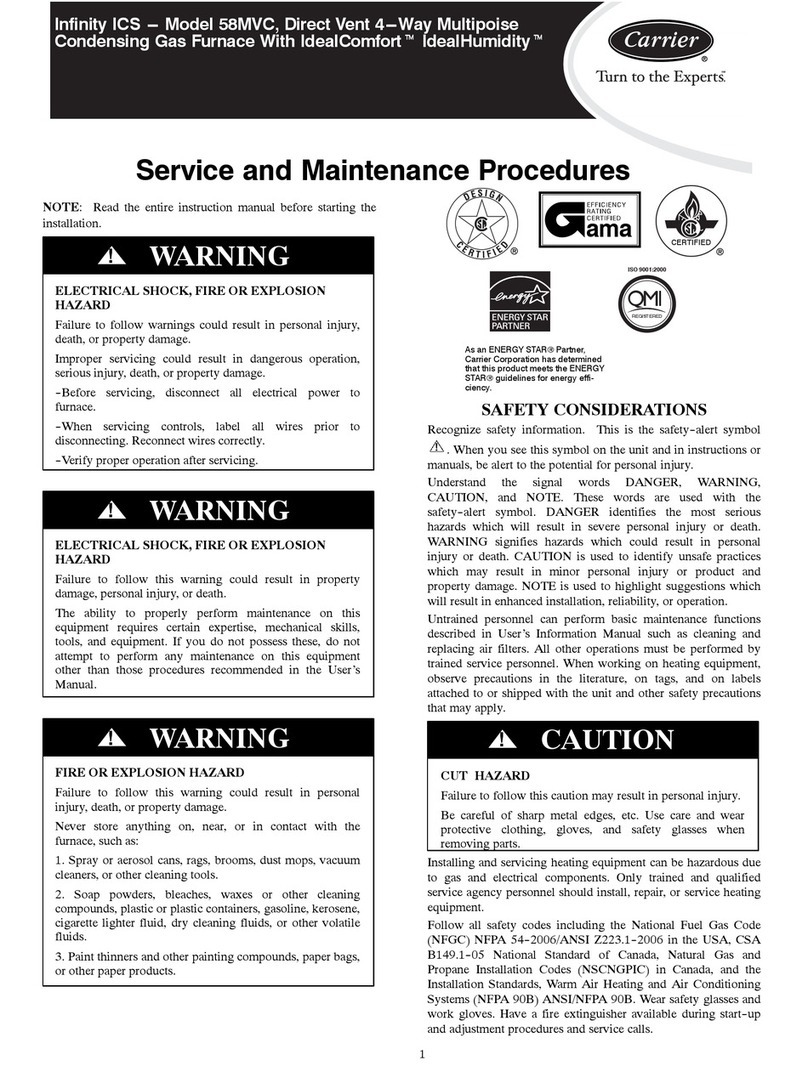

3 Safety Guidelines

•Operate the instrument in room temperatures

between 5-50°C (41-122°F). Allow sufficient

air circulation by leaving at least 6 inches of

space between the furnace and nearby ob-

jects.Nothing should be placed over the top of

the furnace.The furnace should not be placed

under cabinets or tables. Extreme tempera-

turescanbegeneratedoutthetopofthewell.If

the furnace is equipped with cooling coils, use

coldwatercirculationwhenthefurnaceisused

above 600°C. (For specifics see Section 4.5

Plumbing.)

•The furnace is a precise instrument. Although

it has been designed for optimum durability

and trouble free operation, it must be handled

with care.The instrument should not be oper-

ated in wet, oily, dusty or dirty environments.

Keep the well of the instrument free of any for-

eign matter. Do not operate near flammable

materials.

•TheModel9115Furnaceutilizeshighvoltages

and currents to create high temperatures.

Caution should always be maintained during

installation and use of this instrument to pre-

vent electrical shock and burns.Fire can be a

hazard for any device that produces high tem-

peratures. Proper care and installation must

be maintained.Responsible use of this instru-

ment will result in safe operation.

•Do not use fluids to clean out the well.

•Thefurnace generates extremetemperatures.

Precautionsmustbetakentopreventpersonal

injuryordamagetoobjects.Probesmaybeex-

tremely hot when removed from the furnace.

Cautiously handle probes to prevent personal

injury. Carefully place probes on a heat resis-

tant surface or rack until they are at room tem-

perature. SPRT’s should be placed in an

annealing furnace if removed at temperatures

greater than 500°C.

•UseonlygroundedACmains supplyofthe ap-

propriate voltage to power the instrument.The

furnace requires 12 amps at 230V (±10%),

50/60 Hz.

•Before initial use, after transport, and anytime

the furnace has not been energized for more

than 7 days, the instrument needs to be ener-

gized for a “dry-out” period of 1-2 hours before

it can be assumed to meet all of the safety re-

quirements of the IEC 1010-1.

•The instrument is equipped with operator ac-

cessible system fuses. If a fuse blows, it may

be due to a power surge or failure of a compo-

nent.Replacethefuseonce.Ifthefuseblowsa

second time, it is likely caused by failure of a

component.If this occurs, contact Hart Scien-

tific Customer Service. Always replace the

fuse with one of the same rating, voltage, and

type. Never replace the fuse with one of a

higher current rating.

•If a main supply power fluctuation occurs, im-

mediately turn off the furnace. Power bumps

from brown-outs and black-outs can damage

the instrument. Wait until the power has stabi-

lized before re-energizing the furnace.

•The unit is not equipped with wheels.It is con-

sideredtobepermanentlysetonceithasbeen

installed. If the unit must be moved for some

reason, be sure that the fixed point cell has

beenremovedbefore movingthe furnace.Any

movement of the furnace with the cell inside

can damage the cell.The unit is not designed

tobeliftedorcarried.Ifitmustbepickedup,itis

advisable that two people pick the unit up by

placingtheirhandsundertheunitandcarefully

lifting at the same time. Never move the fur-

nace if it is hot.

•Air circulated through the gap surrounding the

furnace core keeps the chassis cool.DO NOT

SHUT OFF THE FURNACE WHILE AT HIGH

TEMPERATURES. The fan will turn off allow-

ing the chassis to become hot.Alternatively, if

used, the cooling water should remain on until

the furnace is cool.

•Oncethe unithas been takentohigh tempera-

tures (over 800°C), it takes days for the unit to

cool completely.

•CAUTION

In the unlikely event that the heat pipe should

leak, do not attempt to put out the fire with wa-

ter or chemical fire extinguishers.Smother the

fire with dry soda ash in accordance with the

MSDS sheets at the end of this manual.

Model 9115 Manual Rev. 761301 13