GEN

INFO General information

1-3 62Y5A11

Safety while working 1

To prevent an accident or injury and to

ensure quality service, follow the safety pro-

cedures provided below.

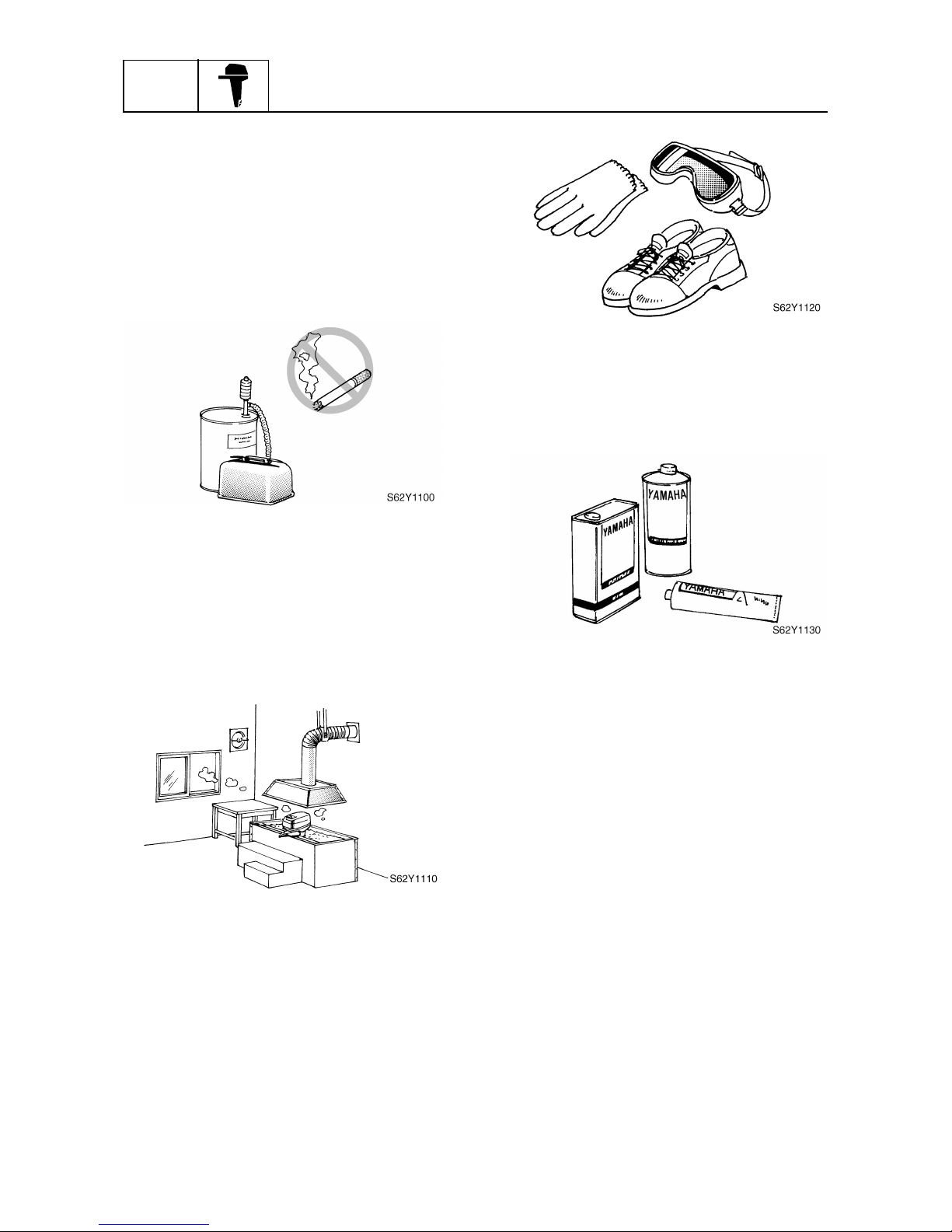

Fire prevention

Gasoline is highly flammable.

Keep gasoline and all flammable products

away from heat, sparks, and open flames.

Ventilation

Gasoline vapor and exhaust gas are heavier

than air and extremely poisonous. If inhaled

in large quantities they may cause loss of

consciousness and death within a short time.

When test running an engine indoors (e.g., in

a water tank) be sure to do so where ade-

quate ventilation can be maintained.

Self-protection

Protect your eyes by wearing safety glasses

or safety goggles during all operations involv-

ing drilling and grinding, or when using an air

compressor.

Protect your hands and feet by wearing pro-

tective gloves and safety shoes when neces-

sary.

Parts, lubricants, and sealants

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the

outboard motor.

Under normal conditions, the lubricants men-

tioned in this manual should not harm or be

hazardous to your skin. However, you should

follow these precautions to minimize any risk

when working with lubricants.

1. Maintain good standards of personal and

industrial hygiene.

2. Change and wash clothing as soon as

possible if soiled with lubricants.

3. Avoid contact with skin. Do not, for

example, place a soiled rag in your

pocket.

4. Wash hands and any other part of the

body thoroughly with soap and hot water

after contact with a lubricant or lubricant

soiled clothing has been made.

5. To protect your skin, apply a protective

cream to your hands before working on

the outboard motor.