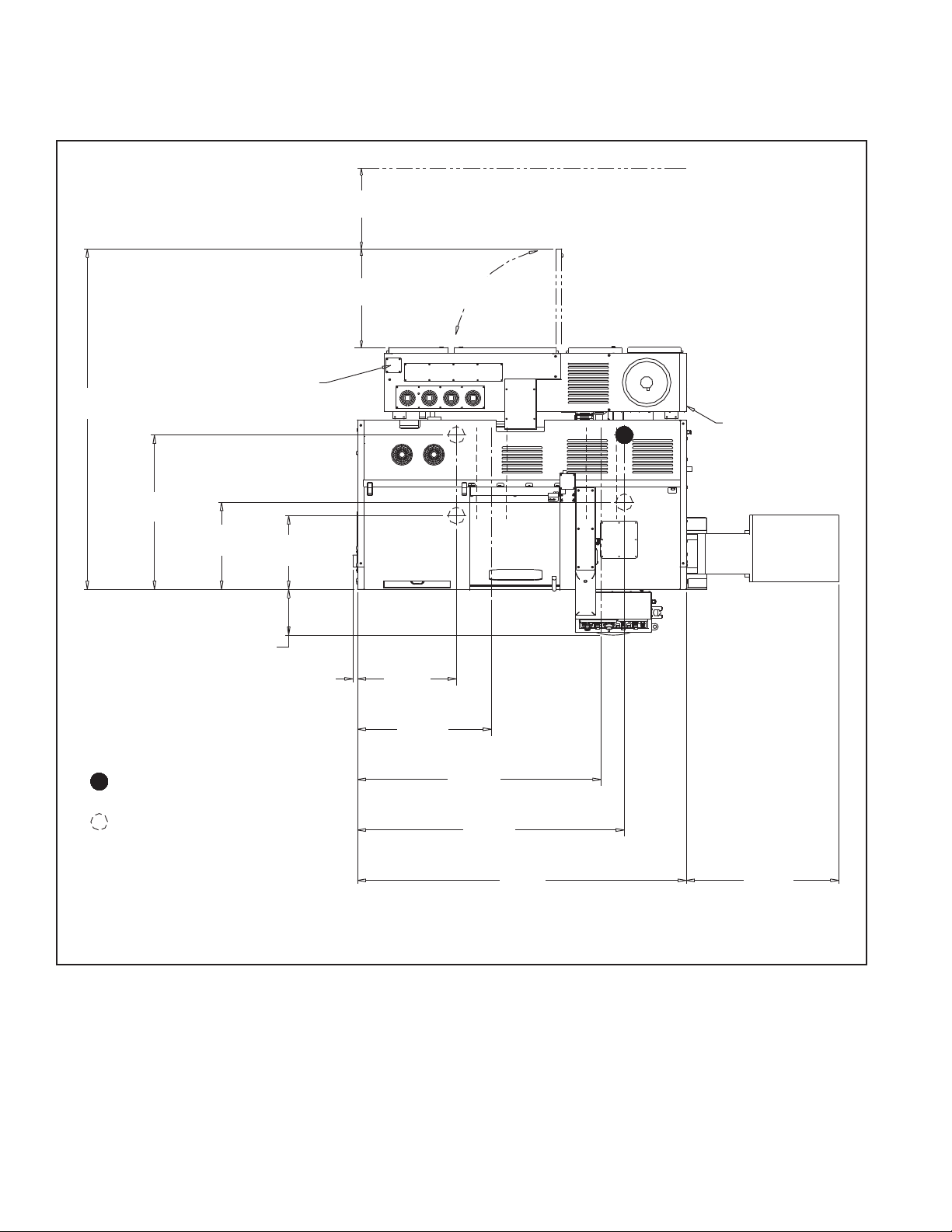

T-42 AND T-42 BIG-BORE LATHES

1-2 M-507C

Figure 1.1 - Machine Dimensions and Support Feet Locations: T-42 Lathe

TI5696E

101.4

[2576]

21.9

[557]

30.0

[762]

43.5

[1106]

Provide Clearance for

Power Case Door Swing

Note: Dimensions are Inches [Millimeters]

Optional

Chip Conveyor

46.0

[1168]

25.9

[658]

98.0

[2488]

72.6

[1844]

80.0

[2031]

Adjustable Foot

Non-Adjustable Feet

13.7 [348]

Main Power Entrance

39.9

[1015]

Lift Slot

Lift Slot

1.4 [35]

Main Air Connection

(at bottom of platform)

29.4

[747]

24.0

[610]

Minimum Recommended Space to Allow

Power Case Platform to be Moved to Perform

Service at the Back of the Machine.

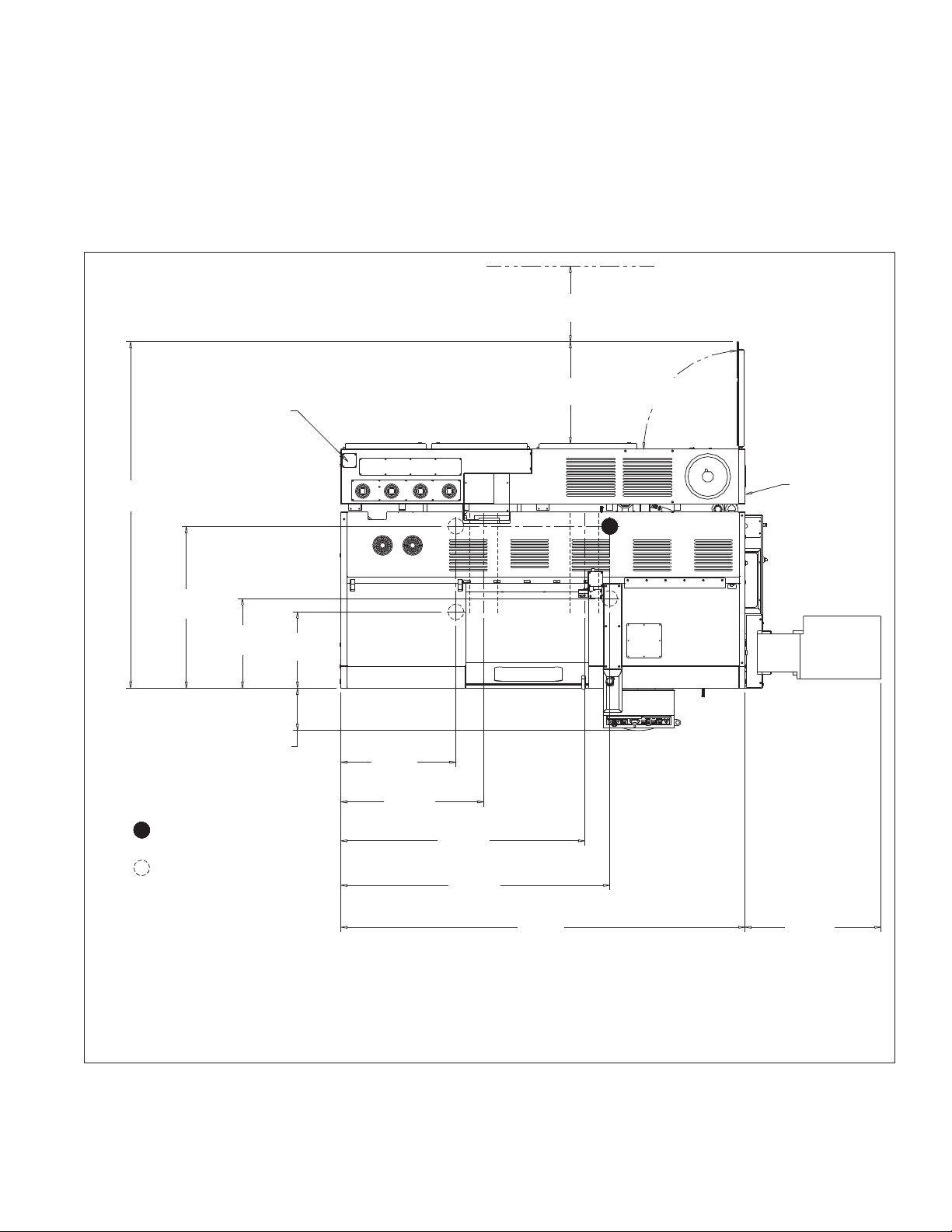

T-51 AND T-65 LATHES

- NOTE -

Refer to Figure 1.2 for T-51 and T-65 lathes with serial numbers DQ-101 through

DQ-110, DQ-112, DQ-117, and DQ-120.

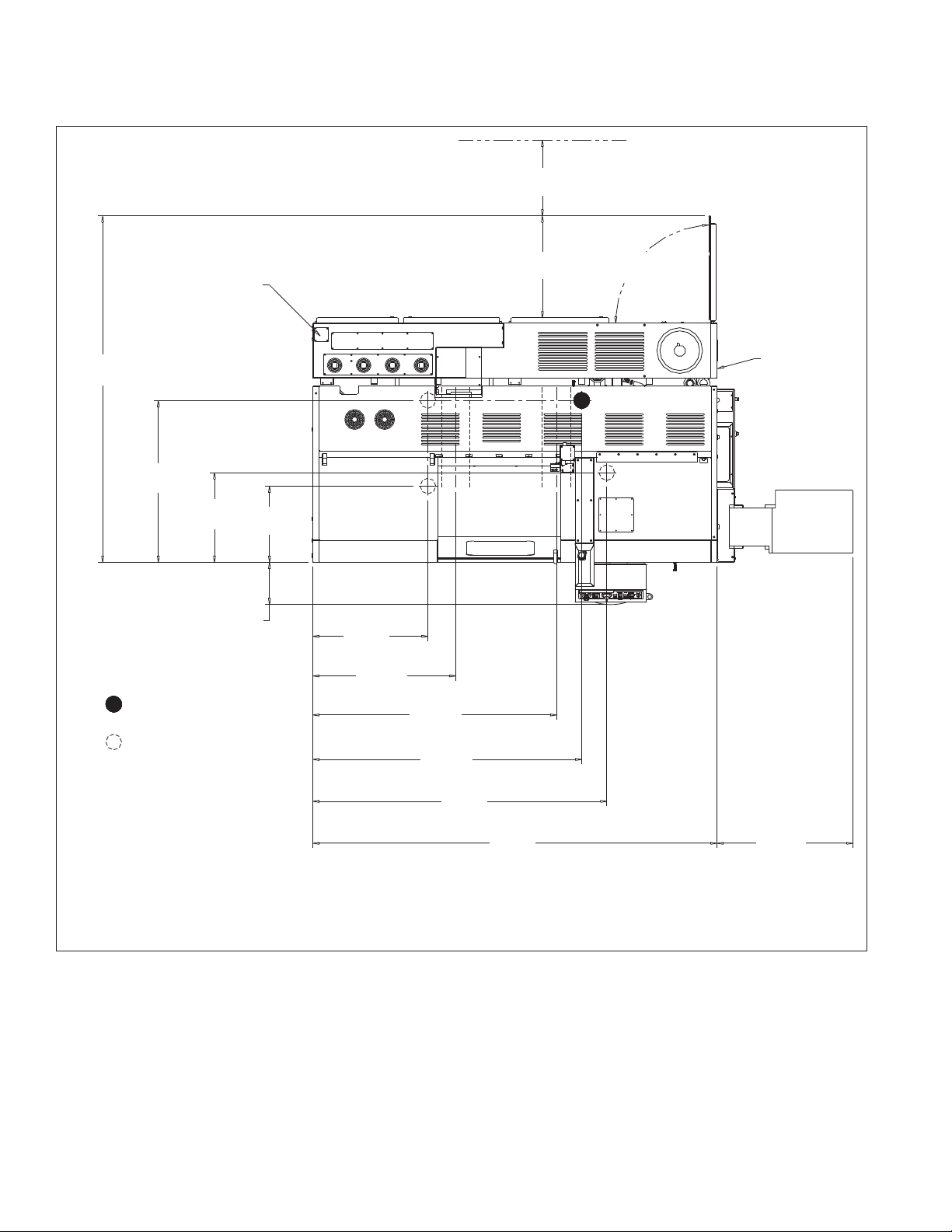

Refer to Figure 1.3 for T-51 and T-65 lathes with serial numbers DQ-111, DQ113

through DQ-116, DQ-118, DQ-119, DQ-121 and later.

M-507C 1-3

Figure 1.2 - Machine Dimensions and Support Feet Locations: T-51 and T-65 Lathes

(Machine Serial Numbers DQ-101 through DQ-110, DQ-112, DQ-117, and DQ-120)

TI5850

Provide Clearance for

Door Swing

32.3

[820]

24.0

[610]

Minimum Recommended Space to Allow

Power Case Platform to be Moved to Perform

Service at the Back of the Machine.

Main Power Entrance

Main Air

Connection

(at bottom of

platform)

109.9

[2791]

24.2

[615]

51.4

[1304]

28.4

[723]

36.5

[927]

43.2

[1097]

Optional

Chip Conveyor

128.2

[3257]

77.3

[1964]

85.3

[2167]

45.3

[1151]

Lift Slot

Lift Slot

13.4 [341]

Note: Dimensions are Inches [Millimeters]

Adjustable Foot

Non-Adjustable Feet

1-4 M-507C

Figure 1.3 - Machine Dimensions and Support Feet Locations: T-51 and T-65 Lathes

(Machine Serial Numbers DQ-111, DQ113 through DQ-116, DQ-118, DQ-119, DQ-121 and Later)

TI5886

Provide Clearance for

Door Swing

32.3

[820]

24.0

[610]

Minimum Recommended Space to Allow

Power Case Platform to be Moved to Perform

Service at the Back of the Machine.

Main Power Entrance

Main Air

Connection

(at bottom of

platform)

109.9

[2791]

24.2

[615]

51.4

[1304]

28.4

[723]

36.5

[927]

43.2

[1097]

Optional

Chip Conveyor

128.2

[3257]

77.3

[1964]

85.3

[2167]

45.3

[1151]

Lift Slot

Lift Slot

13.4 [341]

Note: Dimensions are Inches [Millimeters]

Adjustable Foot

Non-Adjustable Feet

93.3

[2370]

SETTING THE MACHINE

- NOTE -

Review the machine installation requirements on page 1-1 before beginning the

installation.

1. Verify that the foundation for the machine meets the requirements, as outlined on page 1-1.

2. Leave the machine on the skid and move it to the installation location.

3. Remove any parts boxes from the skid.

- NOTE -

Retain the M12 screws, washers, lock washers, and hold-down brackets in the

event the machine is to be used with a bar feed system. Refer to page 1-6 for

information on securing the machine to the floor.

4. Remove the M12 screws, washers, and lock washers that secure the hold-down brackets to the

machine.

5. Remove the hold-down brackets from the skid.

6. Thread the adjustable foot, shown in Figures 1.1 through 1.3, all the way up for clearance.

Initially, the machine is supported by the three non-adjustable feet.

- WARNING -

Raise the machine high enough to make certain that the machine feet and sup-

port screws clear the skid.

- NOTE -

There are two lift slots running front to rear under the machine base. Refer to

Figure 1.1, 1.2, or 1.3. Lift the machine slowly to make certain that the fork lift

truck maintains balance.

7. Use a fork lift truck or the rigging to lift the machine from the skid. Lift the machine slowly while

making certain that it remains balanced.

8. Carefully lower the machine into position. The machine will be supported by the three

non-adjustable feet. Rough align the machine.

9. Thread the adjustable foot down until it makes contact with the floor.

10. Tighten the adjustable foot an additional one-sixteenth turn.

11. Secure the adjustable foot lock nut up against the machine base.

M-507C 1-5

SECURING THE MACHINE TO THE FLOOR

- CAUTION -

The hold-down brackets MUST be installed if the machine is to be used with a bar

feed system.

- NOTE -

The lag screws, flat washers, and expansion shields used to secure the hold-down

brackets to the floor are provided with the machine

1. Align the hold-brackets with the mounting holes on the machine base. Refer to Figure 1.4.

2. Mark two drilling locations on the floor for each bracket.

3. Drill 3/4 inch [19 millimeter] diameter holes, 4 inches [102 millimeters] deep.

4. Remove any debris from the drilled holes.

1-6 M-507C

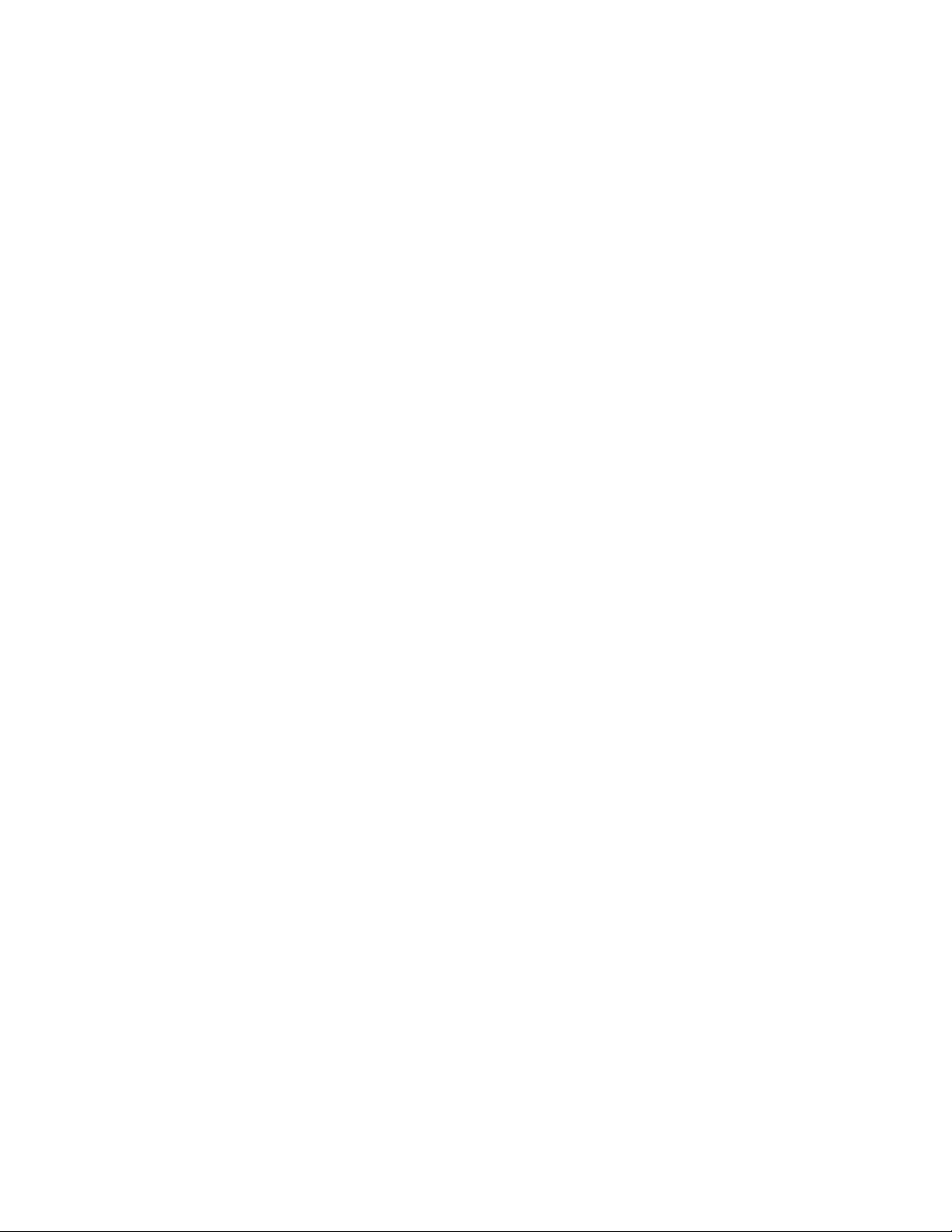

Figure 1.4 - Machine Hold-Down Brackets

(T-51 Machine Shown)

TI5849

Left End of Machine Right End of Machine

Hold-Down Brackets

5. Drive an expansion shield down to the bottom of each hole. Refer to Figure 1.5.

6. Attach the brackets to the machine base using the M12 screws, washers, and lock washers

retained during the previous procedure.

7. Secure the brackets to the floor using the lag screws and flat washers provided.

M-507C 1-7

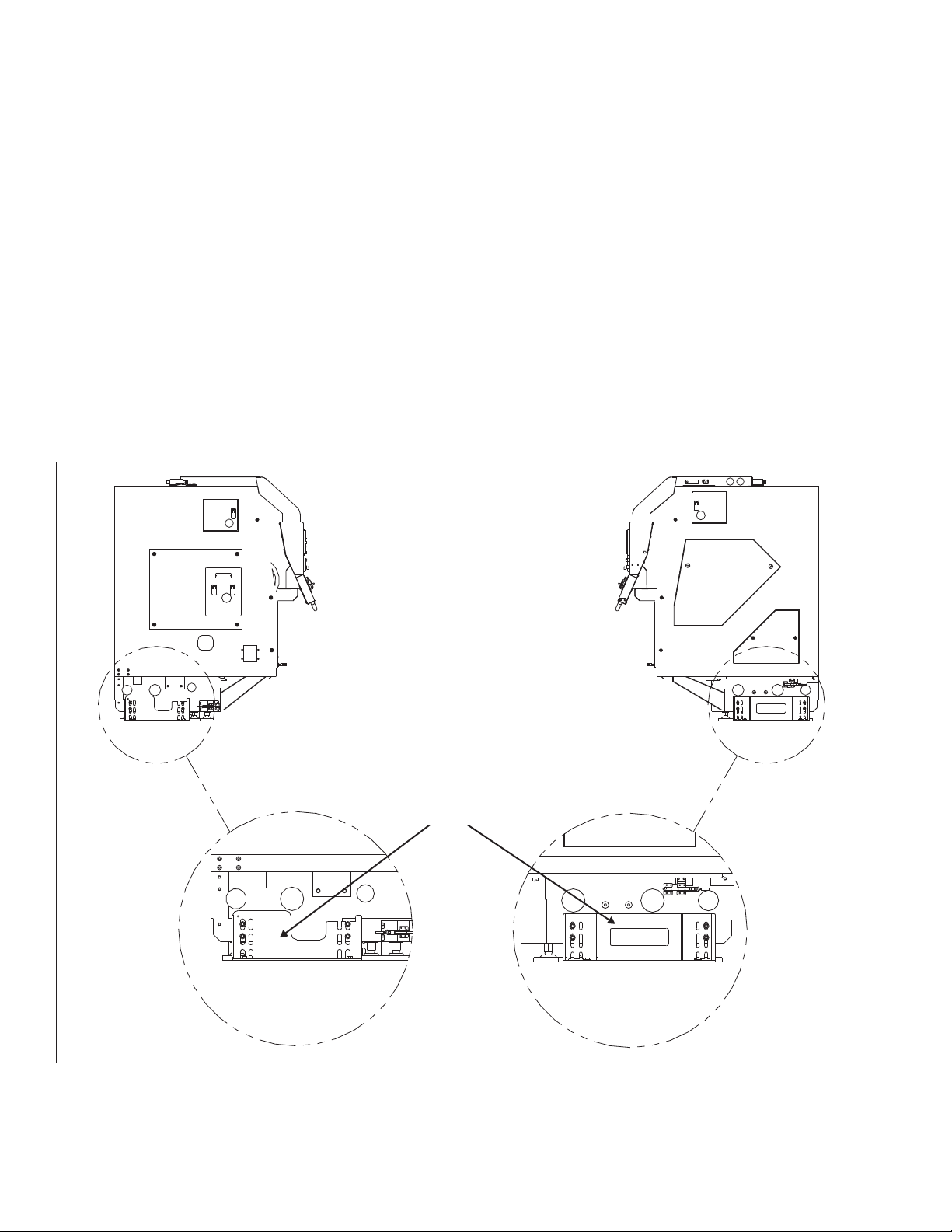

Figure 1.5 - Expansion Shield and Lag Screw

TI5851

Lag Screw

Flat Washer

Hold-Down Bracket

Expansion Shield

Concrete

SHIPPING BRACKETS

- CAUTION -

DO NOT attempt to move the machine axes until the shipping brackets have been

removed.

- NOTE -

The shipping brackets are painted RED for easy identification.

DO NOT discard the shipping brackets or mounting hardware. The brackets must

be installed whenever the machine is to be moved.

T-51 and T-65 lathes shipped in containers have the control pendant mounted at

the right end of the machine during shipment. Information on mounting the control

pendant in operating position begins on page 1-15.

SHIPPING BRACKET LOCATIONS

•Control pendant (Refer to note above)

•Guard door (T-51 and T-65 lathes only)

•Left and right front corners of coolant guard (T-51 and T-65 lathes only)

•Left end of power case platform (Viewed from back of machine)

•Machine carriage

1-8 M-507C

REMOVING THE PENDANT SHIPPING BRACKET

1. Remove the screws connecting bracket "A", Figure 1.6, to the top of the machine.

2. Swing the control pendant out to access the screws holding the bracket to the pendant.

3. Remove the screws to release the bracket from the pendant.

4. Install all screws back in location to seal the holes.

REMOVING THE GUARD DOOR SHIPPING BRACKET (T-51 AND T-65 LATHES)

Remove guard door shipping bracket "B", Figure 1.7.

M-507C 1-9

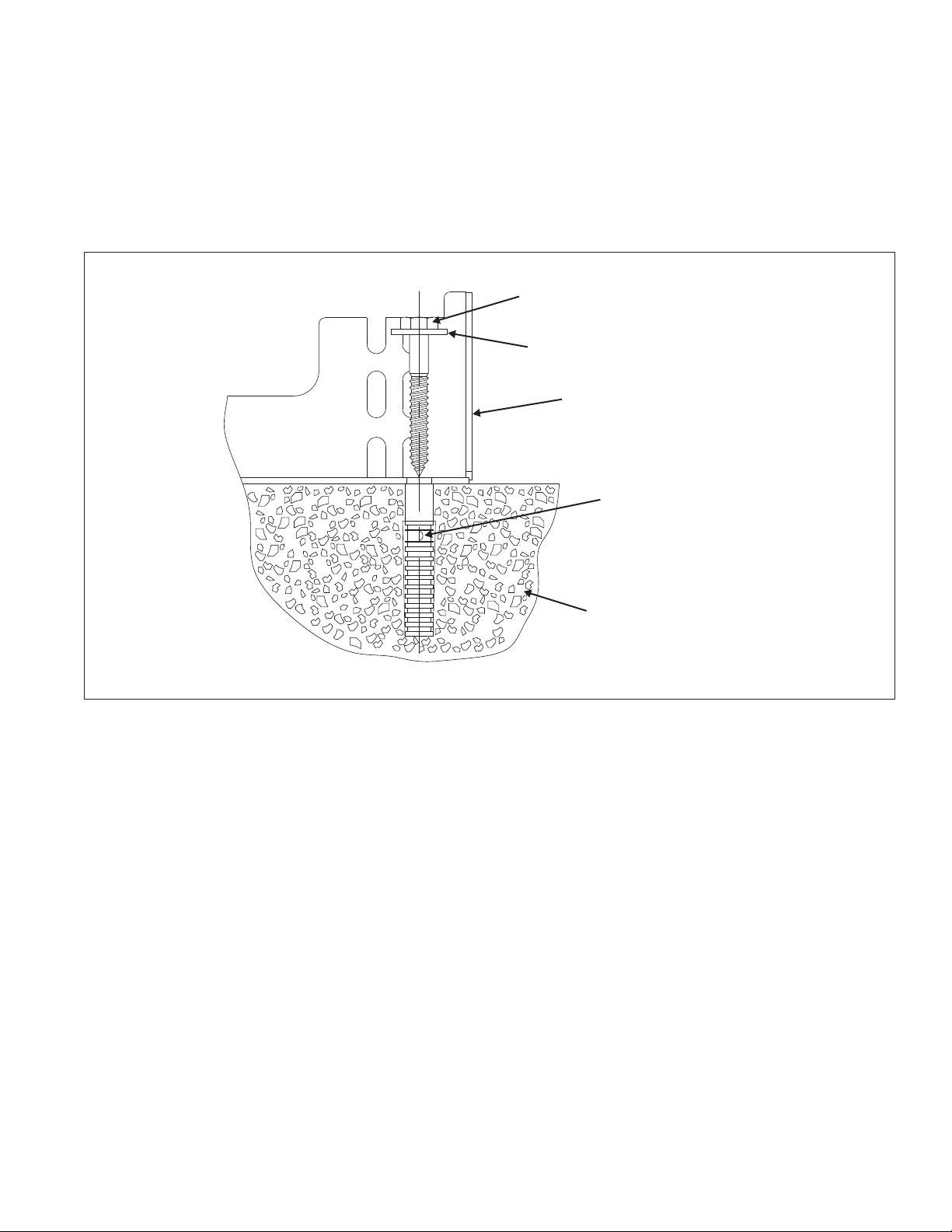

Figure 1.6 - Control Pendant

Shipping Bracket

A

TP7955A

Figure 1.7 - Guard Door Shipping Bracket

(T-51 and T-65 Lathes)

TP8319

B

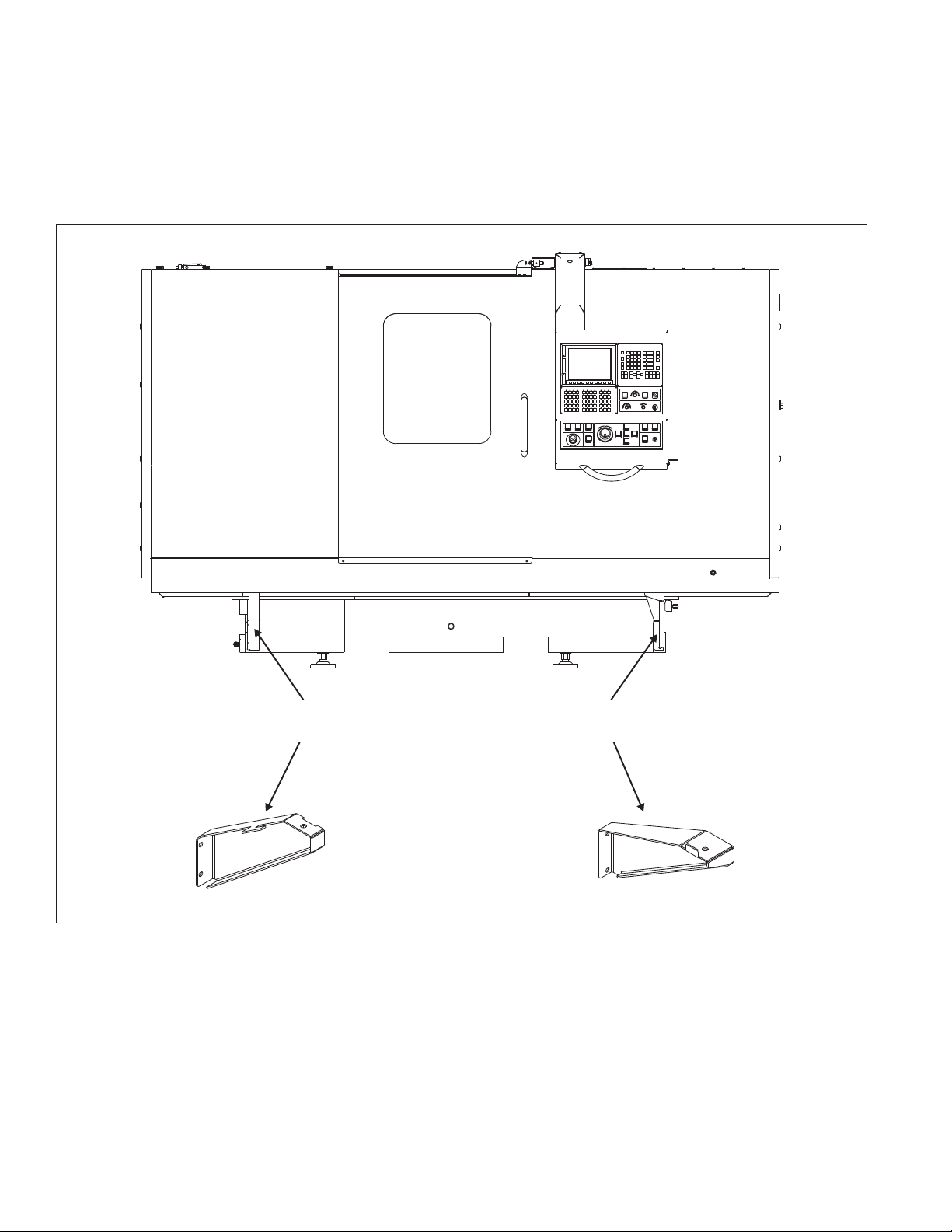

REMOVING THE GUARD SUPPORT BRACKETS (T-51 AND T-65 LATHES)

Remove the left and right guard support brackets, shown in Figure 1.8.

1-10 M-507C

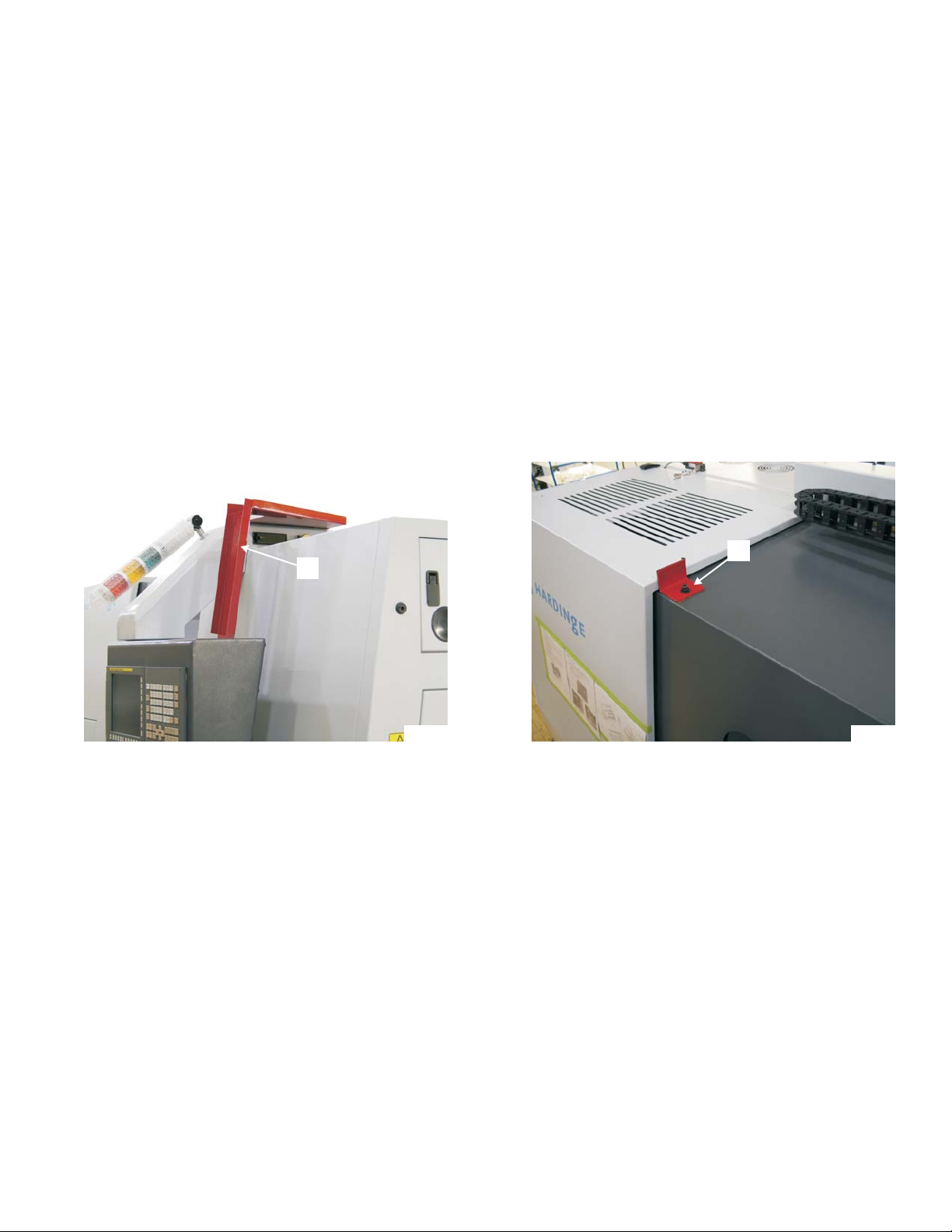

Figure 1.8 - Guard Support Brackets

(T-51 and T-65 Lathes)

TI5852

Isometric View

of Brackets

Left Guard

Support Bracket

Right Guard

Support Bracket

REMOVING THE PLATFORM AND CARRIAGE SHIPPING BRACKETS

1. Release latch "C", Figure 1.9, and open the

access doors.

2. Remove the nut and washer under the platform

to release the lower end of bracket “D”, Figure

1.10, from the platform.

3. Release the upper end of bracket "D" and

remove.

4. On T-51 and T-65 lathes:

A) Remove the nut and washer under the tray

to release the lower end of bracket “E”,

Figure 1.11, from the machine.

B) Release the upper end of bracket "E" and

remove.

5. Remove carriage bracket "F", Figure 1.12.

M-507C 1-11

Figure 1.9 - Hydraulic System

Access Doors

C

TP7863

Figure 1.10 - Lower Power Case

Platform Shipping Bracket

TP7953

D

Figure 1.11 - Upper Power Case

Platform Shipping Bracket

(T-51 and T-65 Lathes)

E

TP8328

Figure 1.12 - Carriage Shipping Bracket

F

TP7954

INSTALLING THE INTERLOCK SWITCH ON THE REAR ACCESS DOOR

For shipping purposes, the rear access door interlock switch is stowed next to the hydraulic unit

heat exchanger. Refer to Figure 1.13.

1. Using the fasteners supplied with the switch, mount the interlock switch on the access door, as

shown in Figure 1.14.

2. Close and latch the access doors.

1-12 M-507C

Figure 1.13 - Shipping Location

for Door Interlock Switch

TP8278

Interlock Switch

Shipping Location

Figure 1.14 - Interlock Switch

Mounted on Access Door

TP8279

This manual suits for next models

2

Table of contents

Other Hardinge Lathe manuals