1

Contents

Appreciation Letter To Users......................................................................................................2

Limited Warranty............................................................................................................................ 3

General Safety Rules.....................................................................................................................4

Introduction......................................................................................................................................5

Features............................................................................................................................................ 5

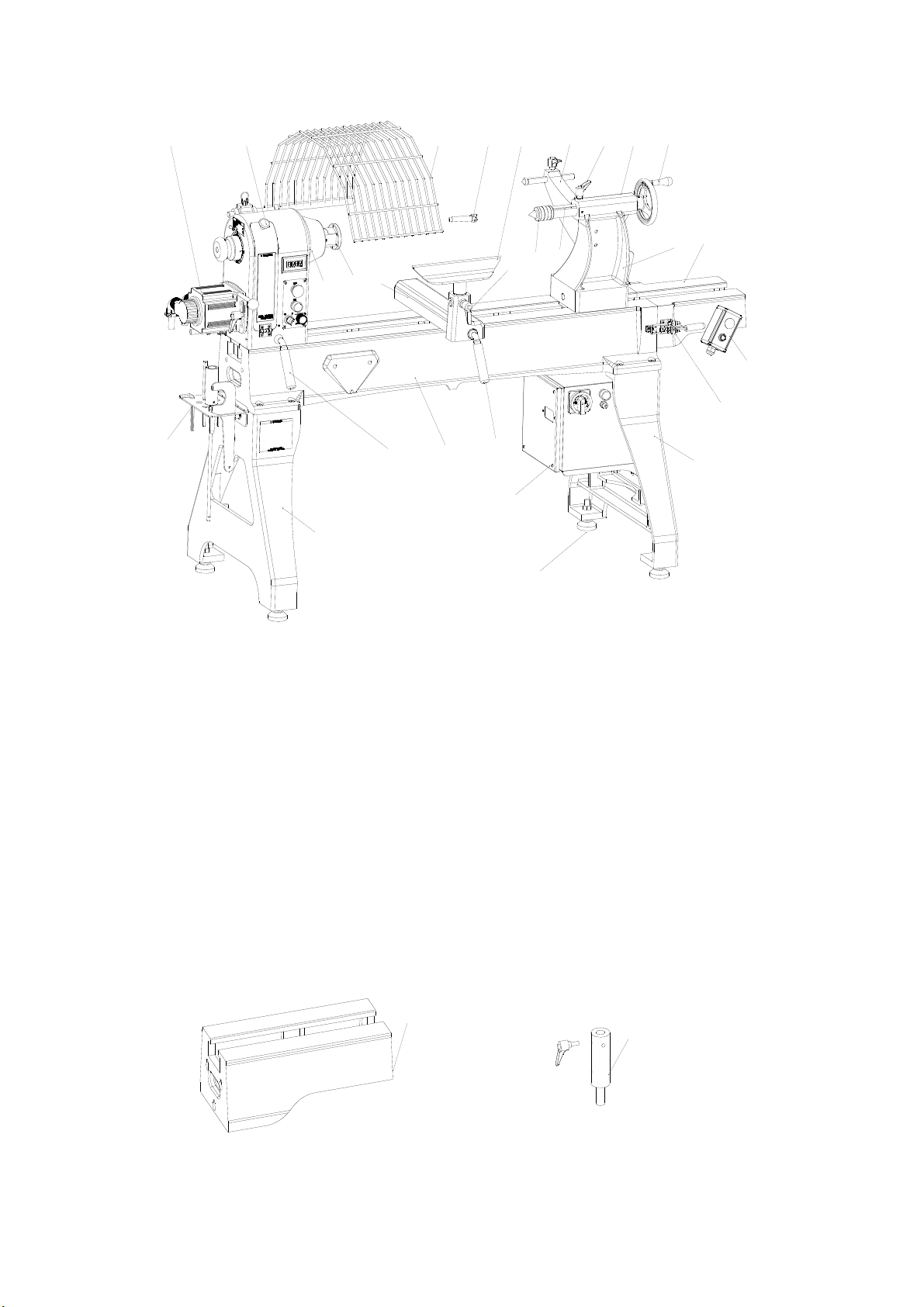

Features Identification.................................................................................................................. 6

Optional Accessories.................................................................................................................... 6

Specifications..................................................................................................................................7

Power Supply.................................................................................................................................. 7

Assembling and Adjustment.......................................................................................................8

Base........................................................................................................................................... 8

Unpacking................................................................................................................................8

Packing Contents................................................................................................................... 8

Legs Installation..................................................................................................................... 9

Tool Storage Bracket............................................................................................................ 9

Comparator Brackets..........................................................................................................10

Spindle Shield....................................................................................................................... 10

12”Swing Away Extension Bed..................................................................................... 11

20”Extension Bed (Optional)...........................................................................................12

Operation........................................................................................................................................13

Control Panel.........................................................................................................................13

Speed Range Adjustment.................................................................................................. 14

Recommended Turning Speed Table............................................................................. 14

Tool Rest Base (Banjo).......................................................................................................15

Tool Rest................................................................................................................................15

HeadStock and TailStock...................................................................................................15

Spur Centers Installation/Removing.............................................................................. 15

Face Plate Installation and Removing........................................................................... 16

Tailstock Quill....................................................................................................................... 16

Live Centers Installation/Removing............................................................................... 16

General Maintenance.................................................................................................................. 17

Trouble Shooting......................................................................................................................... 18

Wiring Diagram............................................................................................................................. 19

Inspection Certificate..................................................................................................................20

Exploded View and Parts List...................................................................................................21