HCW MAHRW020W/P(03) Service manual

AIR TO WATER HEAT PUMP

WATER HEATER

AIR TO WATER HEAT PUMP

WATER HEATER

Installation & instruction manualInstallation & instruction manual

MK3068/MK3069MK3068/MK3069

HCWHCW////

I Specification................................................................

1. ...............................................................

2. Parameter of multi-function air to water heat pump...................

3. Product appearance and installation dimension......................

II Installation..................................................................

1. Unit installation position........................................................

2.

. Water Pipe connection.........................................................

5. Electric wiring....................................................................

6.Selection of Electrical Wire...................................................

7.Trial operation(should be operated by professionals)..............

III Use...........................................................................

1. Function diagram of the remote controller..............................

2. Use of remote controller......................................................

3.Operation data setting.........................................................

IV Maintenance and repair............................................

1. Malfunction Indicating Table................................................

V Installation sketch.....................................................

1. The choice of installation ways.............................................

VI

1. Indoor unit wiring diagram...................................................

2.Outdoor unit wiring diagram .................................................

Model Nomenclature

The refrigerant piping connection for split type unit..................

3. Refrigerant recovery method................................................

4

Appendix .................................................................

CONTENTS

Air To Water Heat Pump Water Heater

1

1

2

3

4

4

5

7

7

7

7

8

9

10

10

10

14

16

16

17

17

23

23

23

Notice

1.1 In order to use this product better and safer, please read this instruction carefully before install

and operate it. Please pay attention to all the notice in operation and maintenance. Save all

manuals and documentation for future reference.

1.2 All in one heat pump is a special appliance. Improper installation will cause damage and danger.

It should be installed and maintained by the professionals. Please contact our authorized local

service point for installation and maintenance. Please read and follow this instruction carefully

before and during installation.

Remarks:

We will not bear the responsibility for any personal injury or unit damage caused by

non-Compliance of the regulations and instruction in this manual.

1.3 Please check whether the distribution power capacity, switch and socket are compliance with

the requirements of our unit power. Details please refer to the rating label or parameter table

in this manual.

1.4 The power should be equipped with leakage protection separately. Power cable should be

chosen in accordance with the operation requirements of the unit.

1.5 The unit must be grounded safely. Do not use the unit if grounded unsafely. Do not connect

the ground line to the neutral and or tap water pipe.

1.6 The wire must be joined in compliance with the requirements of the wiring chart. Do not

alternate and or repair the unit personally.

1.7 Do not install the unit closed to inflammable, explosive and naked light spot.

1.8 To ensure the unit operate properly, please equipped with a filter in the water input when

installation.

1

1 Model Nomenclature

MA HR W - - W A B / P S ( )

Source medium

MA: Airsource

MW: Ground source

Function of the unit

HR:heating

Energy exchange medium

A: Refrigerant

W: Water

Z: Integrated type

W: Split type(indoor unit )

A: coil heating

B: circulating heating

(Omit the split type unit model)

A: Horizontal fan direction

B: Upward fan direction

C:Double air duct type

(Omit the split type unit model)

01:hot water+solar

02:hotwater (EVI)

03:hot water+heating/cooling+solar

The figure represents the horse power of unit

eg:010 means 1 horse power

P:with built inpump

(without built in pump omitted)

S:3phase (single phase omitted)

I SpecificationI Specification

Air To Water Heat Pump Water Heater

The figure represents the horse power of unit

eg:010 means 1 horse power

A: Horizontal fan direction

B: Upward fan direction

Design alternative serial number

MA FP - - A ( )

Energy exchange medium

MA: Refrigerant

MW: Water

FP: Fan coil

Outdoor unit model nomenclature

020W/P(03)

020A

5.0

17100

1.55

7.0

6.0

20500

1.75

8.0

50

Rotary

1

1

1/4

1/2

1

2-3

610 440 750

665 480 770

840 350 610

980 410 665

52

57

39

44

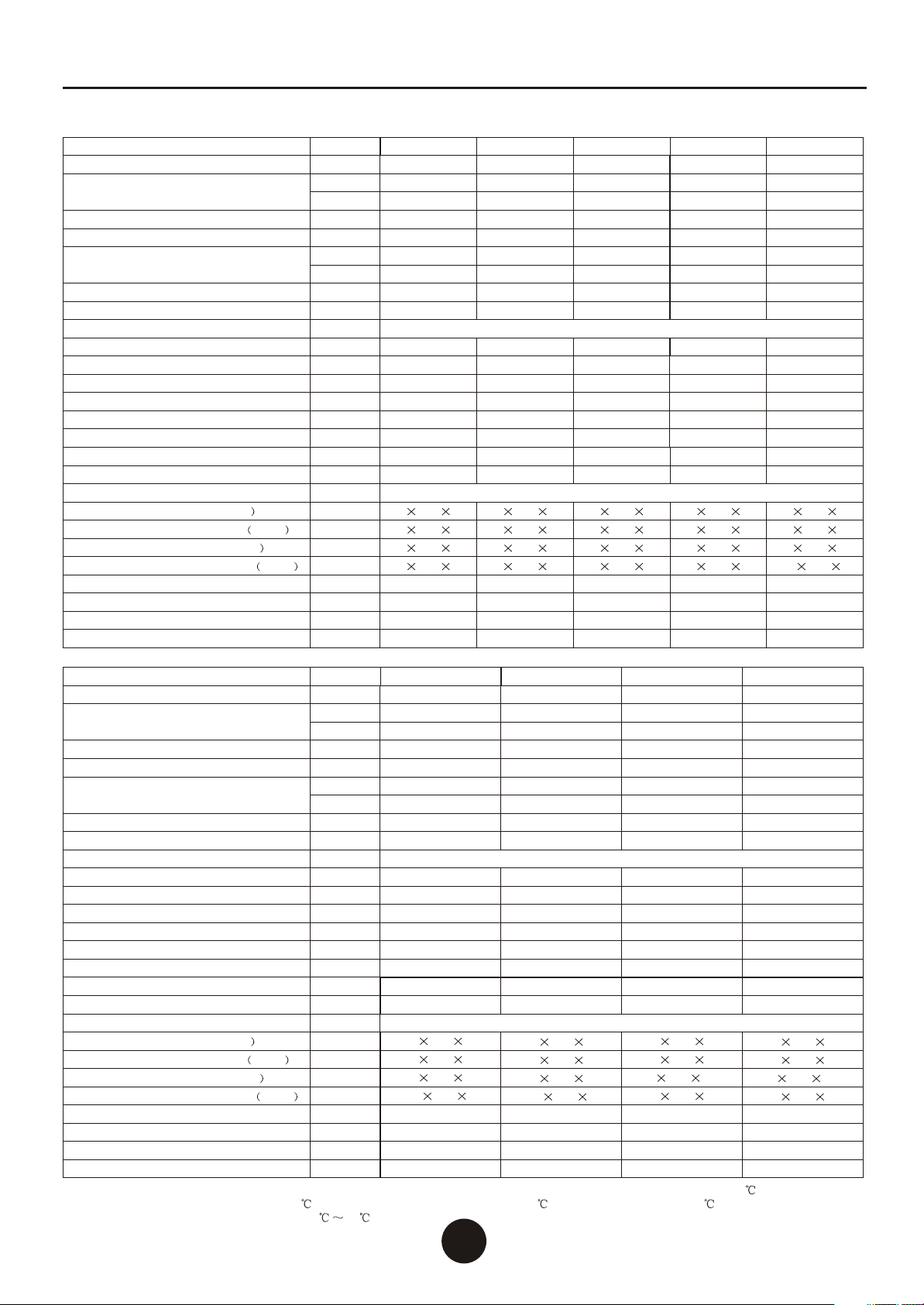

Indoor Unit Model

Outdoor Unit Model

Rated Input Power

Rated Input Current

Rated Input Power

Rated Input Current

Power Supply

Noise

Compressor

Compressor Qty

Fan Qty

Refrigerant Liquid Pipe

Refrigerant Gas Pipe

Water Outlet/Water Inlet

Water Flow Volume

Refrigerant Gas Type

Indoor Unit Net Dimensions(L/M/H

Indoor Unit Shipping Dimensions L/M/H

Outdoor Unit Net Dimensions(L/M/H

Outdoor Unit Shipping Dimensions L/M/H

Indoor Unit Net Weight

Indoor Unit Shipping Weight

Outdoor Unit Net Weight

Outdoor Unit Shipping Weight

MAHRW

MAFP

kW

BTU/h

kW

A

kW

BTU/h

kW

A

V/PH/Hz

dB(A)

inch

inch

inch

3

m/h

mm

mm

mm

mm

kg

kg

kg

kg

R410A

(208~230)ACV/1PH/60Hz

Rated Cooling Capacity

Rated Heating Capacity

025W/P(03)

025A

6.5

22200

2.10

9.5

7.5

25600

2.30

10.5

50

Rotaty

1

1

1/4

1/2

1

2-3

610 440 750

665 480 770

840 350 610

980 410 665

53

58

39

44

030W/P(03)

030A

7.5

25600

2.40

10.9

9.0

30800

2.70

12.3

50

Rotaty

1

1

3/8

1/2

1

2-3

610 440 750

665 480 770

830 380 710

965 410 750

55

60

45

50

035W/P(03)

035A

9.0

30800

2.90

13.2

10.5

35900

3.10

14.1

50

Rotaty

1

1

3/8

1/2

1

2-3

610 440 750

665 480 770

830 380 710

965 410 750

57

62

45

50

040W/P(03)

040A

10.0

34200

3.10

14.5

12.0

41000

3.60

16.4

50

Scroll

1

1

3/8

1/2

1

3-4

600 630 785

710 750 915

880 420 800

1020 450 830

100

108

58

65

Indoor Unit Model

Outdoor Unit Model

Rated Input Power

Rated Input Current

Rated Input Power

Rated Input Current

Power Supply

Noise

Compressor

Compressor Qty

Fan Qty

Refrigerant Liquid Pipe

Refrigerant Gas Pipe

Water Outlet/Water Inlet

Water Flow Volume

Refrigerant Gas Type

Indoor Unit Net Dimensions(L/M/H

Indoor Unit Shipping Dimensions L/M/H

Outdoor Unit Net Dimensions(L/M/H

Outdoor Unit Shipping Dimensions L/M/H

Indoor Unit Net Weight

Indoor Unit Shipping Weight

Outdoor Unit Net Weight

Outdoor Unit Shipping Weight

MAHRW

MAFP

kW

BTU/h

kW

A

kW

BTU/h

kW

A

V/PH/Hz

dB(A)

inch

inch

inch

3

m/h

mm

mm

mm

mm

kg

kg

kg

kg

R410A

(440~460)ACV/3PH/60Hz

Rated Cooling Capacity

Rated Heating Capacity

040W/PS(03)

040A

10.0

34200

3.20

5.6

12.0

41000

3.6

6.3

50

Scroll

1

1

3/8

5/8

1

3-4

600 630 785

710 750 915

880 420 800

1020 450 830

100

108

58

65

045W/PS(03)

045A

11.5

39300

3.60

6.3

13.5

46100

4.0

7.0

50

Scroll

1

1

3/8

5/8

1

3-4

600 630 785

710 750 915

880 420 800

1020 450 830

105

112

58

65

050W/PS(03)

050A

12.5

42700

4.0

7.0

15.0

51200

4.5

7.9

50

Scroll

1

2

3/8

5/8

1

3-4

600 630 785

710 750 915

880 470 1250

1010 525 1280

110

118

60

75

060W/PS(03)

060A

15.0

51200

4.70

8.2

18.0

61500

5.30

9.3

50

Scroll

1

2

3/8

5/8

1

3-4

600 630 785

710 750 915

880 470 1250

1010 525 1280

115

122

60

75

2.Parameter of multi-function air to water heat pump

Air To Water Heat Pump Water Heater

22

Note: (1)The manualis a technicalparameters measured inthe following conditions: outdoor dry temperature is 20

and wet bulbtemperature is 15 ,the temperature ofwater inflow is 15 and of wateroutflow is 55 .

(2)Using in ambienttemperature:-15 45

3. Product appearance and installation dimension

33

Air To Water Heat Pump Water Heater

DC

A

B

D

A

B

C

D

A

B

C

A

B

C

D

DA

B

C

A

B

C

D

3.1Installation dimension of integrated type unit

3.2Installation dimension of split type unit

A

B

C

D

Size

Units: mm

MODEL

360

405

550

750

MAHRW020W/P(03)

MAHRW025W/P(03)

MAHRW030W/P(03)

MAHRW035W/P(03)

A

B

C

D

Size

Units: mm

MODEL

495

320

840

610

MAFP020A

MAFP025A

A

B

C

D

Size

Units: mm

MODEL

515

340

830

710

MAFP030A

MAFP035A

A

B

C

D

Size

Units: mm

MODEL

615

390

880

800

MAFP040A

MAFP045A

A

B

C

D

Size

Units: mm

MODEL

525

440

885

1250

MAFP050A

MAFP060A

A

B

C

D

Size

Units: mm

MODEL

635

450

780

765

MAHRW040W/P(03)

MAHRW040W/PS(03)

MAHRW050W/PS(03)

MAHRW060W/PS(03)

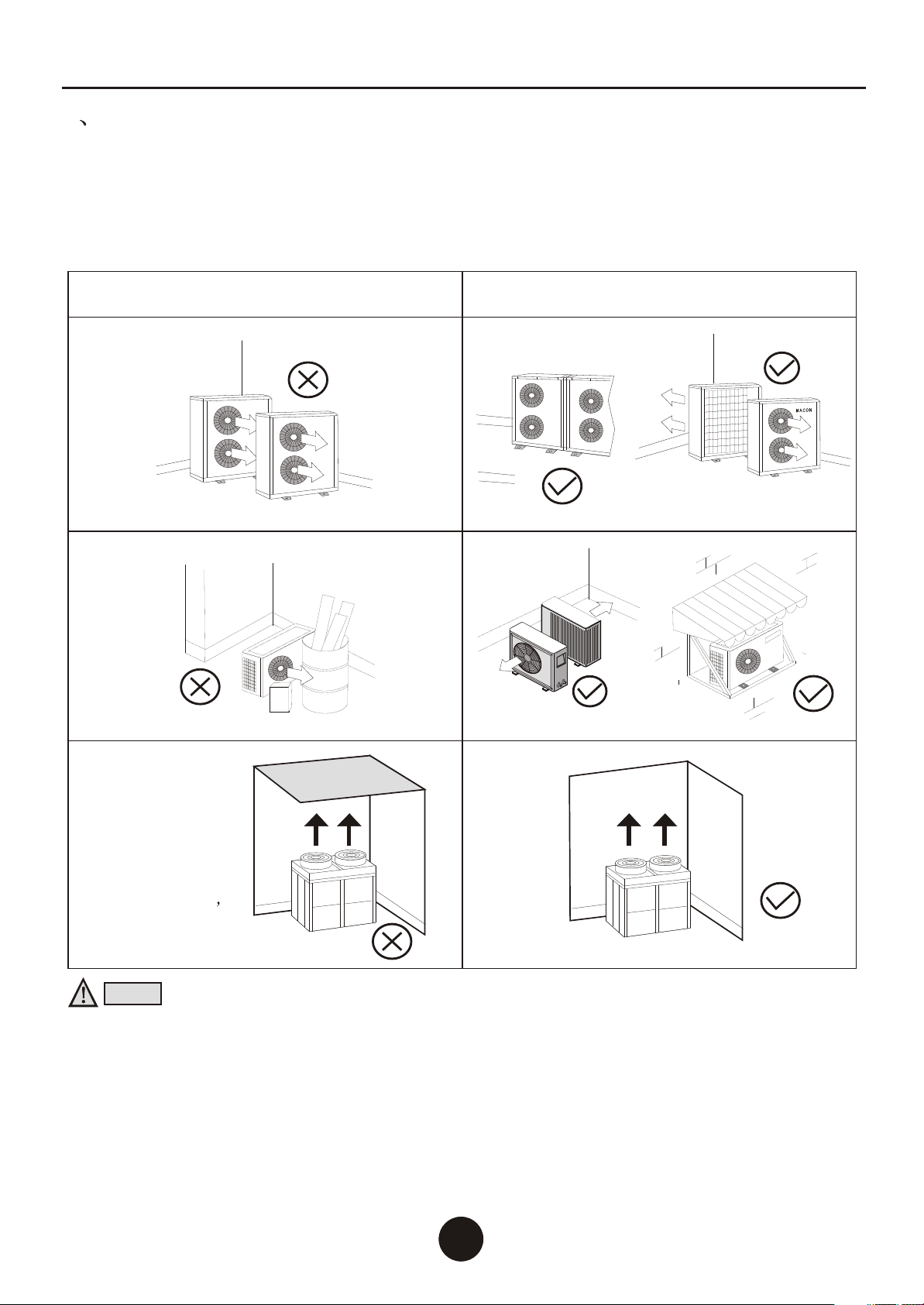

1. unit installation position

The pretty high condensation temperature (cooling) and pretty low evaporation temperature

(heating) will affect the operation of outdoor unit. To achieve maximum efficiency, please select

the installation position under below regulations:

To avoid ventilation short, the outdoor unit discharged air should not return when installation.

Please keep enough space around the outdoor unit for repair. Right and wrong means as below:

Wrong Right

As the upwards fan

direction unit

exhausts air

upwards, do not

place any object up

the unit.

Please built an

introductory

equipment if can t

avoid this object.

Notice:

1. To get enough air for ventilation of the unit, the installation position should be with good

ventilation.

2.The installation position can hold the outdoor unit without noise and shake.

3.No sunlight to the unit. Set an awning if necessary.

4.The water from rain and defrosting can be discharged in the installation position.

5.The unit will not be covered by snow in the installation position.

6.The discharged air will not face strong air in the installation position.

7.Assure the noise caused by the unit ventilation and operation will not affect the neighbor.

8.The installation position will not be affected by garbage, oil and mist.

9.The outdoor unit will be damaged under the condition with oil(engine oil), salt(sea area) and

sulfide air(near thermal spring and refining factory).

44

II Installation

Air To Water Heat Pump Water Heater

55

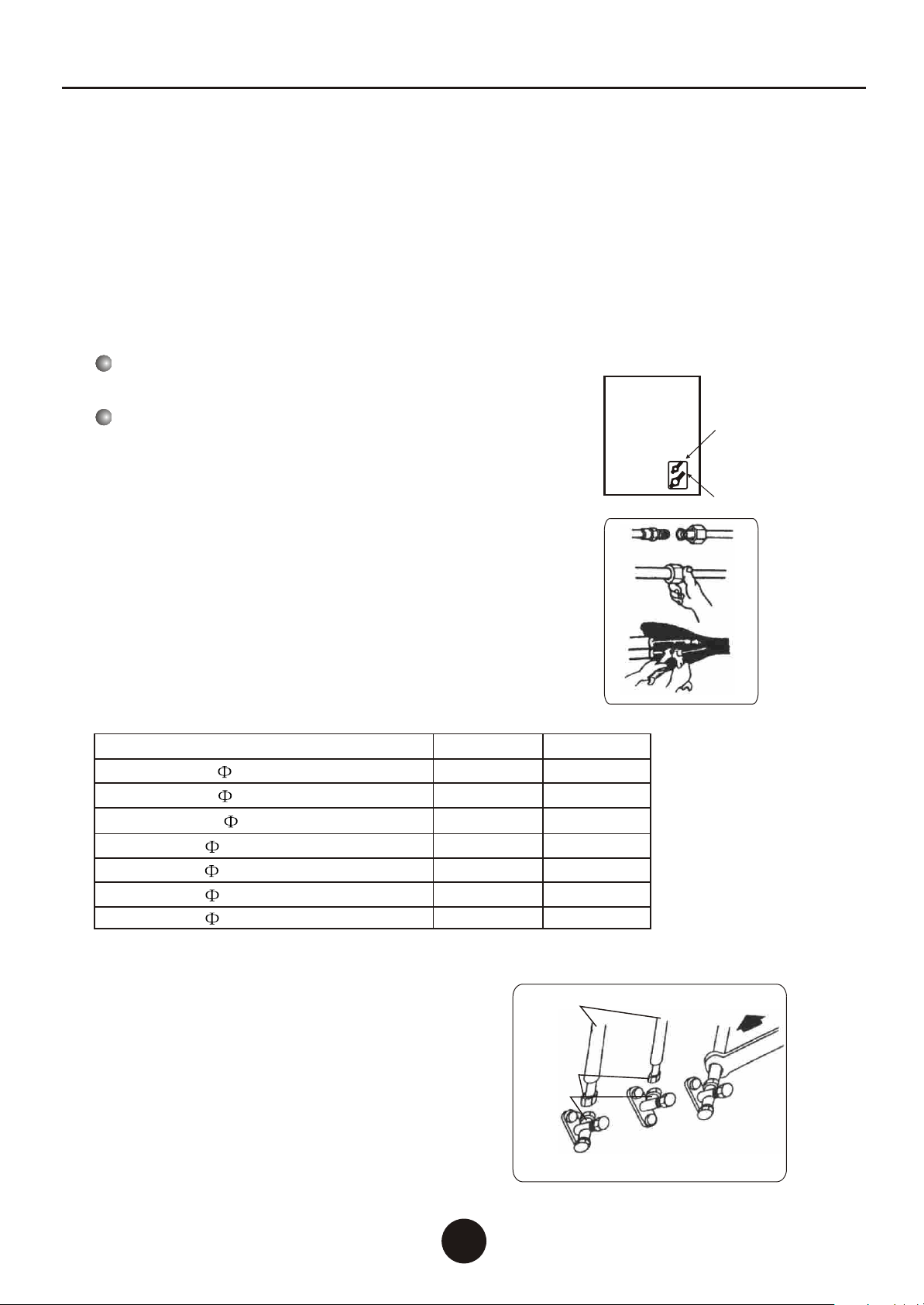

2.1 Refrigerant pipe connecting

2. The refrigerant piping connection for split type unit

b. Pre-tighten them with fingers at first, then use the wrenches.

a. Connect indoor unit pipes with two wrenches. Pay special

attention to the allowed torque as shown below to prevent

the pipes, connectors and flare nuts from being deformed

and damaged.

Piping Connection:

Pipe size

Liquid Side ( 6.35 or 1/4 inch) 1.8kg.m 17mm

22mm

24mm

22mm

27mm

3.5kg.m

3.5kg.m

5.5kg.m

7.5kg.m

Liquid Side ( 9.52 or 3/8 inch)

Gas Side ( 12.7 or 1/2 inch)

Gas Side ( 9.52 or 3/8 inch)

Gas Side ( 15.88 or 5/8 inch)

Torque Nut width

Gas Side ( 19.05 or 3/4inch) 30mm

9.5kg.m

2.1.1.The indoor unit refrigerant pipe connecting

According to the indoor and outdoor unit fixed location and location of holes through the wall, choose a

good direction lead to pipe. Then begin the indoor pipe connection work.

Screw off the nut from the valve body indoor unit,

remove the pipe head plug.

1. When tightened, first press the trumpet

on the connector cone, and keep the out pipe

and connection pipe in the same axis;

2. Gradually use hand to tighten the flare nut in

clockwise, and then use the wrench to tighten.

3. When use a wrench to tighten joints, according

to the moment shown in the following table, if not

tight it will leak, spin too tightly, may damage the trumpet.

Connect the indoor unit and pipe joints

1. Use a wrench to remove the outdoor high and

low pressure valve bonnet;

2. Remove the connection pipe's plastic head;

3. As shown on the right, press the trumpet on the

connector cone, then hold the connection pipe

with one hand, so that keep the connector axis

in the first line, the other hand the gradually

screw the flare nut on the connector, then

tighten with wrench.

2.1.2.Outdoor pipeline construction

Connected the indoor unit and outdoor unit through two matched cooper tubes, one small and

one larger. And the system should be emptied after connection, so opened the 1 / 4 laps of outdoor

unit valve for 5-10 seconds, and then close it, open the large valve needle valve to discharge air in

the indoor unit and the pipe, or vacuum it with a vacuum pump, and then close the needle valve;

check the connection part if leak, confirmed without leaking, then open all the outdoor unit large

and small valve, so that the whole system recycle work, detailed operation as follow.

High pressure valve

Low pressure valve

Tubule

Line Pipe

Connecting pipe

adapter

connector

flare nut

Gas tube

Liquid tube

Liquid Side ( 12.7 or 1/2 inch) 5.5kg.m 24mm

Air To Water Heat Pump Water Heater

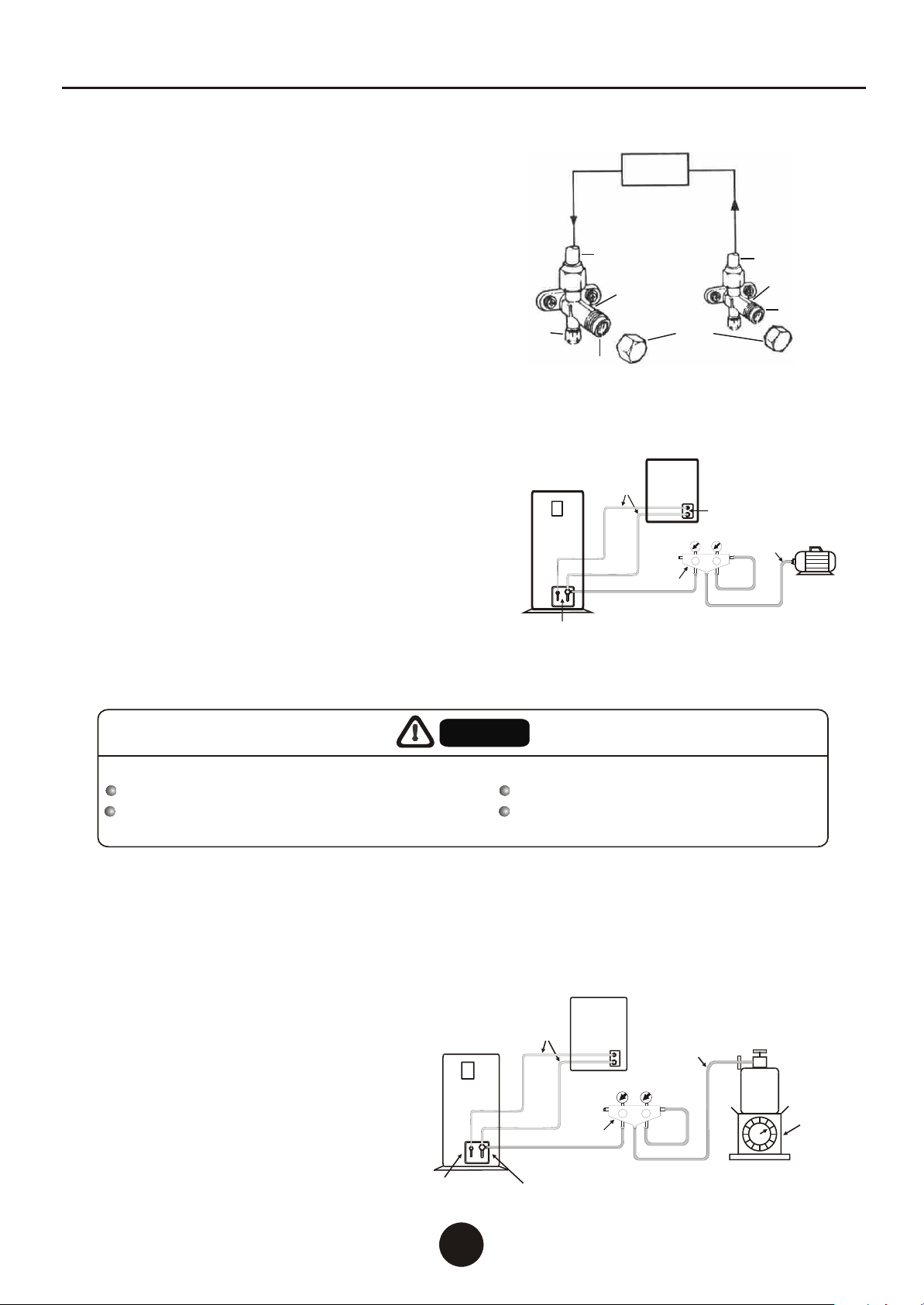

2.1.3.Air discharge (vacuum)

If the system is small, use refrigerant empty way to discharge the pipe and indoor unit air, as

the following steps:

1. Remove the high-pressure valve and low pressure

valve bonnet;

2. Remove the low-pressure valve exhaust nut;

3. Release the high-pressure valve spool 1 / 4 lap;

4. Open low-pressure valve exhaust spool,

exhaust to 15-30 seconds;

5. Tighten the low- pressure valve exhaust nut;

6. Screw the high-pressure valve and

low- pressure valve spool to the end;

7. Tighten the spool cap.

If the system large or after maintenance of outdoor system, should use the vacuum pump

discharge way to empty the air and water within the system, shown as below:

1. Screw off the outdoor unit low-pressure valve's

repair connector nut, connected the compound

pressure gauge to repair connector;

2. Connect the vacuum pump to the compound

pressure gauge, open the compound pressure

gauge and vacuum pump to vacuum the indoor

unit and pipe, so that the absolute pressure

not higher than 130Pa, and keep the pressure

does not rise within 5 minutes after vacuum.

3. After vacuum, turned on the outdoor high and

low pressure valve stem, inject the refrigerant

into the indoor unit.

Thoroughly discharge the air and moisture within the cooling system

if the air and moisture remained in the cooling system, appear the following adverse effects:

System pressure increases. Cooling (or heating) effect decreased.

Moisture will freeze plug the cooling system. Moisture can rust some parts of the

cooling system.

AttentionAttention

Valve

Valve

Copper

pipe

Outdoor unit

Indoor unit

Vacuum pump

Low pressure

side gauge

High pressure

side gauge

Hose

Composite table

2.1.4.Add refrigerant

The outdoor unit already with refrigerant before delivery, but when the pipe is too long,

please add additional refrigerant as following formula:

Additional refrigerant amount= (one-way tube length -5) x (0.015-0.02) kg, choose 0.015-0.02

according to the size of diameter. When the tracheal diameter = 12.7, choose 0.015; when the

diameter = 15.88, choose 0.02 .

Indoor unit Exhaust when refrigerants

Flow direction

Tubule

Low pressure valve High pressure valve

Line Pipe

Spool

Spool cap

Spool

Exhaust nut

The methods to add refrigerant

refer to the diagram bellow:

Indoor unit

Outdoor unit

Low-pressure valve

(suction valve)

High-pressure valve

(exhaust valve)

Low pressure

side gauge

High pressure

side gauge

Hose

Scale

Refrigerant charge tank

Piping

Composite table

66

Air To Water Heat Pump Water Heater

77

After discharge the air, use electronic leak detector or soapy

water to test all the connectors in the indoor and outdoor unit.

2.1.5.Leak check

First use hex wrench closed the high-pressure valves (1/2 ") of the unit, and then start hot

mode; after the compressor start-up , check the low pressure gage , when the pressure is close

to "0" , close the low-pressure valve (3/4 ")quickly , turn off the unit at the same time. the

refrigerant recovery will take about 25 seconds.

3. Refrigerant recovery method

4.Water Pipe connection

4.1 Pipe should be a kind of pipe that heat-resistant,rust-proof, uneasy-fouling.and in conformity

with national health and safety standards, which can be stainless steel pipe, copper pipe,

aluminum water pipe, hot water PPR pipes and so on.

4.2 Water tank outlet pipe and overflow pipe is better to installed around the gutter or sewer,

so that to convenient to drainage.

4.3 The connection of the heat pump unit and water tank must be installed a stop valve or

dismountable loose joint, for maintenance use.

4.4 Water pipes are arranged reasonably to minimize bending and reduce the pressure loss of

water system .

4.5 The connection of tap water pipe and water filling connection must install one-way valve,

filter, supply water solenoid valve (for tank-type water tank) and pressure relief devices

(for close-type valve the parameter value is 0.7MPa), installed when valve body arrow is

same as with the flow direction to prevent water block. The cycle water outlet of the heat

pump unit should connect to the inlet of water tank , The cycle water inlet of the heat pump

unit should connect to the outlet of water tank, the water supply inlet of the tank should

connect to the heat water supply outlet . The entire piping system should be clean, no rust

and dirt residue to prevent pipe blockage.

4.6 After the installation of the water filling pipe and cycle water pipe and hot water supply pipe ,

all the pipes should take the water tightness test. And ensure that the system is clean. and

then cover insulation on the pipe and valve (including the supply water pipes and valves).

4.7 For the metal pipe, must be used above 50mm thickness of glass fiber or high-density fire-

retardant PE foam to protect (PPR hot water pipe can use 30mm thickness of glass fiber or

high-density fire retardant PE foam for thermal insulation).

4.8 the unit water inlet and outlet must fit with thermometer, water pressure gage, to facilitate

inspection when operate.

Note: 1. tubing pipeline should be separate test pressure, must not test with heat pump unit

or tanks.

2. The water system working pressure: 0.2-0 .6 MPa.

3. The water system operating temperature: 5~75 .

5. Electric wiring

5.1 Unit supply cable must be used copper. Power supply voltage in line with the rated

voltage and the rated current.

5.2 The unit, power supply circuit must have a grounding wire, and the power supply ground wire

must with the external grounding wire, and an external grounding wire to be effective.

5.3 W must be installed by professional technicians carried out in accordance

with circuit.

5.4 S up a good leakage protection devices

should be

connect to

iring installation

etting and in accordance with the relevant national

technical standards.

Air To Water Heat Pump Water Heater

Power supply

PCB

Compressor

Unit

12

6.2 Specification Table of Electrical Wire

Power supply installation condition: The touching space of breaker should be more than 3mm,

must use copper wire only.

within 5m

2.0

3.5

5.5

8.0

Within 10m

2.0

3.5

5.5

8.0

14.0

Within 15m

2.0

3.5

5.5

8.0

14.0

22.0

Within 20m

3.5

5.5

8.0

14.0

22.0

30.0

Within 30m

5.5

8.0

14.0

22.0

30.0

38.0

50.0

Within 50m

8.0

14.0

22.0

30.0

38.0

50.0

60.0

80.0

Within 1m

2.0

3.5

5.5

8.0

14.0

Starting current

(A)

Below 20

Below 30

Below 40

Below 50

Below 60

Below 70

Below 80

Below 90

Below 100

Below 110

Below 120

Below 140

Below 160

Below 180

Below 200

Below 220

Below 240

Mark (Heat resistance temperature above 60 )

The wiring specifications (mm2)

Mark (Heat resistance

temperature above120 )

6.1 Voltage drop may occur due to the large current draw during compressor starting, and may be

result in the compressor is difficult to stat. So we recommend selecting the wire specification from

the table below.

6. Selection of Electrical Wire

88

5.5 Power line and signal line layout should be neat, rational, strong and weak lines separating

cable and Can not interfere with each other, without contact with the connecting pipe and

valve.

5.6 he construction of all wiring is completed, carefully check the correct order to connect

the power.

5.7 Unit electric wire connection: connect to the appropriate terminals according to wiring diagram,

and fix it by the pressure line of board in the electrical box.

5.8 All the wiring construction is completed, can be plugged in only after careful examination

correctly.

5.9 Unit control board fuse parameters: 5A/220V.

5.10 The unit wire controller must be fixed in the bottom of standard electrical switch box.

After t

Air To Water Heat Pump Water Heater

6.3 Caution of Ground

The internal motor protector does not protect the compressor against all possible conditions.

Please be sure that the system utilizes the ground connection when installed in the field.

6.4 Warning:

To avoid fire, electric shock and other accidents, keep in mind about these tips:

6.4a Only use power supply voltage indicated on the label, if you do not know the family of voltage,

contact the dealer or local power company.

6.4b When you use the unit by the maximum current please view the specifications, so make sure

your home's power supply (current, voltage and cable) to meet the machine's normal load

requirements.

6.4c To protect the power lines. Power lines should be fixed, so that people will not be trip over or

the lines damaged by other things. Paying particular attention to plugs, which should be easily

plug into the socket, careful the plug position.

6.4d Do not overload wall plugs or extension the cable. Line overload can cause fire or electric

shock.

6.5e To ensure your safety, you must plug the power lines into the socket with a grounded

three-phase, and check to ensure your socket is accurate and reliable grounding.

99

Air To Water Heat Pump Water Heater

7.Trial operation(should be operated by professionals)

7.1 Check before trial operation

7.1aCheck the pipe system. Check the whole pipe system. Ensure the water volume in the system

is full and the air is exhausted completely. Check whether the valve is open throughout the

system and the thermal insulating of the pipe is well.

7.1b Check the power supply and distribution system. Check whether the power supply voltage is

normal, the power distribution accessory screws all tighten, supply power is in compliance

with the wiring diagram and the wire is grounded well.

7.1c Check the air cooled water chiller. Check whether any screw loose. Check the signal indicator

light(green) of the outdoor unit control panel is illuminated normally and the fault indicating

lamp(red) is illuminated. Connect the pressure gauge to the freon feed mouth for checking the

pressure during operation. Disconnect them after test is ok.

7.2 Trial operation

7.2a Turn on the circulating water pump by remote control(refer to IV Use ) and check whether

the water pump operates normally. Observe and determine whether air pipe is exhausted

completely, flow switch is closed, hydraulic pressure indicated in the pressure gauge is more

than 0.2MPa.Come to next step after confirm the circulating water system works normally.

7.2b Press on/off in the remote controller, the water pump and fan start immediately.

The compressor start after the unit operates for some time. Observe and determine if there s

any abnormal sound during operation. Stop to check the unit if there s abnormal sound. The

unit can continue to run only when there s no abnormal sound. Check whether the cooling

system pressure is normal at the same time.

7.2c Check whether the input power and current of the unit are compliance with the parameter in

this Instruction. If not, stop to check the unit.

7.2d Observe whether the outlet water temperature is normal.

7.2e Parameter of the remote controller has been set before leave of the factory. Never alternate

them personally.

button operate

operate mode display

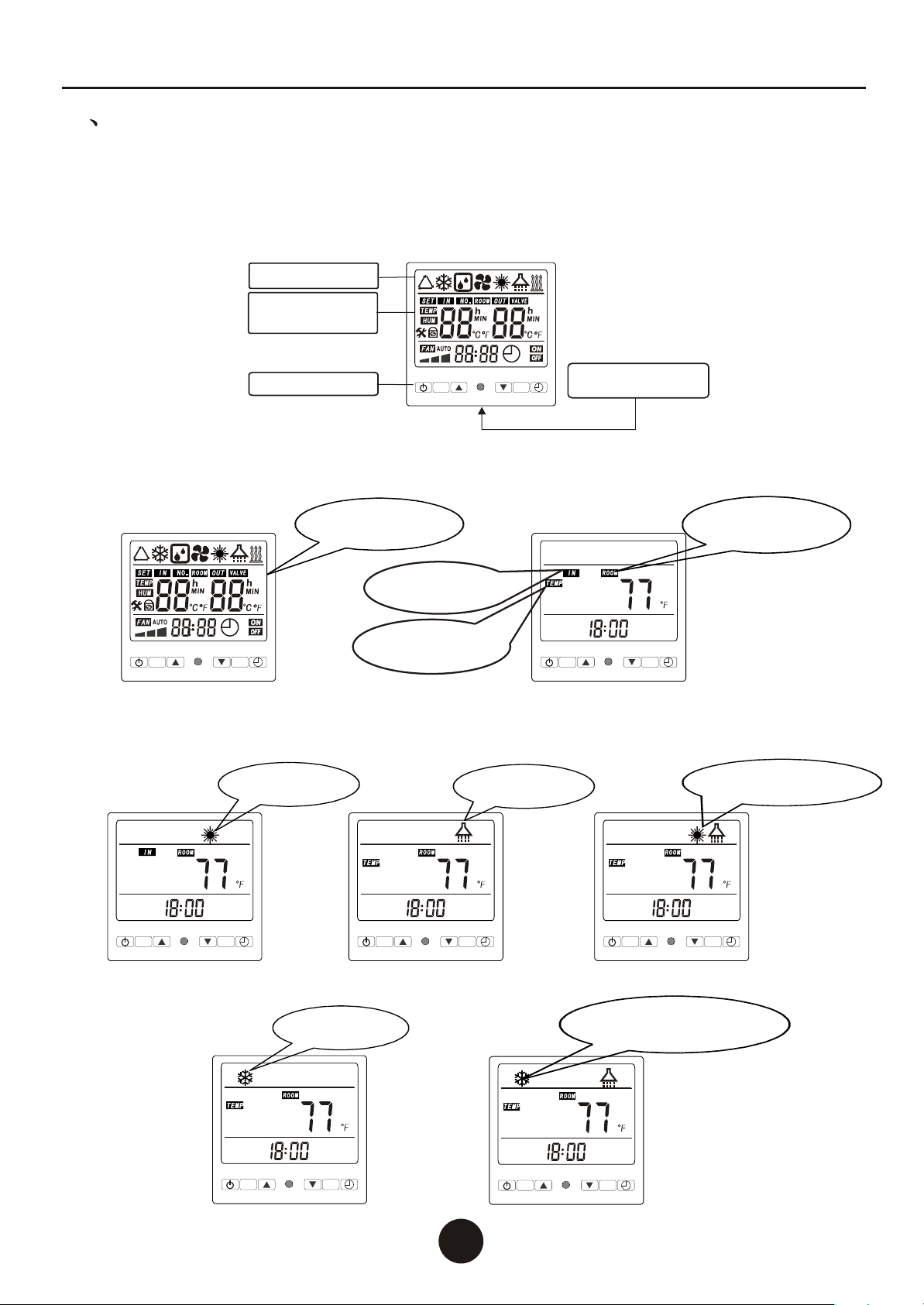

1.Function diagram of the remote controller.

2.Use of remote controller

The remote controller is designed and employed standard electrical box dimensions(86*86,fixed hole

distance 60mm). The electrical box and three core can be built in the wall before decoration, which makes

the interior decoration more perfect. The user interface and function shows as below:

operate status,

parameter setting display

2.1 Initial power on and stand by status: Power on after check and confirm the unit is normal. The remote

controller will be full-screen display. The main unit will be on stand by status 10 seconds later . Distance

will display the standby.

1010

2.2 Under boot-up status ,press ' M' button to switch therunning mode , when the parameter 22 isset be '0 '

to switch off the cooling function, so theunit will has 3modes at that time :1. air heating mode 2. domestic

hot water mode 3. Air heating and domestic hot water mode.

SETSET

MM

1

2

%%

SETSETSETSET

MM

1

2

%%

2.3. when the parameter 22 is setbe '1 '(that means switch onthe cooling function), there will be more

the following 2 modes, and you also canpress ' M 'to switch the modes.

Initialization mode Indoor environment

temperature icon

III UseIII Use

Air To Water Heat Pump Water Heater

Water inlet

temperature icon

Indoor environment

temperature sensor

SETSET

SETSET

Hot water tank

temperature icon

Domestic hot

water mode

Air heating and domestic

hot water mode

SETSET

Air colling mode

SETSET

Air colling and domestic

hot water mode

SETSET

Air heating mode

MM

MMMMMM

MMMM

SETSET

1111

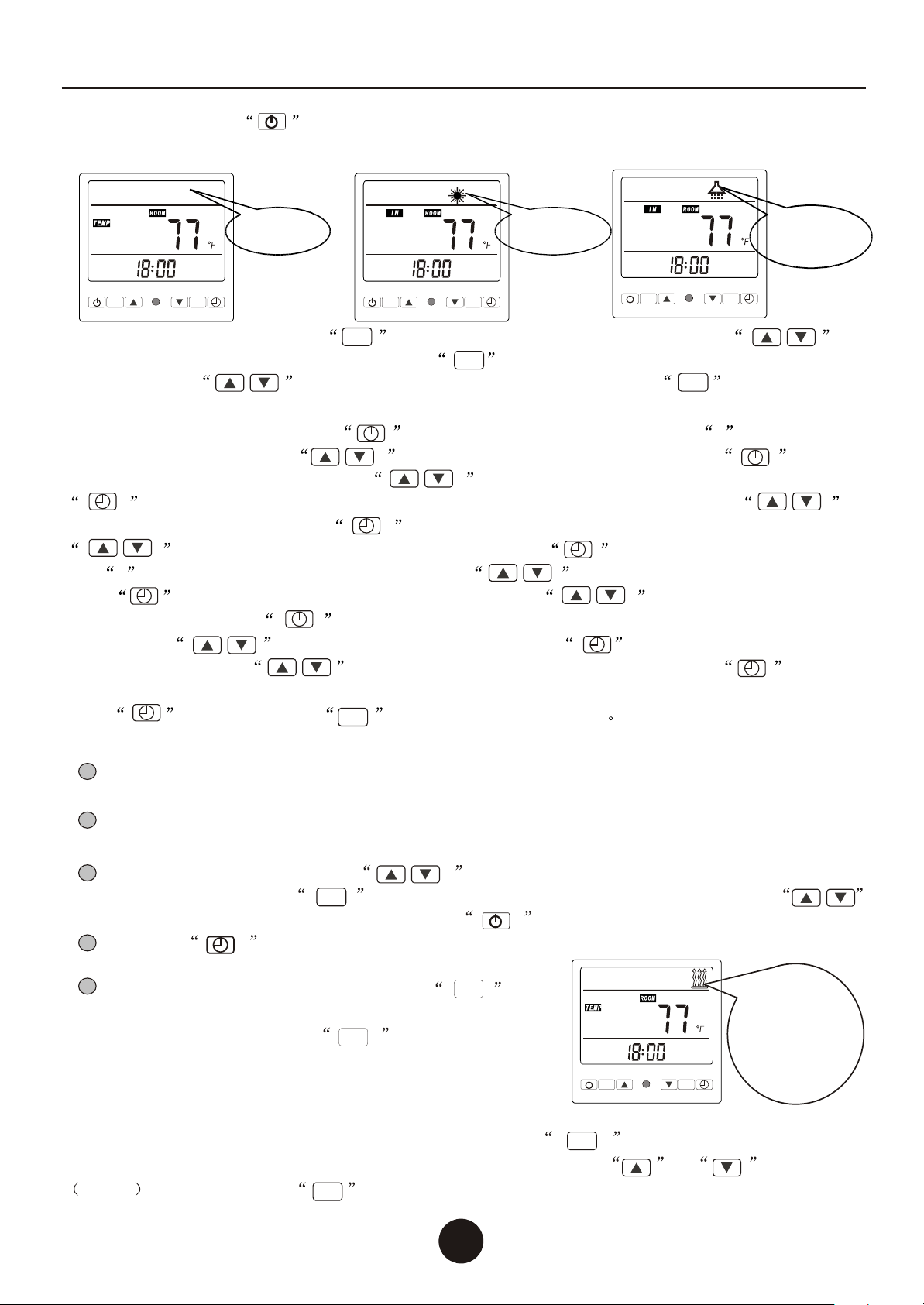

2.4 Clock setting. Press button , the place of hour keeps flicking, press to

adjust the setting of hour . Then press button and the place of minute will keep flicking .

Press the button to adjust the setting of minute. Press button again to

complete and exit the time setting mode.

SETSET

SETSET

2.5 Timed ON/OFF setting. Press botton,and the of place hour and 1 Timing ON

symbol keep flicking. Press to adjust the setting of the hour. Press button

again,and the bit minute flicks. Press buttons to adjust the setting of minute; Press

button again and the place of hour and timing OFF symbol flicks. Press to

adjust the setting of hour. Press button again, and the bit minute flickers. Press

buttons to adjust the setting of minute. Press botton,and the of place hour

and 2 Timing ON symbol keep flicking. Press to adjust the setting of the hour.

Press button again,and the bit minute flicks. Press buttons to adjust the

setting of minute; Press button again and the place of hour and timing OFF symbol

flicks. Press to adjust the setting of hour. Press button again, and the bit

minute flickers. Press buttons to adjust the setting of minute. Press button

again to complete and exit the timed ON/OFF setting mode. Cancel timing setting operation.

press button and press button to cancel the timing

SETSET

2.7 These settings are for Engineers only, please call if you require to change any of the Optional

Parameters. Under the power on or standby status, press buttons at the same time for

10 seconds to enter Operation Parameter setting interface. Press or to view

01-36 parameter,press button again to set data you need. Parameter setting as below:

SETSET

SETSET

2.3 Power on/off: Press button to start the unit, Then the LCD will display the current mode and

two temperature value(Both different kinds of temperature value will display 5 seconds each on the

interface,one after one to display automatically .)

Air To Water Heat Pump Water Heater

SETSET

MM

Standby state

SETSET

MM

working state

Note:

The Timing function only can be used under the parameter 26 is set be ''1' ,otherwise, there's

no the timing function.

Domestic water tank temperature and indoor environment temperature, and can be modified

under standby state or working state, others can be modified under standby state.

In the working state, press the buttons can set up the user common use setting

parameters ,press the buttons to switch to modified parameters, press

button to modify the parameters,press the buttons,exit the setting interface.

1

2

3

SETSET

4

5

press the button for 5 seconds to switch the display between centigrade degree and

fahrenheit.

SETSET

MM

Icon constantly flickering,

enter into manual electrical

heating output mode.

When boot-strap and on standby, press button

for 5 seconds for the manual operation electric heater

heating output, press the button for 5 seconds

again,shutdown the manual operation electric heater

heating output

MM

MM

Icon do not twinkle,enter

into automatic electric

heat output mode.

SETSET

MM

Keep falsh

Defrost state

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

Parameter 05

hot water temp.

difference between the unit stop

heating and restartheating

Alternative range: 2 to 30 .

Default: 10

Domestic

Parameter 06

Cooling return water temp.

difference between the unit stop

heating and restartheating .

Alternative range: 2 to 30 .

Default: 10

Parameter 07

Heating return watertemp.

difference between the unit stop

heating and restartheating .

Alternative range: 2 to 30 .

Default: 10

Parameter 08

Room temp. difference

between the unit stop heating

and restart heating .

Alternative range: 2 to 30 .

Default: 4

1212

Air To Water Heat Pump Water Heater

Parameter 01

Alternative range:

50 to 158 .

Default: 131

Domestic hot watertank

temperature setting

Parameter 02

Air cooling

Alternative range:

46 to 82 .

Default: 54

return water

temperature setting

Parameter 03

Air heating returnwater

temperature setting

Alternative range:

59 to 140 .

Default: 104

Parameter 04

Room temperature setting

Alternative range:

50 to 113 .

Default: 77

Parameter 09

Alternative range:

30minutes to 90minutes.

Default: 40minutes

Heating defrost cycle

Parameter 11

Alternative range: 36 to 86 .

Default: 55

Exit defrost temperature.

Parameter 12

Alternative range:

1 minutes to12 minutes.

Default: 8 minutes

Exit defrost timecondition

Parameter 10

Alternative range: -86 to 32

Default: -45

Into defrost temperature

Parameter 13

Single or double

1 is single system,

2 is double system

Default: 1

system

selection.

Parameter 14

1:with memory function

2:without memory function

Default: 1

Whether power-down memory

Parameter 15

wire cotrol sensor or the

:wire control sensor

0:multi-room switch

Default: 1

multi

-room switch Selection.

1

Parameter 16

W

:Turn off

1:Turn on

Default: 1

hether turn on automatic

electric heating function.

0

SETSET

MM

SETSET

MMSETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

SETSET

MM

1313

Air To Water Heat Pump Water Heater

Parameter 18

0:long time workingfor water

pump

1:water pump turnsoff after

the whole unitpower offfor 30s

Default:1

Parameter 19

Alternative range: 140 to 194

Default: 140

(The unit havecancled the high-temperaturedisinfection )

High-temperature disinfection

per week setting,

Parameter 20

Alternative range: 10~90Min.

Default: 30Min.

High-temperature disinfection

maintain time,

Parameter 17

0:

: Air

Default: 0

Domestic hot waterpriority,

or heating andcooling priority

Domestic hot waterpriority

1 heating and aircooling

priority

Parameter 21

The room temp. difference setting

between non-sleeping status mode

and sleeping status mode

Alternative range: -30 to 30 .

Default: 10

Parameter 22

Whether turn on air cooling

function model

0: turn off

1: turn on

Default: 0

Parameter 23

The start timeof non-sleeping

status mode.

Default: 05:00

Parameter 24

The end timeof non-sleeping

status mode.

Default: 23:00

SETSET

MMSETSET

MMSETSET

MMSETSET

MM

Parameter 27

Actual testing value:

Living hot watertank

temperature

Domestic hot watertank temp.

Parameter 28

water return temp.

Actual testing value:

Unit inlet watertemperature

Parameter 29

water outlet temp.

Actual testing value:

Unit outlet watertemperature

Parameter 30

Indoor environment temp.

Actual testing value:

Indoor environment

temperature

Parameter 31

Out door environmenttemp.

Actual testing value:

Outdoor environment

temperature

Parameter 32

Pipe temp.1

Actual testing value:

pipe temperature (system1)

Parameter 25

The temp. difference setting

between solar temp. and water tank

temp. for turn on the water pump

Alternative range: 2 to 40

Default: 12

Parameter 26

whether turn on the timing function

0: Turn off

1: Turn on

Default: 0

1414

Air To Water Heat Pump Water Heater

SETSET

MMSETSET

MMSETSET

MM

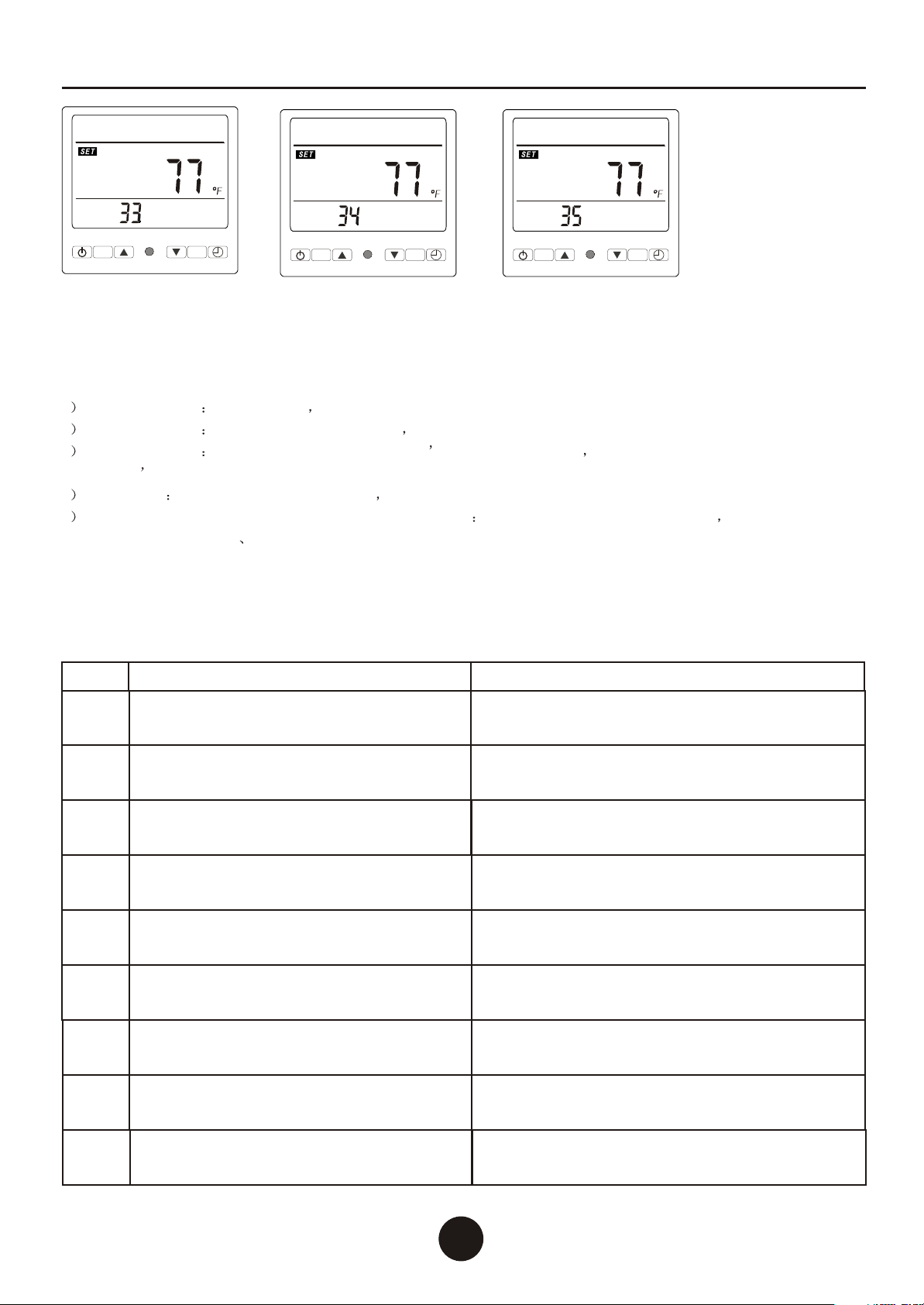

Parameter 34

Exhaust 1 temp.

Actual testing value:

exhaust temperature (system1)

Parameter 35

Exhaust 2 temp.

Actual testing value:

exhaust temperature (system2)

Parameter 33

Pipe temp.2

Actual testing value:

pipe temperature (system2)

Remark :

1 Parameter value 13 1:single system 2:double system

2 Parameter value 14 0: without power-down memory 1: with power-down memory

3 Parameter value 15 0: uncontrolled by the wire controller s temp. sensor function 1: controlled by the wire

controller s temp. Sensor function

4 Parameter 16 0: without electric heater auxiliary 1: with electric hear auxiliary (efficient for the unit with electric heater auxiliary )

5 Water pump working way introductions for the parameter value 18 0:starts 10 seconds before compressor stops 30

seconds after compressor 1:always open

3:Operation data setting

The unit's operation data can be set on the wire controller.

Please set according to the table below.

Parameter

NO . meaning explanation of parameters

01

Domestic hot water tank temperature

setting

02

Air cooling return water temperature

setting

03

Air heating return water temperature

setting

This parameter fortank temp. canbe set bythe up and down

arrow buttons byuser under boot-state.

04

Room temperature setting

This parameter forhot water inlettemp. can controlthe compres

-sor ON/OFF whenworking the coolingmode.

This parameter for hot water inlet temp. can control the compres

-sor ON/OFF whenworking the heatingmode.

05

Domestic hot water temp. difference

between the unit stop heating and restart

heating

06

Air cooling return water temp.difference

between the unit stop heating and restart

heating .

07

Air heating return water temp.difference

between the unit stop heating and restart

heating .

08

Room temp. difference between the unit

stop heatingand restart heating .

09

Heating defrost cycle

This parameter can set the roomtemp. and control the floor

heating water pumpON/OFF by the up and downarrow keys on

the wire controller.

This parameter isused for re-heating the water after

and in hotwater mode by means of setting how many

temp. value ofthe hot water tank has been decreased .

thermostat

stop heating

This parameter isused for re-cooling the water after

and in coolingmode by means of setting how many

temp. value ofthe inlet water temp. has been rise.

thermostat

stop cooling

This parameter forre-house heating after

and in heatingmode by means of setting how many temp.

Value of the inlet water temp. has been decrease .

thermostat stop heat-

-ing

This parameter forre-working floor heating/cooling water pump

after by means ofsetting how

many temp. valueof the room temp. has been decrease/rise .

thermostat stop heating/cooling

Period setting forunit cycle defrost

1515

Air To Water Heat Pump Water Heater

10

Into defrost temperature setting.

11

Exit defrost temperature setting.

12

Exit defrost time condition setting .

13

Single or double system selection.

14

Whether power-down memory .

15

Wire cotrol sensor or the" multi-room

switch" Selection.

16

W

hether turn on automatic electric

heating function.

17

Domestic hot water priority, or heating

and cooling priority .

18

Room temp. difference between the unit

stop heating and restart heating .

19

High-temperature disinfection per week

setting .

20

High-temperature disinfection maintain

time.

21

The room temp. difference setting

between non-sleeping status mode

and sleeping status mode .

22

Whether turn on air cooling function

model .

23

The start time of non-sleeping status

mode .

24

The end time of non-sleeping status

mode .

25

The temp. difference setting between solar

temp. and water tank temp. for turn on the

water pump .

26

Whether turn on the timing function.

The coil temperaturesetting for enter into defrost status

The coil temperaturesetting for exit the defrost status.

The maximum runningtime for defrost state.

Setting for dualsystem selection.

This parameter isused for setting whether keep the original

operation statues afterunit power off and restart.

This parameter isused for setting whether use the sensor on wire

controller or usethe multi-room switch to control the room temp-

-erature.

This parameter isused for setting whether turn on automatic

electric heating mode.If ON, there's electric heating after the

compressor running for1 hour.

This parameter isused for setting whether priority turn on the

heating water modeor priority turn on the cooling water mode.

This parameter iscycle water pump operation setting. whenin hot

water mode, setit constant temperature closing is thebest, when in

cooling or heatingmode, set it constant temperature startingis the

best.

This parameter iswhether to open the cooling mode to the user.

Press the 'mode'button to set it ON/OFF.

This parameter isthe start time setting for the non-sleep period.

The unit hascanceled the high temp.sterilization function

The unit hascanceled the high temp.sterilization function

The unit hascanceled the high temp.sterilization function

This parameter isthe ending time setting for the non-sleep period.

This parameter isthe temperature difference setting between

solar collector temp.and the water tank temp. , this setting is

used for controlthe solar pump ON/OFF.

This parameter isthe setting whether open the timing function to

user for theuser.

Wire

Controller

Wire

Controller MalfunctionMalfunction

1.Malfunction Indicating Table. Determine and solve the malfuction by malfuction code as below:

1.1.operate display fault code mode

1616

E01

E02

E03

E04

E05

E06

E07

E08

E09

E10

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

ReasonReason ResolutionResolution

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

Check or change the sensor

The sensor is open or short circuit

Water inlet temp. Sensor failure

Water outlet temp. Sensor failure

System 1discharge sensor

failure

System 1 pipe sensor failure

System 2 Pipe sensor failure

Indoor environment temp.

Sensor failure

Outdoor environment temp.

Sensor failure

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

The sensor is open or short circuit

High pressure 1

switch protection

High pressure 2

switch protection

Low pressure 1

switch protection

Low pressure 2

switch protection

Flow switch 1 protection

Flow switch 2 protection

system 1 high pressure

protection

system 1 low pressure

protection

system 2 high pressure

protection

system 2 low pressure

protection

3 times of excessive temp.

differentials of inlet water

and outlet water in 30minutes

Water flow volume not enough,

water pressure difference is too low

Check the water flow volume,

or water system is blocked or not.

Communication failure

Wire controller and The

PCB connection failure. Check the wire connection

No water/little water

in water system.

Check the water flow volume,

water pump is failure or not.

No water/little water

in water system.

Check the water flow volume,

water pump is failure or not.

Check whether the pressure switch

and system return route failure.

Check whether the pressure switch

and system return route failure.

Check whether the pressure switch

and system return route failure.

Check whether the pressure switch

and system return route failure.

Tank temp. Sensor failure

Phase failure protection

electric heater auxiliary overheating

& dry heating protection

Frost-protection

High discharge 1 temperature

protection

High discharge 2 temperature

protection

Power supply phase failure /lacking

Check whether power supply phase failure or

lacking, if failure, please connect it in according

to the proper way.

when the outdoor temp. below 0

under standby model

after the antifreezing procedure ,unit will

return to the original state automatically

Check the over heating switch normal or not

The protector open circuit or

short circuit

1.whether gas of system leak or not

2.the tank temp. Be set too high

1 check the refrigerent amount inthe system

2 check whether the tank temp.Setting value too high

1.whether gas of system leak or not

2.the tank temp. Be set too high

1 check therefrigerent amount in the system

2 check whether the tank temp. Setting value too high

IV Maintenance and repairIV Maintenance and repair

Air To Water Heat Pump Water Heater

System 2 discharge sensor

failure

1717

1 The choice of installation ways

1.1 the installation way for domestic hot water model

TankTank

house hot

water area

Tank temperature

Remark :

1) In the working state, press the buttons can set up the parameters 1 , at this time you can adjust the

setpoint of the water tank temperature,press the buttons, exit the setting interface.

2) Circulating water pump working way introductions for the parameter value 18:

0:starts 10 seconds before compressor

stops 30 seconds after compressor

1:always open

3) The port of 29 30 on PCB should connect to the water tank to detect the tank temp.

Cycle water out

Drain out

Hot water out

Cold water in

Cycle water in

Wire controller

Hot water tank temp.

Disconnecting valve

One way-valve

The parameter setting for domestic hot water model:

01 50 ~140 131 Adjustable

05 2 ~30 10

Digit Meaning Range Default Parameter setting for

domestic water mode

18 0/1 10

Adjustable

Domestic hot water tank temperature setting

Circulating water pump works option

Domestic hot water return temperature

V Installation sketchV Installation sketch

Air To Water Heat Pump Water Heater

POWER INPUT

(208~230V)

PCBPCB

L1 L2

29 30

01 02 03

L1 L2 L1 L2 L1 L2 L1 L2 L1 L2 L1 L2

PUMP

Outdoor fan

(208~230V)

Auxiliary electric

heater

(208~230VAC)

Solar cycle

pump

(208~230VAC)

Cycle water

pump 1

(208~230VAC)

Electric three-way

valve

(208~230VAC)

Cycle water

pump 2

(208~230VAC)

This manual suits for next models

15

Table of contents

Popular Water Heater manuals by other brands

Vaillant

Vaillant VPS R 100/1 M Operating and installation instructions

Cooper & Hunter

Cooper & Hunter CH-HP3.5SWNK owner's manual

Solarbayer

Solarbayer HSK-SLS Product information

Rommelsbacher

Rommelsbacher RT 350 instruction manual

Eccotemp

Eccotemp 20 Series Use & care manual

PVI Industries

PVI Industries COBREX Installation & maintenance manual

Intellihot

Intellihot i200X Operation manual

3P Technik

3P Technik 3P Barrique instruction sheet

Poloma

Poloma PH-28 C DVSN Installation and operating instruction manual

A.O. Smith

A.O. Smith T-H3J-DV Service manual

TLV

TLV SteamAqua SQ10 instruction manual

Maxwell

Maxwell MSxxxC2T series Installation and instruction manual