Harol SC900 User manual

INSTALLATION INSTRUCTIONS

SUN PROTECTION

PROTECTION SOLAIRE

SHUTTERS

VOLETS

GATES

PORTES

SURFACE-MOUNTED SCREEN

SC900 - SC910

art.no. 60447

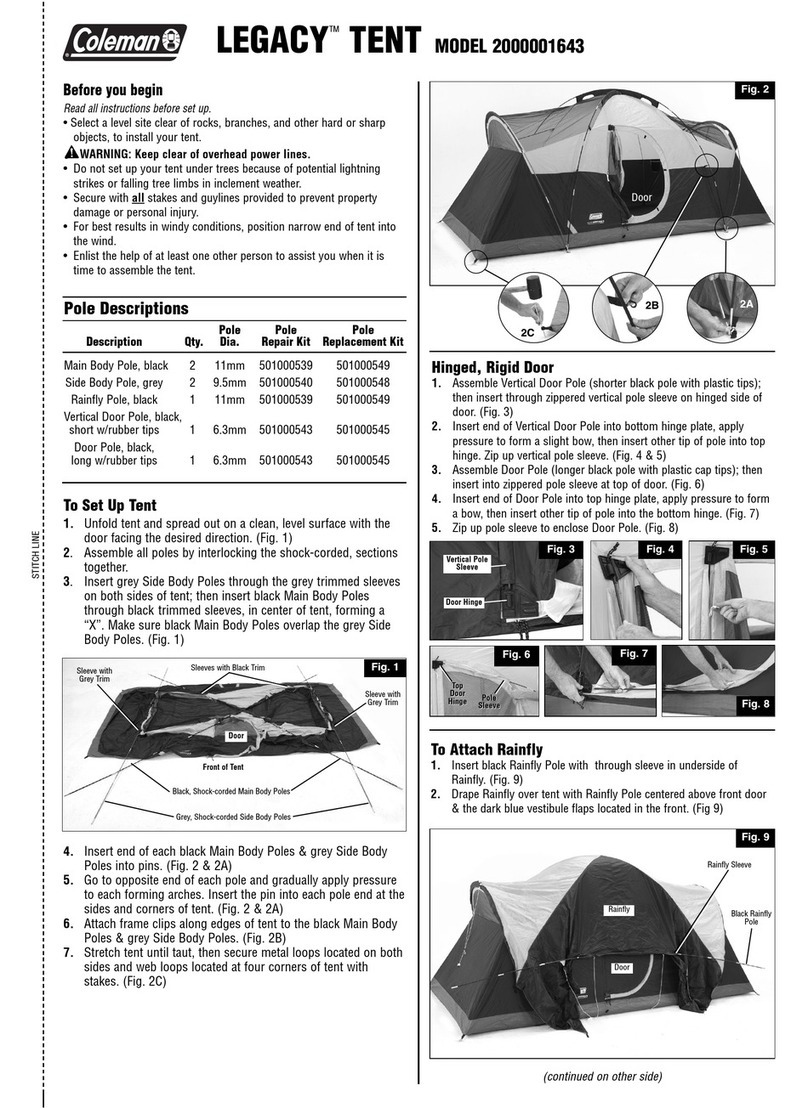

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |2

TABLE OF CONTENTS

1. INTRODUCTION 3

2. GENERAL WARNINGS 3

3. LIST OF TOOLS REQUIRED 4

4. INSTALLATION STEPS 5

4.1. Determine the type of screen 5

4.2. Check the package 5

4.3. Check the product 5

4.4. Check the height and width 5

4.5. The actual assembly in 10 steps 6

4.6. Installation of two or more adjacent screens 14

4.7. Checking the assembly 16

5. ELECTRICAL CONNECTIONS 17

5.1. Connection diagram for a single pole switch 17

5.2. Adjusting the motor - limit switches 18

6. TROUBLESHOOTING AND REPAIRS 20

6.1. The screen will not roll up or down 20

6.2. The motor hums 20

6.3. The motor does not stop in time 20

6.4. Bottom lath is slanted at the top 20

6.5. Bottom lath drops out of the lateral guides 20

6.6. The fabric tension is too slack; the bottom lath sticks

or shudders when the screen is lowered or raised 20

6.7. Folds and waves in the fabric 20

6.8. The direction of the motor’s rotation does not match the arrows on the switch 20

6.9. The fabric does not stop and roll up again 20

6.10. Automatic control does not operate properly 21

6.11. The bottom lath sticks or shudders when the screen is lowered or raised 21

7. REPAIRS 21

8. DISMANTLING AND REMOVAL 21

9. NOTES 22

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |3

1. INTRODUCTION

The SC900 screen is a flat hanging sun screen, which is fitted on top of the window with

a'zipper system' on each side of the fabric. This makes the screen particularly resistant to high

winds and keeps the fabric perfectly in place. In the down position the screen keeps out the

sun's rays, which can cause overheating, while at the same time it gives a view to the outside.

Moreover, this screen oers practical protection against insects, as the space between the

box, the guide rails and the fabric is completely sealed o.

The SC900 can also be fitted with fabrics that are almost fully opaque, making it especially

suitable to black out presentation rooms in oce buildings, laboratories, hospitals etc.

The installation of this sun protection system is explained step by step in these instructions.

The SC910 screen is a flat hanging sun screen with the same properties, but without the

insulation and cover (for the box). It is basically a 'naked' version of the SC900 screen.

Attention!

Open box, standard version without the back covered. This version requires a suitable

finish to avoid damage to and prevent dirt from settling on the fabric. (possible option =

full support plate instead of brackets)

2. GENERAL WARNINGS

A number of precautions have to be taken for the safe installation, operation and maintenance

of this screen. Please take notice of the following warnings for the safety of everyone concerned!

!These instructions have been drawn up for use by trained installers and therefore are

not suitable for use by amateurs or trainees.

!Please read these instructions carefully before starting the installation.

!Proceed carefully. Ensure that you have a robust footing.

!Make sure there is adequate lighting in the place of assembly. Remove any obstacles

and dirt. Ensure that no other persons other than the installers are present.

Unauthorised persons can get in the way or be at risk during the installation.

!The screen must be kept clearly in view at all times during installation and operation.

Persons in the vicinity may be at risk of injury.

!The installer must comply with the local regulations and standards with regards to

electrical connections.

!Our products must be installed in such a way that all parts remain accessible at all times

for maintenance and repairs. If this is not the case, Harol cannot be held responsible for

any additional costs (e.g. demolition work, repairs to exterior or interior walls) whichmay

result from this.

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |4

Guarantee, terms and conditions

• Harol has endeavoured to design and manufacture the screen in compliance with

the current CE standards. Always check that our version complies with your own

national standards institute.

• No rights can be derived from these instructions whatsoever. Technical modifications

are reserved without written notification.

• For large projects we strongly advise you to first fit 1 complete awning before fitting

the remaining awnings. This will help detect any potential faults early on and enable

them to be remedied at the lowest possible cost.

• For our general terms and conditions of sale, please refer to the price list.

• Make sure the screen box can always be opened so the mechanical parts inside can

be reached easily. If these rules are not respected, Harol cannot be held responsible

for the cost of demolition work or any paint work or wallpapering.

Harol NV

Industriepark 3 – 3290 Diest

Belgium

+32 (0)13 38 01 11

+32 (0)13 31 48 03

info@harol.be

www.harol.com

3. LIST OF TOOLS REQUIRED

• Ladder(s)

• Tape measure and pencil

• Cross-slotted screwdrivers

• Spirit level, plumb line or water hose

• Drill

• Set of drills

• Voltage meter or 220 V testing lamp

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |5

4. INSTALLATION STEPS

4.1. Determine the type of screen

Check the type of screen: SC900 (with insulation) or SC910 (without insulation)

4.2. Check the package

Check the package for any damage before removing the complete packaging from around

the box and guide rails.

4.3. Check the product

Check the product: ensure all guide rails and clip profiles are included and check if each

guide rail contains a holder with zipper profile.

Also check the bag with accessories. Verify that the screws for securing the support plate,

the clips for the bottom profile and the screws for securing the clip and bottom profiles

are there, together with the guarantee card.

4.4. Check the height and width

Check the width of the screen box and measure the window opening.

Verify that both match the desired mounting position.

Also check the height of the guide rails, including the end stop, and make sure they

correspond to the height of the window.

In the following steps logos are used to show the dierence between mounting the SC900

and SC910 screens.

SC900 SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |6

4.5. The actual assembly in 10 steps

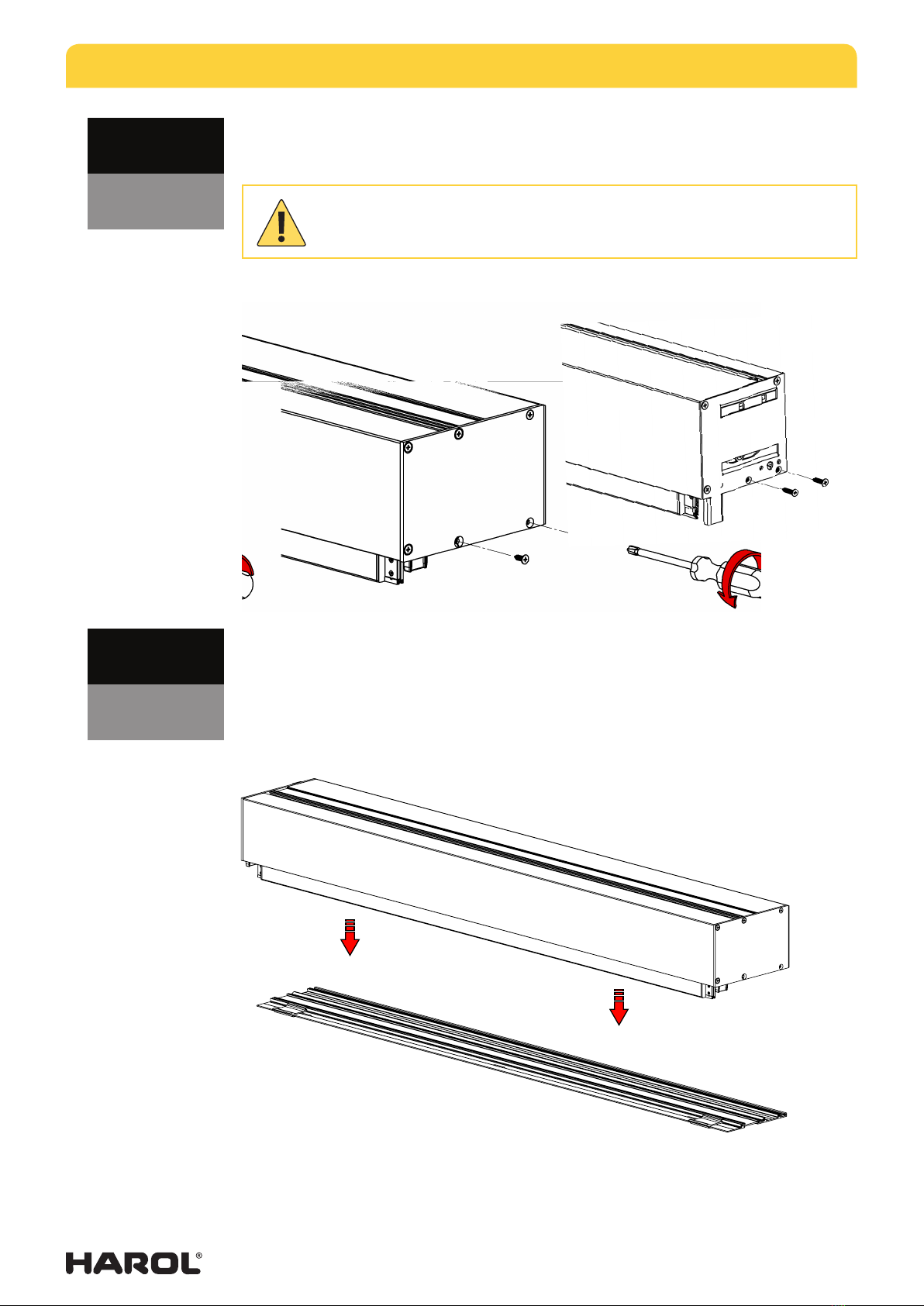

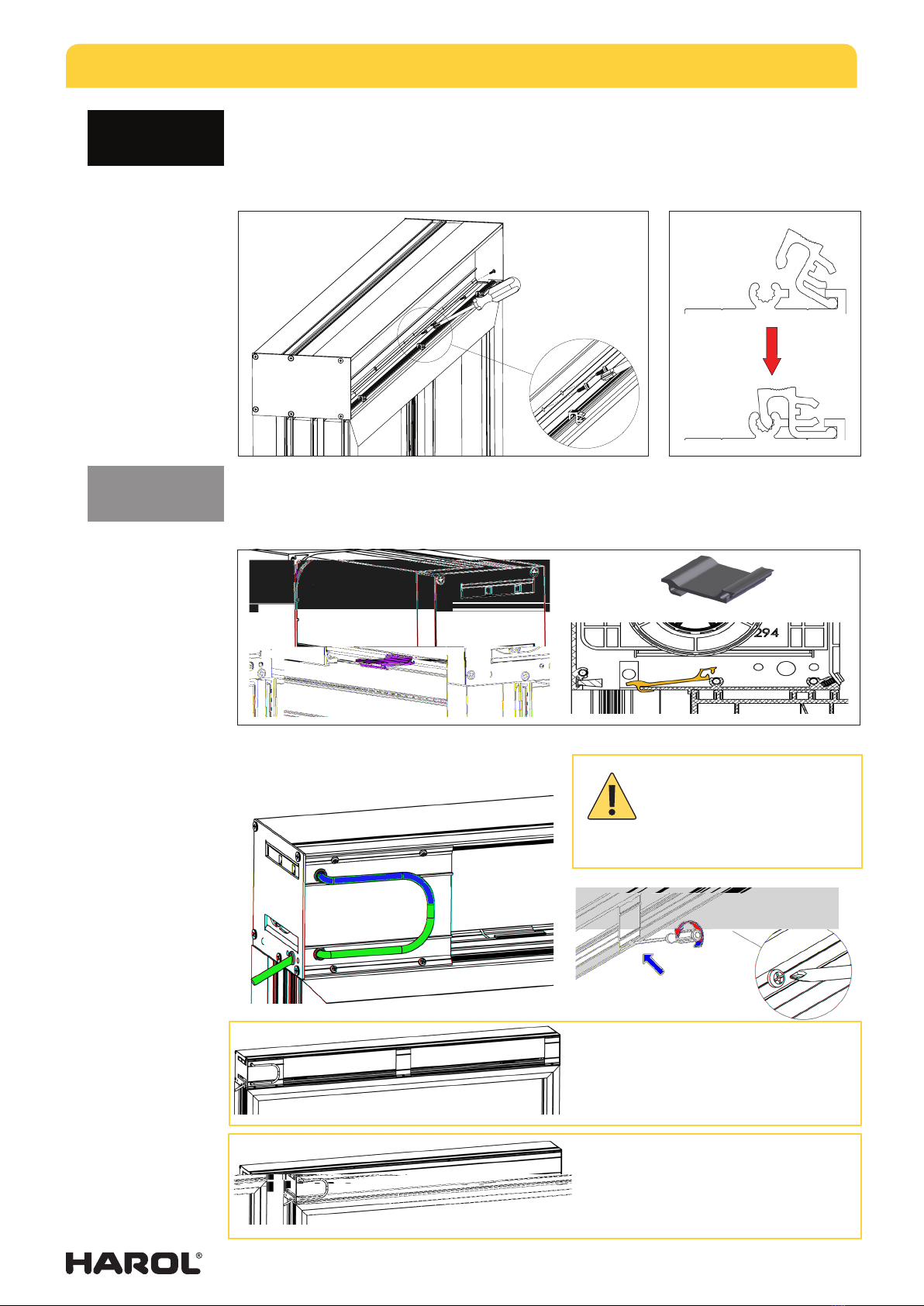

Step 1

• Remove the cover and the insulation.

• (SC900) The support plate and base plate are connected. The advantage of thisis

that the base plate does not bend when handling the box. Remove these screws

before mounting the screen!

• (SC910) Unscrew the brackets or support plate (optional) at the bottom, to free the

base plate.

SC900

SC910

SC900

SC900 SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |7

• Then unscrew the two screws at the back that connect to the base plate.

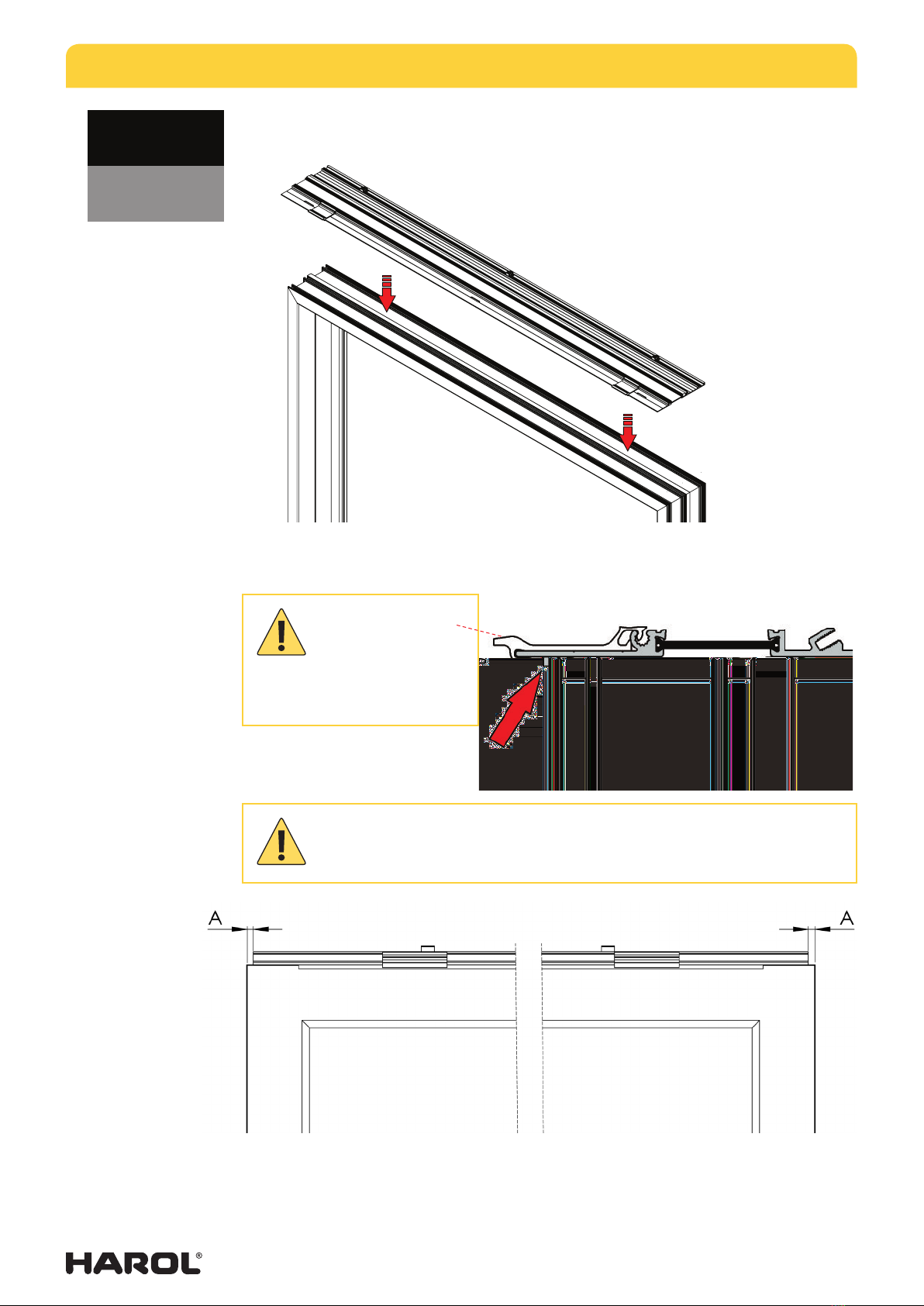

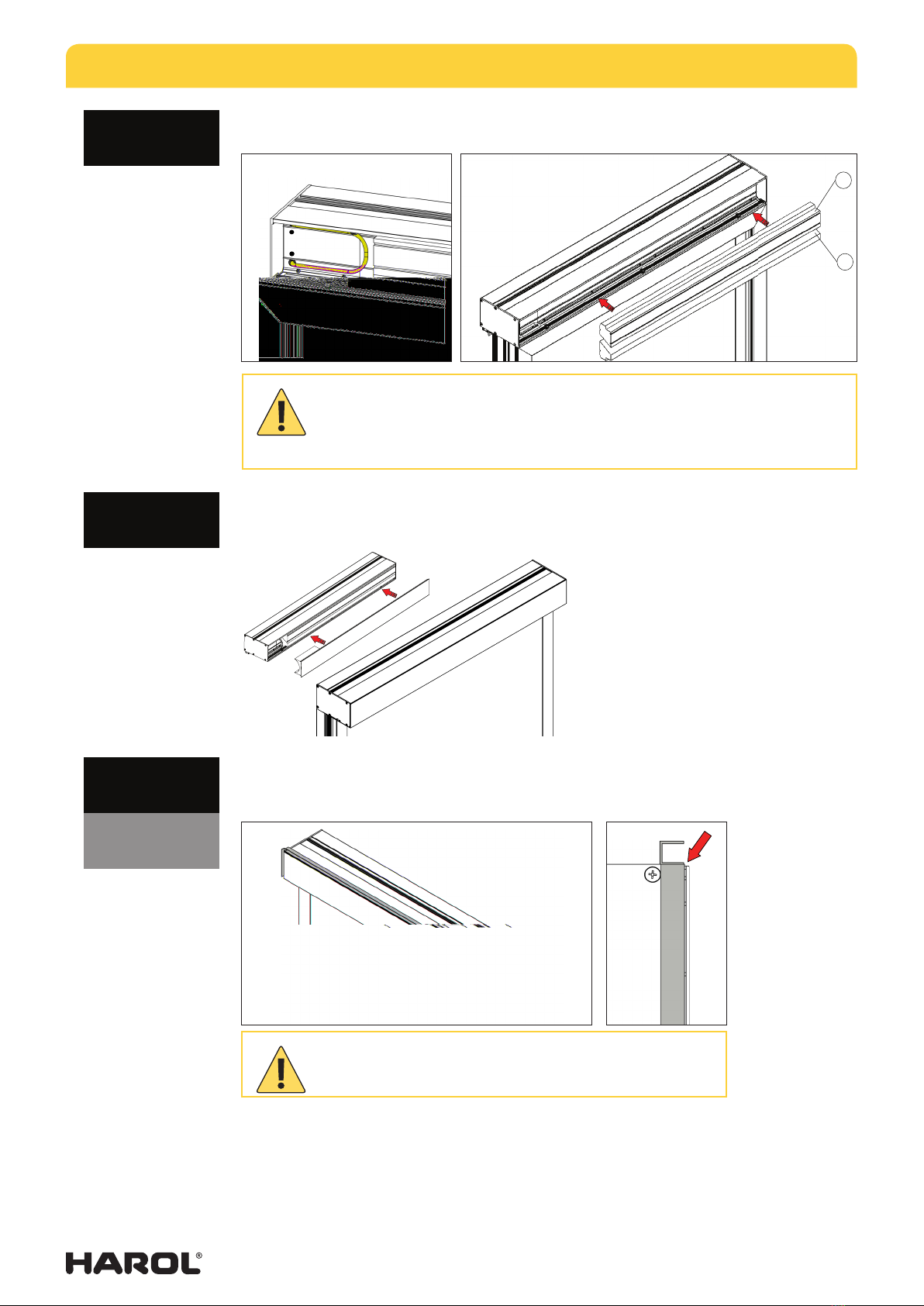

Step 2

• Carefully let the base plate slide from the box.

Please note that this operation must be carried out on both sides of the box

before proceeding to the next step.

SC900

SC910

SC900

SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |8

Step 3

• Centre the base plate on the window and screw it down.

• Make sure the base plate is correctly centred on the window.

• Distance (A) must be the same on both sides.

Tab at the bottom of the base profile forms the abutment with the window.

SC900

SC910

The touch component

for the bottom lath of

the SC910 screen is supplied

separately. This is mounted on

the base plate at a later stage!

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |9

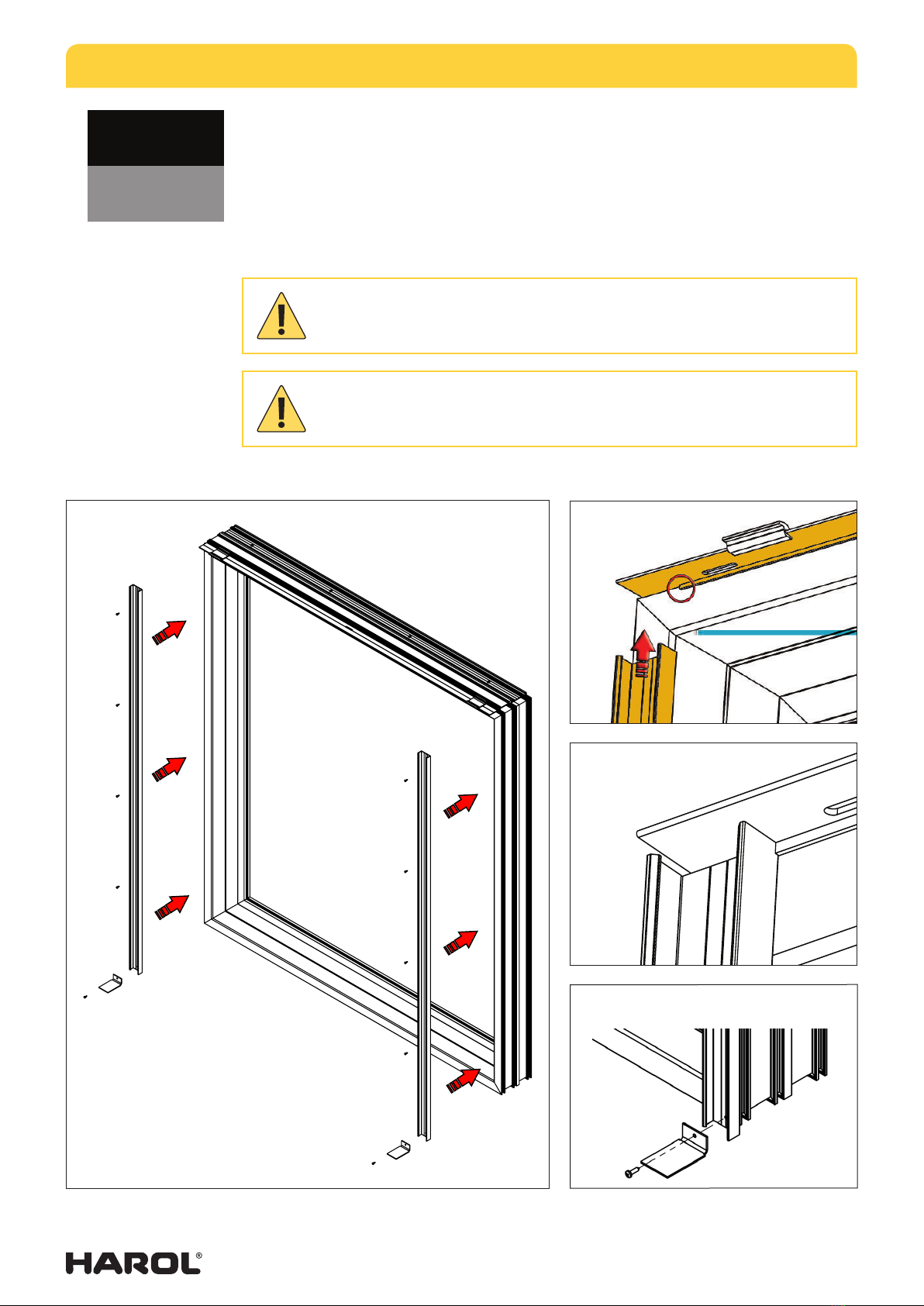

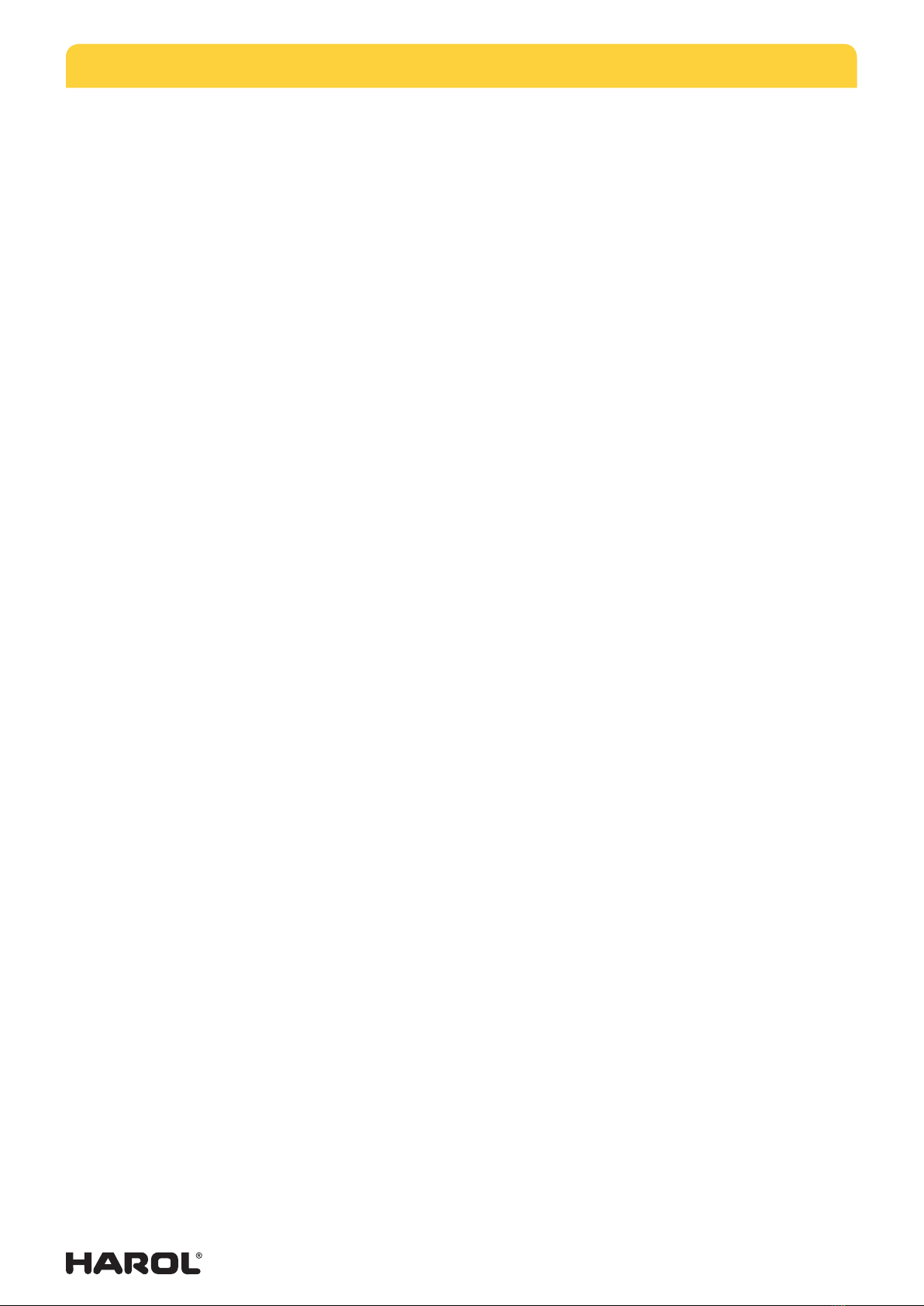

Step 4

• Attach the clip profiles with the hole in a downward position.

• First position the upper side of the clip profile against the tab on the bottom side of

the base plate (Fig. 1a-1b).

• Next, drill holes at regular intervals to secure the clip profile and attach it to the window.

• In the bottom pre-drilled hole, the clip profile must be secured together with the end

stop (Fig. 2).

Make sure the clip profiles are mounted perpendicular, and check the diagonals

(see 4.6).

There is a hole in the clip profile to secure the end stop (Fig. 2).

Fig. 1a

Fig. 1b

Fig. 2

SC900

SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |10

Step 5

• Clip both lateral guides - together with the holder with zipper profile - onto the

clipprofile.

• No screws are required!

Plan view of the clip profile

and guide rail

SC900

SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |11

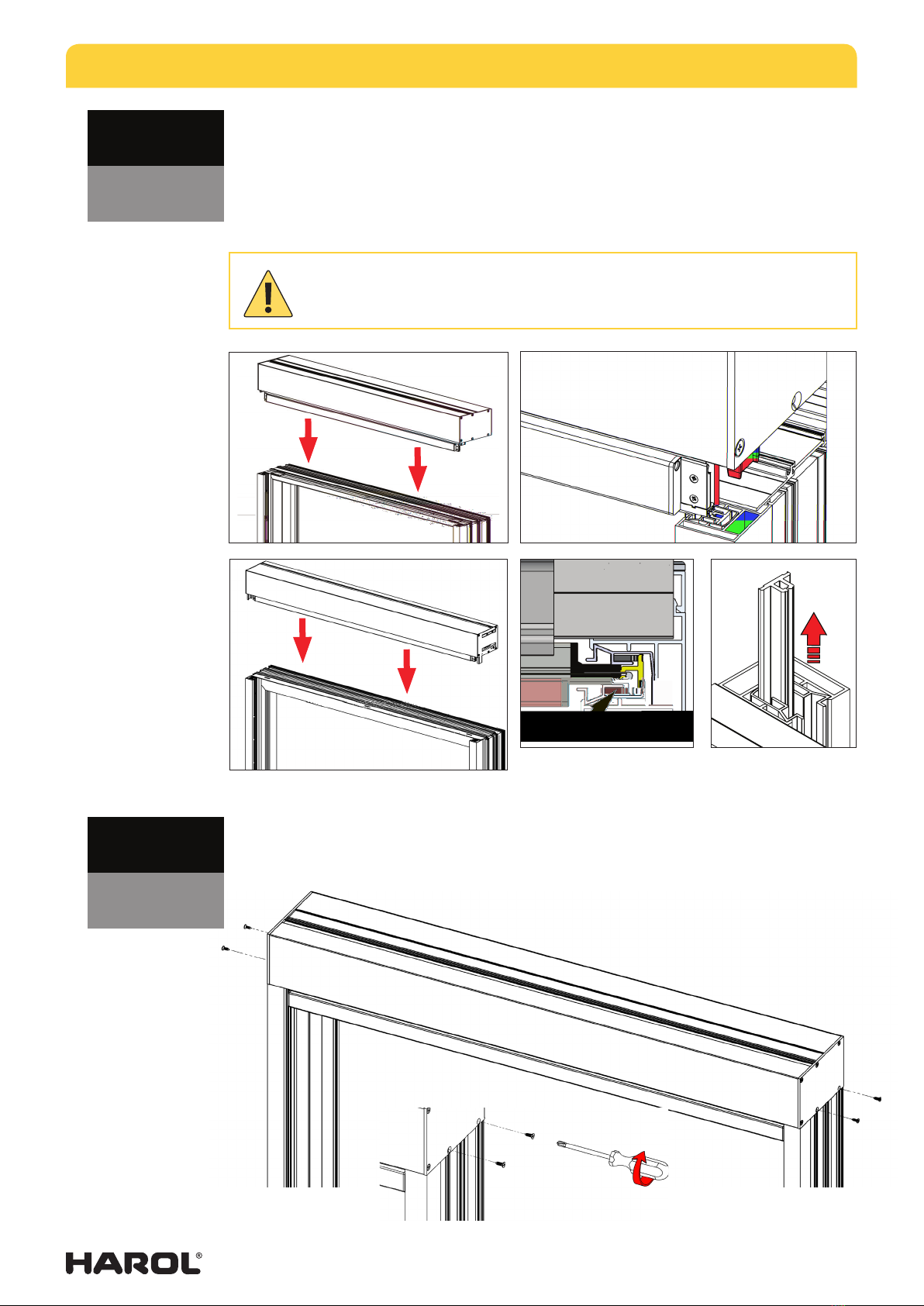

Step 6

• Place the box back on the base profile exactly as it was initially constructed (Fig. 3a-3b)

(see Step 1).

• Guide the bottom lath to the zipper guide profile, position the zipper in the zipper

guide profile and let it drop down (Fig. 5).

• To make it easier to slide the fabric zipper into the zipper profile, slide the zipper

guide upwards, so it is very slightly out of the holder (Fig. 6).

Step 7

• Screw the box back onto the base plate.

Pay attention when positioning the pin in the lateral guide and sliding the zipper

into the zipper guide (Fig. 4)! Make sure the zipper is placed correctly in the

zipper guide.

Fig. 3a

SC900 Fig. 4

Fig. 5

Fig. 6

SC900

SC910

Fig. 3b

SC910

SC900

SC910

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |12

Step 8

• Use the supplied screws to screw the bottom of the support plate to the base plate

(Fig 7).

• Position the supplied clips into the base profile and clip until fastened (Fig. 8).

• Now insert the supplied touchers for the bottom lath at approx. 100 mm from the sides

and clip to secure (Fig 9). For better accessibility lower the fabric.

• Tighten the supports with the supplied

screws (Fig 7).

Fig. 8

Fig. 7

SC900

SC910

Fig. 7

Fig. 9

Always provide a loop for

securing the motor cable.

This loop determines the

available movement of the

insert module! (Fig. 8.)

STANDARD cover for the box.

Ensure that the fabric is protected when

finishing the work!

OPTION

Complete support plate as cover for the box.

The fabric is fully protected by the

supportplate

Fig. 8

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |13

Step 9

• Place the thermal insulation blocks back in the box.

Step 10

• Close the box with the cover, push it down and secure with the appropriate clips

(seeStep 8).

Step 11 finishing profiles (optional)

• Glue down the supplied finishing profiles. One on each side console (small profiles)

and one length at the top of the box (flush with the cover profile!).

Window anchors

In order to fix the box into the wall recess, the following window anchor types can be used:

for the SC900 a minimum length of 160 mm is required.

− ALIPLAST ACVL 130 (160x38x2).

− REYNAERS window cl. Fulchs 439.119 (200x25x2) - available from Harol (optional).

Leave cover unobstructed! (SC900)

SC900

SC900

SC910

- First position the bottom (1) insulation profile and then the top one (2) (Fig. 10).

- Provide a cable wrap (loop) of approximately 20 cm in the chamber furthest

back (Fig. 9). In the event of subsequent maintenance or repair, the insert

module can be taken out of the box.

Fig. 9

1

2

SC900

Fig. 10

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |14

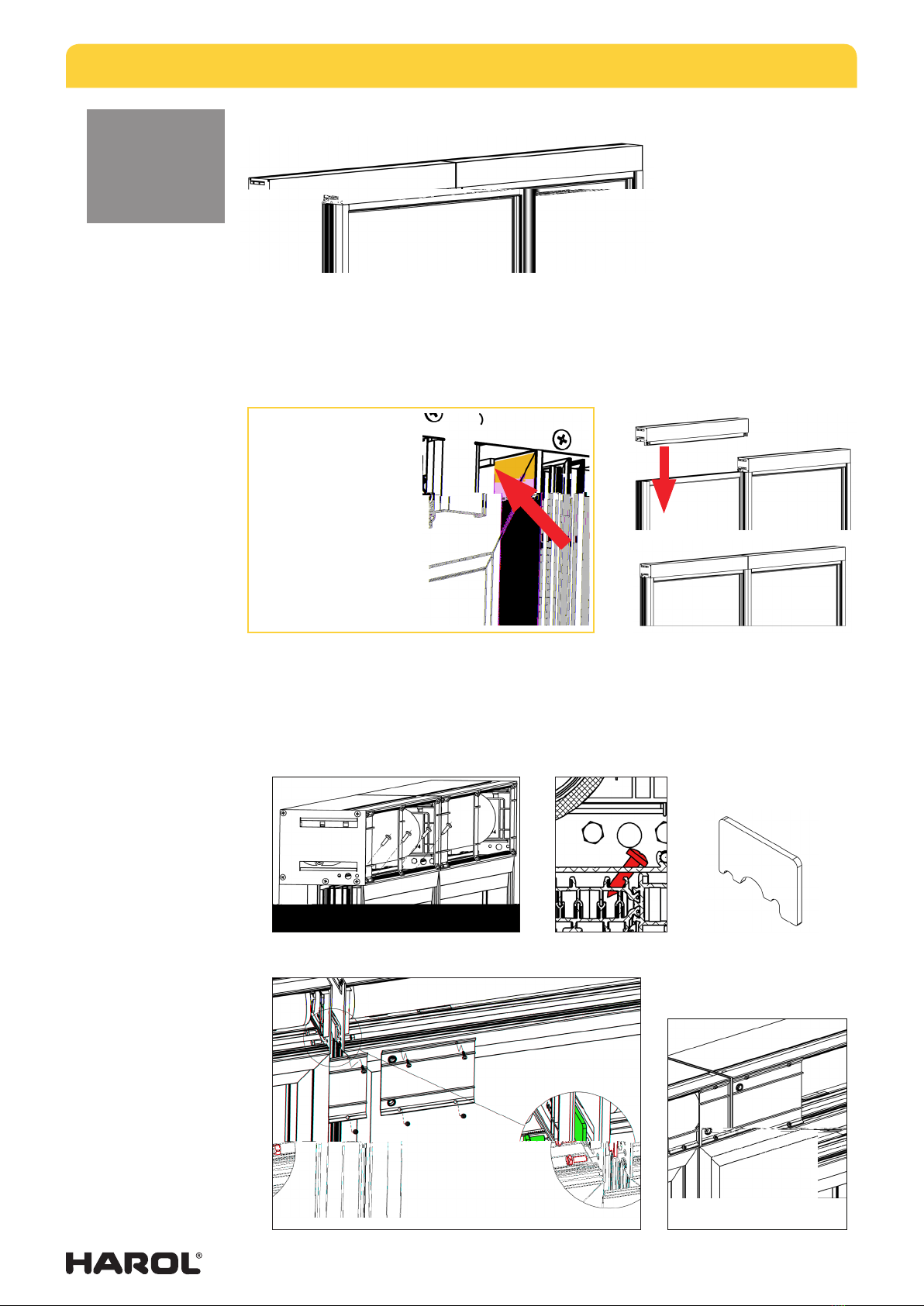

4.6 (a). Installation of two or more adjacent screens

Step 1

• Mount box uaccording to the prescribed installation procedure.

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |15

SC910

4.6 (b). Installation of two or more adjacent screens

Step 1

• Mount box uaccording to the prescribed installation procedure.

Step 3

• Position box v onto the mounted guide rails (Fig. 15), and slide the bottom lath/fabric

into the zipper guides. Screw the screen onto the window profile (Fig. 16a - 16b).

• Connect both screens using the supplied bolts and intermediate plate (Fig. 17).

Step 2

• Mount the guide rails for the second/next box vonto the window.

uv

• Finally, fit the supports plates (Fig. 18).

fig. 16b

fig. 17

fig. 17b

fig. 15

adjacent

fig. 16a

In order to determine the

correct position of the

second guide rail, secure

the second box onto

the window. The correct

position of the guide rail is

determined by the recess

in the base plate toucher.

fig. 17a

fig. 16b

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |16

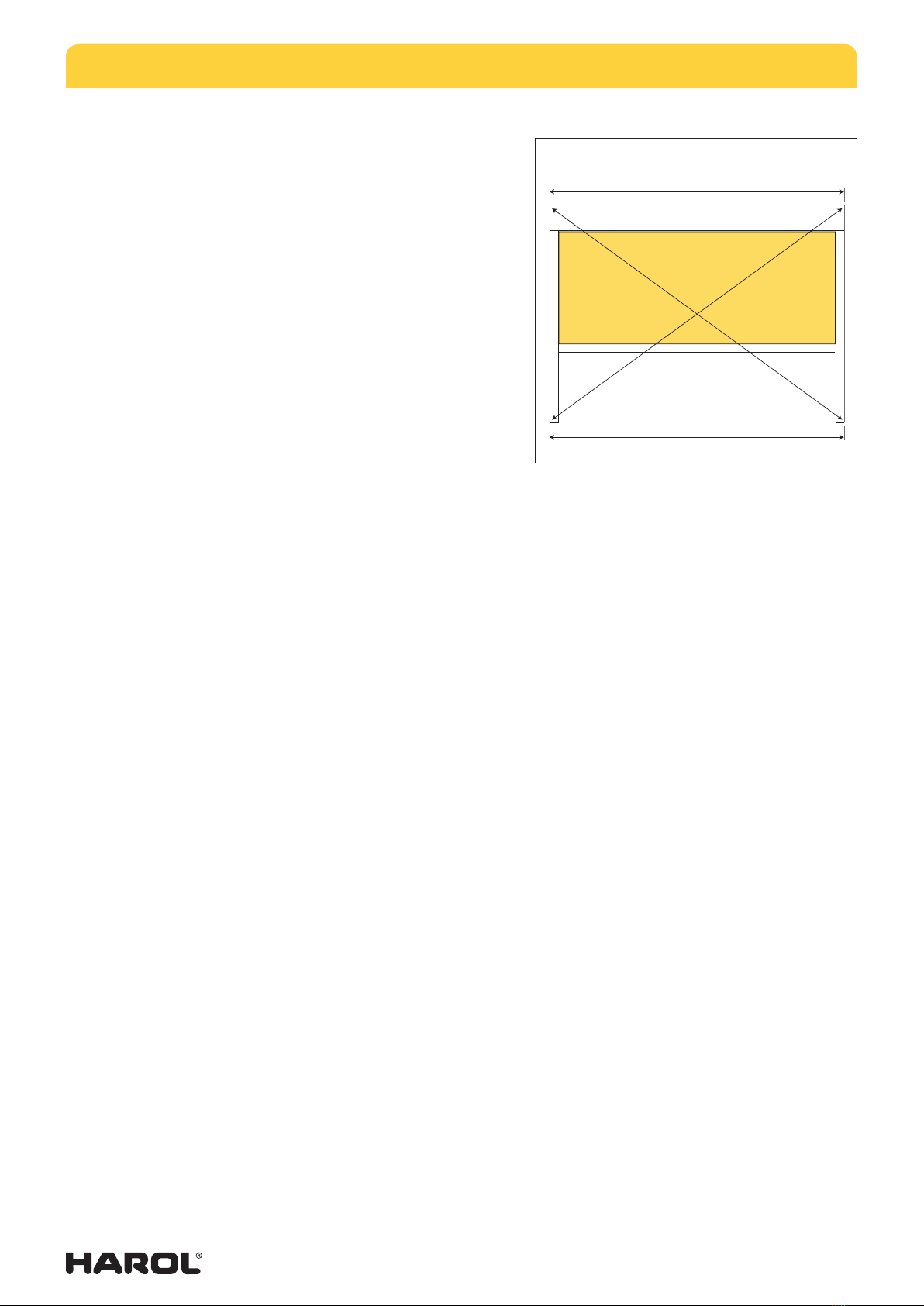

−4.7. Checking for squareness

Make sure that the screens are always dead

level and installed perfectly square. This can

be checked and corrected in one way only.

1. Check first whether the whole

assembly is mounted dead level.

2. Check whether the guide rails

run parallel and perpendicular

to the box. Measure the distance

between the guide rails exactly

and to the millimetre. Begin

directly under the box. Deviations

of more than 2 mm can lead to

hitches with the screen and/or

bottom lath and the fabric may

not hang suciently taut.

3. Next measure accurately across

the diagonals, down to the exact

millimetre.

If the box and guide rails are not correctly fitted, then the bottom lath may roll up askew

into the box and the screen cloth will have diagonal or crosswise creases.

Once the screen has been accurately positioned and fitted, the potential small openings

between guide rails and wall (box and wall) can be sealed with silicon mastic.

4.8. Checking the assembly

The assembly is checked by testing its functionality.

The fabric is lowered and rolled back up. This should happen without any hitches and there

should be no pleats when let down again.

B1= B 2and D1= D2

B2

B1

D1 D2

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |17

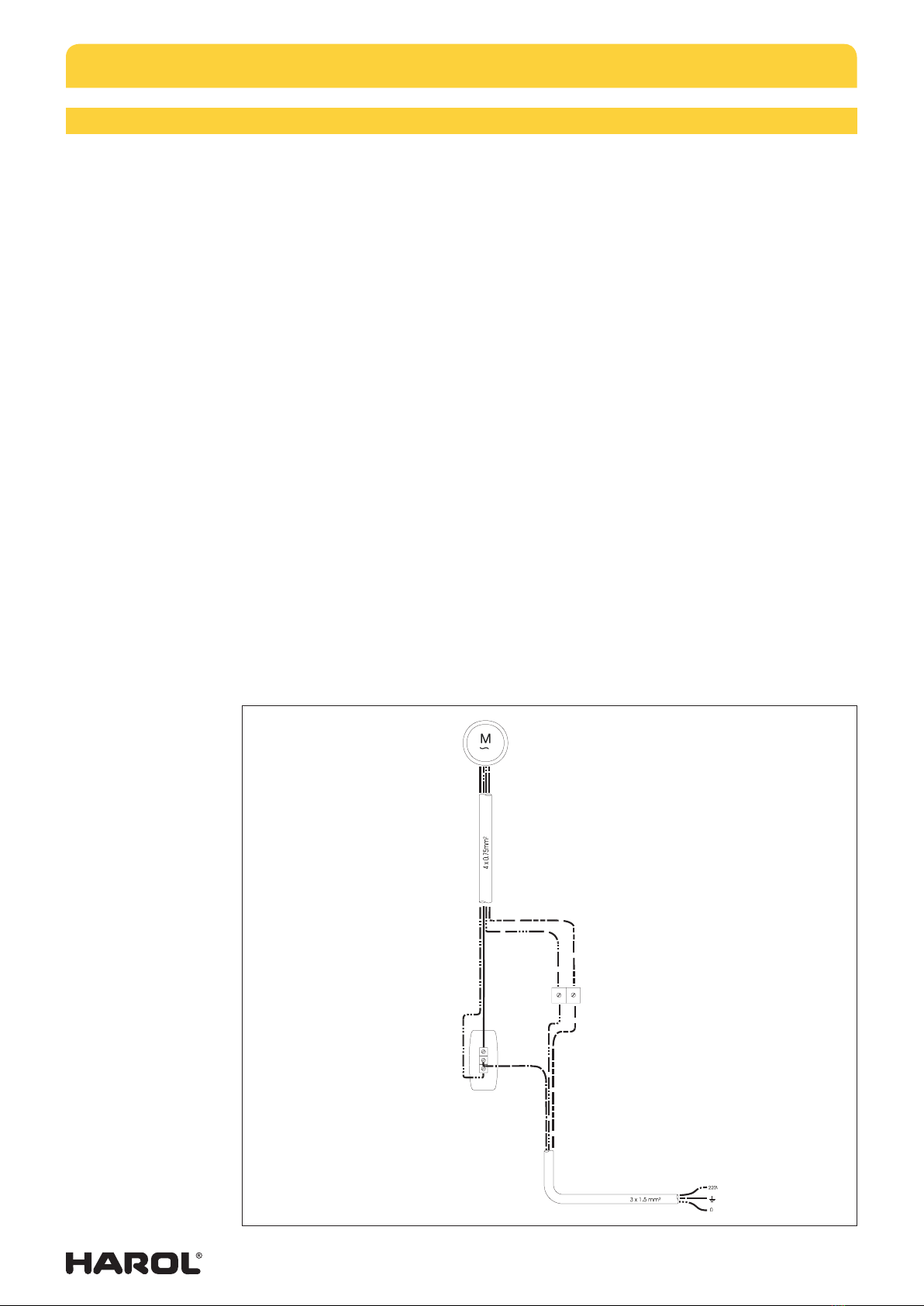

5. ELECTRICAL CONNECTIONS

Note: The connections must be carried out by a registered installer (refer to guarantee card

2.1.) Electrical installation and connection diagrams must be applied correctly, the electrical

accessories employed must comply with the current standards and/or requirements.

5.1. Connection diagram for a single pole switch

The motor has 4 wires. Yellow-green (earth), blue (neutral), brown and black (up and down

control). There should be three wires available from the mains electricity circuit. Yellow-

green (earth), blue (neutral) and phase. Connect the wires following the diagram. The phase

wire of the mains is to be connected to terminal L.

If required, reverse the brown and black wires from the motor in the switch so that the

arrows correspond to the up and down movement of the screen. The two earthing wires

are interconnected by means of separate terminals. The arrangement for the two neutral

wires is similar.

Connecting and installing the motor:

Feed the motor cable in a discreet manner into the control switch. Connect the motor

cable and the power supply to the single pole switch. See above. Interchange the brown

and black cable if necessary to follow the arrows on the switch. It is mandatory to use one

or more relay boxes when two or more motors are connected to a single switch. Refer to

diagram RI2 for making the connections.

Notes on the motor:

If the motor concerned is of the standard LT type, please continue using these instructions.

As regards the LS motor, the end positions are not set with push buttons but with adjustable

Allen key-setting pins (refer to the instructions supplied).

If it concerns an Altus RTS type, a Sunea IO type or the Altea ZIPWT, please consult the

user instructions supplied for the motor concerned.

yellow / green

brown / black

brown / black

red blue

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |18

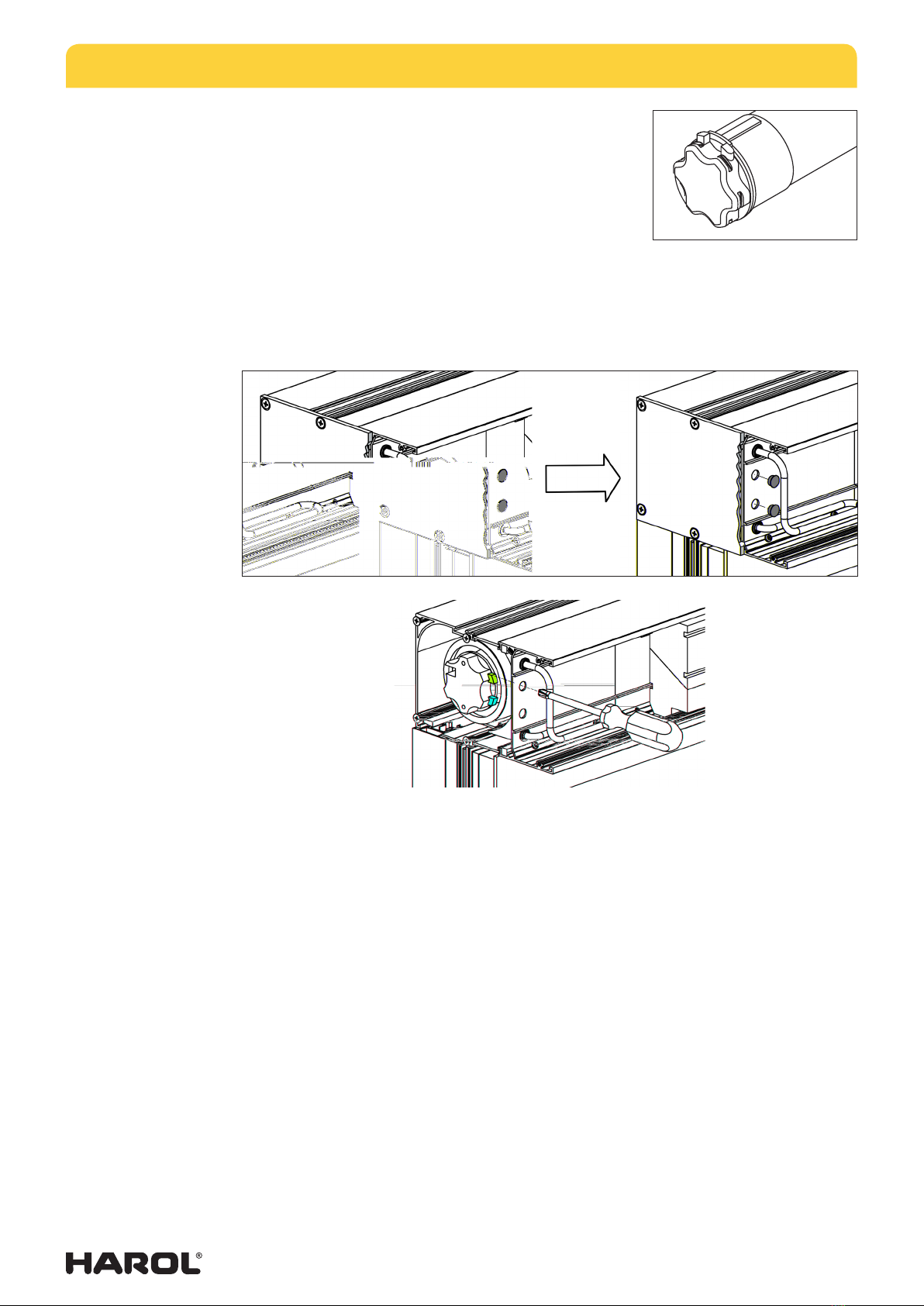

5.2. Adjusting the motor - limit switches

Temporarily connect the motor to a test cable.

On the control side of the screen, at the height of the

support plate, there is a viewing panel.

To adjust the end positions of the fabric (both top and

bottom), you can use the access holes provided in the

viewing panel. Once the plastic stops have been removed,

you can use a screwdriver to reach the motor adjusting

buttons (see Fig. 18).

If this does not have the desired result, remove the four screws to release the panel and

slide it away.

Make sure that when you replace the viewing panel, the cable does not remain in the most

front chamber. Make sure to tighten the wire.

1. Winding the motor down - Setting the bottom limit position

Let the motor wind down. Make sure that it stops at the correct point and not past the

final down position as the fabric could otherwise be rolled up in reverse and be damaged.

Themotor has not been set to any limits. Both buttons on the motor have been completely

pushed in as the factory setting (or press them both down if that is not the case). Themotor

will not stop by itself.

Let the screen wind down completely until the desired bottom position has been reached. Next

put the switch in the neutral position. Then push the white or yellow button (depending on

which side the motor is fitted), so that it rises slightly. The bottom position has now been set.

2. Running the motor up - Setting the top limit position

Now let the motor run up. Make sure that it stops in time. Just below the top limit. Nextput

the switch in the neutral position.

Then push the yellow or white button (depending on which side the motor is fitted), so

that the button rises slightly. The top position has now been set. The two limit positions

have now been set.

If it becomes necessary to reset the motor, the procedure can be repeated by simply pushing

in both buttons. By doing this the existing settings are deleted and the new settings can

be made following the instructions from point 1.

Fig. 18

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |19

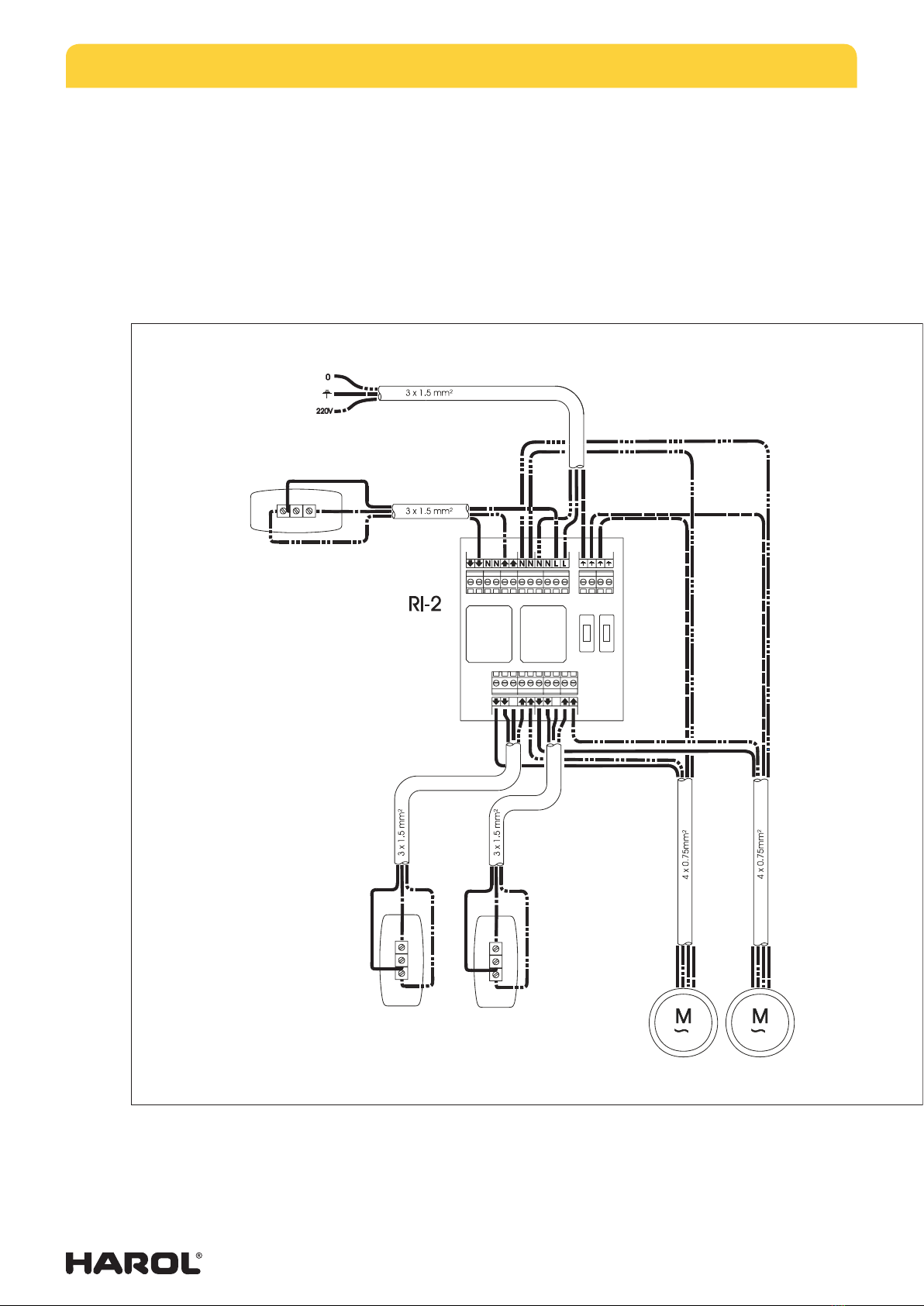

Why use an RI2 relay box?

If several LT or LS motors are operated using the same switch, you must always use a relay

box. If relay boxes are not used, the integral limit switches will soon burn out due to the

high inductive and capacitive voltages which are mutually generated.

A useful tip: Always use the relay boxes and switches supplied by us for single operation

of 2 or more motors. The same applies to an automatic wind/sun screen.

yellow / green

brown / black

red

blue

yellow / green

blue

INSTALLATION INSTRUCTIONS SURFACE-MOUNTED SCREEN SC900 - SC910

03/15 |20

6. TROUBLESHOOTING AND REPAIRS

6.1. The screen will not roll up or down.

• The internal limit switch of the motor has not been activated in any direction. Pressboth

setting buttons and proceed with the setting of the end positions.

• Wire making poor contact when motor cable is extended. Check connections.

• Motor has overheated and runs in thermal safety mode. Leave 1/2 hour to cool down.

• Faulty adjustment of limit switches.

• No current supplied to switch. Check with a voltage meter.

• Motor is incorrectly connected. Check the connection diagram.

6.2. The motor hums.

• Check whether everything can turn freely in both directions. Is anything blocking

themotor?

• Capacitor in motor is broken (as a result of faulty connection to the motor).

• Motor is incorrectly connected, check the correct connection of the motor cables to

the switch using the diagram. A phase wire (brown or black) has been interchanged

with the neutral wire (blue). The motor will run in one direction, but in the other

direction it will just hum.

6.3. The motor does not stop in time.

• Faulty adjustment of limit switches.

6.4. Bottom lath is slanted at the top.

• The guide rails run parallel but not perpendicular to the box. First check whether

thebox is dead level, then measure along the diagonals and correct the installation.

6.5. Bottom lath drops out of the lateral guides

• Check if the end stops are fitted at the bottom of the guide rails.

6.6. The fabric tension is too slack; the bottom lath sticks or shudders when the

screen is lowered or raised.

• Check if the guide rails are aligned. The bottom lath is snug inside the guide rails.

• The zipper is not in the zipper guide profile.

• The bottom lath is not suspended properly from the fabric but rests for instance on the

window sill instead.

• The fabric is not positioned correctly in the fabric guide profile.

• Fabric is too wide.

• Lower end switch of the motor is too low or too loosely set.

6.7. Folds and waves in the fabric.

• Box and/or guide rail are not level. Position box and guide rails level.

6.8. The direction of the motor's rotation does not match the arrows on the switch.

• Swap the brown and black cable in the switch.

6.9. The fabric does not stop and roll up again.

• Use a relay box (RI2).

This manual suits for next models

1

Table of contents

Other Harol Tent manuals

Popular Tent manuals by other brands

Suncast

Suncast GS8500 owner's manual

PartySpace

PartySpace Casa Africa SAVANNA LODGE RONDE... manual

Oxybul

Oxybul 303334 quick start guide

Creative Play

Creative Play OCTAVIA OS117 installation instructions

Campvalley

Campvalley WMT-1010A Setup instructions

Rocktrail

Rocktrail POP-UP TENT 2.1 Operation and safety notes