Hazloc Heaters SRH2 User manual

SRH2SRH2SRH2

Steam Rig Heater

CRN: 0H14931.2C

Owner’s Manual, Version: SRH2-OM-B

This manual covers installation, maintenance,

repair, and replacement parts.

Industrial Grade

Heat-Exchanger Unit Heaters

WARNING!

Please adhere to all instructions published in this manual.

Failure to do so may be dangerous and may void your warranty.

The SRH2 heat-exchanger core is covered by the Safety Codes Act and therefore is not field repairable.

Contact factory for a replacement core if fluid leakage occurs.

www.HazlocHeaters.com

Part No. SRH2-OM-B

Printed in Canada

2

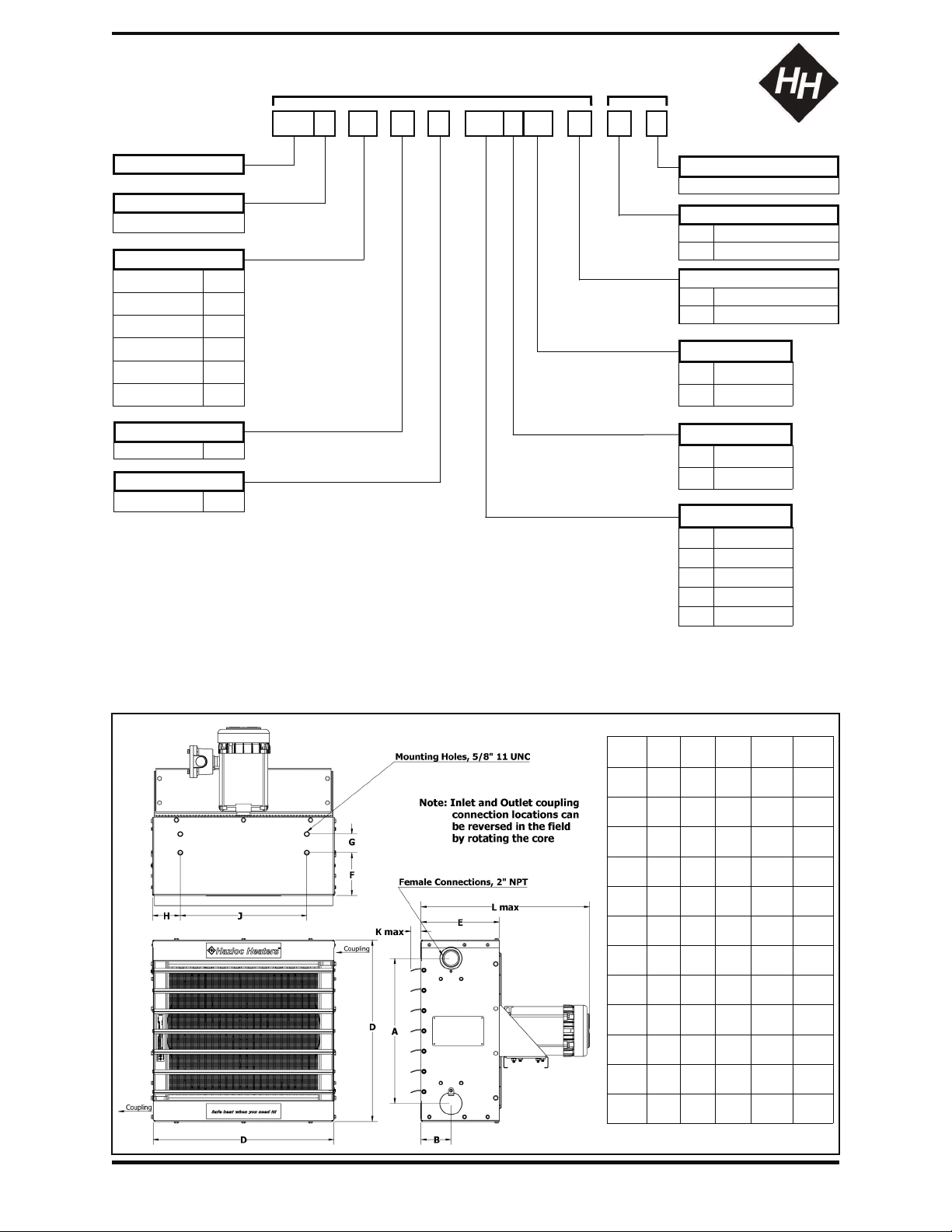

SRH2 Model Coding

SRH2 Physical Dimensions (12 inch to 30 inch models)

Model Code Sequence Required for Ordering

Model Series

Generation

For major revisions

Factory

Assigned

SRH 2 - 12 - C - 1 - 115 1 60 - E - S - A

Product Revision No.

For minor revisions

G General Purpose

Motor Type

E†Explosion proof

50 50 Hertz

Frequency

60 60 Hertz

Phase*

1 1 Phase

3 3 Phase

Motor Voltage*

115 115 Volts

208 208 Volts

230 230 Volts

460 460 Volts

575 575 Volts

#Available in single-pass configuration only due to SafeDeformTM design.

* Other voltages and 3-phase motors available upon request. Longer lead times may

apply. Contact factory.

Motors are designed to be operated at rated voltage with tolerances of ± 10%.

Ensure explosion-proof motors meet the requirements of your hazardous area rating.

†Standard ex-proof motor suitable for Class I & II, Div. 1 & 2, Groups C, D, F & G; T3B.

Approvals

CRN C

Tube Passes

1 Pass#1

12 Inches 12

16 Inches 16

20 Inches 20

24 Inches 24

30 Inches 30

Fan Size

36 Inches 36

S Standard product

Special Items

C Custom product

Heater

Size 16 20 24

Dim. Inches

(mm)

Inches

(mm)

Inches

(mm)

A 15.51

(394)

19.49

(495)

23.46

(596)

B 4.02

(102)

4.02

(102)

4.65

(118)

C 2.38

(60.5)

2.4

(61)

2.4

(61)

D 20.28

(515)

24.29

(617)

28.27

(718)

E 9.76

(248)

10.51

(267)

11.81

(300)

F 5.77

(146.5)

5.75

(146)

6.69

(170)

G 1.75

(44.5)

2.5

(63.5)

2.76

(70)

H 2.64

(67)

3.62

(92)

4.29

(109)

12

Inches

(mm)

12.6

(320)

4.02

(102)

1.85

(47)

16.3

(414)

9.76

(248)

6.77

(172)

(2 holes)

2.64

(67)

30

Inches

(mm)

29.53

(750)

5.71

(145)

2.4

(61)

34.33

(872)

13.78

(350)

7.48

(190)

3.15

(80)

4.37

(111)

J 11.02

(280)

15

(381)

17

(432)

19.69

(500)

25.59

(650)

K 1.38

(35)

1.38

(35)

1.38

(35)

1.38

(35)

1.38

(35)

L 21.65

(550)

21.65

(550)

22.83

(580)

21.21

(615)

27.36

(695)

3

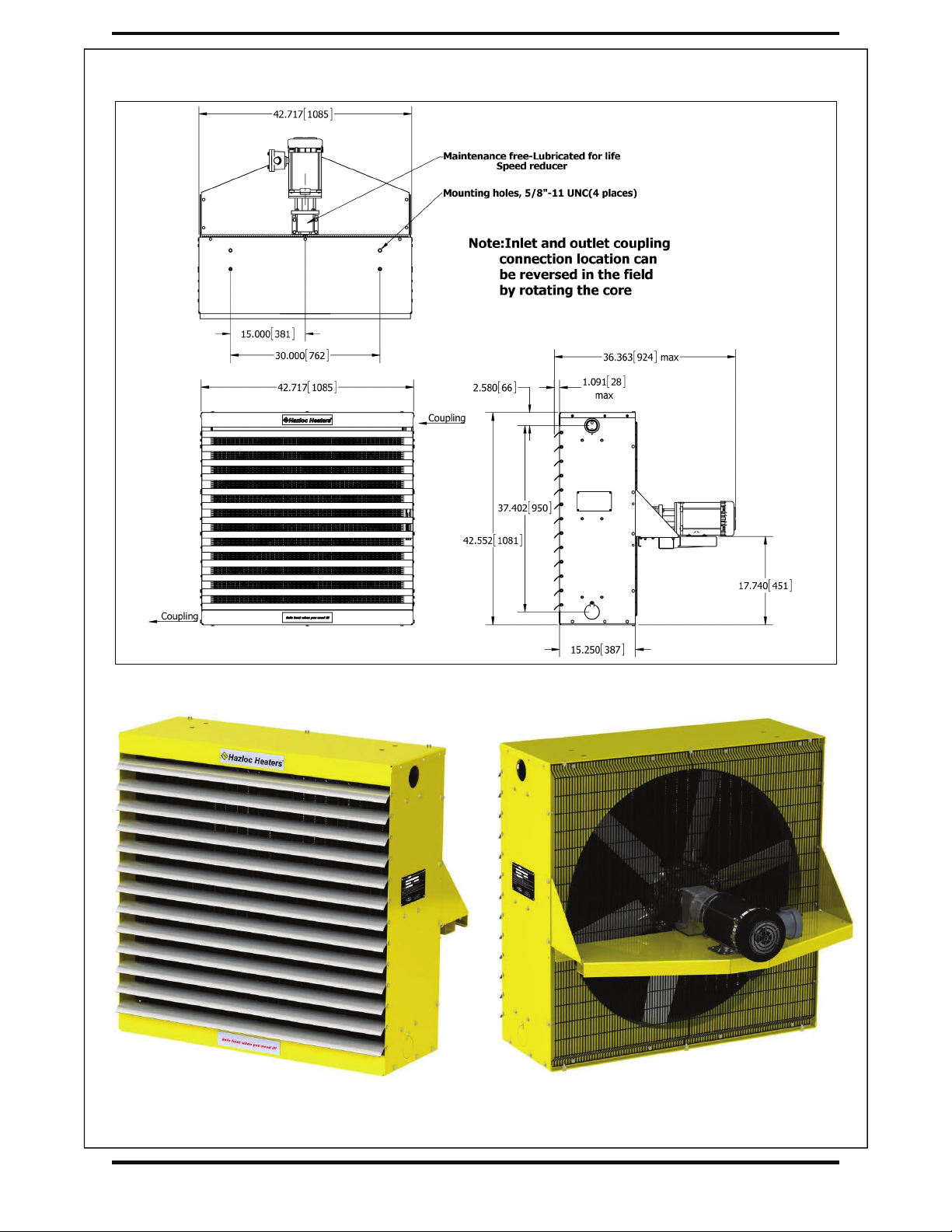

SRH2 Physical Dimensions (36 inch model)

SRH2-36 Front & Rear Views

4

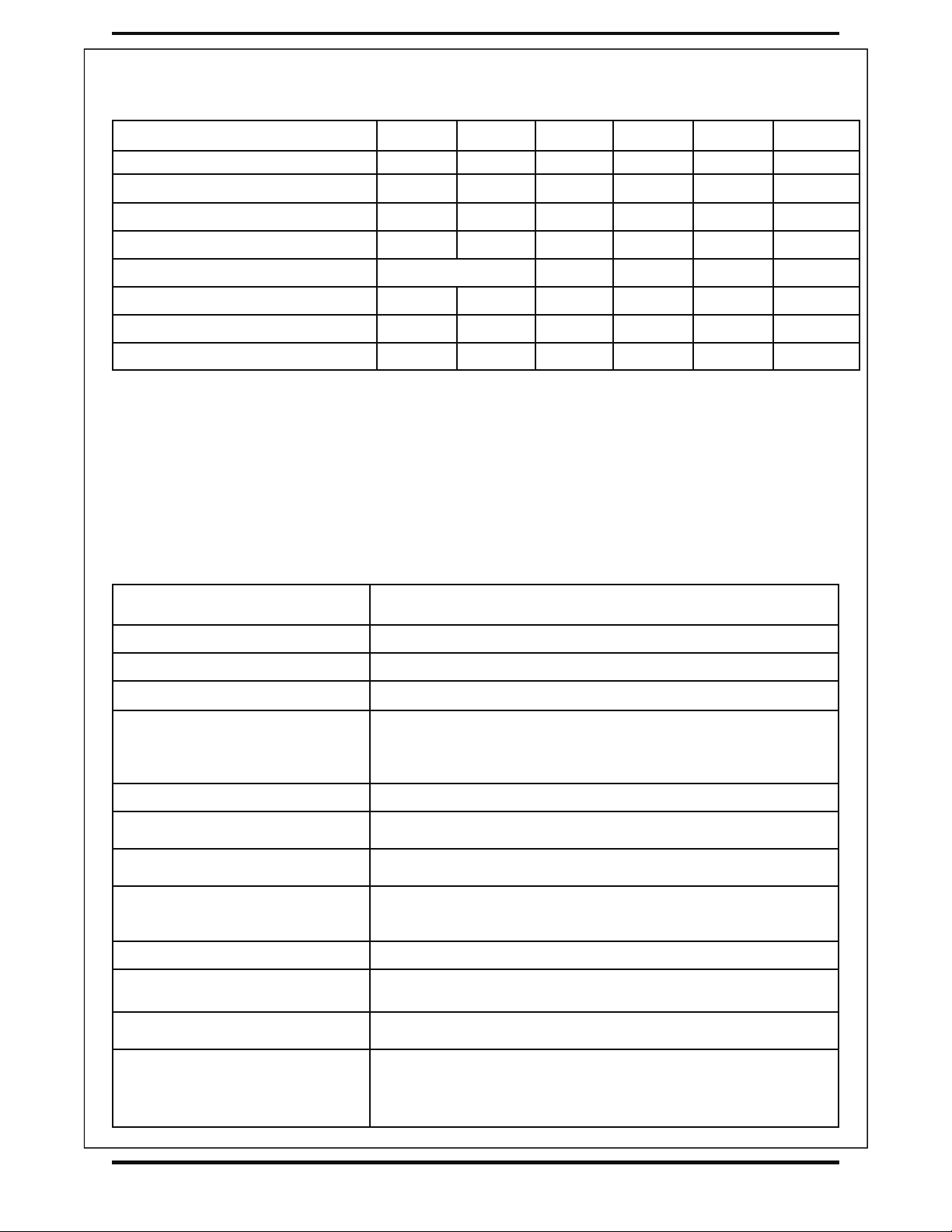

Approvals CRN: 0H14931.2C - steam or fluids (not for use with lethal fluids

as defined by ASME, Section VIII, Div. 1, UW-2).

Maximum Pressure Rating 150 psig (1,034 kPa).

Maximum Design Temperature 550 °F (288°C).

Cabinet Material

14-gauge (0.075 in.) (1.9 mm) steel. SRH2-36 is 12-gauge (0.105

in.)(2.7 mm) steel on top & bottom panels & motor mount. Yellow

epoxy/polyester powder coated with five-stage pretreatment, in-

cluding iron phosphate.

Louver Blades Anodized extruded aluminum.

Fan Spark-proof 3-blade aluminum (SRH2-30 is 2 blade and SRH2-36

is 6 blade).

Fan Guard Split design with close wire spacing. A 3/8 in. (9.5 mm) diameter

probe will not enter.

Motor Drive

Thermally protected CSA or UL Listed 1725 RPM permanently

lubricated ball bearing type with 56 frame. SRH2-36 is a 56C

frame motor and a maintenance-free speed reducer.

Mounting Holes 5/8 in. – 11 UNC – 4 holes at top of heater (2 holes, SRH2-12).

Fluid Connections 2 in. NPT female inlet and outlet (configuration of fluid connection

locations can be reversed by rotating the core).

Header Material 12-gauge (0.105 in.) (2.7 mm) and 3/16 in. (4.8 mm) carbon steel

conforming to ASME requirements.

Finned Tubes

5/8 in. (15.9 mm) outside diameter [16-gauge, 0.065 in. (1.6 mm)

wall thickness] carbon steel tubes with 1-1/2 in. (38.1 mm) outside

diameter copper-free, L-foot, tension-wound aluminum fins @ 10

fins per in.

Minimum Design Metal Temperature -20°F (-29°C).

SRH2 General Specifications

Model SRH2-12 SRH2-16 SRH2-20 SRH2-24 SRH2-30

Fan Diameter in. (mm) 12 (304.8) 16 (406.4) 20 (508.0) 24 (609.6) 30 (762.0)

Air Delivery* CFM (m3/hr) 1090 (1852) 1650 (2803) 3000 (5097) 3800 (6456) 5500 (9344)

Approx. Air Velocity* FPM (m/s) 1305 (6.6) 1111 (5.6) 1309 (6.6) 1138 (5.8) 1066 (5.4)

Air Throw* @ 15 psi steam ft (m) 45 (13.7) 65 (19.8) 70 (21.3) 80(24.4) 85 (25.9)

Motor Power HP (Watts) 1/2 (373) 1/2 (373) 3/4 (559)

Rec. Min. Mounting Height ft (m) 7.5 (2.3) 7.5 (2.3) 7.5 (2.3) 7.5 (2.3) 7.5 (2.3)

Net Weight Lbs (kg) 78 (35.4) 98 (44.4) 132 (59.9) 200 (90.7) 257 (116.6)

Shipping Weight Lbs (kg) 138 (62.6) 158 (71.7) 207 (93.9) 275 (124.7) 332 (150.6)

1/4 (186) or 1/3 (248)

SRH2-36

36 (914.4)

8350 (14186)

928 (4.7)

70 (21.3)

1(746)

7.5 (2.3)

482 (218.6)

594 (269.4)

SRH2 Specifications By Model Size

* At 70°F (21°C), 60 Hz and sea level.

5

— WARNING! —

Read and follow the instructions in this manual. Failure to do so may result in severe or fatal injury.

1. Heater is to be connected and serviced only by qualified personnel experienced in electrical, and piping

work.

2. Installation and wiring of the heater must adhere to all applicable codes.

3. For use with non-lethal fluids only, see ASME Section VIII, Div 1, UW-2.

4. Heater is suitable for maximum operating pressure of 150 psi (1,034 kPa) and maximum operating

temperature of 550°F (288°C). Refer to heater and heat-exchanger data plate.

5. Heater is suitable for use in hazardous locations only if fitted with an approved electric motor and the heat

exchanger fluid temperature is below the ignition temperature of the atmosphere. Ensure installation and

service work is performed by a qualified electrician experienced with hazardous location equipment.

6. Do not operate heater in atmospheres which are corrosive to aluminum or steel, unless it has been coated

with a factory approved protective coating.

7. Heater must be kept clean. When operating in a dirty environment, regularly clean the fin tubes, fan, and fan

guard. Refer to recommended maintenance procedures.

8. Use factory approved replacement parts only.

— INSTALLATION —

These instructions are to be used as a general guideline only.

Location

Please follow guidelines below for optimum heating results:

1. Do not install heaters such that airflow is blocked or impeded by equipment or walls.

2. For occupant comfort, position heaters so that air discharge is directed across areas of highest heat loss,

such as doors, windows, and outside walls.

3. For large areas, arrange heaters such that the air discharge of one heater is directed towards the inlet of the

next heater. This sets up a rotational airflow with air circulation in the central area of the building.

4. For equipment freeze protection, direct air discharge at required equipment.

5. For large workshops or warehouses it may be acceptable to use fewer, but larger heaters.

6. Do not direct air discharge towards a room thermostat.

7. Heater inlet and outlet coupling connection locations can be reversed in the field by removing the core,

rotating it 180 degrees, and then re-installing it. Core-coupling plugs can then be repositioned.

Mounting

1. A variety of mounting brackets are available from the factory to aid in installation.

2. The heater is designed to be installed in an upright and level position. While it may be installed in other

positions, for steam service, the inlet must be above the outlet and the bottom of the heat exchanger must

drain towards the outlet.

3. Heaters are designed to be suspended from the top of the cabinet using either two or four 5/8 – 11 UNC

bolts or threaded rod.

4. It is essential that adequate structural support be provided for installation. The mounting structure must be

strong enough to support the heaters weight, provide sufficient stiffness to prevent excessive vibration, and

withstand all probable abusive situations such as transportable installations where truck off-loading impacts,

etc. may occur.

Mounting Heights and Clearances

1. To ensure that warm air reaches the floor, heaters are usually mounted 7-1/2 ft. (2.3m) to 12 ft. (3.6 m)

above the floor. Heaters may be mounted at higher elevations and still provide warm air at floor level

however, the maximum mounting elevation at which this occurs depends on location and operational

conditions.

6

2. Louvers may be adjusted to provide greater downward deflection of the discharge air. However, it is

recommended that louvers not be set less than 15 degrees from the closed position.

3. Leave at least 22 in. (559 mm) clearance between the rear of the motor and the nearest obstruction.

4. For easy removal of the heat exchanger core assembly, leave clearance beneath the heater equal to the

height of the heater cabinet plus 3 in. (76 mm).

— PIPING SUGGESTIONS —

Suggested piping arrangements only, refer to ASHRAE HVAC Systems & Equipment for more detail

Return Main

Thermostatic Air

Vent option

Petcock (install if trap

does not have air vent)

OR

Hazloc Heaters

Hazloc Heaters

Gate Valve

Steam Main

Union

6" Long

Full Size

Dirt Pocket

Inverted

Bucket Trap

Return Main

Union

Swing

Check

Valve

Gate Valve

15"12"

Gate Valve

Steam Main

Gate Valve

Float &

Thermostatic Trap

Strainer

6" Long

Full Size

Dirt Pocket

10" Min.

Unit Heater Connection for High Pressure Steam

Unit Heater Connection for Low Pressure Steam

- Open Gravity or Vacuum Return System

Note: Heater inlet and outlet coupling

connection locations can be

reversed in the field by rotating

the core.

Corrosion in steam and condensate system piping & unit heaters occurs as a result of the formation of acids within the steam and condensate. The

best defense against corrosion is a boiler water chemical treatment program.

Install heaters using proper piping practices.

Do not use with fluids corrosive to steel.

Use a properly sized steam trap. Inspect traps regularly under your routine maintenance program.

In horizontal pipe runs, use eccentric reducers only.

7

— Piping Practices —

1. Steam unit heaters condense steam rapidly, especially during warm-up periods. The return piping must be

planned to keep the heat-exchanger’s core free of condensate during periods of maximum heat output, and

steam piping must be able to carry a full supply of steam to the unit heater to take the place of condensed

steam. Adequate pipe size is especially important when a unit heater fan is operated under on-off control

because the condensate rate fluctuates rapidly.

2. Heater is to be connected and serviced only by qualified personnel experienced in piping work. For

additional piping information refer to industrial piping handbooks and related literature.

3. Eliminate pipe stress by adequately supporting all piping. Do not rely on heater to support piping.

4. Take off all branch lines from the top of steam mains, preferably at a 45° angle, although vertical 90°

connections are acceptable.

5. Pipe the branch supply line into the steam unit heater’s inlet at the top and the return branch line from the

outlet at the bottom. The heater’s inlet and outlet coupling connections can be reversed in the field

by rotating the heat-exchanger core. Refer to Page 9, Heat-Exchanger Core Assembly Replacement.

6. In steam systems, the branch from the supply main to the heater must pitch down towards the main and be

connected to its top in order to prevent condensate in the main from draining through the heater, where it

might reduce capacity and cause noise. In long branch lines, a drip trap may be needed.

7. Allow for pipe expansion to prevent excessive strain on the unit heater’s heat-exchanger core.

8. The return piping from steam unit heaters should provide a minimum drop of 10 in (254 mm) below the

heater so that the pressure of water required to overcome resistances of check valves, traps, and strainers

will not cause condensate to remain in the heater.

9. In steam systems, where horizontal piping must be reduced in size, use eccentric reducers that permit the

continuance of uniform pitch along the bottom of piping (in downward pitched systems). Avoid using

concentric reducers on horizontal piping, because they can cause water hammer.

10. Installing dirt pockets at the outlet of unit heaters and strainers with 0.063 in. (2 mm) perforations to prevent

rapid plugging are essential to trap dirt and scale that might affect the operation of check valves and traps.

Strainers should always be installed in the steam supply line if the heater is valve controlled.

11. In steam systems, rapid air removal is required because entrained air is a cause of corrosion. Proper air

venting for steam systems can be achieved by use of a steam trap with an internal air vent.

12. Steam traps must be located below the outlet of the unit heater. Consult the trap manufacturer for specific

recommendations. Each steam unit heater should be provided with a trap of sufficient size and capacity to

pass a minimum of twice the normal amount of condensation released by the unit at the minimum differen-

tial pressure in the system. Trap capacity is based on the pressure differential between supply and return

mains. Steam systems should be equipped with a float and thermostatic trap or inverted bucket trap with an

air bypass.

13. If the condensate return line is above the heater outlet or is pressurized, install a check valve after the

steam trap and a drain valve at the strainer to drain the system during the off season.

14. Install pipe unions and shut-off valves at connection points of each unit heater to allow maintenance or

replacement of unit without shutting down and draining the entire system.

15. Adequate air venting is required for low-pressure closed gravity systems. The vertical pipe connection to

the air vent should be at least 3/4 in. NPT to allow water to separate from the air passing to the vent. If

thermostatic instead of float-and-thermostatic traps are used in vacuum systems, a cooling leg must be

installed ahead of the trap.

16. In high-pressure systems, it is customary to continuously vent the air through a petcock unless the steam

trap has a provision for venting air. Most high-pressure return mains terminate in flash tanks that are vent-

ed to the atmosphere. When possible, pressure reducing valves should be installed to permit operation of

the heaters at low pressure. Steam traps must be suitable for the operating pressure encountered.

17. On steam systems where the steam supply to the unit heater is modulated or controlled by a motorized

valve, a vacuum breaker should be installed between the unit outlet and a float and thermostatic trap.

8

— Warning —

Wiring should only be connected by qualified personnel experienced in electrical work.

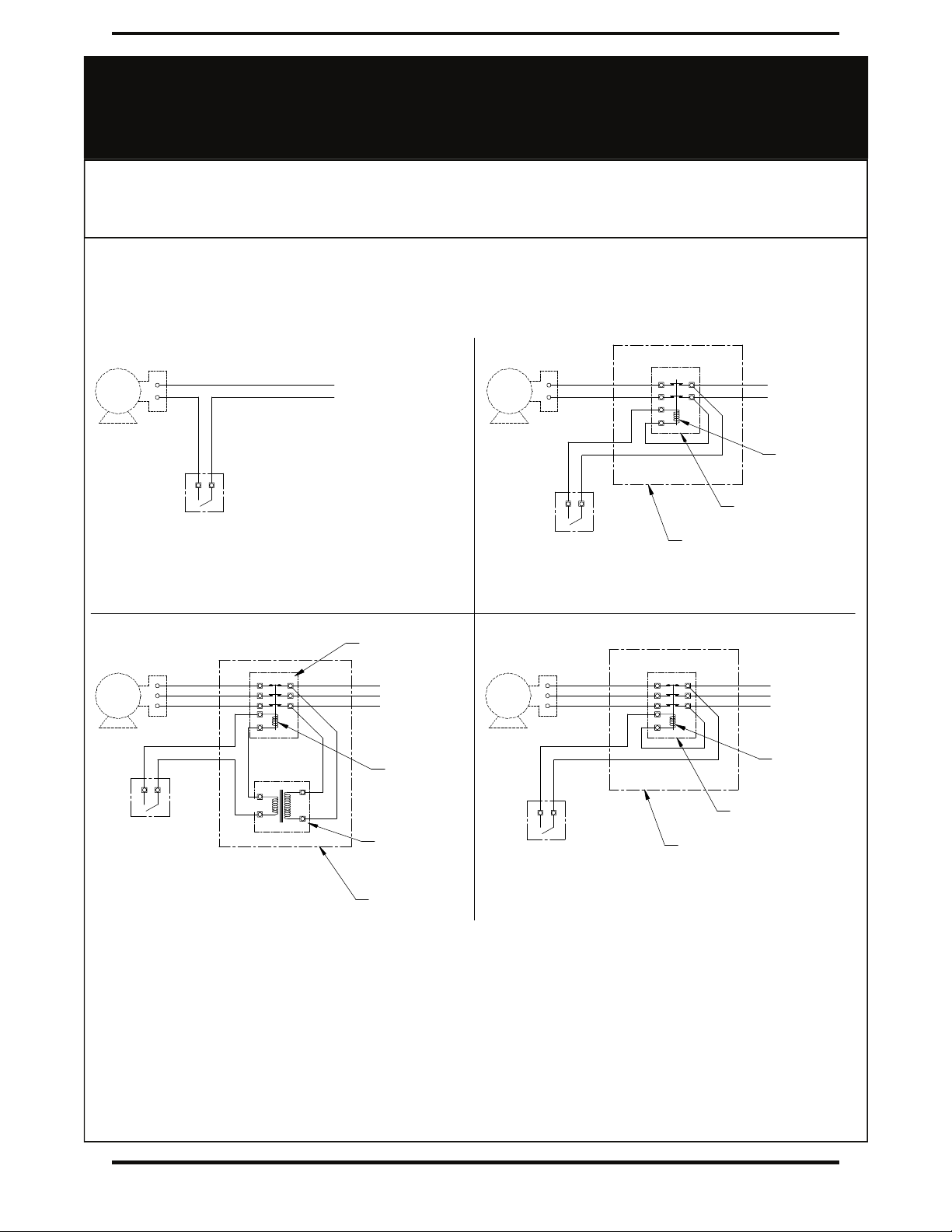

— Electrical Wiring of Motor and Remote Mount Thermostats —

Fan

blade

Motor

Fan

blade

Motor

Fan

blade

Motor

Fan

blade

Motor

Neutral

115 Volt

Thermostat

Supply Voltage

115 Volts,

Single Phase

230 Volt

Thermostat Remote control panel

By customer

2 pole contactor relay

By customer

208/230 Volt

Contactor coil

Supply Voltage

208/230 Volts,

Single Phase

Thermostatic Control for

115 Volts, Single phase motors

Thermostatic Control for

208/230 Volts, Single phase motors

Thermostatic Control for

460/600 Volts, Three phase motors

Thermostatic Control for

208/230 Volts, Three phase motors

Remote control panel

By customer

3 pole contactor relay

By customer

208/230 Volt

Contactor coil

Supply Voltage

208/230 Volts,

Three Phase

Remote control panel

By customer

Voltage Transformer

By customer

24 to 230 Volt

Contactor coil

Supply Voltage

460/600 Volts,

Three Phase

3 pole contactor relay

By customer

24 to 230 Volt

Thermostat

24 to 230 Volt

230 Volt

Thermostat

Motor wiring diagram is located on the motor. On all three-phase heater motors, it is neces-

sary to verify that the fan rotation is correct (counter clockwise when facing the rear of the

heater). If air delivery is not from the front of the heater, reverse any two supply leads in

the motor junction box or the main electrical panel.

9

Heat-Exchanger Core Assembly Replacement

1. Assistance is usually required to remove heat-exchanger core assembly safely.

2. It is not necessary to dismount unit heater from its support structures to remove the heat-exchanger core

assembly. However, it may be advisable in some instances to allow for core assembly removal at ground or

bench level.

3. Remove the bottom heater cabinet cover which is attached with six (6) screws and three (3) bolts.

4. Remove the four bolts on each side of the cabinet while supporting the heat exchanger core assembly.

5. Lower the core assembly from heater.

6. Reverse the procedure to install replacement core and tighten four (4) core bolts to 90 in-lbs torque, bottom

panel screws to 28 in-lbs, and fan panel bolts to 100 in-lbs.

Fan, Fan Guard or Motor Replacement

1. For replacement of fan or fan guard remove four bolts holding motor to the motor mount. For SRH2-36 also

remove speed reducer bolts. If replacing motor only on SRH2-36, only remove motor mounting bolts and

C-face flange bolts.

2. Detach two-piece fan guard assembly by removing top and bottom screws that attach the fan guard to the

cabinet.

3. Remove fan guard pieces through top or bottom. Due to stiffness of fan guards, you may need to remove

two outer top or bottom bolts that attach the fan panel to the top or bottom cabinet panels to provide suffi-

cient clearance.

4. Lift the motor, speed reducer (for SRH2-36 only) and fan assembly off the motor mount.

5. Loosen fan hub screws and remove fan blade from motor shaft.

6. To reassemble, position fan on motor shaft with end of shaft even with face of hub. Ensure the set screw is

faced towards motor and lined up perpendicular to factory-ground flat on motor shaft. This flat is our “Easy-

Off” fan blade replacement feature and only comes on motors purchased from Hazloc Heaters. Tighten set

screw to 150 in-lbs torque.

7. Place motor, speed reducer (for SRH2-36 only) and fan assembly onto motor mount and fasten the two-

piece fan guards to the cabinet.

8. Center fan in fan-shroud opening and leave approximately 1/16” to 3/16” (1.6 to 4.8 mm) gap between

motor face and fan guard.

9. Bolt motor to motor mount, tighten nuts to 250 in-lbs torque. Manually spin the fan blade to ensure it rotates

freely before reconnecting heater to power supply. Fan must rotate counterclockwise when viewed from

rear of heater.

— WARNING! —

Heater should only be service by qualified personnel experienced in electrical and piping work.

Disconnect unit heater from power supply before starting any service or repair work. Lock the disconnect

switch in the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

Failure to follow these procedures may result in severe or fatal injury.

— Repair and Replacement —

Item Torque (in-lbs)

Fan blade set screw 150

5/16 - 18 UNC motor nuts 250

1/4 - 20 UNC core bolts 90

Torque Settings

1/4 - 20 UNC fan panel bolts 100

5/16 - 18 UNC motor mount bolts 250

#10 - 24 UNC bottom panel & louver blade screws 28

1/4 - 20 UNC fan guard self tapping screws 100

Note: Heater inlet and outlet coupling

connection locations can be reversed

in the field by removing the core,

rotating it 180 degrees, and then

re-installing it. Core-coupling plugs

can then be repositioned.

10

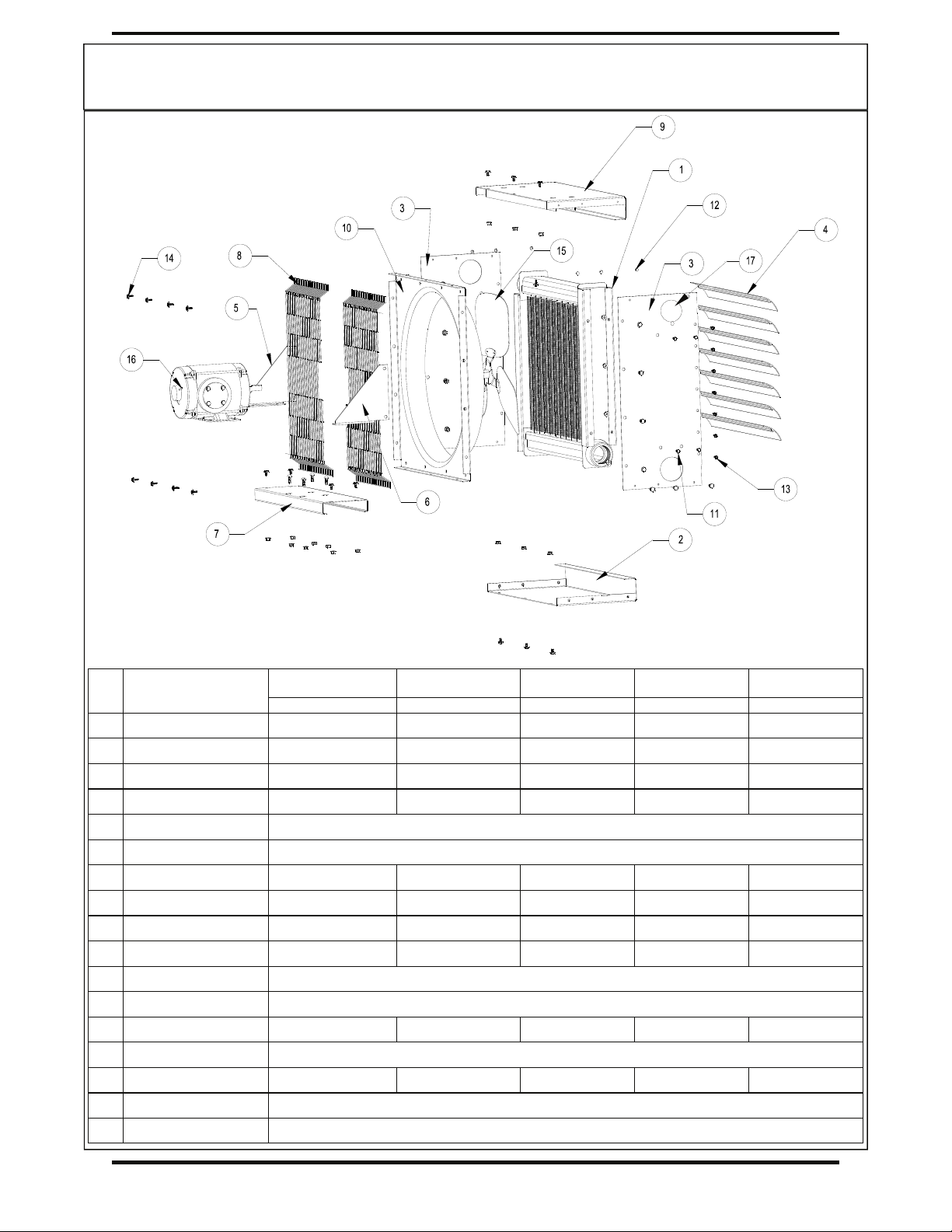

Item

No. Description SRH2-12 SRH2-16 SRH2-20 SRH2-24 SRH2-30

Part Number Part Number Part Number Part Number Part Number

1 Core assembly (1-pass) SRH2-12-10 SRH2-16-10 SRH2-20-10 SRH2-24-10 SRH2-30-10

2 Bottom panel HUH1-12-20-001 HUH1-16-20-001 HUH1-20-20-001 HUH1-24-20-001 HUH1-30-20-001

3 Side panel HUH1-12-20-002 HUH1-16-20-002 HUH1-20-20-002 HUH1-24-20-002 HUH1-30-20-002

4 Louver blade kit HUH1-12-20-003-K HUH1-16-20-003-K HUH1-20-20-003-K HUH1-24-20-003-K HUH1-30-20-003-K

5 Right side motor bracket HUH1-12-20-005

6 Left side motor bracket HUH1-12-20-006

7 Motor base HUH1-12-20-007 HUH1-16-20-007 HUH1-20-20-007 HUH1-24-20-007 HUH1-30-20-007

8 Fan guard (2 pieces) HUH1-12-20-008 HUH1-16-20-008 HUH1-20-20-008 HUH1-24-20-008 HUH1-30-20-008

9 Top panel HUH1-12-21 HUH1-16-21 HUH1-20-21 HUH1-24-21 HUH1-30-21

10 Fan panel HUH1-12-22 HUH1-16-22 HUH1-20-22 HUH1-24-22 HUH1-30-22

11 Core screw kit HUH-CM-SK

12 POP rivet, 3/16” kit HH-TP-RK

13 Louver screw kit HUH1-12-LB-SK HUH1-16-LB-SK HUH1-20-LB-SK HUH1-24-LB-SK

14 Fan guard screw kit HH-FG-SK

15 Fan blade HUH1-12-FB HUH1-16-FB HUH1-20-FB HUH1-24-FB HUH1-30-FB

16 Motor Specify motor voltage, phase, frequency, horsepower and type of enclosure (general purpose or explosion-proof)

17 Coupling-hole plug HUH1-001

HUH1-30-LB-SK

— Parts List —

*** Please have heater model & serial number available before calling ***

Note: Inlet and outlet coupling

connection locations can

be reversed in the field

by rotating the core.

SRH2 (12 inch to 30 inch models)

11

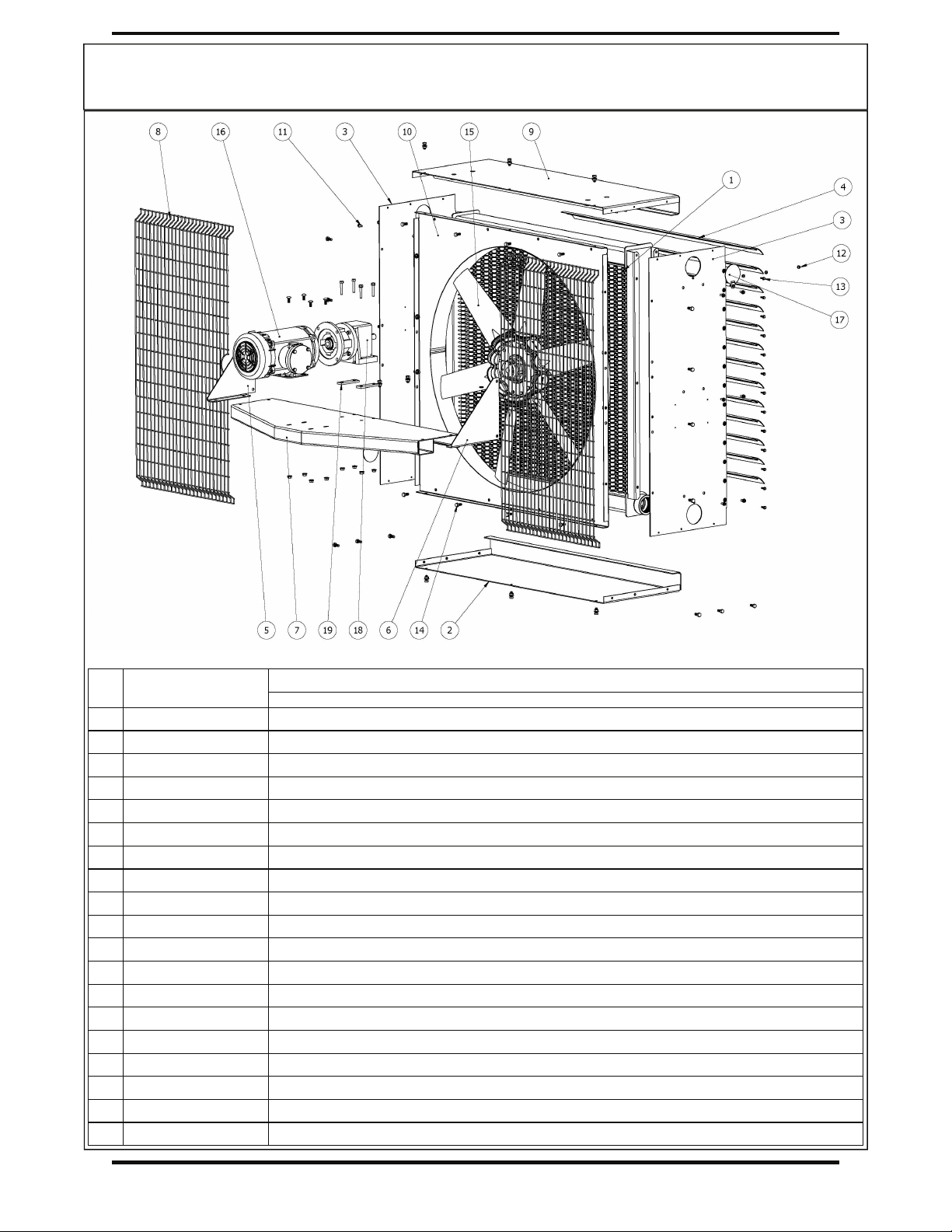

Item

No. Description SRH2-36

Part Number

1 Core assembly (1-pass) SRH2-36-10

2 Bottom panel HUH2-36-20-001

3 Side panel HUH2-36-20-002

4 Louver blade kit HUH2-36-20-003-K

5 Right side motor bracket HUH2-36-20-005

6 Left side motor bracket HUH2-36-20-006

7 Motor base HUH2-36-20-007

8 Fan guard (2 pieces) HUH2-36-20-008

9 Top panel HUH2-36-21

10 Fan panel HUH2-36-22

11 Core screw kit HUH-CM-SK

12 POP rivet, 3/16” kit HH-TP-RK

13 Louver screw kit HUH2-36-LB-SK

14 Fan guard screw kit HH-FG-SK

15 Fan blade HUH2-36-FB

16 Motor Specify motor voltage, phase, frequency, horsepower and type of enclosure (general purpose or explosion-proof)

17 Coupling-hole plug HUH1-001

18 Speed Reducer HUH2-36-SD

19 Speed reducer shim HUH2-36-20-010

— Parts List —

*** Please have heater model & serial number available before calling ***

Note: Inlet and outlet coupling

connection locations can

be reversed in the field

by rotating the core.

SRH2 (36 inch model)

12

Regular inspection, based on a schedule determined by the amount of dirt in the atmosphere, assures

maximum operating economy and heating capacity.

Annual Inspection (before each heating season)

1. Check all terminal connections and electrical conductors for damage, looseness, defects, fraying, etc. and

replace or tighten where applicable.

2. Check for fluid leakage from heat-exchanger core. If fluid leakage occurs, remove heater from service and

have the heat-exchanger core replaced by a factory replacement unit. Refer to “Repair and Replacement”

section for complete details. Note: This heat-exchanger core is covered by the Safety Codes Act and

therefore is not field repairable.

3. Check electrical junction box. Inside of enclosure must be clean, dry, and free from any foreign materials.

The cover must also be completely on and tight.

4. Check motor shaft bearing play. Replace motor if play is excessive or if motor does not run quietly and

smoothly. Motor bearings are permanently lubricated.

5. On SRH2-36 models, speed reducer is maintenance free. Check for excessive noise and vibration.

6. Check fan. Replace immediately if cracked or damaged.

7. Check louvers. Louver screws should be tight. Louvers are not to be set less than 15 degrees of the closed

position.

8. Check the tightness of all hardware. All nuts and bolts, including mounting hardware, must be tightened to

torque settings on Page 9.

9. Turn heater motor on for a minimum of 10 minutes. Check for air exiting heater through louvers and smooth

running of motor.

10. Ensure periodic cleaning of complete heater is done

Periodic Maintenance (before and as required during heating season)

1. Clean the following (remove dust using compressed air):

Finned tubes

Fan

Fan Guard

Motor

Louvers

Cabinet

2. Check the following:

Motor (and speed reducer on SRH2-36) for smooth and quiet operation

Louvers for proper angle and tightness

Electrical junction box covers are secure

— WARNING! —

Heater should only be service by qualified personnel experienced in electrical and piping work.

Disconnect unit heater from power supply before starting any service or repair work. Lock the disconnect

switch in the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

Failure to follow these procedures may result in severe or fatal injury.

— Maintenance Program —

13

HEATER MAINTENANCE RECORD

Heater Model: _________________________ Serial No.: ______________________________

Date of

Maintenance

Performed

By Maintenance Performed

14

NOTES

15

NOTES

PRINTED IN CANADA

©Copyright 2015

The information contained in this

manual has been carefully checked

and verified for accuracy. Specifica-

tions subject to change without

notice.

Hazloc Heaters is a trademark of

Hazloc Heaters Inc.

#1, 666 Goddard Ave. NE

Calgary, Alberta T2K 5X3

Canada

Tel.: +1-403-730-2488

Fax: +1-403-730-2482

Customer Toll Free (U.S. & Canada):

+1-866-701-Heat (4328)

www.HazlocHeaters.com

Limited 18-Month Warranty

Hazloc HeatersTM warrants all SRH2 series of heat-exchanger unit

heaters against defects in materials and workmanship under normal

conditions of use for a period of eighteen (18) months from date of

purchase based on the following terms:

1. The heater must not be modified in any way.

2. The heater must be stored, installed and used only in accordance with

the owner’s manual and attached data plate information.

3. Replacement parts will be provided free of charge as necessary to

restore any unit to normal operating condition, provided that the

defective parts be returned to us freight prepaid and that the

replacement parts be accepted freight collect.

4. The complete heater may be returned to our manufacturing plant for

repair or replacement (at our discretion), freight charges prepaid.

5. Components damaged by contamination from dirt, dust, etc. or

corrosion will not be considered as defects.

6. This warranty shall be limited to the actual equipment involved and,

under no circumstances, shall include or extend to installation or

removal costs, or to consequential damages or losses.

Table of contents

Other Hazloc Heaters Heater manuals

Popular Heater manuals by other brands

flowair

flowair LEO FB 10 Operation manual

Pentair

Pentair ETi 400 installation guide

Goldair

Goldair GBH100 operating instructions

Arcotherm

Arcotherm EC 200 Service manual

Superior Radiant

Superior Radiant eWAVE Series Installation, operation and service instructions

Dimplex

Dimplex XLE Series quick start guide