3

Introductions

Tools express thoughts, and serve as the extension of your hands. An ideal tool should

perform readily as a connection between the hand and the mind; additionally, it ought to

be pleasurable, enlightening and beautiful.

The Harvey team never stops pursuing excellence to enhance a user’s optimal working

experience. After developing the Harvey Turbo T-50/60 heavy duty woodworking lathes,

the Harvey team then spent over two years working to develop a smaller lathe ideally

sized to suit the demands of serious hobbyists and home workshops. Now we are glad to

announce that our efforts have been achieved: the Turbo T-40 Lathe is the result.

In order to overcome long known issues of insufficient torque and “speed loss” on most

small lathes on the market, for the first time in the industry, Harvey Industries has

introduced the Industrial Servo Motor (ISM) system and integrated it in with the T-40

spindle drive.

The exterior and machined surfaces are engineered and crafted with our highest

standards to enhance a user’s experience. The Turbo T-40 lathe is crafted with premium

grade cast iron and machined to the highest tolerances. The guideways are precision

ground for smooth operation. The surface of the T-40 lathe is coated with a high gloss,

stoved varnish.

The T-40 features a 360mm (14”) maximum swing, and a 625mm (24”) distance between

centers. The spindle head can rotate 90° for larger faceplate turning. In addition, 80KG

(178 lbs.) of deadweight makes the T-40 the heaviest lathe in its league. The Harvey

engineering and manufacturing teams sincerely hope the new Turbo T-40 will make a

greatly enjoyable tool for turners of all ages and skill levels.

Features

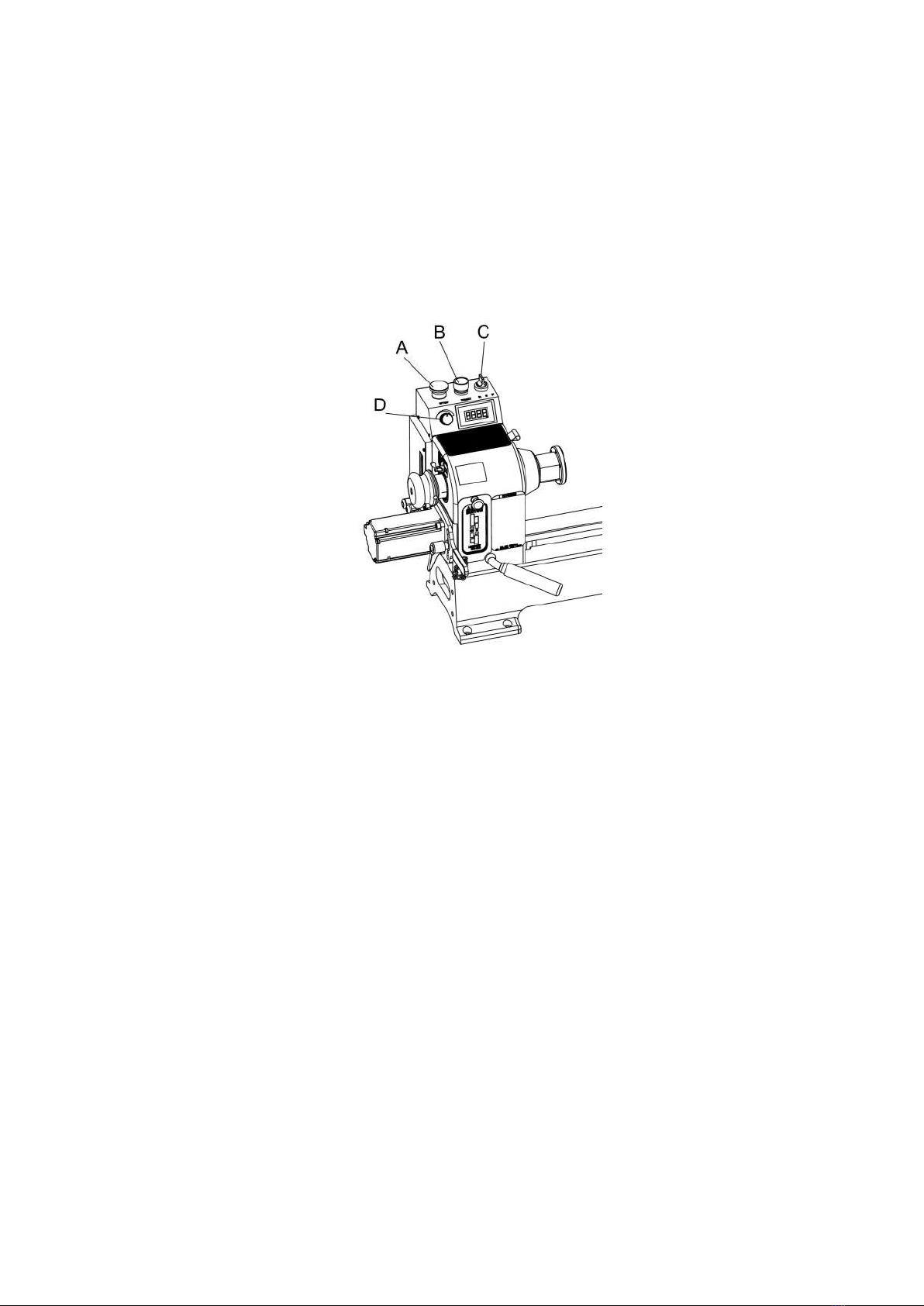

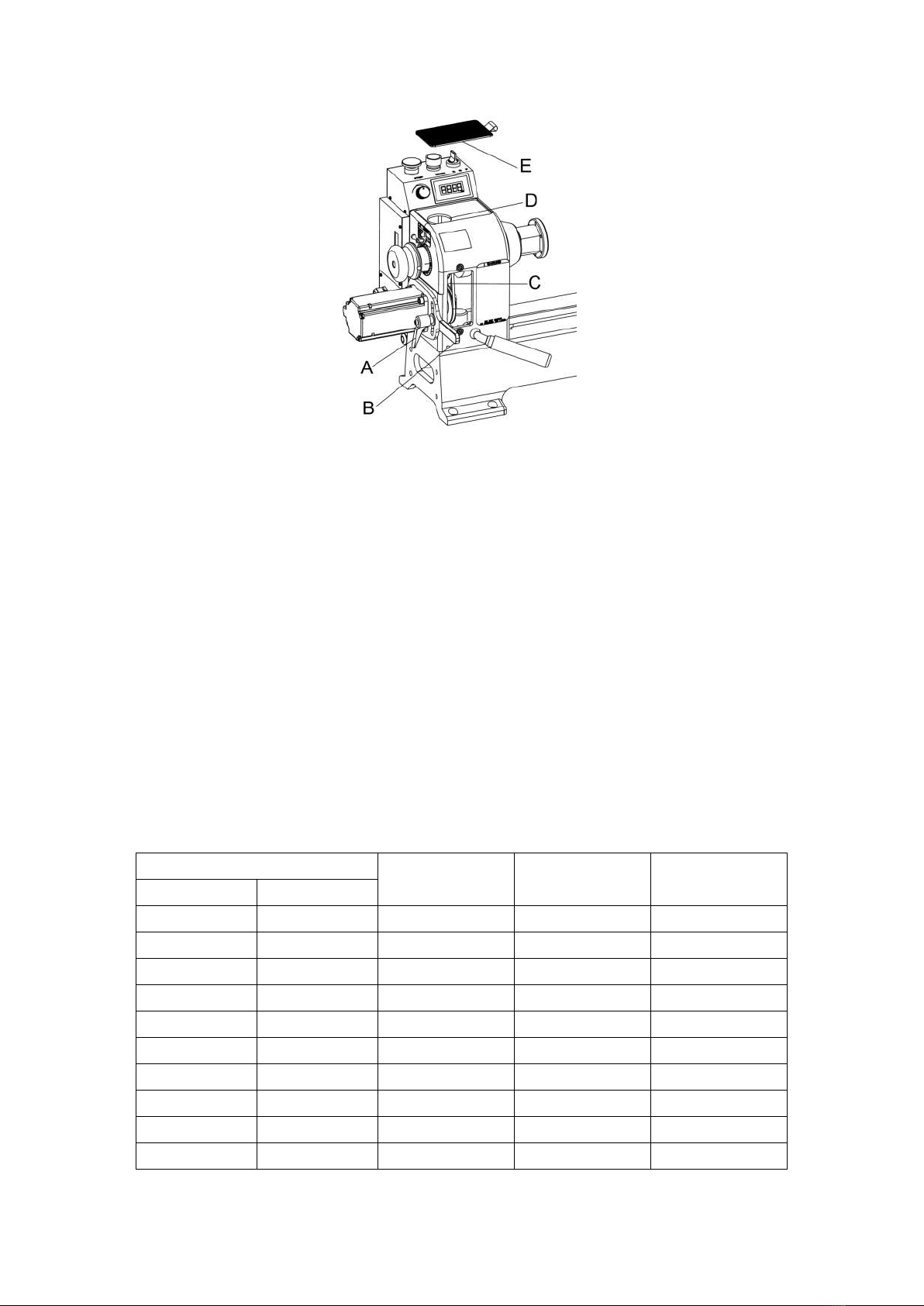

Industrial Servo Motor drive system with 300% overload capacity

Quick spindle stop (less than 1 second)

Forward/Reverse spindle rotation

Variable Speed, maximum 4300rpm

Swivel headstock to 90°(can be positioned from 0-90 degrees) for faceplate turning

Rigid structure with premium cast iron

Precision machined and ground guide ways

Forged and ground alloy steel spindle with 3 oversized bearings

Cast steel tool rest with edge treated to guard against wear

Oversized solid tool slide for smooth operation

Built-in 24 position indexing spindle with quick adjusting mechanism

High gloss baked enamel surface treatment