Harmonic Drive LSA-10A-30-D-130 Technical manual

Galvanometer Scanner System

LSA-10A-30-D-130 Technical Document

(Scanner: LSA-10A-30/Driver: PSM-130)

●We thank you for purchasing the Galvanometer Scanner LSA Series

System.

●Any mishandling or misuse of this product may result in unexpected

accidents and shorten the life of the product. Please read this

document thoroughly and use accordingly to ensure safe prolonged

use.

●Product specifications are subject to change without notice for

improvement purposes.

●Keep this manual in a convenient location and refer to it whenever

necessary in operating or maintaining the units.

●The end user of the actuator should have a copy of this manual.

ISO14001

ISO9001

LSA-10A-30-D-130 Technical Document

-2-

Warning: Indicate anything that may cause

loss of human life or serious

physical injury if mishandled.

Warning

Warning

Warning

Warning

For Safe Use of the

LSA and PSM Series Servo Systems

Caution: Indicate anything that may cause

serious physical injury or cause

physical damage to the product if

mishandled.

Limitation of Applications:

The equipment listed in this document may not be used for the following applications:

*Space equipment *Aircraft & Aircraft Equipment *Nuclear Equipment *Household Apparatus *Vacuum equipment *Automobiles &

Automotive Parts *Game Machines *Machines or Devices effecting directly the human body *Machines or devices to transport people

*Instruments or Apparatus for special environments.

Please consult us if you intend to use the products in one of the areas mentioned above.

* If these products are used in equipment that may cause serious physical injury or loss of human life, please ensure adequate safeguards are in

place to prevent accidents in case the output cannot be controlled due to damage of the product.

Precautions when Using the Scanner/Driver

Please ensure proper protections from interference of noise and adequate installation.

● Interference of noise on the signal line may cause vibrations and malfunctions. Please ensure the following conditions.

* Please separate from a power cable.

* Please use the possible shortest cables for the LSA and PSM.

* Please connect the ground terminals of the scanner and driver to a Type 3 ground at one point.

Caution

Warning

Precautions for Designing Please read this Technical Document before designing.

Please utilize in the following defined environment.

● The scanner is not sealed and must therefore only be used indoors, where the following conditions are provided:

*Ambient OperatingTemperature: 0°C to 40°C *Ambient Operating Humidity: 20% to 85% RH (non-condensing)

* Vibration: Under 24.5 m/s

2

* No contamination by water, oil, or foreign matter * No corrosive, inflammable, or explosive gas

If light beam such as lasers, etc. that may cause physical injury are used, please ensure adequate

safeguards are in place to prevent accidents in case the scanner/driver becomes uncontrollable.

Warning

Operating Precautions Please read this Technical Document before operating.

Disposal

Caution

Please dispose as industrial wastes.

● All products or parts have to be disposed as industrial wastes.

Please do not directly connect the scanner’s

motor and sensor wires to the outlet.

●Please ensure that this

equipment is not directly

connected to a commercial power source. The scann

er

may breakdown and cause a fire.

Caution

Caution

Please protect the scanner

from impacting and

shocking.

●

Please do not bump the scanner as the sensor is directly

connected to the scanner.

●

The operation of the scanner cannot be assured if the sensor

t b k d th t f t l

Please do not pull the wire lead.

●

Pulling the wire lead may damage the connected

component and the scanner may run out of control.

Caution

Please do notapply excessive force to the output shaft.

●When attaching a mirror to the output shaft

, please be

careful not to apply excessive force to the output shaft.

●Accuracy cannot be guaranteed if the output shaft

collapses

due to applying excessive force.

Caution

Please do not apply a voltage to the scanner exce

eding

specifications.

●

Applying an abnormal voltage or faulty wiring may cause the scanner

to burnout or malfunction.

Please do not change wiring while still plugged in.

●

Please ensure that the power is off before removing

wiring and disconnecting plug. There is a

risk of shock

and running out of control.

Caution

Please do not conduct withstand voltage tests.

●Please do not conduct mega or withstand voltage tests.

Doing so

may damage the control circuits of the driver.

Please do not apply a voltage to the driver

exceeding specifications.

● Applying an abnormal voltage or faulty wiring may cause

the driver to burnout or malfunction.

Caution

Please do not touch the circuits inside the

equipment while plugged in. Electric shock

may occur.

Please do not touch the attached heat sink

while plugged in or

within five minutes after disconnecting the power.

●There is a risk of burns as the heat sink becomes hot.

Caution

Caution

LSA-10A-30-D-130 Technical Document

-3-

Table of Contents

Chapter 1 Overview of LSA Series .........................................................................................................................4

1-1 Main Characteristics.....................................................................................................................4

1-2 Example of Equipment Configuration ...........................................................................................4

1-3 Scanner System LSA Series Model..............................................................................................5

1-4 Scanner Model.............................................................................................................................5

1-5 Driver Model.................................................................................................................................5

Chapter 2 System Specifications ...........................................................................................................................6

2-1 System Configuration...................................................................................................................6

2-2 Main Specifications.......................................................................................................................7

2-3 Response Characteristics.............................................................................................................7

2-3-1 Response during Rectangular Wave Drive...............................................................................................8

2-3-2 Triangular Wave Drive Response .............................................................................................................9

2-3-2 Triangular Wave Drive Response ...........................................................................................................10

2-4 Optical Scanner Operating conditions Form ...............................................................................13

2-4-1 Supplementary Explanation of Optical Scanner Operating conditions Form..........................................14

Chapter 3 Scanner Specifications........................................................................................................................15

3-1 Main Specifications.....................................................................................................................15

3-2 Connector Specifications............................................................................................................15

3-3 Dimensions (Third Angle Method)...............................................................................................16

3-4 Environment Specifications ........................................................................................................16

3-5 Output Shaft Precision................................................................................................................17

3-6 Stopper Mechanism....................................................................................................................17

3-7 Caution Regarding Scanner Equipment......................................................................................17

3-7-1 Structure of Output Shaft.........................................................................................................................17

3-7-2 Scanner Cable ........................................................................................................................................17

3-7-3 Caution When Attaching Scanner and Load Equipment.........................................................................18

Chapter 4 Driver Specifications............................................................................................................................19

4-1 Main Specifications.....................................................................................................................19

4-2 Protection Functions...................................................................................................................19

4-3 Dimensions (Third Angle Method)...............................................................................................20

4-4 Environment Specifications ........................................................................................................20

4-5 Connector Specifications............................................................................................................21

4-5-1 Input Power Source Connector (CN1) ....................................................................................................21

4-5-2 Scanner Connector (CN2).......................................................................................................................21

4-5-3 Input/Output Signal Connector (CN3).....................................................................................................21

4-6 Input/Output Interface Specifications..........................................................................................22

4-6-1 Positioning Command Signal Input [SIG IN(+)/SIG IN(-)].......................................................................22

4-6-2 Enable Input (ENABLE) ..........................................................................................................................23

4-6-3 Positioning Command Signal Monitor Output (IN-MON)........................................................................24

4-6-4 Positioning Sensor Signal Monitor Output (POS-OUT)..........................................................................24

4-6-5 Positioning Error Signal Monitor Output (POS-ERR)..............................................................................24

4-6-6 Alarm Output (ALM)................................................................................................................................25

4-7 Trimmer Function and Adjustable Range....................................................................................26

4-8 Status Display.............................................................................................................................27

4-9 The Check Pin on the Board.......................................................................................................27

4-10 Power Source Connection........................................................................................................28

4-10-1 Measures to Avoid Voltage Drop in Power............................................................................................28

4-10-2 Selection of Power Capacity.................................................................................................................28

4-10-3 Caution When Connecting Power Source ............................................................................................28

4-11 Caution Regarding Driver Installation........................................................................................29

4-12 Driver Accessories....................................................................................................................30

4-13 Driver Labels and Descriptions.................................................................................................30

Chapter 5 Options..................................................................................................................................................31

5-1 Extension cable..........................................................................................................................31

Chapter 6 Packaging..............................................................................................................................................31

Chapter 7 Warranty................................................................................................................................................32

7-1 Warranty Period..........................................................................................................................32

7-2 Warranty Terms..........................................................................................................................32

LSA-10A-30-D-130 Technical Document

-4-

Chapter 1 Overview of LSA Series

The LSA and PSM series are Galvanometer Scanner systems that can optically scan with quick response

and high accuracy. Main characteristics of the systems based on compact motor technology and

independently developed optical sensor technology, so the following applications are available:

measurement devices, laser processing equipment, laser displays, shutters, laser markers, etc.

1-1 Main Characteristics

♦Quick Response and High Torque/Inertia Ratio

The motor component of the scanner is a moving magnet system and the stator utilizes a core and coil

configuration. This allows for a heavy load/quick response. The LSA and PSM devices are available

for a wide torque range applications.

♦Low Heat Generation (Low Drift)

The temperature rise caused by the quick-response/high-frequency scanner operation is minimal and

results in low drift.

♦High Accuracy/Environmentally Strong Scanner

The sensor component of the scanner can position with high accuracy (system positioning repeatability:

within ± 5μrad [1”]) as it utilizes an optical potentiometer independently developed by our company.

In addition, this sensor is strong against external electrical noise (increased S/N ratio) and is not affected

by the exterior atmospheric environment.

♦Adjustable Functions with Broad Ranging Applications

The driver maximizes the capacity of the combined scanner and possesses numerous adjustment

functions to adjust to customers’ usage conditions.

In addition, we will adjust the drive if necessary based on the study of customer’s operating conditions and

specifications.

1-2 Example of Equipment Configuration

Reference Example: Summary of Laser Marker System

Y

Axis Driver

X Axis Driver

Y Axis LSA

X Axis LSA

* Laser Oscillator

*DC Power Source

* f θ Lens

* Target workpiece

The items marked with “*” should

be prepared by the client

* Miror

*External analogue

command signal

LSA-10A-30-D-130 Technical Document

-5-

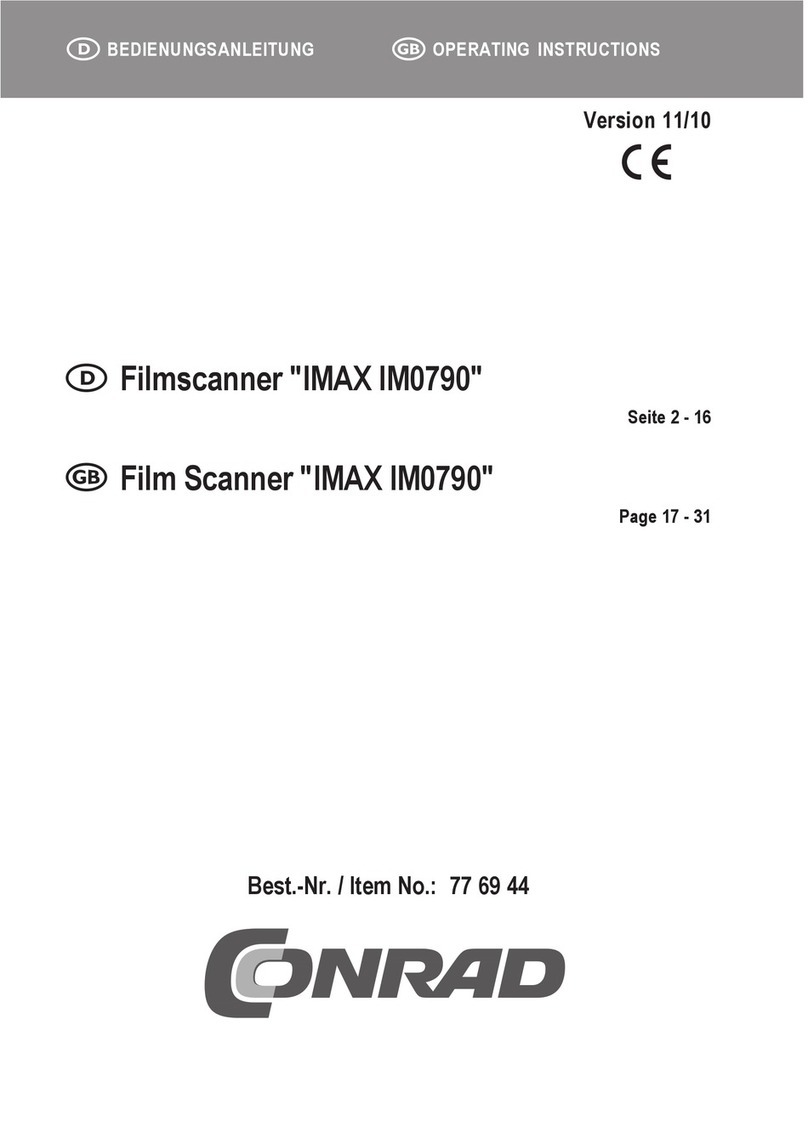

1-3 Scanner System LSA Series Model

The model name and symbols of the Galvanometer Scanner System are as follows.

1-4 Scanner Model

The model name and symbols of the LSA Series Galvanometer Scanner are as follows.

1-5 Driver Model

The LSA Series Galvanometer Scanner is combined with the PSM series driver.

The model name and symbols of the PSM series driver are as follows.

LSA - 10 A - 30 -

□□

Model: Galvanometer Scanner System

LSA Series

Maximum Torque

10: 0.1 Nm

Version Symbol

Maximum Swing Angle

30: ±15° (mechanical angle)

Specification Symbol

No Symbol: Standard Specification Product

SP: Special Specification Product

PSM – 1 30 -

□□

Model: Optical Scanner Driver

PSM Series

Version Symbol

Specification Symbol

No Symbol: Standard Specification Product

SP: Special Specification Product

Analogue Command Type

LSA-10A-30 - D - 130 -

□□

Scanner Model

System Notation

Combined Driver Model

Specification Symbol

No Symbol: Standard Specification

Product

SP: Special Specification Product

LSA-10A-30-D-130 Technical Document

-6-

Chapter 2 System Specifications

The specifications of the LSA-10A-30-D-130 scanner system are as follows. The angles within these

specifications are all “mechanical angles”, unless specified otherwise.

2-1 System Configuration

The product configuration of the LSA-10A-30-D-130 is as follows.

Product Configuration Model Units Remarks

Scanner LSA-10A-30 1

Driver PSM-130 1 With accessories.

Load Device -1 Load device for adjustment

Our Galvanometer Scanner System can provide maximum response performance as it can be

appropriately adjusted for our customer’s actual load device (such as mirror, etc.) and operating conditions.

Our drivers are adjusted with the combination of scanner : driver (including adjustment specifications) :

load device=1 : 1 : 1. Please utilize properly adjusted combinations.

Please refer to “Driver Labels and Seal Details” (4-13) to distinguish properly adjusted combinations.

♦Caution when Using Driver

The driver needs to be adjusted for the actual load device attaching to the scanner (mirror, etc.) or for an

artificial load device identical to the actual load device. The customer is responsible for preparing the load

device.

Although we can evaluate and provide data for our load device for testing during the advanced testing

stage, during the product shipment stage, the customer will be responsible for supplying the actual load

device. They will be shipped after adjustment with the actual load device.

If the load device conditions (shape, moment of inertia, material, etc.) are changed, the adjustments of the

driver’s internal constant needs to be changed. In this case, please provide us with details of any

changes.

We will review the adjustment specifications. (There will be a charge for any adjustments after the

product has been shipped.)

If there are big changes to the fixed adjustment conditions (even when there is no load on the drive) of the

load device or the drive command, the scanner may oscillate unexpectedly.In this case, refer to the Over

Position Alarm Output (4-4-6) and configure the sequence to turn off “Enable”.

If the scanner oscillates unexpectedly, the driver resistance may

generate abnormal amounts of heat and start to smoke. In this case,

immediately cut the power source.

Caution

LSA-10A-30-D-130 Technical Document

-7-

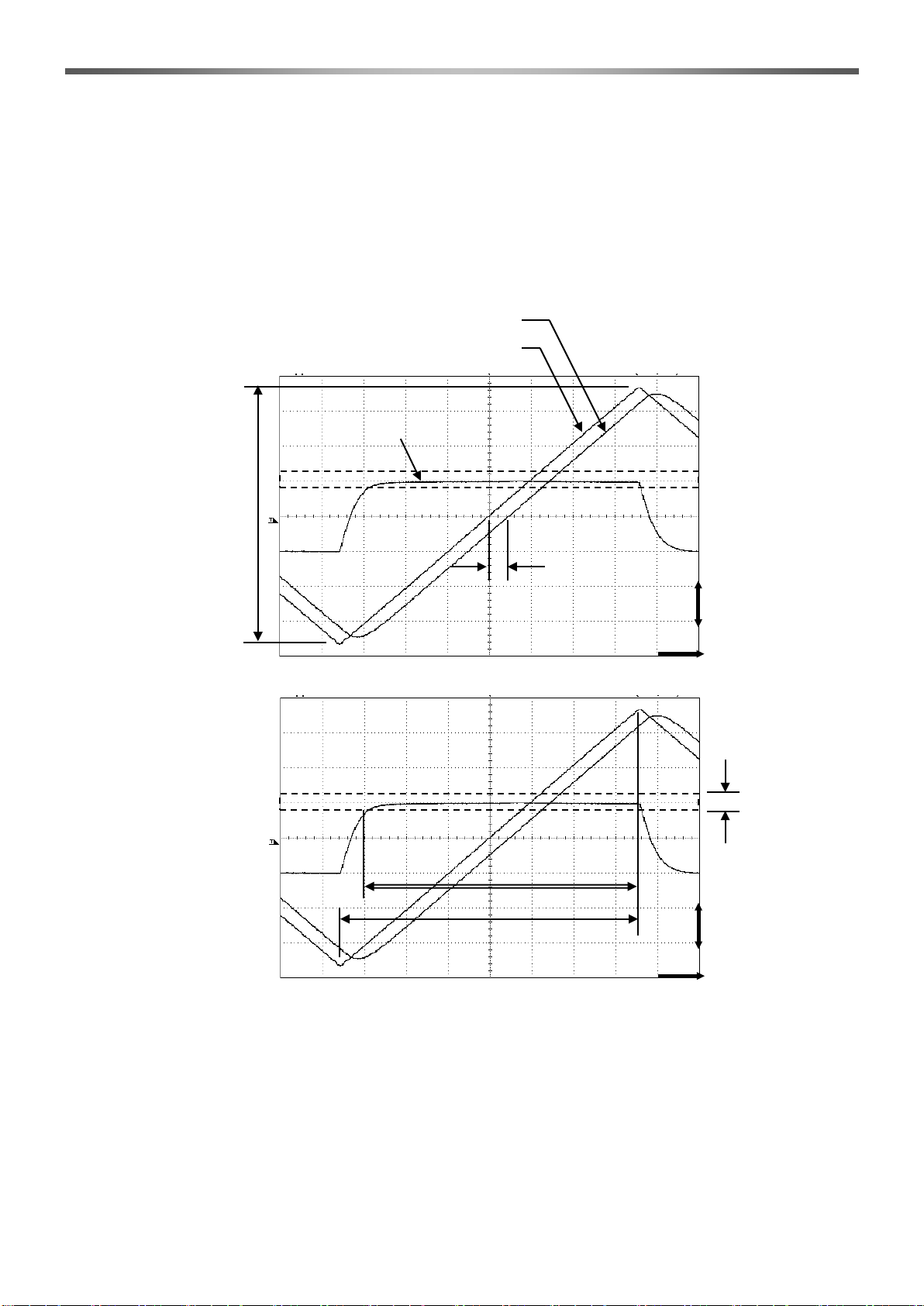

2-2 Main Specifications

No. Items Specifications

1

Repeatability of Positioning

*1

[μrad]

±5

Testing Conditions

Positioning seven times from arbitrary forward and backward positions respectively, and

take the maximum deviation. Divide this by half and place a ± sign.

Utilize an auto-collimator and measure in a room temperature environment.

Waiting Time (including positioning time): within tens of seconds

2 Temperature

Drift

Offset Drift

[μrad / °C]

30

Scale Drift

[% / °C]

0.01

3 Response Characteristics

Response characteristics based on the customer’s

operating conditions will be confirmed on actual equipment

during the advanced testing stage, as deemed necessary.

The results will be presented as adjustment specifications*2

.

Representative characteristics are listed in Response

Characteristics (2-3).

*1 Repeatability of Positioning refers to a value at a certain temperature and a short period of time,

excluding drift.

*2 The selections of the applicable models may change in accordance with the customer’s operating

conditions. Therefore, please fill-in the “Optical Scanner Drive Form” (2-4) and contact

our company before manufacturing the load devices or mounting parts.

2-3 Response Characteristics

By specifying the operating conditions and adjusting appropriately the driver according to the conditions,

the scanner system can provide an optimal performance for the focused characteristics. Therefore, the

response characteristics are different for adjustments emphasizing on accuracy and adjustments

emphasizing on response. In addition, if different conditions from adjusted operating conditions are

utilized, the operation of the drive may become unstable.

Our scanner system is appropriately adjusted to the customer’s operating conditions and is fundamentally

provided as a system. The explanation of the response characteristics of the rectangular and triangular

wave drives are on the following pages Using this as reference, please fill out the your usage conditions

in the “Optical Scanner Drive Form” (2-4) and submit this document to an agent or to our sales

representative.

LSA-10A-30-D-130 Technical Document

-8-

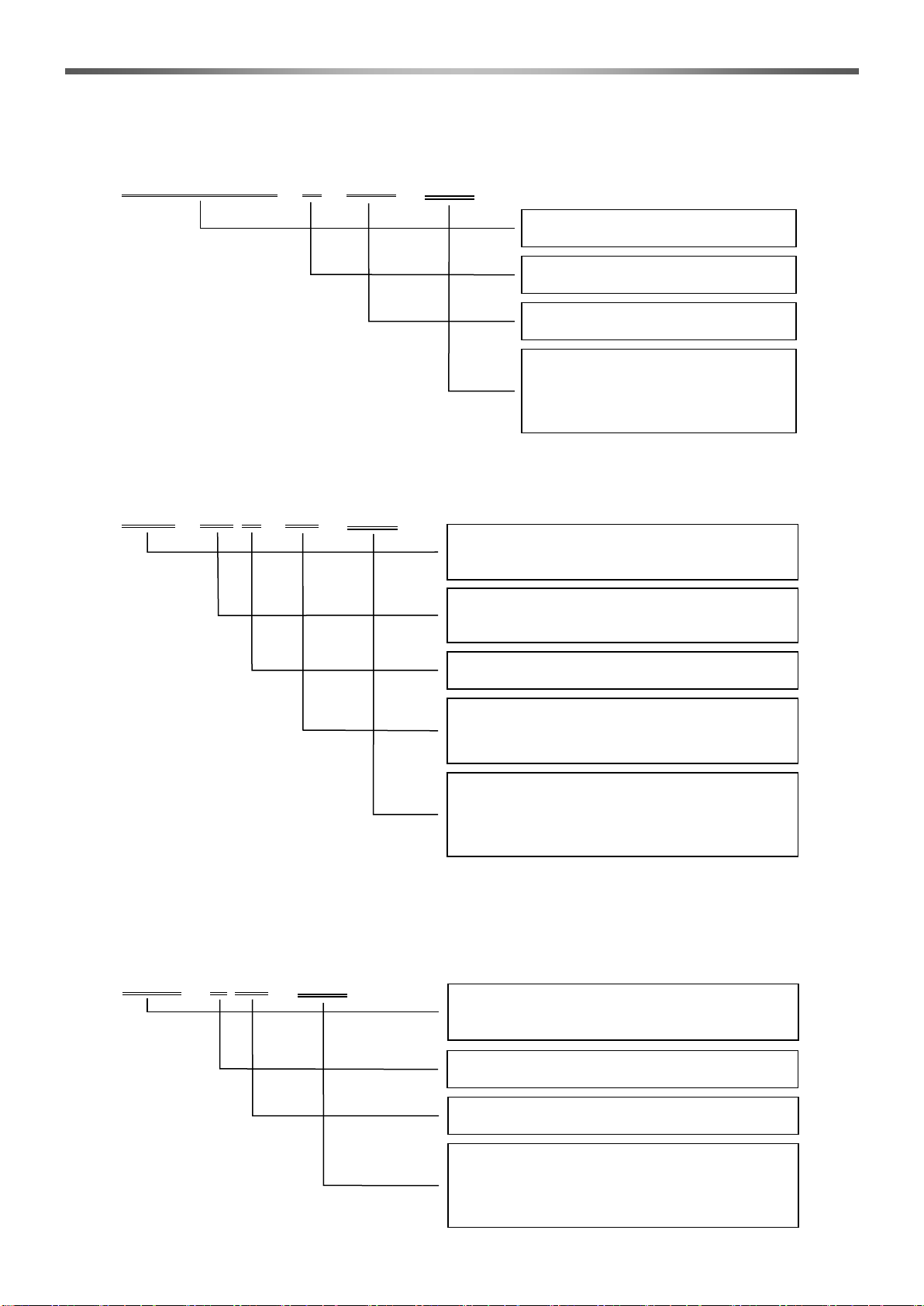

2-3-1 Response during Rectangular Wave Drive

The responses of the rectangular or trapezoid wave operations are important for utilizing the positioning

operation. Generally, the trapezoid wave drive settles easier and is better for applications of fluctuating

amplitudes, than the rectangular wave drive.

Rectangular wave drive is showed as an example as follows, and the conditions need to be considered are

discussed.

♦Rectangular Wave Drive Step Response Characteristic (example observed by oscilloscope)

[1] Emphasized Adjustment Amplitude (Unit: [°])

This indicates the optimally adjusted amplitudes during adjustment. Generally, the amplitudes with the

most often used frequency are taken as the emphasized adjustment amplitudes. In case of large

amplitude operation, the command waves of step inputs (stacking small amplitudes) or trapezoid wave

inputs, etc. are utilized

・Response and stability are well balanced and optimal when the actual drive amplitude is equal to the

adjustment amplitude.

・The gain can be raised and the Settling Time decreases as the size of the emphasized adjustment

amplitude decreases.

・If the amplitudes are not constant, the largest amplitude has to be the emphasized adjustment

amplitude.

・If a command with an amplitude larger than the emphasized adjustment amplitude is input, longer time

is necessary for setting after reaching the command position. On the other hand, when a command with

an amplitude smaller than the emphasized adjustment amplitude is input, the setting time will be

identical to the setting time when the emphasized adjustment amplitude is input.

[2] Convergence Criteria (Unit: [°] or [arc-sec])

This indicates the width of the allowable positioning error that is for setting judgment for the commanded

position. Generally, necessary and sufficient conditions of positioning accuracy are considered as

convergence criteria. The device is adjusted to the shortest Settling Time as conditions are satisfied.

・For quick-response operation, the convergence criteria are set broadly and the gain is adjusted high.

Although response increases, longer time is necessary till the device matches the commanded

position.

・During accurate positioning operation, the convergence criteria are set narrowly and the gain is

adjusted low. Although response decreases, the device matches the commanded position in a short

amount of time.

・If the Settling Time is the same, the convergence criteria can be narrowed as the size of the

Positioning Command Signal

Positioning Sensor Signal

Positioning Error Signal

[2] Convergence Criteria

[3] Settling Time

Time

Position

[1] Emphasized Adjustment

Amplitude

LSA-10A-30-D-130 Technical Document

-9-

emphasized adjustment amplitude decreases.

[3] Settling Time (Unit: [ms] or [μs])

A completion of positioning is judged by the positioning error signal that is within the range of the

convergence criteria. The Settling Time is the time from a command input to a completion of positioning

Generally, adjustments are made ensuring the shortest Settling Time being satisfied within the other

operating conditions .

[4] Drive Frequency (Unit: [Hz])

This indicates the actual drive frequency.

Please refer to “Supplementary Explanation of Optical Scanner Operating conditions Form” (2-4-1) for other

features.

♦Rectangular Wave Drive Response Characteristics (Settling Time for amplitudes with load moment of

inertia as the parameter)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0.01 0.1 1 10

振幅 [°]

整定時間 [ms]

J

L

=3.5 g-cm2

2.2

1.0

Load (JL): Mirror for Our Test Equipment (1.0g-cm2,2.2g-cm2,3.5g-cm2)

Convergence Criteria: 0.005° (amplitude less than 0.5° )/0.01° (amplitude higher

than 0.51° )

Power Source Capacity: ±24V, 240W

Amplitude [°]

Settling Time [ms]

LSA-10A-30-D-130 Technical Document

-10-

2-3-2 Triangular Wave Drive Response

Dynamic characteristics of keeping positioning error within the definite range are important for scanning

operations. In the operations, the response characteristics of the saw-tooth wave drive or the triangular

wave drive are important. It is necessary to adjust the conditions during the steep section of saw-tooth

wave drive.

Here, the triangular wave drive is shown as a typical example, indicating conditions that need to be

examined.

♦Triangular Wave Drive Perspective of Response Characteristics (observed by oscilloscope)

[5] Emphasized Adjustment Amplitude (Unit: [°])

This indicates the optimally adjusted amplitudes during adjustment.

・Response and stability are well balanced and optimal when the actual amplitude is equal to the

adjustment amplitude.

・The gain can be raised and the range of the constant speed is increased as the size of the emphasized

adjustment amplitude decreases.

・If the amplitudes are not constant, the largest amplitude has to be the emphasized adjustment

amplitude.

[6] Convergence criteria (Unit: [°] or [arc-sec])

[5] Emphasized Adjustment

Amplitude

Positioning Command Signal

Positioning Sensor Signal

Position

Positioning Error Signal

Time

[6] Convergence

Criteria

[7] Constant Speed Interval

Command Interval

Time

Position

[8] Position Delay

LSA-10A-30-D-130 Technical Document

-11-

This indicates the width of the allowable positioning error for following the positioning command signal.

Generally, necessary and sufficient conditions of positioning accuracy are considered convergence criteria.

The device is adjusted to the conditions that a range of constant speed is maximized.

・In case of quick operation, set the convergence criteria broadly and adjust the gain for extending the

range of constant speed. In case of high accuracy operation, set convergence criteria narrowly.

・If the range of constant speed is the same, the convergence criteria can be narrowed as the size of the

emphasized adjustment amplitude decreases.

[7] Range of Constant Speed (Unit: [%])

Assuming that the positioning command signal is a constant slope, the portion of the positioning error

signal being kept within the convergence criteria is a constant speed range. The proportion of the

constant speed interval and the command interval is the constant speed range [%].

As the shaft rotates inverse direction in the triangular wave drive, positioning error immediately after

inversion is large.

[8] Position Delay (Unit: [ms] or [μs])

This indicates time delays between positioning sensor signals and positioning command signals.

Normally, position delay is measured at the position of the sensor origin point. (There may be fluctuations

based on measurement positions.)

[9] Drive Frequency (Unit: [Hz])

This indicates the actual drive frequency.

As the frequency increases, the range of constant speed decreases.

Please refer to “Supplementary Explanation of Optical Scanner Operating conditions Form” (2-4-1) for other

features.

♦Triangular Wave Drive Response Characteristics Example 1 (range of constant speeds vs.

frequencies with amplitude as the parameter)

50

60

70

80

90

100

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280

周波数 [Hz]

等速範囲 [%]

Amplitude: 30°5°10°20°

Load (JL): Mirror for Our Test Equipment (2.2g-cm2)

Convergence Criteria: 0.2% Amplitude/Power Source Capacity: ±24V, 240W

Heat Radiation Conditions During Continuous Drive:

Driver 150x150x6mm Aluminum Heat Sink + Air Cooling Fan (8W)

Clamp the entire surface of the scanner mount surface

Constant Speed Range [%]

Frequency [Hz]

LSA-10A-30-D-130 Technical Document

-12-

50

60

70

80

90

100

0 20 40 60 80 100 120 140 160

周波数 [Hz]

等速範囲 [%]

♦Triangular Wave Drive Response Characteristics Example 2 (range of constant speeds vs.

frequencies with moment of inertia as the parameter)

♦Triangular Wave Drive Response Characteristics Example 3 (comparison of constant speed ranges

vs. frequencies for continuous and short-time operation)

3.5 2.2 J

L

=1.0g-cm2

Load (J

L

): Mirror for Our Test Equipment (1.0g-cm2,2.2g-cm2,3.5g-cm2)/Amplitude: 30°

Convergence Criteria: 0.06° (0.2% Amplitude)/Power Source Capacity: ±24V, 240W

Heat Radiation Conditions During Continuous Drive:

Driver 150x150x6mm Aluminum Heat Sink + Air Cooling Fan (8W)

Clamp the entire surface of the scanner mount surface

50

60

70

80

90

100

0 20 40 60 80 100 120 140 160

周波数 [Hz]

等速範囲 [%]

Short Time

Continuous

Load (J

L

): Mirror for Our Test Equipment(2.2g-cm2)/Amplitude: 30°

Convergence Criteria: 0.06° (0.2% Amplitude)/Power Source Capacity: ±24V, 240W

Heat Radiation Conditions During Continuous Drive:

Driver 150x150x6mm Aluminum Heat Sink + Air Cooling Fan (8W)

Clamp the entire surface of the scanner mount surface

Frequency [Hz]

Constant Speed Range [%]

Frequency [Hz]

Constant Speed Range [%]

LSA-10A-30-D-130 Technical Document

-13-

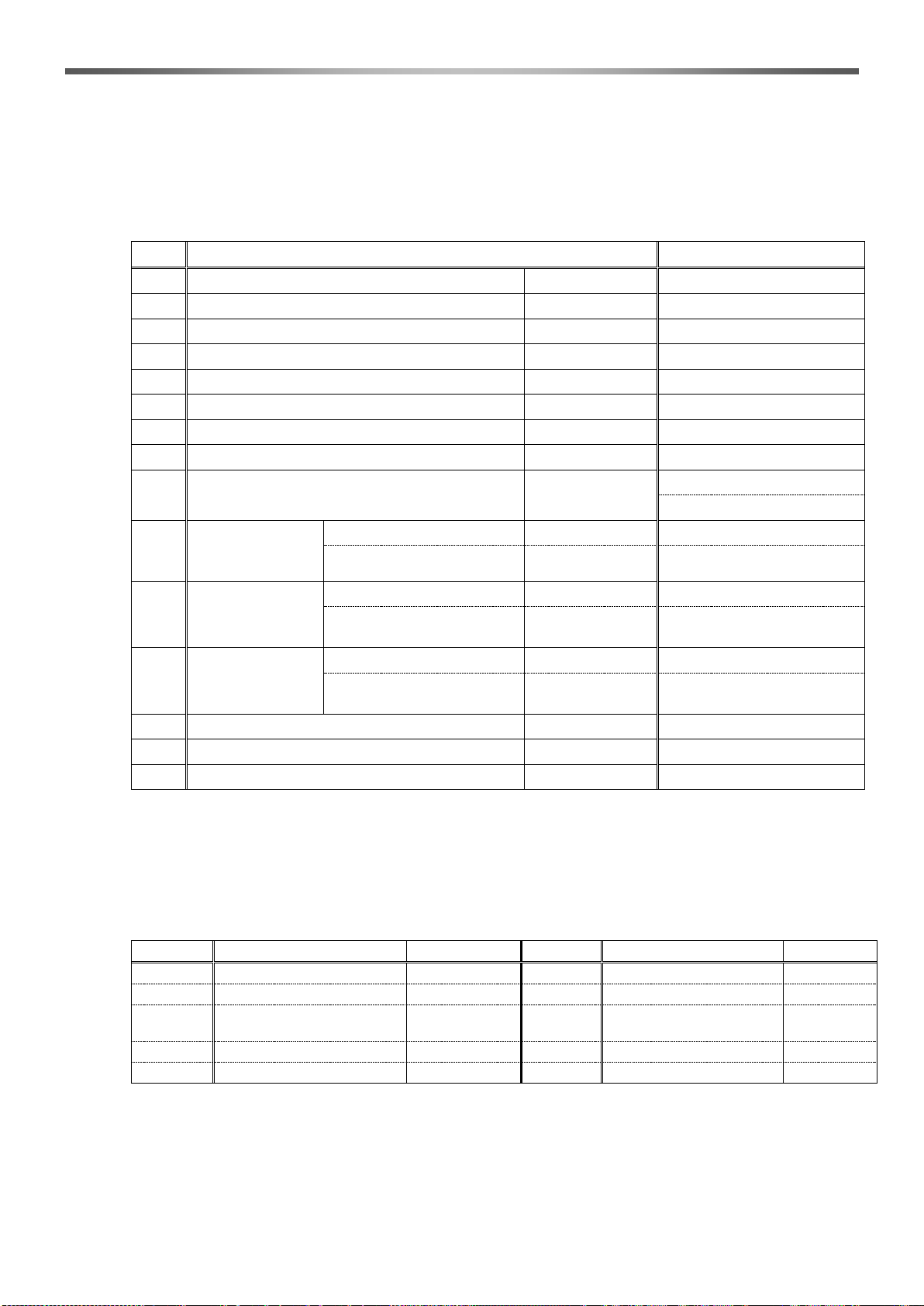

2-4 Optical Scanner Operating conditions Form Requested Date:

Company Name

Position/Title

Name

Address

TEL/FAX

TEL:/FAX:

E-mail

Applications

Please check the

appropriate classification.

In addition, please enter

specific details.

Classifications

Laser Processing

Measurements

Image Processing

Laser Display

Other

Details

Please refer to the technical data in 2-3 and 2-4-1 and enter the operating conditions. Based on these conditions

we will submit the adjustment specifications, including the model selection. If necessary operating conditions are

not indicated, the appropriate adjustment specifications may not be submitted.

Operating conditions

No.

Items Specifications

Supplementary ([ ] refers to the

technical data in 2-3 and 2-4-1)

(1)

Input Command Wave (Basic

Waves)

Rectangular Wave

Trapezoid Wave

Saw-Tooth Wave Triangular Wave

Sine Wave

If the wave has a slope, please

attach the slope data.

(2) Emphasized Adjustment Amplitude [°]

[1] [5] Sine Wave Conditions

(3) Drive Frequency [Hz]

[4] [9] Sine Wave Conditions

(4)

Convergence criteria (positioning

accuracy)

[°] or [arc-sec]

[2] [6]

(5) Settling Time [ms] or [μs]

[3] Time after the input becomes

constant during trapezoid wave

drive.

(6) Range of Constant Speed [%]

[7] Please also list targeted slope

during saw-tooth drive.

(7) Position Delay [ms] or [μs]

[8] Sine Wave Conditions

(8) Amplitude Error [%]

Output/Input Amplitude Error, Sine

Wave Conditions

(9) Load Moment of Inertia (GD2/4) [g-cm2]

[10] May attach diagram (material)

as a replacement

(10)

Maximum Amplitude [°]

[11]

(11)

Voltage at Full Scale

Input Voltage: Amplitude during [Vp

-p]: [°] [12]

(12)

Extended Cable Distance Between

Scanner and Driver

[m]

[14] No extension when blank.

(13)

Power Capacity (perfo

rmance or

capacity-emphasized) [W]

[15] 240W when blank. Enter

either performance or power

capacity-emphasized.

(14)

Priority Characteristics

Please enter items to be

emphasized.

(15)

Work (Optical Scanning) Range [mm]

Reference Value

(16)

Distance of Work and Mirror [mm]

Reference Value

(17)

Cable Length Between Power

Source and Driver

[mm]

Reference Value

(18)

Others (including details of

adjusted stamped labels)

If the entry space is insufficient,

please attach as separate pages.

* Please list all angles as mechanical angles. * Please enter data on the copy of this form.

Space to be filled in by our company:

(Management No.: )(Sales Branch: )(Sales Representative:)

LSA-10A-30-D-130 Technical Document

-14-

2-4-1 Supplementary Explanation of Optical Scanner Operating conditions Form

[10] Load Moment of Inertia (Unit: [g-cm2])

This indicates the moment of inertia of the load device attached to the output shaft of the mirror, shutter,

etc.

・The possibility of reducing settling time increases as the load moment of inertia decreases.

Caution: If the rigidity of the load device is too low, the resonant frequency decreases. When the

resonantfrequency decreases correspond to the control zone, the response characteristics

may be affected adversely. Please take into consideration moment of inertia and rigidity

when designing the load device.

[11] Maximum Amplitude (Unit: [°])

This indicates the maximum range of movement while in use, including offset.

・The control range of LSA-10A is ±15° centered on the origin of the scanner (the position when input is

0V).

[12] Full Scale Voltage (Unit: [V])

This indicates the ratio between the input command voltage and the swing angle of the output shaft.

・If there is nothing specifically specified, the other conditions are taken into consideration and

adjustments are made according to one of the following.

a) Input Command Voltage: Positioning command signal (IN-MON) at 20Vp-p is 8.25V (corresponds

to 30°) ± 5%

b) Input Command Voltage: Positioning command signal (IN-MON) at 20Vp-p is 5.5V (corresponds

to 20°) ± 5%

・Please refer to “Trimmer Function and Adjustable Range” (4-7) regarding adjustable range.

・Values change according to the scanner (angle sensitivity). a) and b) above are the values of

LSA-10A-30.

[13] Offset Position (Unit: [V])

This indicates the offset of the origin of the scanner and the electric origin of the position command input.

・If there is nothing specifically specified, the command signal during 0V input is adjusted to 0V ±5mV

(corresponding to ±0.018°).

(LSA-10A Angle Sensitivity: if 0.275V/°)

[14] Extended Cable Distance Between Scanner and Driver (Unit: [meter])

This indicates the length of cable between the scanner and driver.

When extending the length, please use cable thickness over AWG22 for both the motor and sensor wiring.

(As an option, a Extension cable [refer to 5-1] has been included.) If there is nothing specifically specified,

make adjustments without utilizing the extension cable.

・If a Extension cable exceeding 2m is utilized between the scanner and driver, adjustments must be

made with the Extension cable attached in advance.

・The allowed cable length of the sensor lead wire utilized with this scanner is 10m.

・Increasing the length of the sensor lead wire may increase noise, increasing the possibility that the

scanner malfunction.

[15] Power Capacity (Unit: [W])

If power capacity is limited, please notify us of the power capacity used.

In addition, please notify us of whether the device is performance or power capacity-emphasized.

・The power source used in our adjustments is ±24V and 240W (AD240-24: COSEL).

(We will select a power source closest to the expected power capacity among those available to our

company and we will assess the device.)

・The cable length between the power source and the driver during our adjustments is 1m.

LSA-10A-30-D-130 Technical Document

-15-

Chapter 3 Scanner Specifications

The specifications of the scanner (LSA-10A-30) are as follows.

3-1 Main Specifications

No.

Items

Specifications

1 Maximum Swing Angle (Control Range) (*1) [°] ±15

2 Output Shaft Rotation Range (Stopper Range) [°] 40

3 Rotor moment of inertia [g-cm2] 1.9

4

Torque Constant

[Nm/A]

0.0077

5 Coil Resistance [Ω] 0.28±10% at 20℃

6 Coil Inductance [mH] 0.098±10%

7

Sensor Linearity

[%]

±0.06 (Full Scale)

8

Sensor Angle Sensitivity

[V/°]

0.275±5%

9 Sensor Power Source Voltage [V] +5±5%

-15±5%

10 Sensor

Consumption

Current

+5V ±5% [mA] 90 Max

-15V ±5% [mA] 120 Max

11 Insulation

Resistance (*2)

Motor Coil - Case [MΩ] 100 (DC500V Mega)

Sensor Power Source

Common - Case

[MΩ] 100 (DC500V Mega)

12 Dielectric

Strength (*2)

Motor Coil - Case

[V]/1min

AC500

Sensor Power Source

Common - Case

[V]/1min AC500

13 Offset Drift [μrad/°C] 25

14

Scale Drift

[%/°C]

0.005

15 Mass [g] 180

*1 The origin (0°) position of the control range is the position when the sensor output voltage is at 0[V].

*2 Please do not conduct insulation tests on the sensor power source common - case.

3-2 Connector Specifications

Connectors Connected to Driver [Scanner Connector Model: DF18-10DS-2.5RC (Hirose)]

Pin.No.

Functions

Wire Color

Pin.No.

Functions

Wire Color

1

Motor (-)

Black

6

N.C.

-

2

Motor (+)

Red

7

Case Ground

Yellow

3

Power Source Common

(*1)

Green

8

Sensor (-)

Brown

4

-

15V

Black

9

Sensor (+)

White

5

+

5V

Red

10

Shield (*2)

Shield

*1 Power source common is connected to the case ground through the capacitor(voltage endurance:

50V).

*2 The shield is not connected to the case.

LSA-10A-30-D-130 Technical Document

-16-

Note 2

3-3 Dimensions (Third Angle Method)

The dimensions of the LSA-10A-30 are as follows.

Note 1: Please confirm the details of the dimension with the supplied specification diagram published by

our company.

Note 2: When attaching the customer’s load device, the screw may directly press against and scratch the

output shaft during our adjustments. In this case, the precision of scratched section may be

below the precision of the specifications.

3-4 Environmental conditions

The environmental conditions of the LSA-10A-30 are as follows.

No. Items Specifications Remarks

1 Operating Temperature [°C] 0 ~40

2 Humidity [%RH] 20 ~85 No condensation

3 Storage Temperature [°C] -10 ~70

4 Humidity [%RH] 20 ~90 No condensation

5 Vibration

Resistance

(*1)

Vibration

Acceleration [m/s

2

]

24.5

Testing Conditions

Frequency: 10→1000→10 [Hz]

Time: 1 Cycle 20 [min]

No. of Times: 3 times each in x, y,

and z directions.

6 Shock

Resistance

(*1)

Vibration

Acceleration [m/s

2

]

294

Testing Conditions Shock Time: 11 [ms]

No. of Times: 3 times each in x, y,

and z directions.

*1 The vibration/shock resistance tests are to ensure there is no degradation in performance during

non-operation period, but they do not guarantee the performance while operating.

Furthermore, please avoid applying shock directly to the output shaft.

Unit: mm

Unifying Tube

2 Locations

LSA-10A-30-D-130 Technical Document

-17-

3-5 Output Shaft Precision

The output shaft precision of the LSA-10A-30 is as follows.

Measurement

Point

Precision [mm] Remarks

A 0.004

Output shaft run-out

(range of maximum

swing angle: ±15°)

(Estimated value from a whole rotation

measurements)

B φ0.03

Parallelism of attachment area (φ30) and

output shaft

C 0.05 Perpendicular of a

ttachment face and

output shaft

3-6 Stopper Mechanism

For protection during malfunctions, a stopper mechanism has been

installed to restrict the rotation angle of the output shaft.

The angle of the output shaft starts to contact the stopper mechanism at

a range of about 40°. The final shutdown angle by snap action is at a

range of about 45°. The allowable torque of the stopper mechanism is

1.5[Nm]. If the strength exceeds the allowable torque, the attached

stopper may become damaged and displaced. The control range

(±15°) then may not be maintained.

The stopper mechanism is a protection mechanism during malfunctions.

Refer to the over position alarm output (4-6-6) and configure the circuit to

enable off(4-6-2).Ensure that stopper pin of the output shaft is not

contacted to the stopper during normal operation.

3-7 Caution Regarding Scanner Installation

3-7-1 Structure of Output Shaft

As the output shaft is not an airtight structure, please take measures to ensure that dust does not penetrate

the device. (Please take special caution when attaching the output shaft in an upright position.)

3-7-2 Scanner Cable

Please do not pull on the scanner cable with excessive force (exceeding 20[N]). The connector or and

cable may become damaged. Please ensure there is sufficient length to the cable when connecting the

device and ensure there is no tension on the cable. In addition, please ensure a sufficient bending radius

(exceeding r=40 mm) when repeatedly bending the cable.

Stopper

Stopper Pin

Output

Shaft

(Top View)

Stopper

LSA-10A-30-D-130 Technical Document

-18-

Clamp

Load Device

A

3-7-3 Caution When Attaching Scanner and Load Equipment

If the attachments to the scanner device or to the output shaft of the mirror’s load device are inappropriate,

the scanner will not sufficiently perform and may cause the device to malfunction. Please be cautious

when attaching this device to the equipment.

♦Attachting the Scanner Body to an equipment

Secure the clamp to Side A in the diagram on the right, when attaching

with clamp. Please ensure that the clamp strength is under 500[N].

Please ensure that the screw does not directly come in contact with Side

A when using other methods of securing attachments. Deformations,

etc. may affect accuracy.

♦Attaching the Load Device to the Output Shaft

For the driver combined with the customer’s load device and adjusted by our company, please ensure the

servo is turned on after installing the load device. Without a load, the Output Shaft will start to oscillate

unexpectedly when the servo is turned on.

If the scanner starts to oscillate unexpectedly, the driver resistance

may generate abnormal amounts of heat and start to smoke.

In this case, immediately cut the power source.

♦Attachment Order to the Output Shaft of the Load Device

The following order is recommended when attaching the load device and

deciding the position of the attachment.

(1) Secure the load device to the output shaft at a rough position with

the stopper pin of the output shaft as a guide.

(2) Temporarily secure to the device and turn the servo on (input

command: 0V)

(3) Determine the position by turning the scanner body while observing

the device’s laser light or image, then secure the equipment.

♦Lubrication of the Scanner’s Roller Bearing

Attention must be paid to the lubrication of the scanner’s roller bearing during continuous small amplitude

movement in the same location. The lubrication of the roller bearing can be more adequately maintained

by periodical large amplitude moving(ideally, slow triangular waves) for lubrication. It is strongly

recommended that the device is lubricated to the extent that it does not affect usage conditions.

Caution

LSA-10A-30-D-130 Technical Document

-19-

Chapter 4 Driver Specifications

The specifications of the driver (PSM-130) are as follows.

4-1 Main Specifications

No.

Items

Specifications

1 Power Source Voltage [V] DC ±24±10%

2 Continuous Output

Current

[A] 5

3

Instantaneous

Maximum Output

Current

[A] 25

4 Input Signal - Position command input (±10V, differential input,

impedance: 10kΩ)

- Enable

5 Output Signal

- Monitor Output (positioning command signal,

positioning sensor signal, positioning error signal)

- Alarm

6 Protection Functions - Protection when Enable OFF → ON

- Protection when Power OFF

- Prevents Power IC from overheating

7

Insulation Resistance

(*1)

[Ω] 100M (DC500V)

8 Offset Drift [μrad/°C] 5

9 Scale Drift [%/°C] 0.005

10 Mass [g] 160

*1 Please do not conduct insulation tests.

4-2 Protection Functions

No. Name Functions

1 Protection when Enable Off → ON

(*1)

Prevents unstable operation when Enable OFF → ON

(Controls swing angle within ±10° when Enable OFF →

ON)

2 Protection when Power Off Prevents unstable operation when Power ON → OFF

(Controls swing angle within ±10° when Power ON →

OFF)

3 Power IC O

verheating Protection

(*2)

Stops supplying power (shut down) to the scanner when

the internal temperature of the Power IC is over

Typ.160°C (surface temperature: Typ.130°C) and prevents

further overheating.

As the temperature of the Power IC decreases an

d falls

below the threshold, the power is supplied again (auto

return).

*1 Please do not turn the power on when Enable is on.

*2 The Power IC Overheating Protection is to protect against damage due to the heat from the driver.

Intermittent instability may occur during beginning of shutdown and auto return.

Refer to Overheat Alarm Output (4-6-6) to form the sequence configuration of Enable OFF before

operating the Power IC Overheating Protection.

LSA-10A-30-D-130 Technical Document

-20-

Product

Label

Adjustment

Label

4-3 Dimensions (Third Angle Method)

The dimensions of the PSM-130 are as follows.

Note: Please confirm the details of the dimension with the supplied specification diagram issued by our

company.

4-4 Environmental Specifications

The environmental specifications of the PSM-130 are as follows.

No. Items Specifications Remarks

1 Operating Temperature [°C] 0 ~40

2 Humidity [%RH] 20 ~85 No condensation

3 Storage Temperature [°C] -10 ~70

4 Humidity [%RH] 20 ~90 No condensation

5 Vibration

Resistance

(*1)

Vibration

Acceleration [m/s

2

]

24.5

Testing Conditions

Frequency: 10→1000→10 [Hz]

Time: 1 Cycle 20 [min]

No. of Times: 3 times each in x, y,

and z directions.

6 Shock

Resistance

(*1)

Vibration

Acceleration [m/s

2

]

294

Testing Conditions Shock Time: 11 [ms]

No. of Times: 3 times each in x, y,

and z directions.

*1 The vibration/shock resistance tests are to ensure there is no degradation in performance during

non-operation period, but they do not guarantee the performance while operating.

Unit: mm

Heat Release

Fin

Table of contents