Contents

Leuze electronic RS4 4

6.5.3 Protective field contour and reference boundary........................................................................................................36

6.6 Mobile danger zone guarding on DTSs ......................................................................................................................36

6.6.1 Basic requirements.....................................................................................................................................................37

6.6.2 Minimum distance D ...................................................................................................................................................37

6.6.3 Protective field dimensions ........................................................................................................................................39

6.6.4 Test mode for MotionMonitoring.................................................................................................................................39

6.7 Mobile side guarding on DTSs....................................................................................................................................40

7 Technical data ............................................................................................................................................................41

7.1 Safety..........................................................................................................................................................................41

7.2 Optics..........................................................................................................................................................................41

7.3 Protective field ............................................................................................................................................................42

7.4 Warning field...............................................................................................................................................................42

7.5 Measured data............................................................................................................................................................42

7.6 Electrical power supply ..............................................................................................................................................43

7.7 Software......................................................................................................................................................................44

7.8 Ambient conditions .....................................................................................................................................................44

7.9 Dimensions, weight.....................................................................................................................................................45

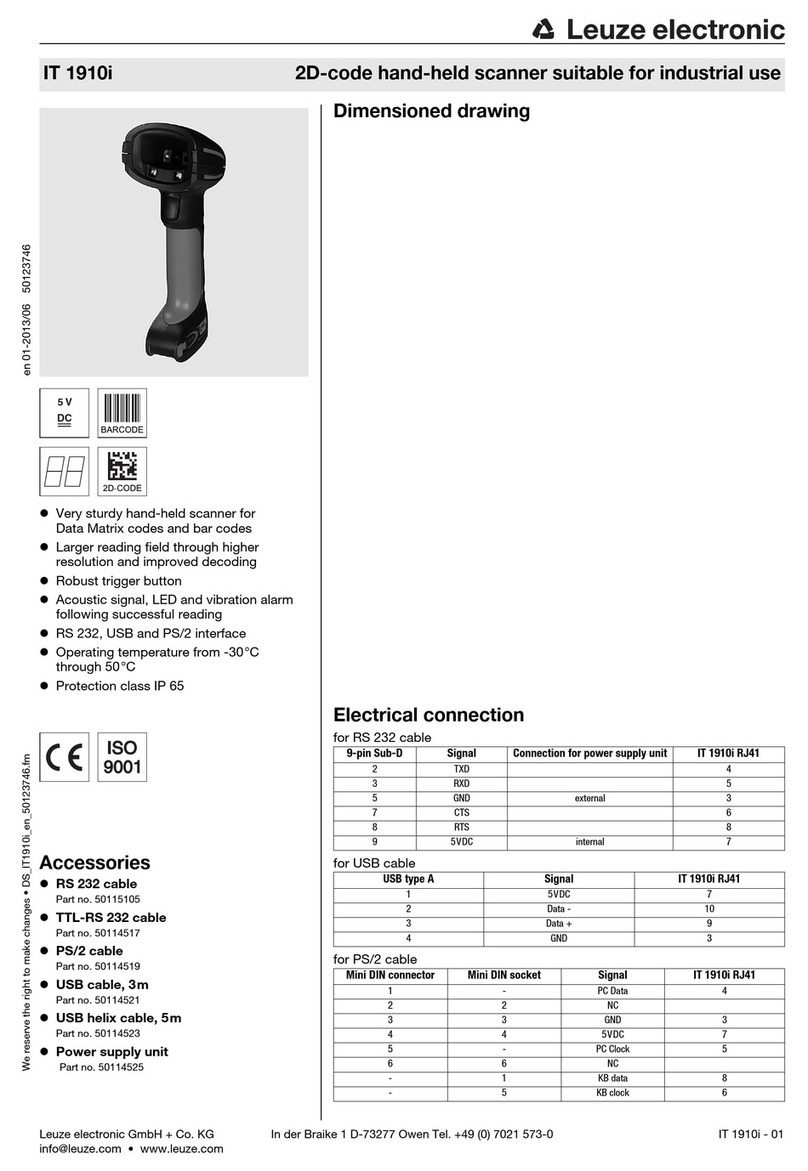

8 Electrical connection...................................................................................................................................................47

8.1 Electrical power supply...............................................................................................................................................47

8.2 Interfaces....................................................................................................................................................................47

8.2.1 X1 plug interface assignment .....................................................................................................................................48

8.2.2 Interface assignment, plug X2....................................................................................................................................49

8.3 Assemble cables.........................................................................................................................................................50

8.4 Integrating the safety sensor into machine control system.........................................................................................51

8.4.1 Downstream safety circuit with start/restart interlock, contactor monitoring, without field pair switchover.................51

8.4.2 Programmable logic controller (PLC) with corresponding safety level and field pair switchover................................51

9 Parameters .................................................................................................................................................................53

9.1 Administrative parameters..........................................................................................................................................53

9.1.1 Safety Laser Scanner name.......................................................................................................................................53

9.1.2 Description..................................................................................................................................................................53

9.1.3 Start segment output ..................................................................................................................................................53

9.1.4 Stop segment output...................................................................................................................................................53

9.1.5 Output resolution ........................................................................................................................................................53

9.1.6 Serial interface baud rate............................................................................................................................................54

9.1.7 Alarm incident.............................................................................................................................................................54

9.1.8 Precalculated measured values output.......................................................................................................................54

9.1.9 2nd measured value calculation segment ..................................................................................................................54

9.1.10 3rd measured value calculation segment ...................................................................................................................54

9.2 Safety-relevant parameters ........................................................................................................................................55

9.2.1 Application ..................................................................................................................................................................55

9.2.2 Response times..........................................................................................................................................................55

9.2.3 Dust suppression........................................................................................................................................................55

9.2.4 Applicable field pair selection with scanner start ........................................................................................................56

9.2.5 Permitted field pair switchovers..................................................................................................................................56

9.3 Field pair.....................................................................................................................................................................56

9.3.1 Protective field/description..........................................................................................................................................56

9.3.2 Warning field/description ............................................................................................................................................56

9.4 MotionMonitoring ........................................................................................................................................................56

9.4.1 Vehicle width...............................................................................................................................................................56

9.4.2 Protective field side additional distance......................................................................................................................56

9.4.3 Laser scanner installation point..................................................................................................................................57

9.4.4 Warning field prerun time............................................................................................................................................57

9.4.5 Vehicle response time ................................................................................................................................................57

9.4.6 Brake wear and tear additional distance.....................................................................................................................57

9.4.7 Ambient influences additional distance.......................................................................................................................57

9.4.8 Speed with PF ............................................................................................................................................................58

9.4.9 Braking distance with PF ............................................................................................................................................58

9.4.10 Standstill monitoring ...................................................................................................................................................58

9.4.11 Creep and reverse......................................................................................................................................................58