4. Holes in the fuel line. The tear resistance of silicon tubing

is verylowandit’snotuncommontodevelopa hole where the

fuel line is assembled over the edges of brass tubing. If the

engine runs well on the first half of tank and then quits, it’s

almost always caused by a hole in the pick up line inside the

tank. Look for bubbles in the fuel line while the engine is run-

ning, this is a sign of holes somewhere in line.

5. Pressure tap in muffler plugged or restricted. Some fuels

contain oil that can collect on the interior of the muffler and

plug off the pressure tap causing the fuel tank to loose pres-

sureand starve theengine for fuel.This will causethe engine

torunlean then rich thenlean.Try running the enginewiththe

pressure line removed from the muffler to see if the problem

still exists.

MAINTENANCE

Whenyouarefinishedrunningforthe day,run your engine dry

byremovingthe fuel line atamoderatespeed or allow thefuel

tanktorun dry.It is best tosquirt someK&BAFTER RUN OIL

in the carburetor, then flip the propeller about 10 to 20 times.

Thisoilwillkeepcastorbasedfuelsfrom gumming and protect

internal engine parts from rust and corrosion. When storing

your model between running sessions, it is best to wrap your

engine in a rag or plastic to prevent dust, dirt and moisture

fromenteringthe engine. Theengineshould also be wrapped

in a rag between running sessions at the pond.

CHECKTIGHTNESSOFALLSCREWS

On a regular basis you should check all screws associated

withtheengine.Mounting,head,backcover,muffler,prop,lower

unit,etc.These screws must be properly torqued and not over-

tightened.Alwaysuseacrosstorquingtechniqueasmentioned

below.

BEARINGCARE

Your engine operates in an aquatic environment and uses fu-

els which attract moisture which will shorten the life of the

bearingsifnot cared for properly.

Acleaninghole is provided inthefront housing to aidinclean-

ing the front (or top) bearing. Simply place the spout tube of

WD40 (or similar product) up to the hole in the housing and

“back-flush” the bearing until you see fresh lube coming out

from under the flywheel. The bearing may also be oiled with

K&B After Run Oil using this same procedure. Do not use

WD40(or similarproduct) onthe lower unit.

FLEXSHAFT CARE

An access hole is provided in the lower unit for pre operation

lubrication of the flex shaft. We recommend that each time,

beforeyourunthe engine, you lubethe cablewithamixture of

50%STP& 50% 20-50weightoil. In addition,werecommend

that you periodically remove, inspect, and re-lube the entire

flex cable with K&B # 8449 shaft lube or equivalent for maxi-

mum cable life.

FUEL& CLEANLINESS

Alwaysuse fresh, clean fuel toprevent starting problemsand

poorengineperformance. We recommendthatyou use a fuel

filterinthe line betweenthetank and the needlevalveassem-

bly.Afilter will prevent foreign material from reaching the car-

buretorand causing aclog.

The engine will accelerate from idle to full throttle smoothly

andinstantaneouslywhenproperly adjusted. The enginemay

not idle well at a low setting or accelerate as quickly until it is

brokenin.

BREAK-IN

1.BREAK-IN running should bedone at aslightlyrich setting.

The needle valve should be set at a point just into this range

from a four cycle setting. Run the boat in the water at maxi-

mumthrottle for 2 minutes, then throttle backforapproximately

30seconds.Repeatthissequenceuntilapproximately30min-

utes of accumulated running time has been obtained.AVOID

MAXIMUMTHROTTLEFORLONG PERIODSOFTIMEDUR-

ING BREAK IN and AVOID RUNNING FOR LESS THAN 5

MINUTERUNS.

2. After the first 30~45 minutes, run the engine at a normal

peak needle valve setting. This should be a little on the rich

sidetoensureengine received proper lubrication.

BOAT INSTALLATION

Theengine must be mountedfirmlyto the transomofthe boat

usingthe machine screws andplate supplied with theengine.

Neveruse wood screws tomount the engine.

Careshouldbetakentothemountingpositionasrecommended

bytheboat manufacturer.

TROUBLE SHOOTING

Generallymostengine starting problems canbetracedto bad

glow plugs, weak starting batteries, or inadequate fuel sys-

tems.

GLOW PLUGS

The glow plug when connected to a 1.5 volt battery should

glow a bright orange. If the plug slightly glows the battery or

plugshouldbe replaced.

If the seal leaks around the center plug post, replace it.

Theglowplugelementshouldbeexaminedafterseveralflights.

If the element is deformed or touching the side of the plug

body, replace it. If the glow plug element is pitted or has a

frosty look, the engine is running too lean and continued run-

ning will seriously harm the engine.

FUEL SYSTEMS

The most frequent problems encountered with fuel systems

are:

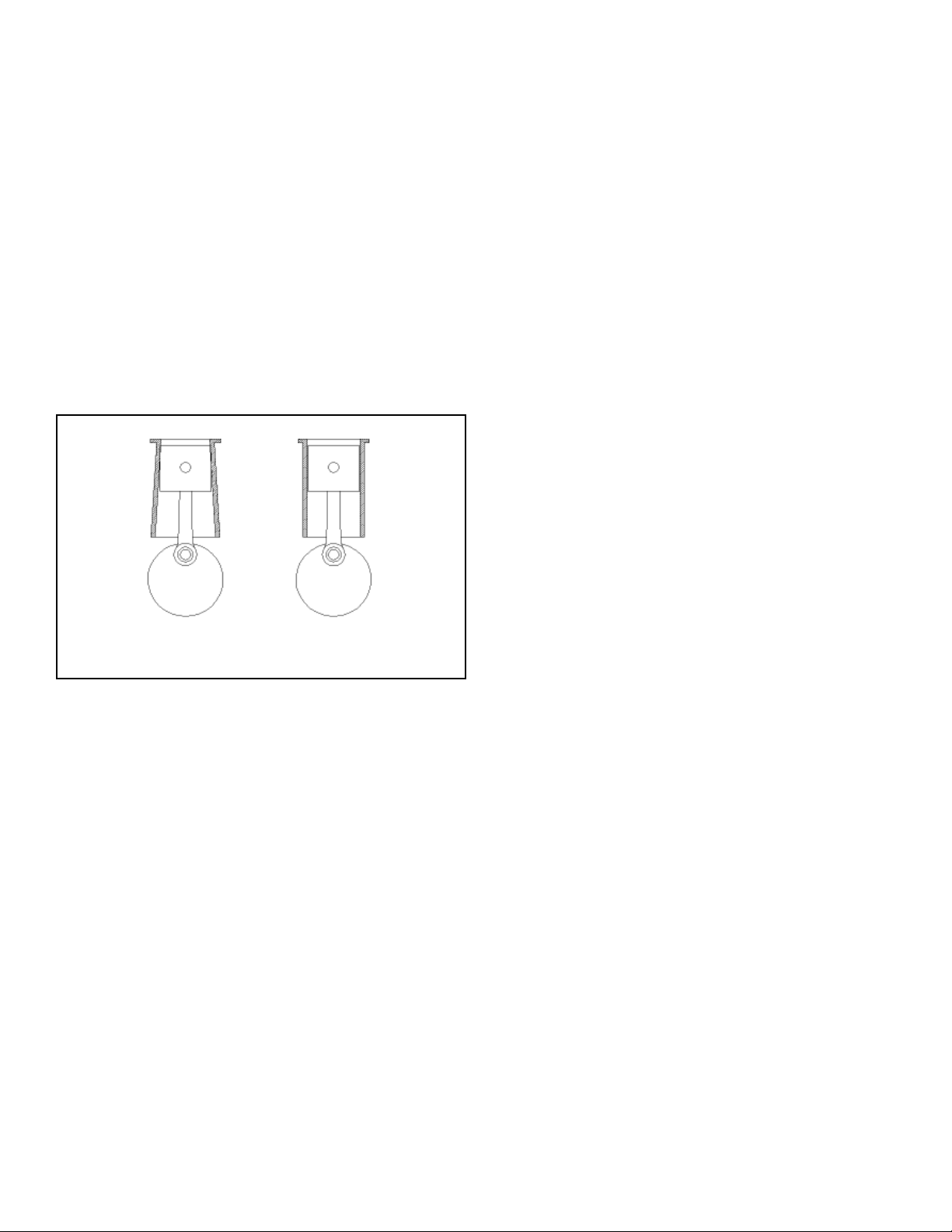

1.Improperfuel tank location.Thefueltank should belocated

as close to the engine as possible.

2. Fuel pick up in tank is not free or in the wrong location. If

the boat runs rich, then lean, then rich, the pick up may be

picking up air, then fuel, then air, as the thrust of the engine

causes the fuel to be forced from the front of the tank to the

back.

3. Dirtorcontaminates in the fuel, tank,lines,filteror carbure-

tor. Many times a sliver of fuel line or other debris will cause

theneedleorifices to becomepluggedintermittently so acon-

sistentmixturesetting can not beobtained.Carefulinspection

andcleaningofthesepassageswillusuallysolvethe problem.

Don't use silicone sealant on areas of the carburetor that in-

volvefuel passages.