Operation Manual SJ320

KAKA®Industrial

- 3 -

body contact with grounded surfaces

such as pipes, radiators, ranges, and

refrigerator enclosures.

14.Replacement parts and accessories.

When servicing, use only identical

replacement parts. Use of any other parts

will void the warranty. Only use

accessories intended for use with this tool.

Approved accessories are available from

the distributor.

15.Do not operate tool if under the

influence of alcohol or drugs. Read

warning labels on prescriptions to

determine if your judgment of reflexes are

impaired while taking drugs. If there is any

doubt, do not operate the tool.

Operation

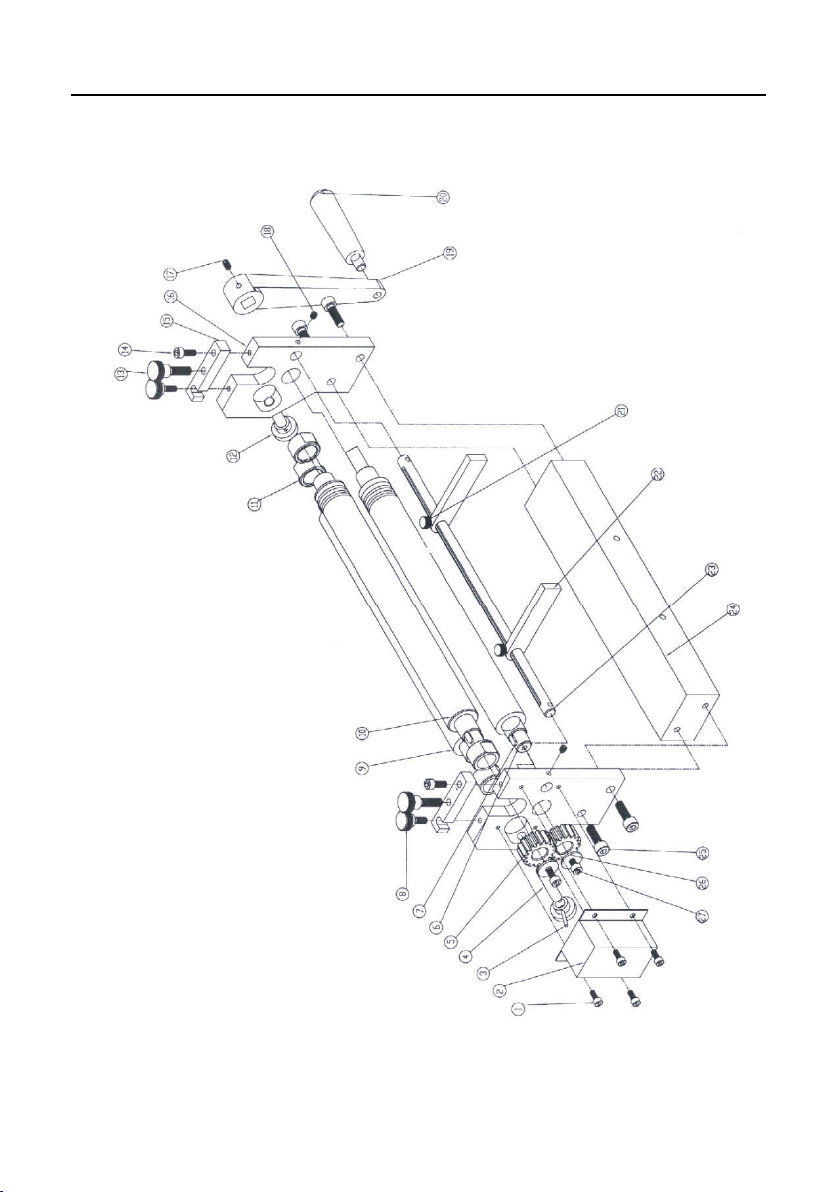

1.Mount the Slip Roll machine to a bench

by bolting the base of the machine(#24) to

the bench. Refer to the Parts Diagram.

2、Before using, check the mounting and

adjustment of this machine. Rotate the

Handle (#19/#20) and check whether the

two gears (#5) have good, firm contact

with each other. Shafts 1, 2 and 3 should

be clean and free of metal debris. Refer to

the Parts Diagram.

3、Adjust distance between Shaft 1 (#6)

and Shaft 2 (#10) if necessary.

b.The distance between Shaft 2 (#10) and

Shaft 1 (#6) can be adjusted by turning

the Adjusting Bolts (#12) and (#4)

c.To decrease the distance between the

two shafts, turn the Adjusting Bolt (#12)

and (#4) clockwise.

d.To increase the distance, turn the

Adjusting Bolt (#12) and (#4)

counterclockwise.

4、Insert the steel plate between Shaft 1

(#6) and Shaft 3 (#9). Tighten Fixing bolt

(#8), Adjusting bolt(#13), Screw M6X22

(#14), Pressing plate (#15). Rotate the

handle (#19/#20), meanwhile screw down

the Nut 3X12 (#3), pole (#4), knob 10X40

(#12) inside, push the Shaft2 (#10) higher

according to the diameter of the roll.

5、After finished the rolling. Loosen the

Fixing bolt (#8), Adjusting bolt (#13),

Screw M6X22 (#14), circumgyrate the

pressing plate (#15) for semicircle, push

the Shaft1 (#6) up, remove the steel plate

from the right.

WARNING: Keep the hands away from

the shafts and metal plate during

operation. Do not attempt to form rolls

from materials other than those specified.