View for clarity only,

do not disassemble

parts , & .

1.2

1.1

2.2 2.1

AI 306 - Issue M / Page 1 of 2

www.ehawke.com

Hawke International

UK Office

Oxford Street West,

Ashton-Under-Lyne,

Lancashire

OL7 0NA. UK

Sales (UK): 0870 606 0105

Sales: +44 (0) 161 830 6698

Technical (UK): 0870 458 9358

Technical: +44 (0) 161 830 6697

Fax: +44 (0) 161 830 6648

E-mail: sales@ehawke.com

International

A member of the Hubbell Group of Companies

Hawke International is a division of Hubbell Ltd.

Registered No. 669157 in England. Registered Office:

Mitre House, 160 Aldersgate Street, London EC1A 4DD.

Connection Solutions

Operating temperature range -60°C +100°C

Assembly Instructions

AI 306 / Issue M - 11/08

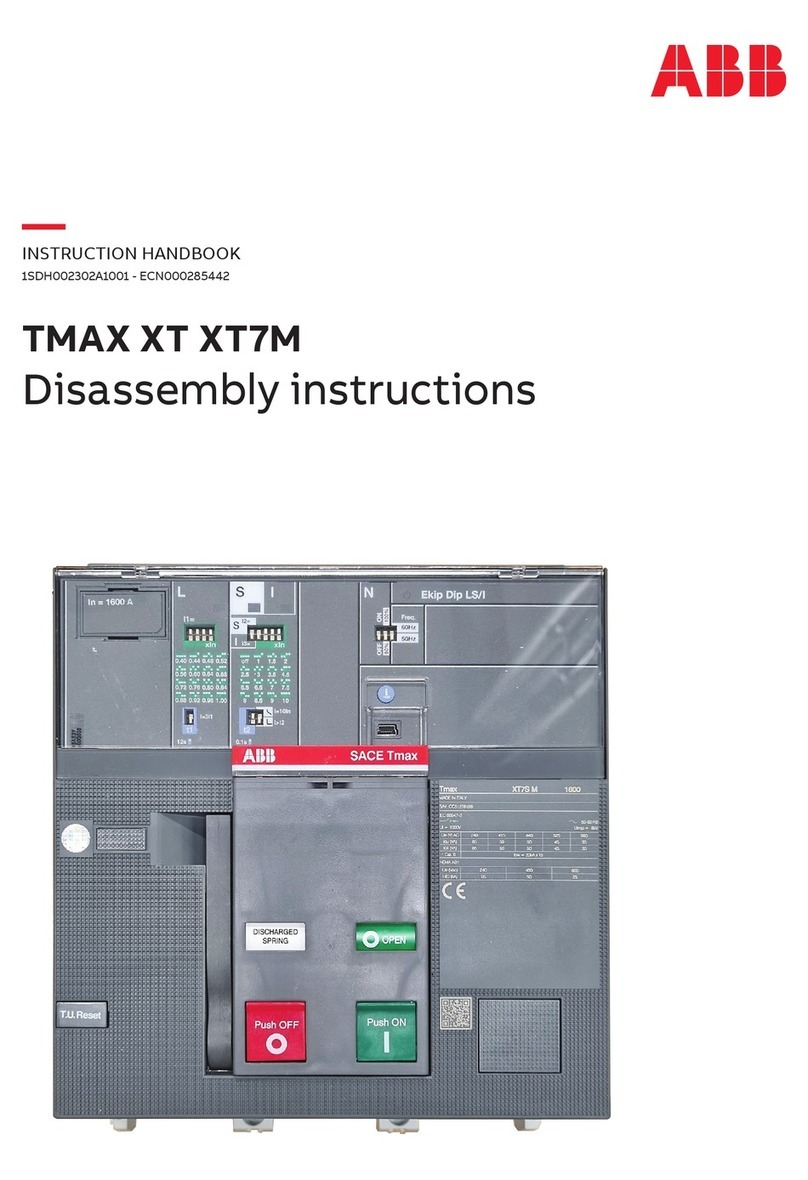

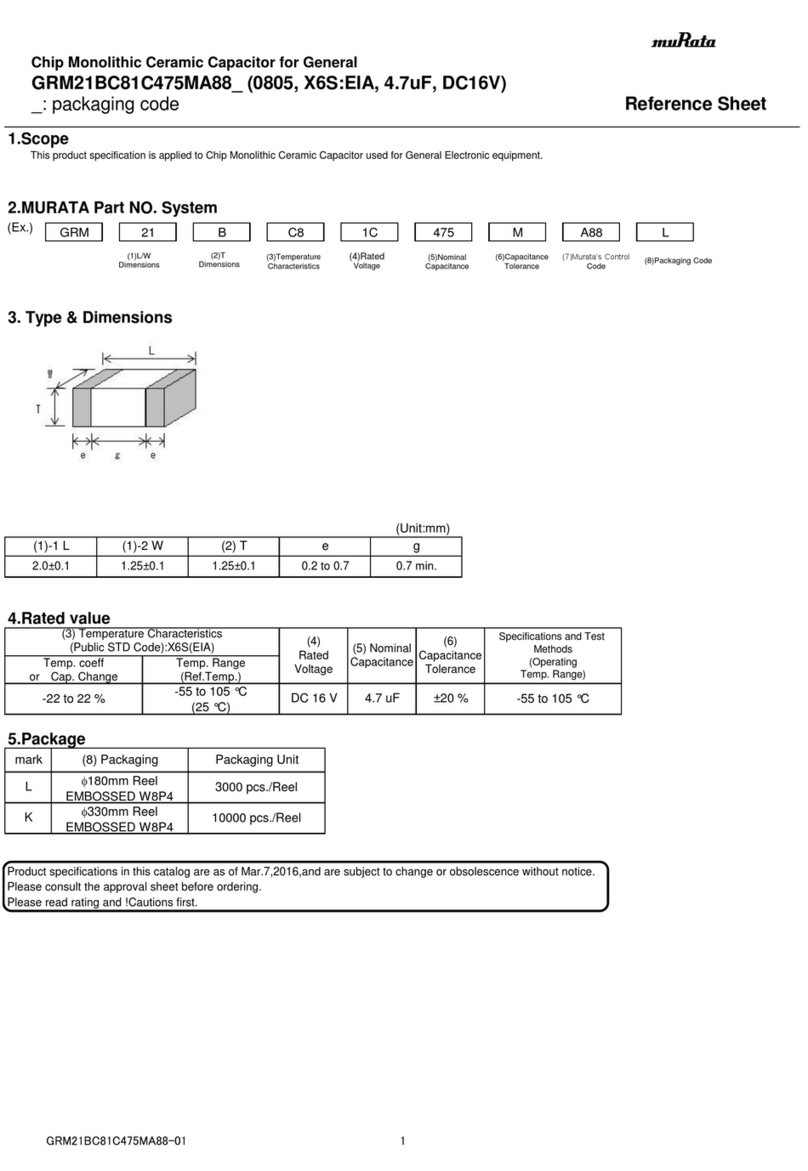

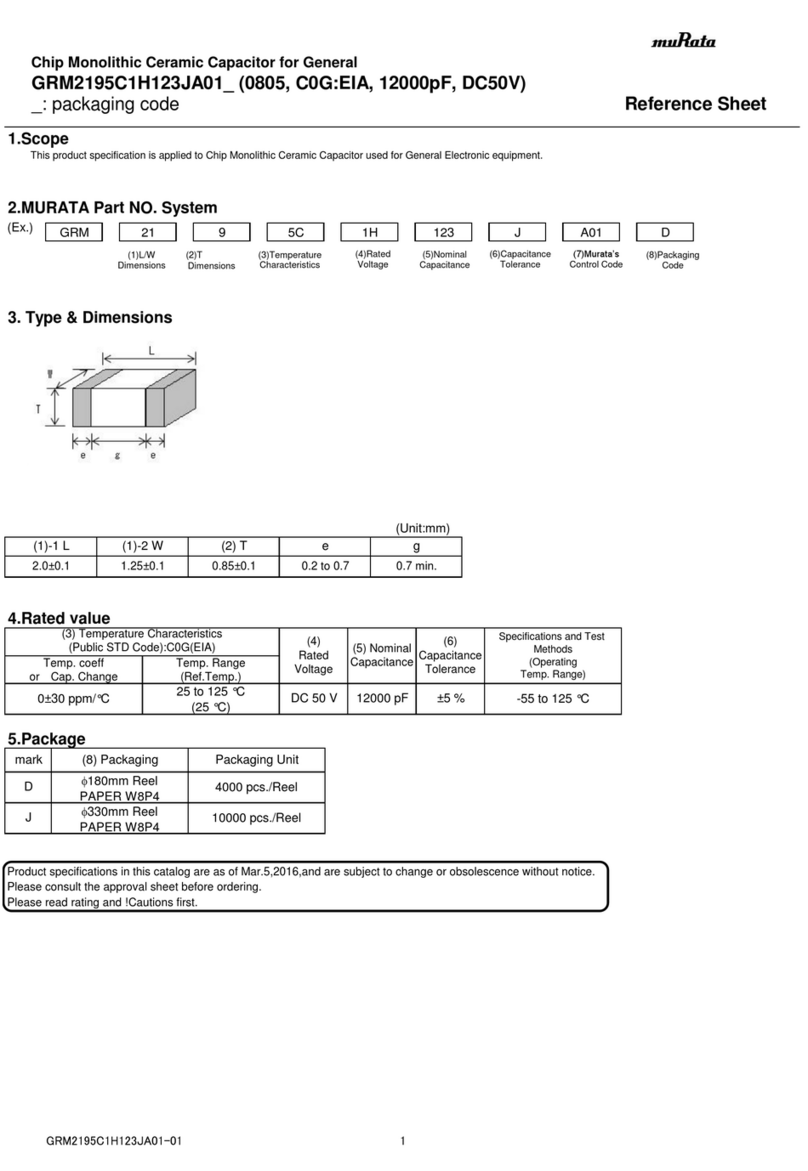

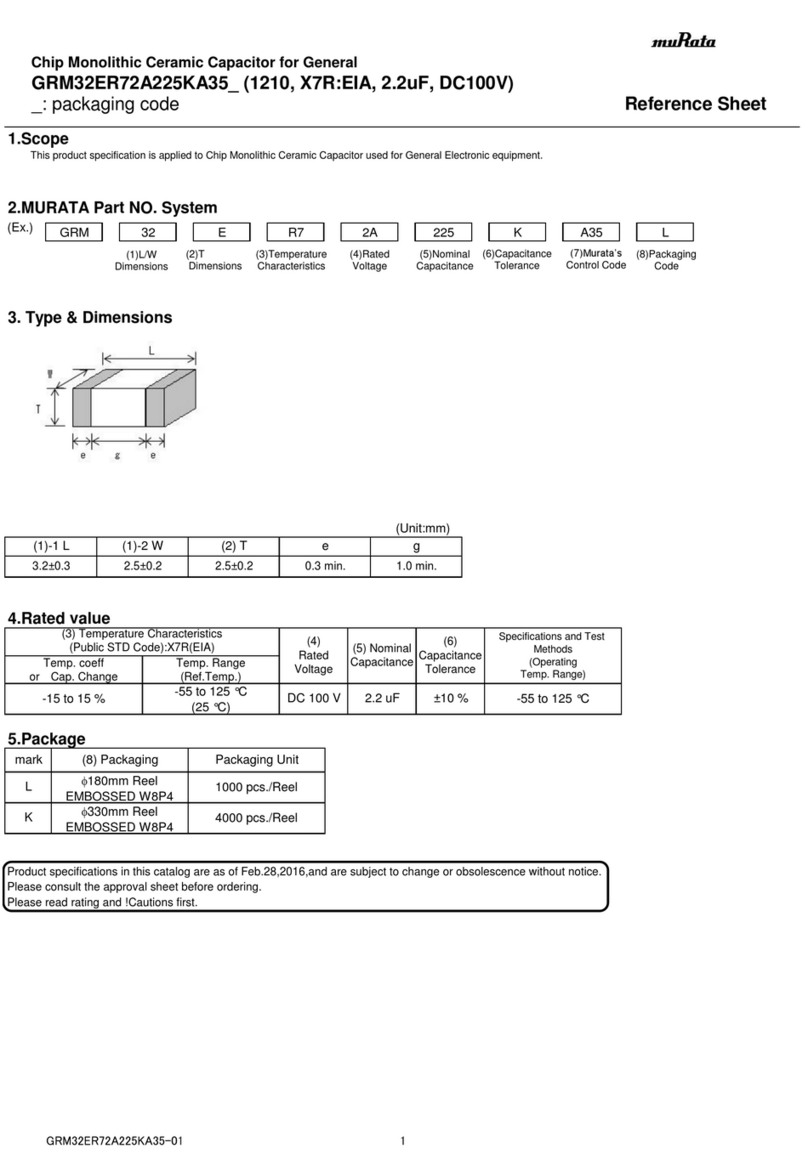

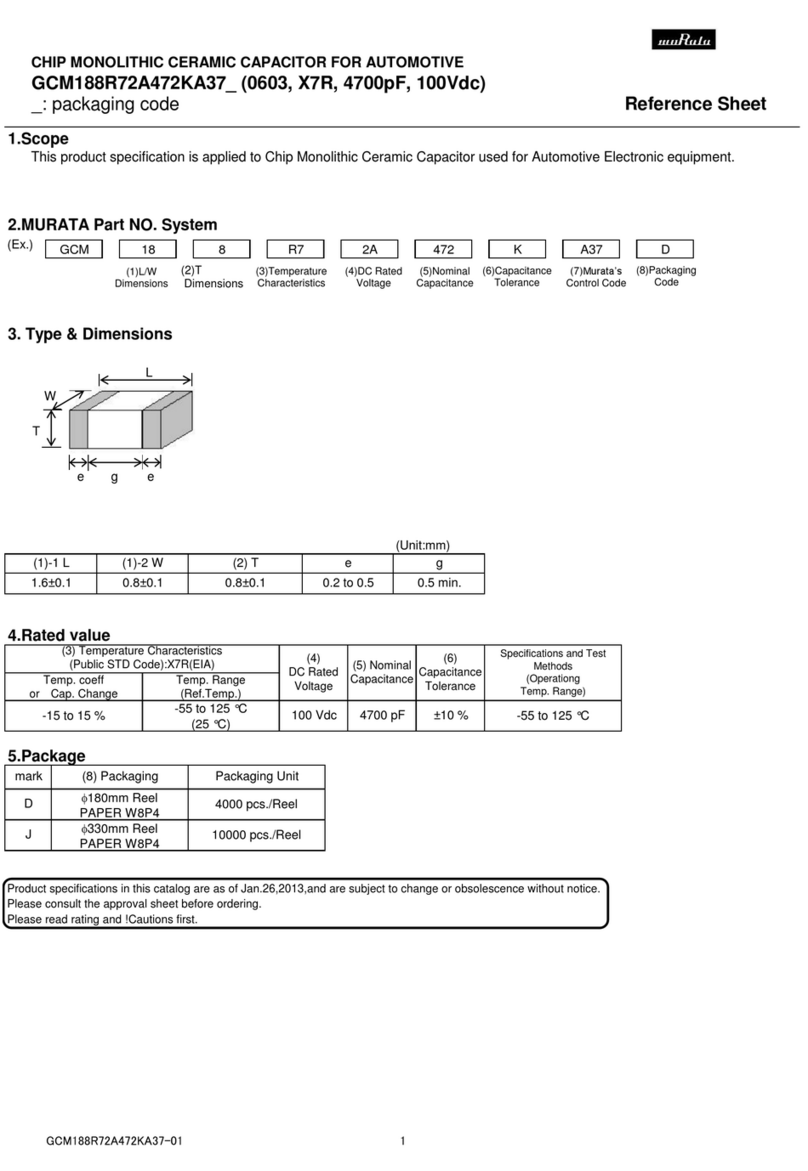

Assembly Instructions for cable gland:

501/423 Exd IIC/Exe II/ExtD

123 Industrial General Purpose

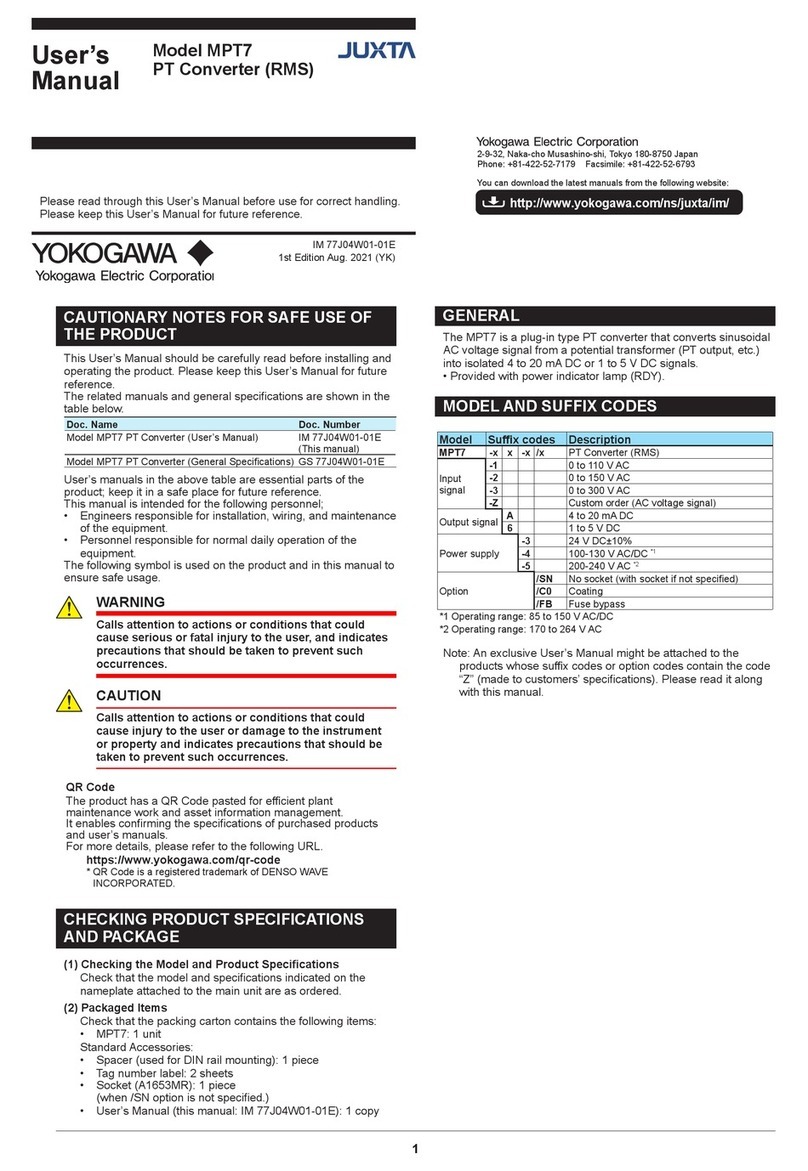

Gland Type: 501/423 Exd IIC/Exe II/ExtD

Baseefa06ATEX0056X II 2 GD A21 IP66

IECEx BAS06.0013X

CEPEL No: CEPEL-EX-060/2001X

CSA No: 1015065 (LR 78713-7)

Gland Type: 123 Industrial

Certified to Hawke Approved Drawings Only

Certification Details

1. Backnut

1.1 Compression Spigot

1.2 Seal

2. Middle Nut

2.1 Compression Spigot

2.2 Seal

3. Entry

Cable Preparation Gland Preparation

A

Allow sufficient length of cable, II, to suit equipment.

If required, fit shroud.

Pass cable through cable gland as shown above.

Note : If the equipment has a threaded entry, it may be

advisable to screw the cable gland into the equipment to

prevent twisting of the cable after Step B & C.

B

Unless already screwed into the equipment hold

the entry

in position with a spanner/wrench to

prevent rotation and tighten the middle nut

using a wrench/spanner until resistance is felt

between the seal and cable.Then turn the middle

nut through a further half to one full turn to

complete the inner seal.

C

Hold the middle nut

in position with a spanner/

wrench to prevent rotation and tighten the backnut

using a wrench/spanner untill resistance is felt between

the seal and cable, then turn the middle nut through a

further half to one full turn to complete the outer seal.

Locate the shroud over the cable gland, if applicable.

To ease wiring inside the equipment it may be beneficial

to strip the outer sheath of the cable, as shown above.

IMPORTANT:

Support the cable to prevent twisting.

II

Shroud Option

5mm minimum

recommended

II

3

2

1

3

2

1

3

2

1

2