HASWING Cayman B GPS Series User manual

User Manual for:

50736 Cayman B GPS 55lbs

50737 Cayman B GPS 80lbs

50738 Cayman B GPS 101lbs

Version: V01 Printed in China

Cayman B GPS series

OWNER’S MANUAL

Should your motor be defective or a technical issue

arise, please contact the local Haswing distributor

for assistance. Visit www.haswing.com for the list

of country distributors.

Yatai Electric Appliances Co., Ltd

No. 4 Xinlong Street, NanLong Industrial Park

SanXiang, ZhongShan, GuangDong Province, China

Postcode: 528463

Tel: +86 760 86692666

Fax: +86 760 86692996

WWW.HASWING.COM

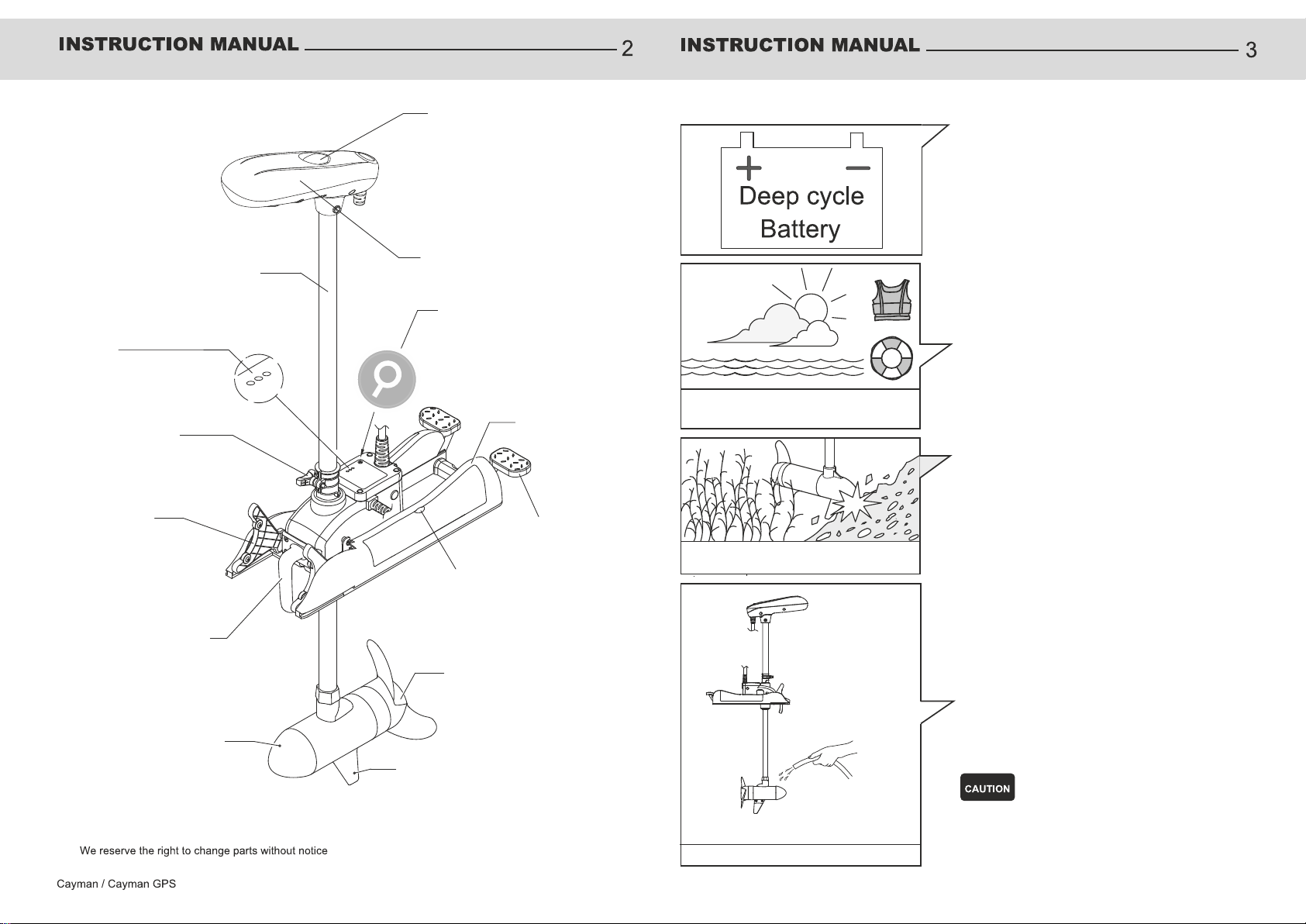

Battery status display

Motor transportation

retainer

Adjustable depth

collar

Motor shaft

Boat controller (Cayman B

GPS model only

Pairing button

Mounting base

Stow/deploy pedal

Access panel

Propeller

Motor lift handle

Durable DC motor

Replaceable fin

(skeg)

Indicator lights (Cayman B

GPS model only

Product features

Product features

Before operating the motor

Only use deep cycle battery or batteries to power the

motor. Incorrect or improper use, or connection of the

battery could cause damage to the motor.

Disconnect the battery when stowing the boat or not

using for an extended period.

Always wear an approved life vest or PFD (personal

flotation device) and comply with local boating

regulations.

When motoring with the electric trolling motor in

shallow water or around obstacles, reduce speed.

Raise or retract the motor when in shallow water. Be

aware of swimmers in close proximity to your vessel.

Before operating the motor

Wash down motor

with fresh water after

using in saltwater

Wash motor after use

Be aware of underwater obstacles

Be mindful of weather conditions

Remove any debris from around the propeller or

propeller drive shaft. Wash with freshwater after

using in saltwater.

IP63 waterproof level for all but the motor

IP68 waterproof level for the motor

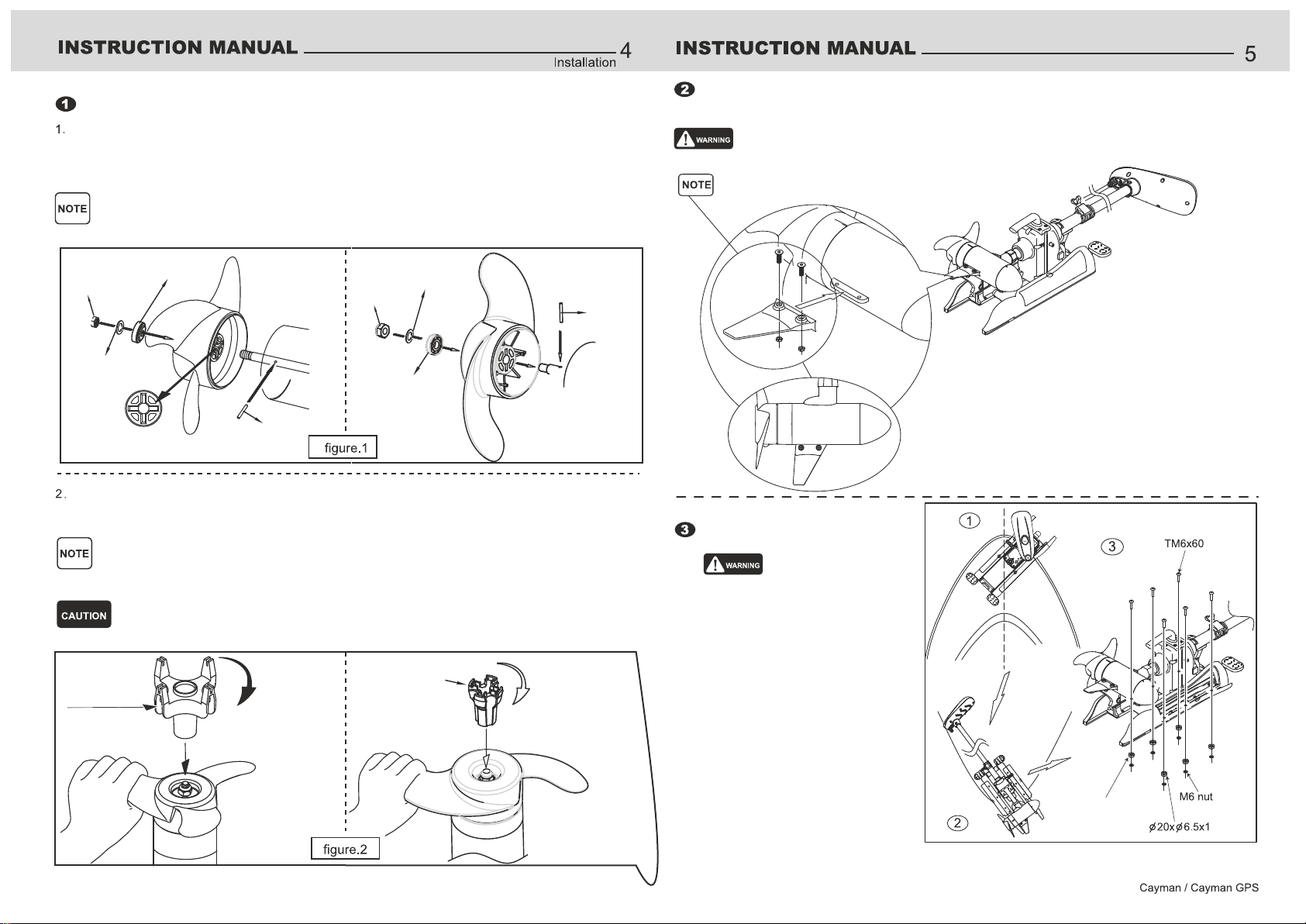

Propeller installation

Install the drive pin (drive pin and cross-shaped slot in the propeller must align in order to

correctly fit the propeller to the motor), anode, washer and self-locking nut onto the drive

shaft. (Fig. 1)

The cross-shaped slot (2 slots) allow the user to re-assemble the propeller if one slot is worn.

55lbs thrust motor

Self-locking nut

Stainless steel

washer

Drive pin

Sacrificial anode

Cross-shaped

slot

80-101lbs thrust

motors

Drive pin

Stainless steel

washer

Sacrificial anode

Self-locking

nut

Hold the propeller to prevent it from rotating and use the propeller wrench to tighten the

propeller nut until firm. Do not over-tighten. (Fig. 2)

Only use the supplied propeller wrench to tighten, other tools may cause over-tightening

resulting in damage. TIP: Keep this hand wrench in your boat in the event that you get debris

such as fishing line around the propeller shaft.

Tighten the nut ¼ turn past the ‘snug’ point. Over-tightening can cause damage to the

propeller.

Propeller wrench

Propeller wrench

55lbs thrust motor 80-101lbs thrust

motors

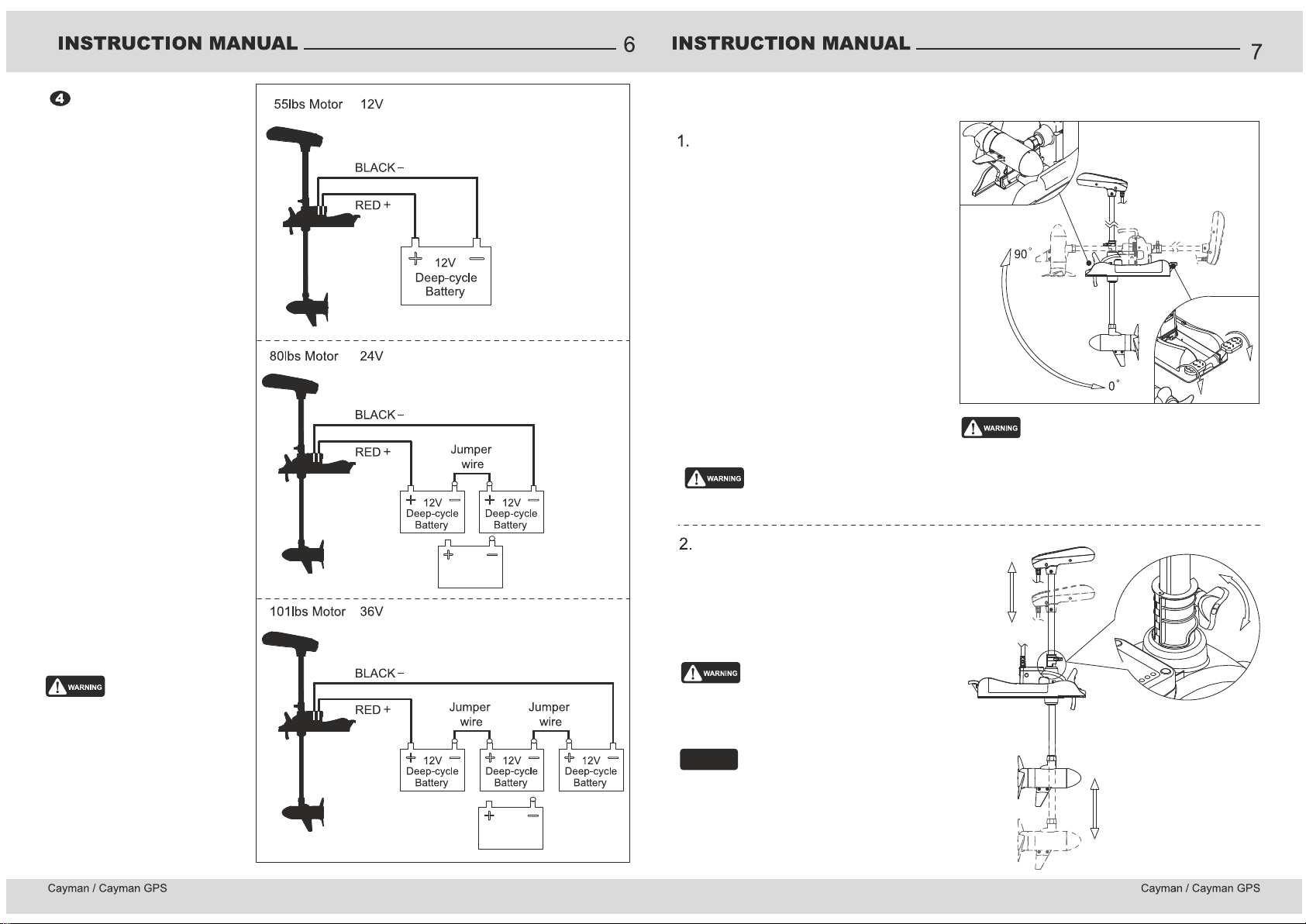

Ensure that the battery is not

connected when initially installing or

when mounting the motor using the

Quick Release Bracket. If not using

the motor for extended period or

when storing the vessel, disconnect

the battery.

The motor can be bolted directly to

the boat OR if using the Quick

Release Bracket, bolt the puck to the

boat. It is recommended to mount

the motor so it is longitudinal with

the boat or on a slight angle. This

will also depend whether your boat

has an electric motor mounting plate.

Installation method

Anti-slip spacers

Installing the lift handle and fin

Ensure that the motor is disconnected from the battery before installing components.

Nuts, bolts and fin supplied in plastic bag.

Fig. 4

Align the fin on the bottom of the motor, note correct

direction before tightening nuts and bolts.

Mounting the motor

Fig. 5

Installation

24V

Or 1 x Deep Cycle

Lithium

36V

Deep Cycle

Lithium

Or 1 x

Connect the battery (+) to the

positive (red) terminal, (-) to the

negative (black) terminal. The

ring connector should always be

in the bottom most location

with any washer sitting above

the ring connector and then the

nut. (Fig. 6)

Always make sure that the

battery or batteries are secured

and free from contact with

metal objects to prevent

shorting out. A battery box is

recommended. Lead acid

technology batteries such as

AGM may require ventilation.

Fig. 6

Battery connection

Only use a deep cycle battery of

the correct voltage for the

motor. Lead acid technology

and lithium technology batteries

are both suitable. Incorrect

battery voltage or connection

could damage the motor’s

electronics.

Always disconnect the motor

from the battery when

recharging the battery. Failure

to do so could damage the

motor’s electronics.

Correct operation of the motor

Deploying and stowing

the motor

Deploying the motor

Press the stow/deploy foot pedal and gently

lower the motor taking care to align the lower

part of the Depth Collar with the Steering

Collar. (Fig. 7)

Stowing the motor

Press the stow/deploy foot pedal, grab the

handle, head or shaft of the motor, lift and

retract , sliding back horizontally until the

motor clicks into the cradle.

The shaft of the Cayman slides smoothly making it easy to deploy and stow. Do

NOT let the motor free-fall when deploying, but gently lower into position,

otherwise damage can occur to the Steering Collar.

When raising or lowering, keep fingers

clear of all hinges and pivot points.

Fig. 7

Adjusting the motor’s depth

Whilst holding the motor by the shaft to

prevent it from accidentally sliding, loosen

the nut on the Depth Collar and lower the

motor to the required depth. Tighten the

nut to secure. (Fig. 8)

When first using the motor, find the correct

depth for general fishing conditions and using

a permanent marker, place at mark at the top

of the Depth Collar so you can easily set the

depth when you next go fishing.

Fig. 8

SUGGESTION

When towing the boat with the trolling motor in

place, ALWAYS lock the Depth Collar against the

gearbox and support the shaft near the head.

Correct operation of the motor

Battery connection

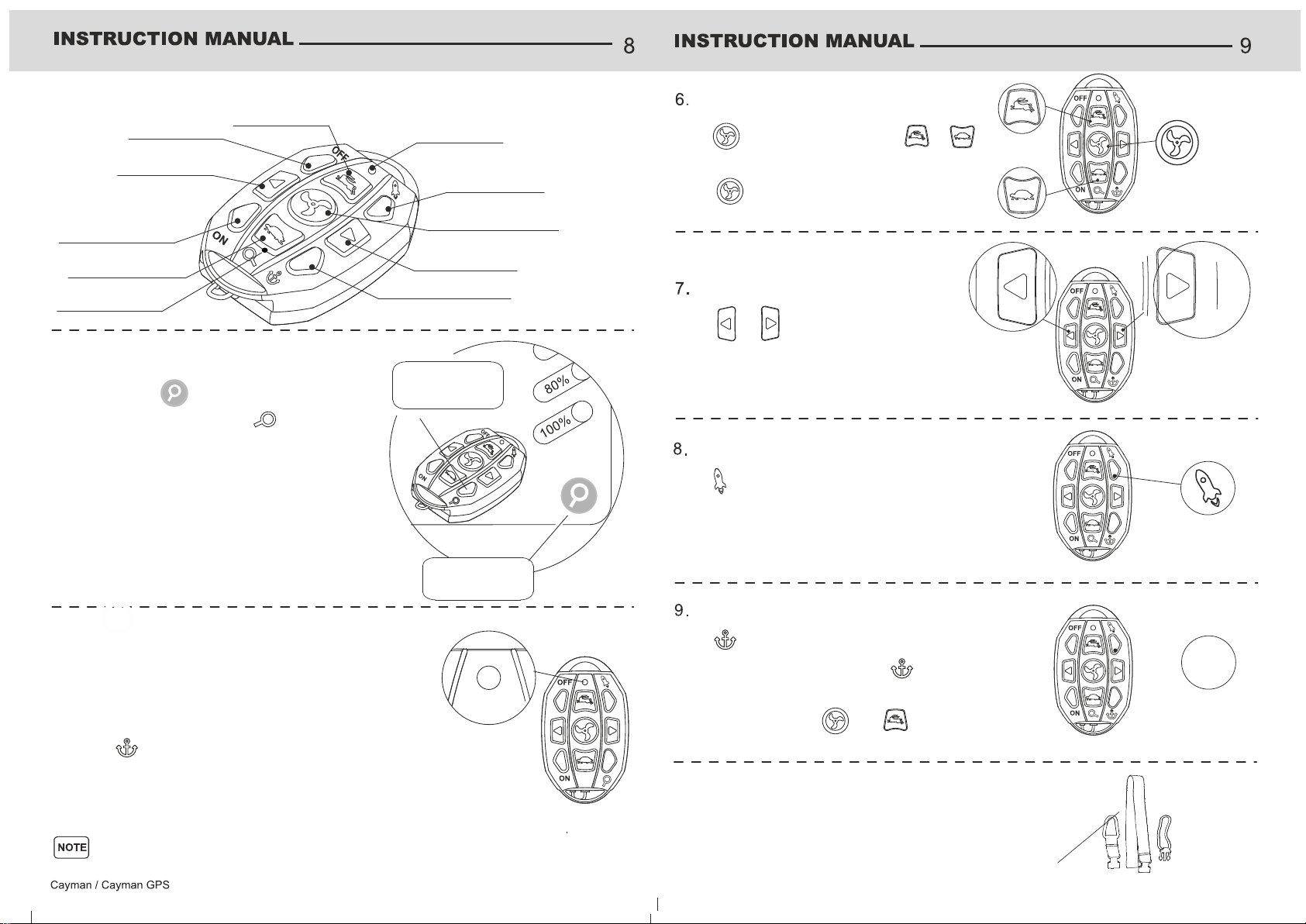

3. Remote control buttons

Power off

Faster

Slower

Power on

Steer left

Steer right

Motor On/Off

Full speed

Mode signal light

Pairing Anchor

3. Pairing remote to motor

Press and hold below the battery status

lights on the motor (fig. 9) and (also the

Slower button) on the remote at the same time

for three (3) seconds or until you hear 3 beeps

indicating that connection has been made and

the remote and motor are paired. Release

fingers from both buttons.

Pairing button

Pairing button Fig. 9

4. Mode signal light

1. Press the ‘ON’ button, indicator light is on solid or flashes,

remote control is on ‘standby’ state.

2. Press any button on the remote control, red indicator light

flashes, indicating signal is sending.

3. Select button, light is two-tone pink/purple, indicating

motor is in the anchor mode.

4. Press ‘OFF’ button to turn of remote control. Light is now off.

(Fig. 10)

Fig. 10

If your press the ‘ON’ button and there is no indicator light or is solid

red, please recharge the remote control as the battery is flat.

Remote control

Speed control

Press to activate the motor. Press or

to adjust the motor’s speed. To stop the motor,

press to cancel. (Fig. 11)

Steering control

Press or to steer the motor direction

left or right. (Fig. 12)

Fig. 12

Fig. 11

Fig. 13

Full speed

Press to select full speed (turbo mode). Press

again to return to the prior speed setting. (Fig. 13)

Spot lock (anchor mode)

10. Lanyard

For your convenience the lanyard can be configured to suit

your preference ie around the neck or use the carabiner to clip

to a belt loop. (Fig. 15) Fig. 15

Press to select spot lock (anchor) function

to anchor the boat in position. Press again to

disengage anchor function, will return the motor

to the stop mode. Press and to select

speed. (Fig. 14)

Fig. 14

Using the remote

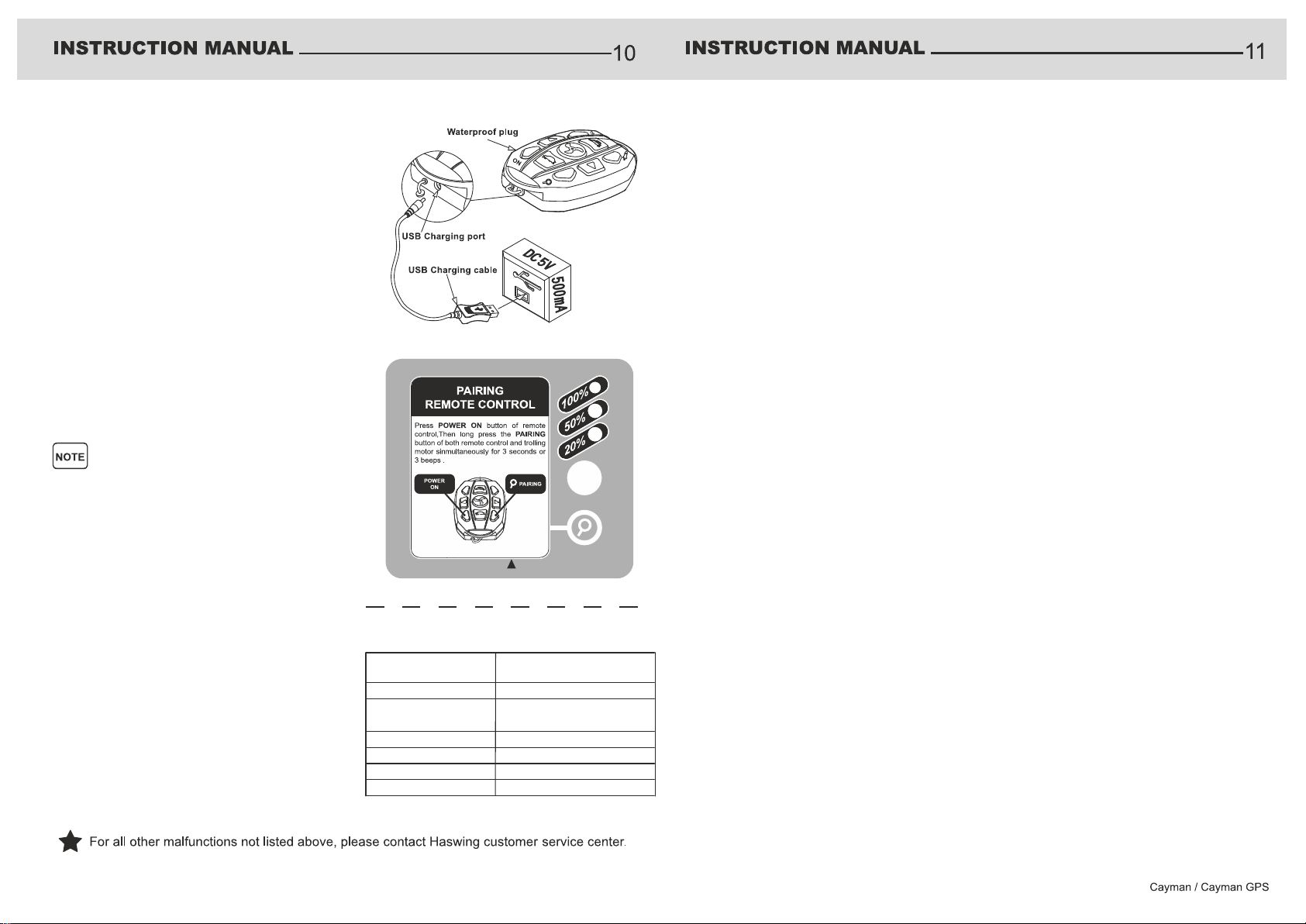

1. To charge the remote, remove the waterproof plug,

connect the USB charging cable. The USB end of the

cable has a charging status light - red light indicates

charging, green light indicates charged.

NOTE: When charging the hand remote for the first

time, the light will turn green fairly quickly, leave it

charging overnight or for several hours. Only ever use

the charging cable supplied with the remote, use of

an incorrect cable can damage the battery and

electronics of the remote.

2. The hand remote can on average be used

continuously for 48 hours. You can have the remote

plugged into a USB charging port (if your vessel has

one fitted) and still use the remote to command the

Cayman motor. (Fig. 16)

In order to maximise the life of the battery in the

remote, please charge the remote every 3 months if

the motor is not being used for extended periods.

Figure 16

Remote charging, pairing & audio signal

11. Charging the remote

12. Battery Status Display

The motor has a Battery Status Display (3 LED

lights) to show the charge status of the battery

being used to power the Cayman motor. As the

voltage of the battery discharges, the status light

percentage will decline accordingly. It is highly

recommended that you recharge the battery once

it reaches 20% for lead acid technology batteries.

Lithium batteries contain a BMS (battery

management system) that actively manages the

battery and when it reaches its maximum depth of

discharge (DoD) the battery will automatically shut

off. (Fig. 17)

NOTE When used with lithium batteries the battery

status display is not entirely accurate due to the

nature of discharge of lithium battery technology.

One (1) beep

Two (2) beeps

Three (3) beeps

Five (5) beeps

Continuous

Continuous long beep Current overload

Low battery warning

Pairing successful

System ready

Function terminated or

returned to the original setting

Operation signal

AUDIO

PATTERN STATUS

Fig. 17

Audio Warning Pattern

Make sure that the power cable from the battery

is connected correctly.

Check that the terminals are clean and

corrosion free.

Make sure that the battery is full. If flat or low

voltage, please recharge.

Make sure that there is no fishing line or weeds

caught up in the propeller. Please detach and

clean up the propeller if there is debris got

caught up inside the propeller. Warning - Make

sure the motor is disconnected from the battery.

Make sure that the propeller drive pin is in good

condition.

Make sure that the propeller is installed

correctly. Inspect the propeller and the

drive/shear pin condition and if necessary,

replace worn or faulty part.

Disconnect the battery cable and examine the

motor by manually turning the propeller. The

propeller should turn freely with some magnetic

resistance. If there is strong resistance, there

may be internal damage. If locked up or

excessive resistance, please contact our

customer service or the dealer.

Troubleshooting

Troubleshooting

A continuous beep indicates a power output

overload. It can happen if the motor is trying to

propel a vessel of too greater weight capacity

or has weed or fishing line has caught up under

the propeller around the propeller or drive

spline.

When the voltage of the battery is too low, the

motor will shut off automatically to help protect

1. Motor fails to run or lack of power

2. Motor vibration

3. Operation error warning signal

This manual suits for next models

6

Table of contents

Other HASWING Outboard Motor manuals