HB-THERM M8095-EN User manual

Temperatur Control Technology

www.hb-therm.ch

M8095-EN 2020-09 1/13

2020-09

Page

Assembly Instructions

M8095-EN

Spare part unit board GIF-51 (O/ID T25240-X, T27401-X)

Contents

Purpose...........................................................................................2

Precondition...................................................................................2

Procedure .......................................................................................2

Product group Thermo-5...............................................................3

Product group Treat-5 and Clean-5............................................10

Parts list........................................................................................13

Assembly Instructions M8095-EN

M8095-EN 2020-09 2/13

Purpose

Replacement of control unit board GIF-51 (A 4)

Precondition

WARNING!

Danger for unauthorized persons!

Conversion work may only be carried out by

specialist staff who have been trained accordingly.

Therefore:

–Keep unauthorized persons away from the work

area.

NOTE!

Knowledge of the Instruction Manual is a

precondition for carrying out conversion work on

the unit.

Procedure

DANGER!

Danger to life caused by electric current!

Touching conductive parts causes a direct danger

to life.

Therefore:

–For all work on the electrical system, for

maintenance, cleaning or repair work,

disconnect from the mains or disconnect all

phases of the external power supply and secure

them against being switched on again. Check

unit is isolated from power supply.

WARNING!

Danger of crushing due to rolling away or

tipping

With an uneven floor or when the castors are not

locked, there is a danger that the unit tips over or

rolls away causing crushing.

Therefore:

–Only install the unit on an even floor.

–Ensure that the castors are locked.

Assembly Instructions M8095-EN

M8095-EN 2020-09 3/13

Product group Thermo-5

1. Switch off master switch and disconnect from mains supply.

2. Loosen the screws in the front panel and hinge it down.

3. Proceed as follows in order to remove the GIF-51 (A 4):

Remove all connectors.

Remove the flexes that are led through current transformers

(TA 1.1, 1.2, 1.3) at the contactor or terminal:

Cable routing

(from to)

Unit type

KM 1

X 86

Housing size 1+2, 8 kW, 400/460 V

KM 1

XT 2

Housing size 1, 8 kW, 210 V

KM 1

XT 2

Housing size 2, 16 kW, 400/460 V

XT 2

V x.x

Housing size 2, 8+16 kW, 210 V

KM 1

FS 4

Housing size 3, Pump type G_, L_, 6_, 8_

Remove the screws on the sides of the board.

On oil unit unplug the printed circuit board level measuring

(A 10).

Fig. 1: Cable routing

Fig. 2: Cable routing housing size 3 pump

G_, L_, 6_, 8_

4. Proceed as follows in order to fit the new GIF-51 (A4):

On oil unit insert the printed circuit board level measuring (A 10)

into new GIF-51.

Fit the GIF-51 and fix with the screws.

Route the wires through current transformers (TA 1.1, 1.2, 1.3)

and connect them (Fig. 1).

Cable routing

(from to)

Unit type

KM 1

X 86

Housing size 1+2, 8 kW, 400/460 V

KM 1

XT 2

Housing size 1, 8 kW, 210 V

KM 1

XT 2

Housing size 2, 16 kW, 400/460 V

XT 2

V x.x

Housing size 2, 8+16 kW, 210 V

KM 1

FS 4

Housing size 3, Pump type G_, L_, 6_, 8_

For housing size 3, pump type G_, L_, 6_, 8_ additionally lead

wires from cable connector (X 63) through current transformer

(TA 1.2) and connect to contactor KM 4/A1, KM 5/A1 (Fig. 2).

Connect all connectors.

Connect main pump cable (X 62/X 64):

Voltage 200–220 V Slot X 62 (triangle)

Voltage 380–480 V Slot X 64 (star)

A 10

fromto

X 62

X 64

TA 1.3

TA 1.2

TA 1.1

KM 4/KM 5

X 63

TA 1.2

Assembly Instructions M8095-EN

M8095-EN 2020-09 4/13

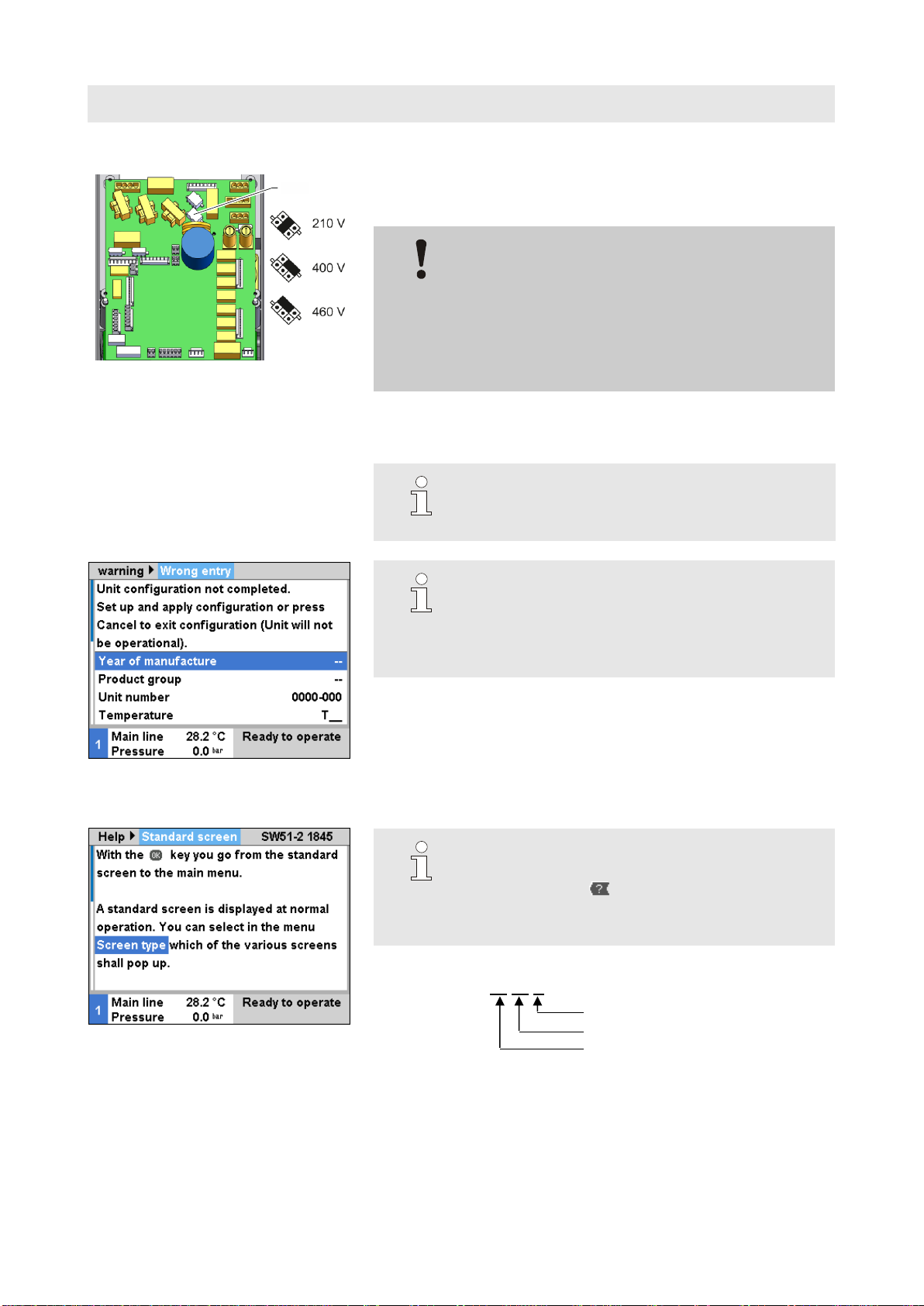

Fig. 3: Voltage selection GIF-51

5. Voltage selection at X 15 with bridge plug (O/ID T21608):

Verify mains voltage (specification on the nameplate)

Place bridge according (Fig. 3)

ATTENTION!

Danger if wrongly connected

Wrong voltage selection or wrong connections can

damage the unit

Therefore:

–Thoroughly check connections and voltage

selection

6. Close and secure the front panel.

7. Reconnect mains plug and switch on main switch.

NOTE!

The unit will maybe perform an automatic software

update.

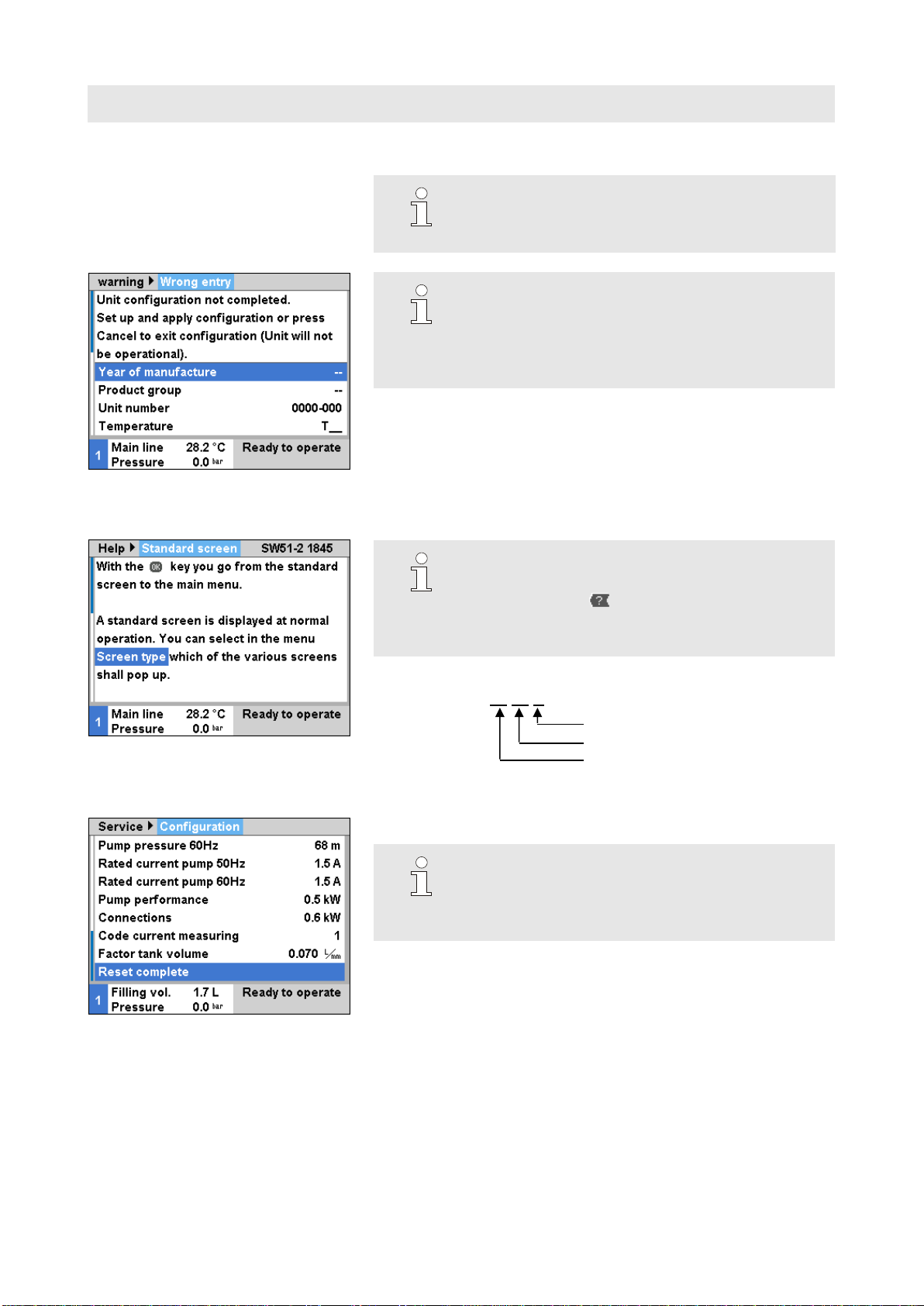

Fig. 4: Input window configuration

NOTICE!

If configuration is incomplete, the warning text

"Wrong entry" will be displayed. By cancelling the

configuration, the user can exit configuration mode

and subsequently conduct a Reset complete.

Fig. 5: Software version display

8. Checking the software version

NOTICE!

You can verify the currently installed software

version using the button on the basic screen.

The software version is indicated in the top right

corner (

Fig. 5).

Software version designation:

Ex. SW51-2 18 45 A

Index (optional)

Calendar week

Year

X 15

Assembly Instructions M8095-EN

M8095-EN 2020-09 5/13

Fig. 6: Reset complete

9. Carrying out a Complete reset

(Software version prior to SW51-1 0849B)

Service \ Support using "Support" user profile

(From software version SW51-1 0849B onwards)

Service \ Configuration using "Support" user profile

NOTICE!

From software version SW51-1 0916 onwards, the

Service \ Configuration menu is accessed using the

code 1?2?.

Fig. 7: Configuration

10.Configure unit

(to Software Version SW51-2 1431)

Service \ Configuration menu using the “Support” user profile.

NOTICE!

When configuring note the following:

- Select product group according to table below

- Check data on the nameplate

- Read appendix of Operating Manual

(for special versions)

Product group

Product type

TG

Thermo-5 temperature control unit

TR

Treat-5 water treatment unit

CL

Clean-5 cleaning unit

Fig. 8: Input window configuration

(from Software Version SW51-2 1449)

NOTICE!

As of software SW51-2 1449, the configuration is

requested after power ON automatically via the

input window (

Fig. 8).

Assembly Instructions M8095-EN

M8095-EN 2020-09 6/13

Fig. 9: Configuration special devices

Additionally with special devices

Parameter Special device type OEM and Special device OEM

version under Service / Configuration as stated on rating plate.

Exa. device type HB160ZM1LE1

OEM version

OEM type

11.Check that the unit is free of pressure

(Pressure gauge rear of unit).

12.Calibrating the unit

NOTICE!

A quality check can be carried out if required.

During the automatic check, the most important

measurements of the temperature control unit can

be compared. Points 13–18 are omitted when the

automatic check is carried out.

Requirement:

Software version >SW51-2_1540 is installed.

Checking device HB-TP180/200 for heating unit, proceed

according to the operating instructions for HB-TP180/200

(O8354-X).

Assembly Instructions M8095-EN

M8095-EN 2020-09 7/13

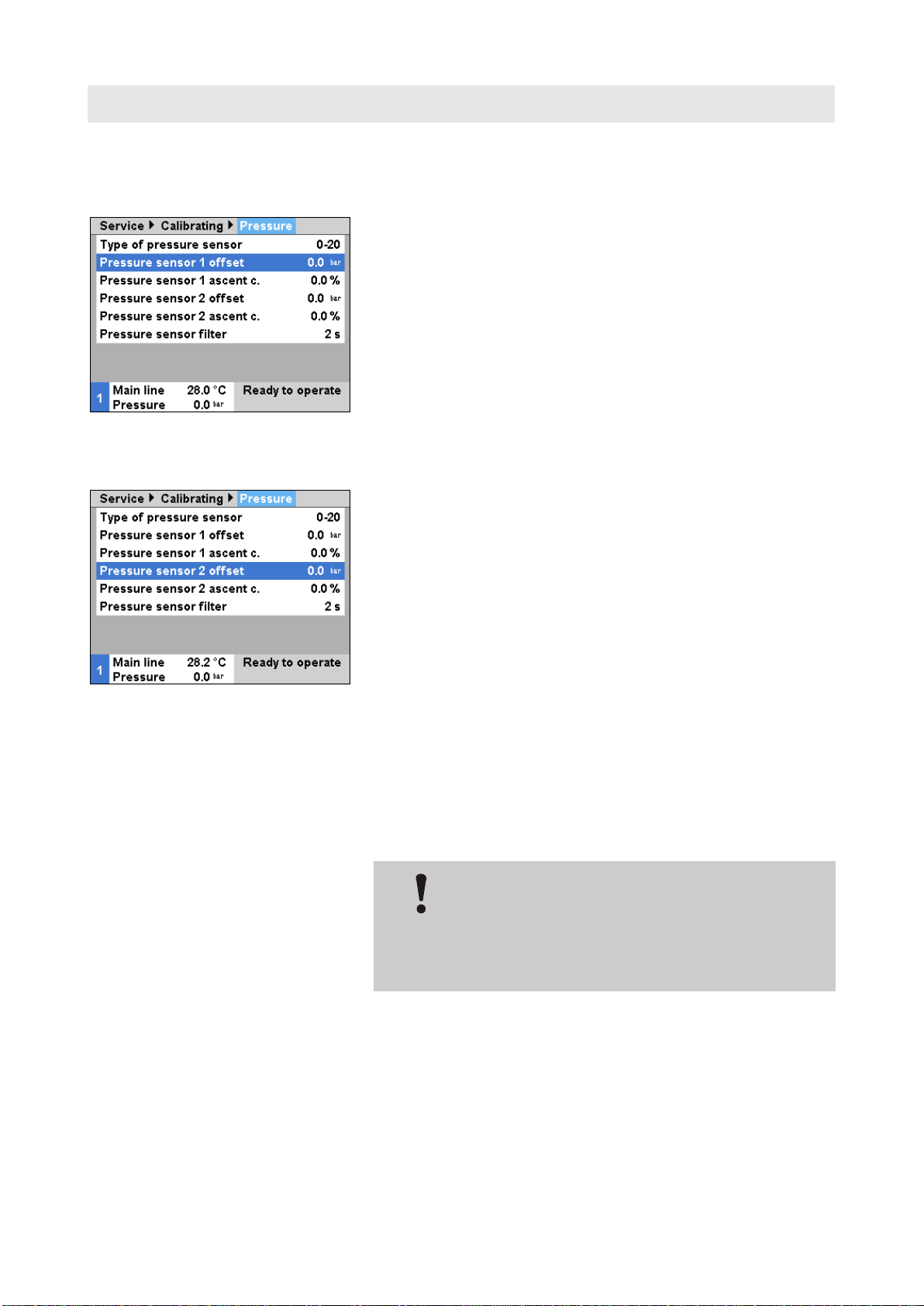

13.Calibrate the pressure sensor

with pressure sensor system (BP 1)

Fig. 10: Calibrate the pressure sensor 1

Read off the current System pressure actual value under

Display \ Actual value.

Set the parameter Pressure sensor 1 offset under Service \

Calibrating \ Pressure according to the following calculation:

Pressure sensor 1 offset new = Pressure sensor 1 offset

current –System pressure actual value current

with pressure sensor main line (BP 2)

Fig. 11: Calibrate the pressure sensor 2

Read off the current Main line pressure under Display \

Actual value

Set the parameter Pressure sensor 2 offset under Service \

Calibrating \ Pressure according to the following calculation:

Pressure Sensor 2 offset new = Pressure Sensor 2 offset

current –Main line pressure current

14.Check calibration pressure sensor

Parameter System pressure actual value resp. Main line

pressure under Display \ Actual value must be 0 bar ± 0,1.

If this is not the case, item calibration pressure sensor must be

repeated.

ATTENTION!

Risk of incorrect calibration!

False calibrations can lead to faults witch the unit.

Therefore:

–Check the calibrations.

Assembly Instructions M8095-EN

M8095-EN 2020-09 8/13

Fig. 12: Calibrating the flow rate

15.Flow rate calibration

(Software versions prior to SW51-1 0849B)

Operate unit in regular mode at 40 °C for at least 10 minutes.

Set Flow rate internal offset parameter in Service \ Calibrating \

Flow rate internally to "5 L/min".

Close shut-off valve between main or return line and wait for

1 minute.

Note current Flow rate.

Set Flow rate internal offset according to the following

calculation:

New Flow rate internal offset = 5 –current Flow rate

Open shut-off valve.

Fig. 13: Calibrating the flow rate

(From software version SW51-1 0849B onwards)

Operate unit in regular mode at 40 °C for at least 10 minutes.

Only for water units:

If available, set Pressure relief with unit OFF parameter in

Setting \ Miscellaneous to "OFF".

Switch off unit using button and wait at least 10 seconds.

Set Flow rate calibration parameter in Service \ Calibrating \

Flow rate internally to "ON".

The flow rate is calibrated automatically.

Only for water units:

If available, set Pressure relief with unit OFF parameter in

Setting \ Miscellaneous to "ON".

Switch on the unit using the key.

Assembly Instructions M8095-EN

M8095-EN 2020-09 9/13

16.Check flow rate calibration:

After calibration, run the unit for at least 5 minutes at 40 °C in

normal mode.

Close shut-off valve between feed and return lines.

Flow rate switches to 0 L/min and alarm indication ‚Flow rate

zero’is given.

NOTE!

The alarm message ‚Flow rate zero’ is delayed in

time.

If this is not the case, repeat the flow rate calibration.

ATTENTION!

Risk of incorrect calibration!

False calibrations can lead to faults witch the unit.

Therefore:

–Check the calibrations.

17.Acknowledge alarm and open shut-off valve.

18.Check unit functions.

19.Switch the unit off by press the key.

Assembly Instructions M8095-EN

M8095-EN 2020-09 10/13

Product group Treat-5 and Clean-5

1. Main switch off, remove the plug from the mains and empty

the unit.

2. Loosen the screws in the front panel and hinge it down.

3. Proceed as follows in order to remove the GIF-51 (A 4):

Remove all connectors.

Remove screws on the sides of the board.

Unplug the printed circuit board level measuring (A 10)

Fig. 14: Front panel

4. Change unit board GIF-51 (A 4):

Remove the printed circuit board level measuring (A 10) and

plug in on the new GIF-51.

Install new GIF-51 and fasten it with screw.

Connect plug connections.

Connection main pump cable (X 62/X 64):

Voltage 200–220 V Slot X 62 (triangle)

Voltage 380–480 V Slot X 64 (star)

Fig. 15: Voltage selection GIF-51

5. Voltage selection at X 15 with bridge plug (O/ID T21608):

Verify mains voltage (specification on the nameplate)

Place bridge according (Fig. 15)

ATTENTION!

Danger if wrongly connected

Wrong voltage selection or wrong connections can

damage the unit

Therefore:

–Thoroughly check connections and voltage

selection

6. Close and secure the front panel.

X 15

Assembly Instructions M8095-EN

M8095-EN 2020-09 11/13

7. Reconnect mains plug and switch on main switch.

NOTE!

The unit will maybe perform an automatic software

update.

Fig. 16: Input window configuration

NOTICE!

If configuration is incomplete, the warning text

"Wrong entry" will be displayed. By cancelling the

configuration, the user can exit configuration mode

and subsequently conduct a Reset complete.

Fig. 17: Software version display

8. Checking the software version

NOTICE!

You can verify the currently installed software

version using the button on the basic screen.

The software version is indicated in the top right

corner (

Fig. 17).

Software version designation:

Ex. SW51-2 18 45 A

Index (optional)

Calendar week

Year

Fig. 18: Complete reset

9. Carrying out a complete reset

Service \ Configuration using "Support" user profile

NOTICE!

From software version SW51-1 0916 onwards, the

Service \ Configuration menu is accessed using the

code 1?2?.

Assembly Instructions M8095-EN

M8095-EN 2020-09 12/13

Fig. 19: Configuration

10.Configure unit

(to Software Version SW51-2 1431)

Service \ Configuration menu using the “Support” user profile.

NOTICE!

When configuring note the following:

- Select product group according to table below

- Check data on the nameplate

- Read appendix of Operating Manual

(for special versions)

Product group

Product type

TG

Thermo-5 temperature control unit

TR

Treat-5 water treatment unit

CL

Clean-5 cleaning unit

Fig. 20: Input window configuration

(from Software Version SW51-2 1449)

NOTICE!

As of software SW51-2 1449, the configuration is

requested after power ON automatically via the

input window (

Fig. 20).

11.Calibrate the pressure sensor

Fig. 21: Calibrate the pressure sensor 2

Read off the current Main line pressure under Display \

Actual value

Set the parameter Pressure sensor 2 offset under Service \

Calibrating \ Pressure according to the following calculation:

Pressure Sensor 2 offset new = Pressure Sensor 2 offset

current –Main line pressure current

Assembly Instructions M8095-EN

M8095-EN 2020-09 13/13

12.Check calibration pressure sensor

Parameter System pressure actual value resp. Main line

pressure under Display \ Actual value must be 0 bar ± 0,1.

If this is not the case, item calibration pressure sensor must be

repeated.

ATTENTION!

Risk of incorrect calibration!

False calibrations can lead to faults witch the unit.

Therefore:

–Check the calibrations.

13.Check unit functions.

14.Switch the unit off by press the key.

Parts list

Pos

Description

O/ID

O/ID

T27401

T27401-1

T27401-2

T25240

T25240-1

Pcs

Pcs

Pcs

Pcs

Pcs

01

Unit board GIF-51

T27400

1

-

-

1

-

02

Unit board GIF-51 finished

T27400-1

-

1

-

-

1

03

Unit board GIF-51 UL

T27400-2

-

-

1

-

-

04

Plug jumper voltage pre-selection

(mounted on X 15, 400 V as standard setting)

T21608

1

1

1

1

1

05

Assembly instructions German

M8095-DE

1

1

1

1

1

06

Assembly instructions English

M8095-EN

1

1

1

1

1

07

Assembly instructions French

M8095-FR

1

1

1

1

1

Table of contents