HARWI ORCA Series User manual

MANUAL

ORCA

Harwi Holland BV

Lage Dijk 28

5705 BZ Hel ond

the Netherlands

Tel. + 31 (0)492 543355

Fax + 31 (0)492 522305

2

Orca Eng. 9-2004

3

CONTENTS

GENERAL SAFETY REGULATIONS.........................................................................................6

GENERAL INFORMATION ....................................................................................................7

TECHNICAL DATA...............................................................................................................8

TRANSPORT FRAME WITH CRANE/FORKLIFTRUCK ...............................................................9

TRANSPORT BEAM WITH CRANE/FORKLIFTTRUCK ............................................................. 10

SETTING UP THE MACHINE............................................................................................... 11

POSITIONING VERTICAL SLIDE WAY ................................................................................. 12

ADJUSTING THE FRAME....................................................................................................13

ADJUSTING THE FRAME....................................................................................................14

CONNECTING TO THE ELECTRICITY SUPPLY......................................................................15

DIRECTION ROTATION OF THE MAIN SAW-BLADE ............................................................. 16

ADJUSTING THE MEASURE FOR VERTICAL CUTS ................................................................17

ADJUSTING THE MEASURE FOR HORIZONTAL CUTS...........................................................18

VERTICAL CUTTING.......................................................................................................... 19

HORIZONTAL CUTTING ....................................................................................................20

REITERATION STOP ......................................................................................................... 21

STOPS FOR HORIZONTAL CUTS ........................................................................................22

ADJUSTING THE RIVING KNIFE .........................................................................................23

FITTING THE MAIN SAW-BLADE........................................................................................ 24

CLEANING ....................................................................................................................... 25

CHECK BRUSHES ON HORIZONTAL TRACKS .......................................................................26

SMOOTHENING MIDWAY FENCES...................................................................................... 27

SMOOTHENING THE BOTTOM SUPPORT ............................................................................28

ADJUSTING MEASURE ......................................................................................................29

ADJUSTING MEASURE FOR HORIZONTAL CUTTING ............................................................ 30

MALFUNCTIONS ...............................................................................................................31

OPERATING THE SCORING BLADE (OPTIONAL)..........................................................32

OPERATING THE SCORING BLADE (OPTIONAL)..........................................................33

TRANSPORT ROLLERS (OPTIONAL)....................................................... 34

DIGITAL READ OUT (OPTIONAL) ......................................................35

DIGITAL READ OUT (OPTIONAL) ......................................................36

DIGITAL READ OUT (OPTIONAL) ......................................................37

DIGITAL READ OUT (OPTIONAL) .................................................... 38

EXPLODED VIEW TYPE ORCA ............................................................................................ 39

PARTS LIST TYPE ORCA.................................................................................................... 40

EXPLODED VIEW FRAME................................................................................................... 41

PARTS LIST FRAME ..........................................................................................................42

PARTS LIST FRAME ..........................................................................................................43

EXPLODED VIEW ALUMINIUM BACK SUPPORT....................................................................44

PARTS LIST ALUMINIUM BACK SUPPORT ...........................................................................45

EXPLODED VIEW TRK-SYSTEM-L (OPTIONAL)................................................................. 46

PARTS LIST TRK-SYSTEM-L (OPTIONAL) ......................................................................47

EXPLODED VIEW TRK-SYSTEM-R (OPTIONAL) ................................................................ 48

PARTS LIST TRK-SYSTEM-R (OPTIONAL).......................................................................49

EXPLODED VIEW MIDWAY FENCE...................................................................................... 50

PARTS LIST MIDWAY FENCE .............................................................................................51

4

CONTENTS

EXPLODED VIEW TRANSPORT ROLLERS (OPTIONAL).......................................................... 52

PARTS LIST TRANSPORT ROLLERS (OPTIONAL)..............................................................53

EXPLODED VIEW LENGTH STOP ........................................................................................54

PARTS LIST LENGTH STOP................................................................................................ 55

EXPLODED VIEW VERTICAL SLIDEWAY..............................................................................56

PARTS LIST VERTICAL SLIDE WAY .................................................................................... 57

PARTS LIST VERTICAL SLIDEWAY .....................................................................................58

EXPLODED VIEW STOPS FOR HORIZONTAL CUTS...............................................................59

PARTS LIST STOPS FOR HORIZONTAL CUTS ...................................................................... 60

EXPLODED VIEW HINGE FENCE (OPTIONAL) .................................................................. 61

PARTS LIST HINGE FENCE (OPTIONAL)........................................................................62

EXPLODED VIEW EXTRACTION PIPE.................................................................................. 63

PARTS LIST EXTRACTION PIPE.......................................................................................... 64

EXPLODED VIEW MOTOR CARRIAGE..................................................................................65

PARTS LIST MOTOR CARRIAGE ......................................................................................... 66

EXPLODED VIEW OPERATING SYSTEM FENCE ....................................................................67

PARTS LIST OPERATING SYSTEM FENCE (OPTIONAL).........................................................68

EXPLODED VIEW REITERATION STOP................................................................................ 69

PARTS LIST REITERATION STOP .......................................................................................70

EXPLODED VIEW HOUSING............................................................................................... 71

PARTS LIST HOUSING ...................................................................................................... 72

PARTS LIST HOUSING ...................................................................................................... 73

PARTS LIST HOUSING ...................................................................................................... 74

EXPLODED VIEW SPINDLE WITHOUT SCORING UNIT ......................................................... 75

EXPLODED VIEW SPINDLE WITH SCORING UNIT (OPTIONAL).............................................76

PARTS LIST SPINDLE WITHOUT SCORING UNIT.................................................................77

PARTS LIST SPINDLE WITH SCORING UNIT (OPTIONAL) ....................................................78

PARTS LIST SPINDLE WITH SCORING UNIT .......................................................................79

5

APPLIANCES

The Orca vertical panel saws are only to be

used for cutting plastics, wood and wood-like

panels (e.g. chipboard, block board, MDF

etc.)

Maxi u panel sizes:

- for type Orca 1850

4,3 * 1,85 * 0,060 eter

-for type Orca 2150

4,3 * 2,15* 0,060 eter

Cutting of other aterials with the standard

saw-blade is prohibited. Cutting other

aterials with a special saw-blade only with

per ission of anufacturer.

All other appliances except for the above are

i proper use of the achine and therefore

prohibited. The producer cannot be held

responsible for da age as a result of

i proper use. Da age will be recovered fro

the user.

The machine may not be operated, used

or maintained by persons not

acquainted with the dangers o the

machine.

Permission or operating, using and

maintaining the machine have to be

clearly described by a person or persons

responsible within the organisation.

Maintenance has to be perfor ed by the

anufacturer or custo er service.

One has to be acquainted and co ply with

the country's applicable safety regulations.

Only original Harwi parts are to be used.

We cannot give warranty or be held

responsible for da age caused by using non-

original Harwi parts.

The anufacturer cannot be held responsible

for da age caused by changes ade to the

achine by the user.

Re aining risks:

If the achine is co pletely used according

to all safety regulations there still will re ain

so e risks:

- Touching o the saw-blade with the

sawing area.

- Touching o the saw-blade when the

lid is opened

- Breaking o the saw-blade or parts o

the saw-blade hurtling out o the

guard.

- Touching o parts under voltage while

junction box or switch is opened.

- Damage to the hearing by constant

use o the machine without ear

protection.

- Throw out o harm ul dusts or vapours.

6

GENERAL SAFETY REGULATIONS

Harwi Holland B.V. has bestowed great care

on co piling this anual. Read the co plete

anual carefully before operating the

achine.

Person under the age of 18 are not allowed

to work on or with circular sawing achines.

Except for a training progra on a legal

basis.

The achine ay only be operated by

educated personnel or under supervision of

educated personnel.

To avoid touching with rotating saw-blades

ake sure that:

Clothing fits tightly to the body

One works with closed fingers

No rings or other jewellery are worn.

A hairnet is used by long hair.

Be careful when changing the saw-blades.

They are sharp and cause injuries.

Do not re ove woodchips when the saw-

blade is running. Stop the achine first.

Broken saw-blades or defor ed blades are

not to be used. Neither are HSS blades

The applied saw-blade is to be used and

sharpened according to the directions of the

anufacturer.

Sharpening only by co petent crafts en.

Stick to ax. ad issible r.p. . entioned on

the blade. Preferably use noise-reduced saw-

blades.

Flexible hoses of the dust extractor have to

be fro a highly infla able quality

(according to DIN 4102).

The safety guard and other safety

equip ent ay not be re oved or put out

of order.

The pressure pad ay not be cla ped. The

riving knife has to be used every ti e except

for drop-in cuts. The riving knife has to be

adjusted properly.

Asse bling or repairs are only to be

perfor ed if the achine cannot be

switched on. The switch or the ain switch

are to be switched off and locked with for

instance a padlock.

Repairs to the electricity supply are only to

be executed by skilled crafts en. Always

disconnect the achine fro the ains

supply.

When leaving the working area ake sure

that the achine cannot be switched on by

inco petent persons.

It is obligatory to wear a dust- ask, ear

protection and safety glasses.

Take care of a clean working area.

The achine has to be lighted. When using

strip lighting take into account the

stroboscopic effect. A rotating saw-blade

see s to be standing still

7

GENERAL INFORMATION

MANUFACTURER

HARWI Holland B.V.

Lage Dijk 28

5705 BZ Hel ond, the Netherlands

Tel: +31 (0)492-543355

Fax: +31 (0)492-522305

E ail: info@harwi.nl

MACHINE

Vertical panel saw Orca

Type:.....................................................

Machine nu ber:...................................

Manufactured:.......................................

EU DECLARATION OF CONFORMITY FOR MACHINERY

(according to Annex II A of the Machinery Directive)

We, HARWI Holland B.V. Lage Dijk 28, 5705 BZ Hel ond, the Netherlands herewith declare, on

our own responsibility, that the product entioned above, which this declaration refers to, is in

confor ity with the following standards;

EG Machine Directive 98/37/EG, changed in 98/79/EG.

EG Low Voltage Directive 73/23/EWG, changed in 93/68/EWG.

EG-EMV Directive 89/336/EWG, changed in 93/68/EWG

Hel ond, the Netherlands,

Date…………………………………………………………………..(signature)

Quality control………………………..…………………………..(na e)

8

TECHNICAL DATA

MEASURES AND WEIGHTS

Type Orca 1850

2150

Length of cut 4300

4300

Height of cut 1850

2150

Depth of cut 60

60

Speed ain blade rp 5000

5000

Speed scoring blade (optional) rp 13000

13000

Dia eter ain blade Ø 250

250

Dia eter scoring blade (optional) Ø 70

70

Motor power kW 4

4

hp 4

4

Voltage V 400

400

Machine-di ensions:

Length 5300

5300

Depth 1400

1400

Height 2700

3000

Weight kg 600

640

NOISE INFORMATION

Used saw-blade:

A-weighed Equivalent Continuous Noise pressure

Idle 80.7 dB(A)

Loaded 83.3 dB(A)

Measuring perfor ed according to DIN 45635 part 1659. Measured when cutting chipboard

thickness 18 , length 2 eter. Safe deviation can be approx. 3 db(A).

The above entioned values are radiated noise pressures and not necessarily noise pressures

to work safely with this achine. Supple entary easures for ear protection can be

necessary. The following can be of influence:

duration of operations

working area

other noises

Maxi u value ay vary per country. Above infor ation can be used for better valuation of

dangers and risks subsequent to using this achine.

9

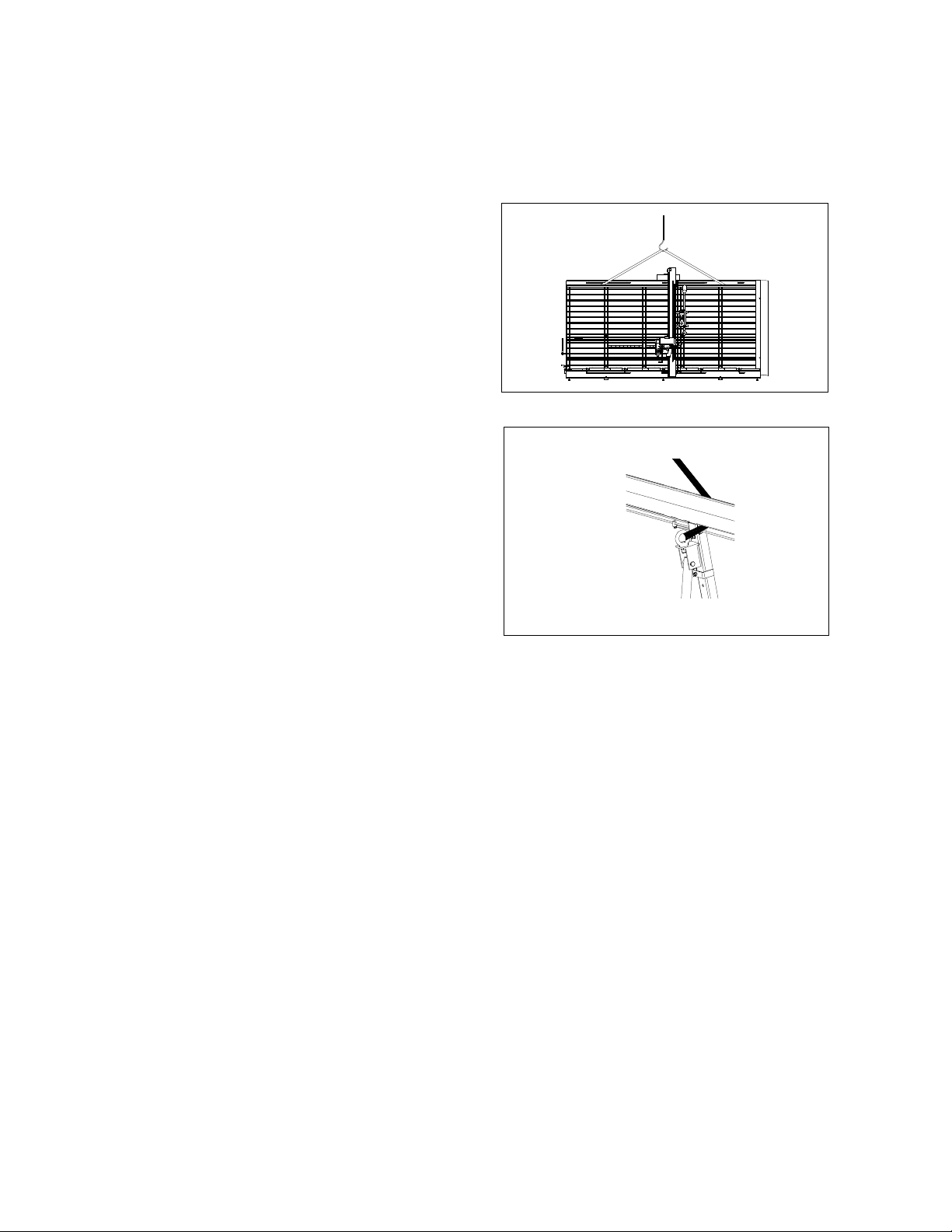

TRANSPORT FRAME WITH CRANE/FORKLIFTRUCK

The rame may only be li ted with the

special cask grips (see ig. 1 and 2)

Recommended carrying capacity o

crane or orkli t

truck:…………….........1000 Kgs.

The fra e ay only be loosened fro the

slings if it is stable on the floor.

The machine may only be installed by

skilled cra tsmen.

Fig. 1

Fig. 2

10

TRANSPORT BEAM WITH CRANE/FORKLIFTTRUCK

The sideway may only be li ted with

the special cask grips (see ig. 3 and 4).

Recommended carrying capacity o

crane or orkli t

truck:……………………………..1000 kgs.

The slide way ay only be lifted with the

special cask grip on the topside of the slide

way.

The vertical slide way ay only be placed on

the fra e after securing the achine to a

flat and solid floor.

The slide way may only be placed on

the rame by skilled cra tsmen.

(See chapter: Positioning vertical slide way).

Fig. 3

Fig. 4

11

SETTING UP THE MACHINE

SETTING UP

1 Place the achine on a flat and solid

floor. The back side of the achine has to

be attainable.

2 Secure the achine to the floor. In both

supports of the achine are holes. Drill

the holes into the floor through these

holes, and secure the achine with

expanding bolts to the floor.

3 Adjust the face plates at both ends of the

achine in such a way that they touch

the floor.

Also adjust the iddle face plate for type

Orca 1850 en 2150.

4 Fasten face plates with the nuts.

5 Re ove the hexagon nut which block the

counter weight (at the botto side of the

track). Secure the hexagon socket head

cap screw ( ounted on the handle of the

depth adjust ent).

6 Connection to the ains supply has to be

perfor ed by an electrical engineer.

7 Check the rotation of the saw-blade.

DUST EXTRACTION

1 If used inside, the achine has to be

connected to a dust extractor.

The dia eter of the connection is 100 or

160 (TRK-syste ).

2 The dust extractor has to be connected

in such a way that otor and dust

extractor are switched on

si ultaneously.

3 The extracting capacity has to be

calculated in such a way that a ini u

air speed of 20 /s is reached at the

connection of the achine.

4 The air speed V is 1450 3 /hour at Vair =

20 /s at a depression of about 2000 Pa.

12

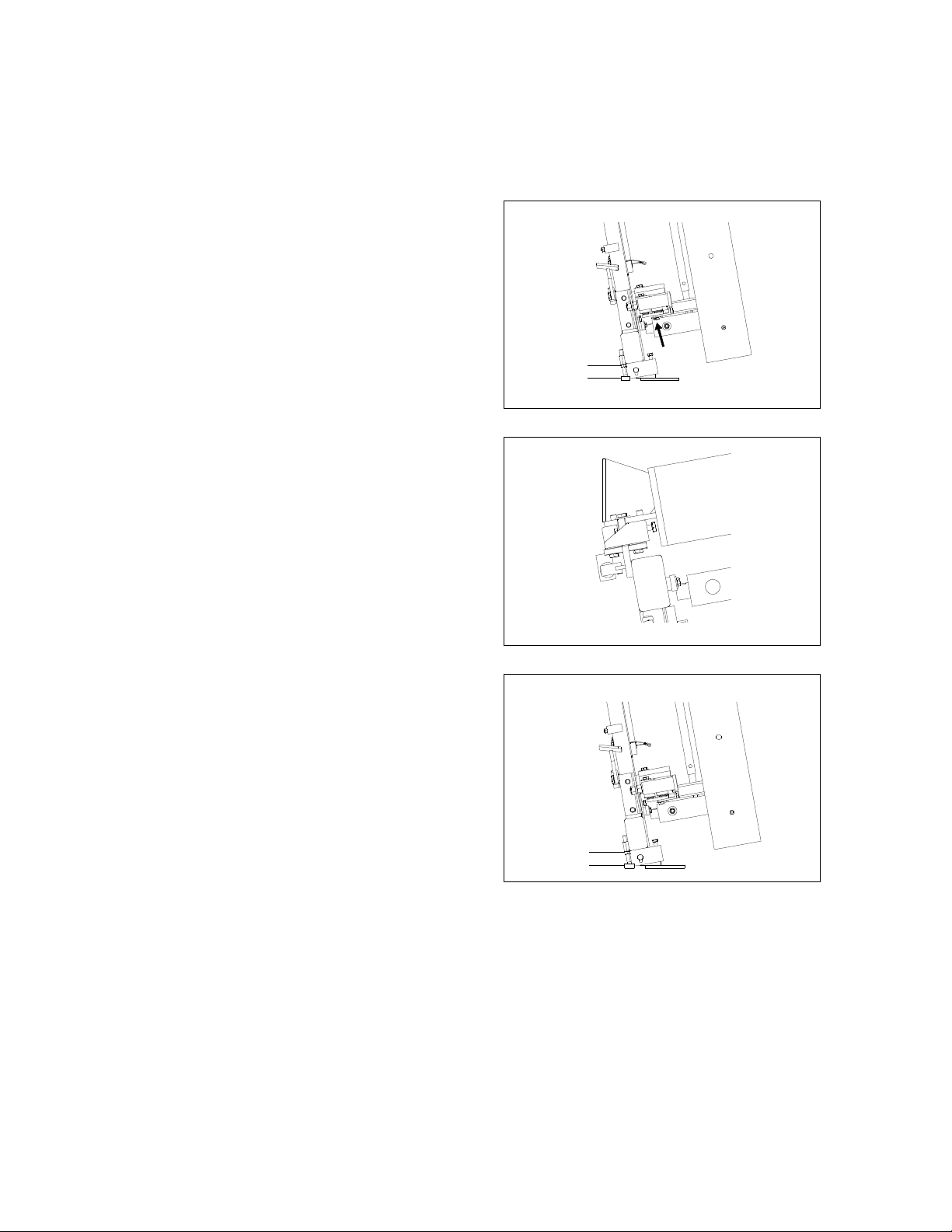

POSITIONING VERTICAL SLIDE WAY

0 Regard the centre of gravity when

re oving the slide way fro the crate or

the supports. Use the cask grips on the

top when lifting the slide way. (see

Transport of the slide way with

crane/forklift truck fig. 3 and 4).

1 Dis antle bearing support at the botto

side of the slide way by re oving the

two bolts (see figure 5).

2 Adjust the two bearings of the slide way

carriage ax. backwards.

3 Place slide way on the fra e.

Notice: At the back side of the slide way is

a T-profile. This has to be lifted over the

tracks (figure 6).

4 Adjust the bearings of the carriage at the

top side of the slide way.

5 Asse ble bearing support on botto

side of the slide way.

6 Push the bearing support tightly against

the adjusting bolts at the front side.

7 Fasten the bearings support with two

M10 bolts.

RELEASE COUNTERWEIGHT

1 Re ove the protruding bolt at the

botto side of the track (figure 7).

2 Insert and tighten the short bolt, stuck

on the grip of the depth adjust ent.

Fig. 5

Fig. 6

Fig. 7

13

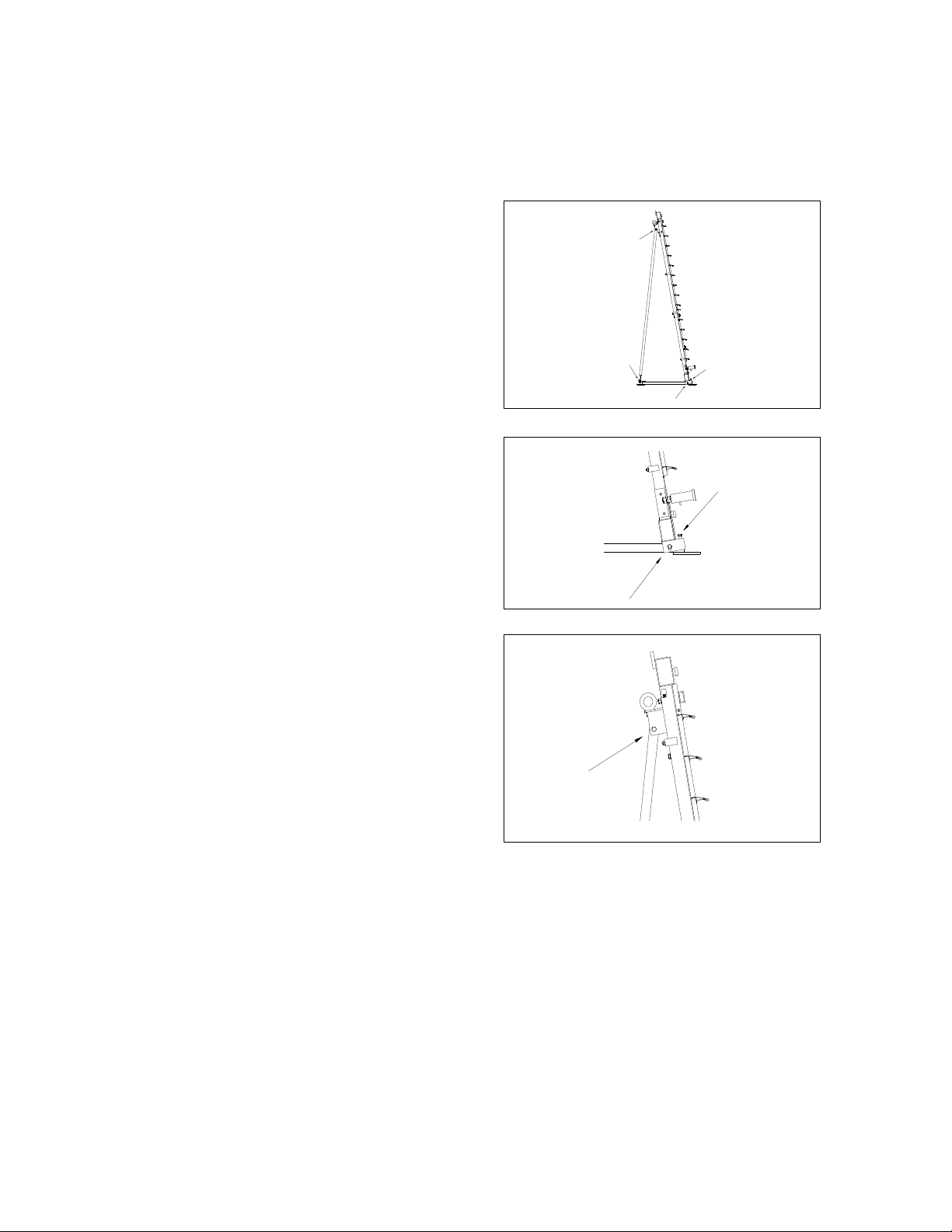

ADJUSTING THE FRAME

In case one o the ollowing

mal unctions occurs, the rame needs

adjusting.

a The vertical slide way cannot be locked

in the notches.

b The fra e is twisted. (The panel is not

fully supported by the alu iniu strips).

0 Overall drawing adjusting points (Fig. 8)

1 Position the vertical slide way near a

vertical support.

2 Loosen the horizontal bolt-nut connection

of the support (Fig. 9).

3 Check if the vertical slide way can be

oved easily fro left to right.

4 If not, adjust the vertical bolts of the

support (Fig. 9). Check oving of the

slide way.

5 Secure the nut of the vertical bolts

without rotating the bolts.

6 Do not secure the horizontal bolt nut

connection at this o ent.

7 Loosen the bolt nut connection of the

vertical supports without re oving the

bolt and the nut (Fig. 10).

Fig. 8

Fig. 9

Fig. 10

14

ADJUSTING THE FRAME

8 Adjust the angle between fra e and

botto at 80º with the M16 nuts (Fig.

11).

9 Attach cables with (lead)weights to the

horizontal bearing track at the sa e

heights as the vertical supports (Fig. 12).

10 Check if the distance between fra e and

cables is identical. If not adjust the M16

nuts of the vertical supports to get the

sa e distance (fig. 11).

11 Fasten the nuts of the vertical supports

(fig. 11).

12 Fasten the bolt nut connection of the

vertical supports (Fig. 10).

13 Fasten the horizontal bolt nut connection

of the fra e support (Fig. 9).

14 Adjust the face plates at both ends of the

achine in such a way that they touch

the floor.

15 Type Orca 1850 and 2150 has also a

iddle face plate. Adjust it the sa e way.

16 Secure the face plates with the nuts.

Check if the vertical slide way can be easily

locked in the notches at the top and botto .

The fra e is adjusted correctly.

Fig. 11

Fig. 12

15

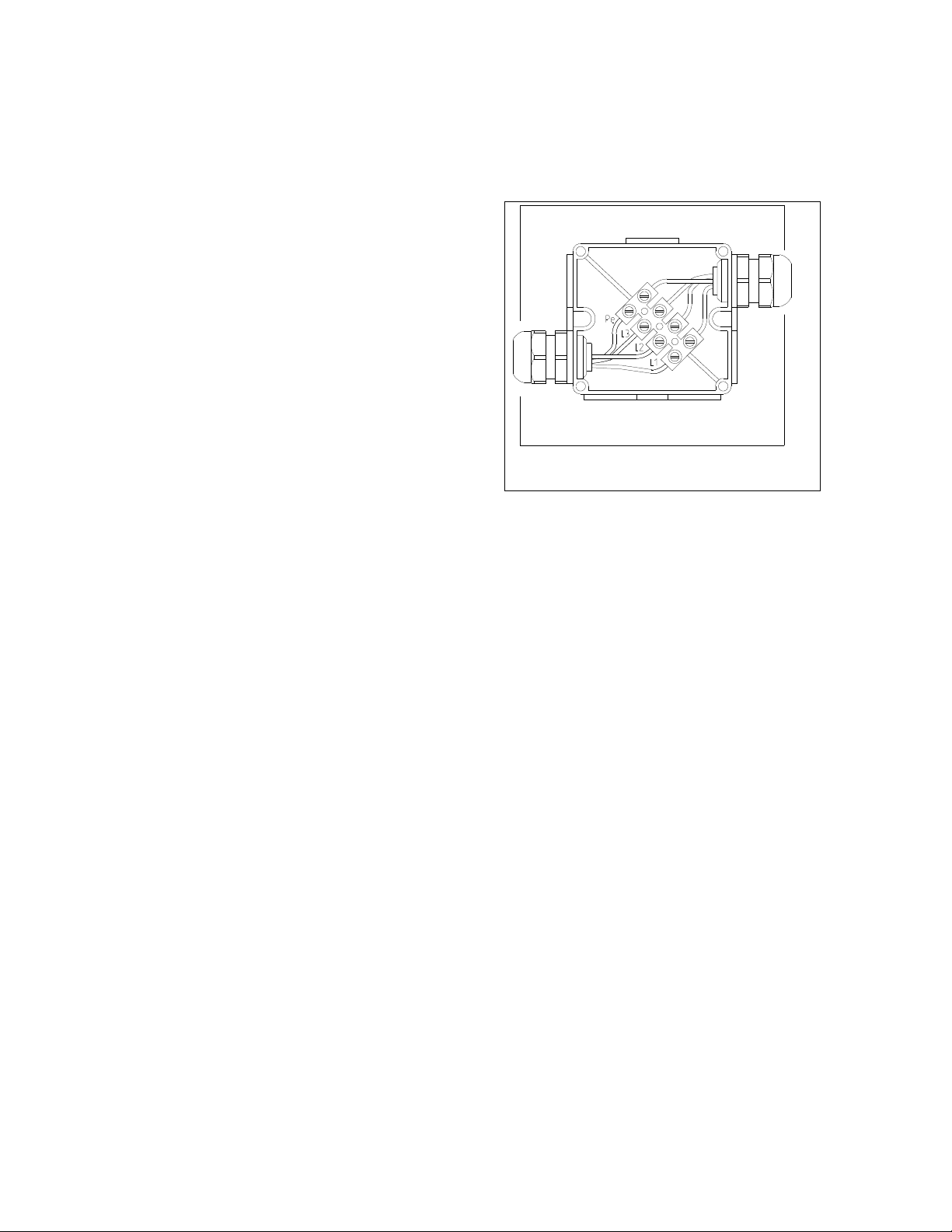

CONNECTING TO THE ELECTRICITY SUPPLY

400V – 3 phase

You will find the wiring diagra in the

switch box.

0 Connecting the achine ay only be

perfor ed by a skilled crafts an.

1 Insert cable with four supply leads with a

dia eter of 1.5 2 into the junction

box at the back side of the fra e. The

quality of the cable has to be ini al

equal to H 07 RN F.

2 The cable has to be connected to the

electric fitting (Figure 13):

the 3 phases (L1, L2, L3)

...................................black or brown

the earth (PE).............yellow /green

3 Close the junction box carefully.

4 Check if the achine is provided with

fuses of 20 A p. slow.

Notice: Check the rotation of the ain saw-

blade *

* The direction of rotation is indicated on

the pressure pad. If the direction is

wrong, interchange two of three phases.

(See first next page spindle rotation).

Fig. 13

16

DIRECTION ROTATION OF THE MAIN SAW-BLADE

0 Block the carriage and put the saw-blade

in vertical position.

The direction of rotation is indicated on

the pressure pad (figure 14).

PROPER DIRECTION IS ANTI-CLOCKWISE

(standing at the left side of the casting)

1 Switch otor on and off.

2 Check if direction is anti clockwise.

WRONG DIRECTION IS CLOCKWISE

(standing at the left side of the casting)

1 Switch otor on and off.

2 Direction is clockwise.

3 Disconnect ains supply.

4 Interchange any two supply leads in the

junction box (at the back side of the

fra e).

5 Close junction box carefully.

6 Connect the ains supply.

Notice: If the saw-blade was turning to the

wrong side the saw-blade ay co e

loose. Check this before operating the

achine.

(see chapter: Changing the saw-blade).

Fig. 14

17

ADJUSTING THE MEASURE FOR VERTICAL CUTS

1 Lock the slide way at the zero point of

the easure scale.

2 Move saw unit upwards.

3 Place length stop at the left or at the

right side of the zero point.

4 Adjust easure and swing the cla p

forwards. Stop cla ps auto atically (Fig

15).

5 If the easure to be adjusted is bigger

than 1000 ove the slide way one

position to the left.

EXAMPLE:

Width of cut has to be 23 c .

Adjust easure at 23 c .

Place the aterial against the alu iniu

cap of the length stop.

Lock the slide way at the zero point of

the easure scale.

EXAMPLE:

Width of cut has to be 123 c .

Adjust easure at 123 c .

Place the aterial against the alu iniu

cap of the length stop.

Lock the slide way at the zero point of

the easure scale

OR

Adjust easure at 23 c .

Place the aterial against the alu iniu

cap of the length stop.

Lock the slide way one position to the

left of the zero point (if the stop was

place at the right side of the zero point).

Fig. 15

18

ADJUSTING THE MEASURE FOR HORIZONTAL CUTS

0 The zero of the easure scale on the

slide way corresponds to the upper side

of the support.

1 Put the saw-blade in horizontal position

(see chapter Horizontal cutting).

2 Set the correct height by eans of the

scale on the slide way (Figure 16).

3 Fasten the knob at the right side of the

otor carriage.

4 Unlock the slide way.

Notice: Always cut fro left to right.

ADJUSTING THE MEASURE FOR

HORIZONTAL CUTTING ON THE MIDWAY

FENCES

0 The zero of the easure scale

corresponds to the upper side of the

idway fence.

1 Put the saw-blade in horizontal position

(see chapter Horizontal cutting).

2 Set the correct height by eans of the

scale on the slide way (Figure 16).

3 Fasten the knob at the right side of the

otor carriage.

4 Unlock the slide way.

Notice: Always cut fro left to right.

Fig. 16

19

VERTICAL CUTTING

LOCKING CONTROLLER VERTICAL CUTS

0 The achine is equipped with a locking

controller against vertical cutting of the

plastic strips. The vertical slide way has

to be locked in the notches and the saw-

unit has to be positioned for vertical

cutting. In case the locking of the vertical

slide way or the positioning of the saw

unit is not done properly, the otor will

not start.

Always cut fro top to botto .

1 Position the otor carriage at the top of

the slide way.

2 Adjust easure and position the aterial

against the alu iniu cap of the length-

stop.

3 Take the handle of the depth

adjust ent.

4 Switch on otor.

5 Push saw unit forward.

6 Pull the saw-blade steadily down through

the aterial (Figure 17).

Meanwhile turn the handle to the left.

7 When the plate is cut, pull the saw-blade

out of the aterial by eans of the

handle.

8 Switch off otor.

9 Swing cla p of length stop upwards.

10 Re ove aterial.

Fig. 17

20

HORIZONTAL CUTTING

PROTECTION HORIZONTAL CUTTING

0 The achine can be equipped with a

anually operated or self- oving panel

support. It prevents da aging the plastic

strips when cutting horizontally. If the

saw-unit is adjusted on the sa e height

as one of the alu iniu supports, the

panel support can be operated anually

or oves auto atically when pushing

the saw unit forward for aking the cut.

The anually operated panel support

can be re-adjusted by using the knob

(Fig. 18A).

Always cut fro left to right.

Notice: If the achine is equipped with a

scoring unit which is not needed at that

o ent, use the 5 allen key to turn it

backwards.

1 Fasten the otor carriage with the knob

at the right side at breast height.

2 Pull back the saw-unit with the handle

and hold it.

3 Pull back the blocking pin and turn the

saw-unit (Fig. 18).

4 Insert blocking pin when the saw-unit is

in its horizontal position.

5 Adjust the saw-unit at the correct height.

6 Block the carriage with the knob at the

right side.

7 Put a panel on the achine.

8 Swing the cla p of the length stop

downwards against the right side of the

panel.

9 Place the aterial against the alu iniu

strip of the length stop.

10 Turn on the otor.

Fig. 18

Fig. 18A

11 Push the saw unit forwards.

12 Cut the aterial steadily fro left to

right.

13 Pull back the saw unit.

14 Turn off otor.

Notice: See to it that the riving knife is

adjusted properly (See chapter adjusting

riving knife).

This manual suits for next models

2

Table of contents