Heat & Glo LifeStyle GEM42 Assembly instructions

1

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

- Do not store or use gasoline or other flam-

mablevaporsandliquidsinthevicinityofthis

oranyotherappliance.

-What to do if you smell gas

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Donotuse any phone inyour building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

thefiredepartment.

- Installationandservicemustbeperformedbya

qualified installer, service agency, or the gas

supplier.

Installers Guide

WARNING: IMPROPER INSTALLA-

TION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN

CAUSE INJURY OR PROPERTY DAM-

AGE. REFER TO THIS MANUAL. FOR

ASSISTANCE ORADDITIONAL INFOR-

MATION CONSULT A QUALIFIED IN-

STALLER, SERVICEAGENCY, OR THE

GAS SUPPLIER.

Underwriters

Laboratories Listed

READ THIS MANUAL BEFORE INSTALLING OR

OPERATING THISAPPLIANCE. THIS INSTALLERS

GUIDE MUST BE LEFT WITH APPLIANCE FOR

FUTUREREFERENCE.

1.This appliance may be installed in an af-

termarket,permanentlylocated,manufac-

tured(mobile)home,wherenotprohibited

bylocalcodes.

2. Thisapplianceisonlyforusewiththetype

of gas indicated on the rating plate. This

appliance is not convertible for use with

othergases,unlessacertifiedkitisused.

Please contact your Heat & Glo dealer with any

questionsorconcerns.Forthe number of your nearest

Heat & Glo dealer, please call 1-888-427-3973.

Printed in U.S.A. Copyright 2005,

Heat & Glo, a brand of Hearth & Home Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

WARNING: IF THE INFORMATION

IN THESE INSTRUCTIONS IS NOT

FOLLOWED EXACTLY,A FIRE OR

EXPLOSION MAY RESULT CAUS-

ING PROPERTY DAMAGE, PER-

SONAL INJURY, OR DEATH.

Model:

GEM42

Thisproductmaybecoveredbyoneormoreofthefollowingpatents:(UnitedStates)4593510,4686807,4766876,4793322,4811534, 5000162, 5016609, 5076254, 5113843,5191877,5218953,5263471,

5328356,5341794,5347983,5429495, 5452708, 5542407, 5601073,5613487,5647340,5688568, 5762062, 5775408, 5890485,5931661,5941237, 5947112,5996575,6006743,6019099,6048195,

6053165,6145502,6170481,6237588,6296474,6374822,6413079,6439226,6484712,6543698,6550687,6601579,6672860,6688302B2,6715724B2,6729551,6736133, 6748940,6748942,D320652,

D445174,D462436; (Canada) 1297749,2195264,2225408; orotherU.S. andforeignpatents pending.

2Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

These units MUST use one of the vent systems

described in the Installing the Fireplace section of

the Installers Guide. NO OTHER vent systems or

components MAY BE USED.

This gas fireplace and vent assembly MUST be

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis to

make sure that no debris is interfering with the air

flow.

The glass door assembly MUST be in place and

sealed, and the trim door assembly MUST be in

place on the fireplace before the unit can be placed

into safe operation.

DO NOT OPERATE this appliance with the glass

door removed, cracked, or broken. Replacement of

the glass door should be performed by a licensed

or qualified service person. DO NOT strike or slam

the glass door.

The glass door assembly SHALL ONLY be

replaced as a complete unit, as supplied by the gas

fireplace manufacturer. NO SUBSTITUTE material

may be used.

DO NOT USE abrasive cleaners on the glass door

assembly. DO NOT ATTEMPT to clean the glass

door when it is hot.

Turn off the gas before servicing this appliance. It is

recommended that a qualified service technician

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing

must be replaced before operating this appliance.

DO NOT place furniture or any other combustible

household objects within 36 inches of the fireplace

front.

READ and UNDERSTAND all instructions carefully

before starting the installation. FAILURE TO

FOLLOW these installation instructions may result

in a possible fire hazard and will void the warranty.

Prior to the first firing of the fireplace, READ the

Using Your Fireplace section of the Owners Guide.

DO NOT USE this appliance if any part has been

under water. Immediately CALL a qualified service

technician to inspect the unit and to replace any part

of the control system and any gas control which has

been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

Installation and repair should be PERFORMED by a

qualified service person. The appliance and venting

system should be INSPECTED before initial use

and at least annually by a professional service

person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

material, etc. It is IMPERATIVE that the unit’s

control compartment, burners, and circulating air

passageways BE KEPT CLEAN to provide for

adequate combustion and ventilation air.

Always KEEP the appliance clear and free from

combustible materials, gasoline, and other

flammable vapors and liquids.

NEVER OBSTRUCT the flow of combustion and

ventilation air. Keep the front of the appliance

CLEAR of all obstacles and materials for servicing

and proper operations.

Due to the high temperature, the appliance should

be LOCATED out of traffic areas and away from

furniture and draperies. Clothing or flammable

material SHOULD NOT BE PLACED on or near the

appliance.

Children and adults should be ALERTED to the

hazards of high surface temperature and should

STAY AWAY to avoid burns or clothing ignition.

Young children should be CAREFULLYSUPERVISED

when they are in the same room as the appliance.

!

!

!

!

!

!

!

!!

!

!

!

!

!

!

!

!

SAFETY AND WARNING INFORMATION

!

!

3

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

TABLE OF CONTENTS

Safety and Warning Information ................................................ 2

Service Parts Lists ..................................................................... 4

Section 1: Approvals and Codes............................................... 7

ApplianceCertification................................................................... 7

Installation Codes.......................................................................... 7

HighAltitudeInstallations............................................................... 7

Section 2: Getting Started ......................................................... 8

Introducing the Heat & Glo Gas Fireplaces................................... 8

Pre-installationPreparation........................................................... 8

Section 3: Installing the Fireplace.......................................... 10

Constructing the Fireplace Chase .............................................. 10

Step 1 Locating the Fireplace ................................................. 10

Step 2 Framing the Fireplace...................................................11

Step 3 Installing the Vent System............................................ 13

A. Vent SystemApprovals........................................... 13

B. Installing Vent Components.................................... 17

C. Vent Termination .................................................... 19

Step 4 Positioning, Leveling,and

Securing the Fireplace................................................. 21

Step 5 Installing the Optional Heat-Out or Heat-Zone Kits ...... 22

Step 6 The Gas Control Systems........................................... 22

Step 7 The Gas Supply Line ................................................... 23

Step 8 Gas Pressure Requirements ...................................... 23

Step 9 Wiring the Fireplace .................................................... 24

Step 10 Finishing ...................................................................... 25

Facing Requirements .................................................. 26

Step 11 Installing Trim, Logs and Ember Material .................... 27

Installing the Trim......................................................... 27

Positioning the Logs .................................................... 27

Placing the Ember Material.......................................... 27

Glass Specifications .................................................... 27

Burner Removal............................................................ 27

Step 12 Before Lighting the Fireplace ....................................... 28

Step 13 Lighting the Fireplace .................................................. 28

Afterthe Installation..................................................................... 28

Section 4: Maintaining and Servicing Your Fireplace......... 29

Î= Containsupdated information.

Î

Î

Î

Î

4Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

*Partnumberlist on following page.

*La liste des numéros de pièce se

trouve à la page suivante.

5 Log set assembly

6

87

9

4

23

12

10

11

(NG, LP) Exploded Parts Diagram

(GN, PL) Vue éclatée des pièces

Service Parts GEM42

Beginning Manufacturing Date: 7-02

Ending Manufacturing Date: ______

1

5

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

ITEM /

PIÈCE DESCRIPTION SERIAL #

/N°DE SÉRIE PART NUMBER

/ N° DE PIÈCE

1 Heat Shield / Protection(Bouclier) de Chaleur 371-130

2 Glass Door Assembly / Porte en verre GLA-GEM42

3 Log Grate / Grille de Bûche PRE 002330771

POST 002330771 370-360A

370-361A

4 Burner / Brûleur PRE 002330771

POST 002330771 SRV371-279A

371-279A

5 Log Set Assembly / Jeu de Bûches LOGS-GEM42

6 Log 1 / Bûche 1 SRV371-700

7 Log 2 / Bûche 2 SRV371-701

8 Log 3 / Bûche 3 SRV371-702

9 Log 4 / Bûche 4 SRV371-704

10 Log 5 / Bûche 5 SRV371-703

11 Log 6 / Bûche 6 SRV371-705

12 Top Heat Shield / Protection(Bouclier) de Chaleur Supérieure 371-140

Flue Restrictor 1-3/4" diameter / Restricteur de conduite de cheminée 371-259

Flue Restrictor 1-1/2" diameter / Restricteur de conduite de cheminée 370-260

Flue Restrictor 2" diameter / Restricteur de conduite de cheminée 371-260

Junction Box / Boîtier de dérivation PRE 5-04

POST 5-04 383-250A

4021-013

3V Adaptor Plug / 3V Bouchon d'adapteur 593-593A

Battery Pack / Paquet de Batterie(Pile) 593-594A

Fan Kit / Module de ventilateur GFK-160A

Mineral Wool / Laine minérale 050-721

Fiberglass Rope / Corde de fibre de verre 060-455

Golden Embers / Braises dorées GE-93

Vermiculite Embers / Vermiculite Braises MYSTIC-EMBERS

Template / Gabarit GEM42-TEMPLATE

ACCESSORIES / ACCESSOIRES

Wall Switch Kit, Off-white / Interrupteur mural, blanc crème WSK-21

Wall Switch Kit, White / Interrupteur mural, blanc WSK-21-W

Multi-functional Wall Switch / Le Commutateur de Mur multi-fonctionnel WSK-MLT

Heat-Out Kit / Chauffe-hors Trousse HEAT-OUT

Heat-Zone Kit / Trousse de chauffe-zone HEAT-ZONE

Trim Door Mesh / Écran porte de garniture MESH-GEM42

LP Conversion Kit / Module de conversion PL LPK-GEM42

Fiber Patch Kit / La Trousse de Pièce de fibre SRV-PACK

Service Parts List / Liste des pièces de rechange

IMPORTANT: THIS ISDATED INFORMATION.Themost currentinformation islocatedon yourdealersVIPsite. Whenorder-

ing,supply serialand modelnumberstoensurecorrect serviceparts./IMPORTANT : L'informationfourniedanscettebrochure

n'est valide que pendant une courte période. Les sites VIP des distributeurs disposent des renseignements les plus récents.

Lorsd'une commande, veuillezfournir les numérosde série etdemodèles pour unremplacement adéquat despièces.

GEM42

6Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

(NG, LP) Exploded Parts Diagram

(GN, PL) Vue éclatée des pièces

Service Parts

Intermittent Pilot Ignition

ValveAssembly

GEM42

Beginning Manufacturing Date: 7-02

Ending Manufacturing Date: ______

1

2

3

4

5

78

9

10

11

12

14

15

16

17

18

6

ITEM /

PIÈCE DESCRIPTION SERIAL #

/N°DE SÉRIE PART NUMBER

/ N° DE PIÈCE

1ON/OFF Rocker Switch / Interrupteur à bascule MARCHE/ARRÊT 060-521A

2Valve NG / Valve GN 750-500

2Valve LP / Valve PL 750-501

3Flexible Gas Connector / Tuyau à gaz flexible 567-301A

4Module / Module 593-592

5Wire Assembly / Module de fil 593-590A

6Rheostat Assembly / Assemblée de Rhéostat 100-510A

7Pilot Assembly NG / Module de veilleuse GN 370-510A

7Pilot Assembly LP / Module de veilleuse PL 370-511A

8PilotBracket / Parenthèse Pilote 370-165

9Ground Strap / Courroie de Raison(Terre) 385-512

10 Valve Bracket / Parenthèse de Valve 370-155

11 Flex Ball Valve Assembly / Fléchir l'Assemblée de Soupape de Balle 302-320A

12 Control Panel / Tableau de commande avant 370-153

13 Flame Control Knob / Flamber le Bouton de Contrôle 571-531

14 Rheostat Knob - Black / Bouton de Rhéostat - Noir 100-512

15 Shutter Rod / Tige d'Obturateur 370-350

16 Temp Sensor / Détecteur de température 107-531

17 Orifice Bracket / Parenthèse d'Orifice 370-120

18 Handle / Poignée 319-167

19 Burner Orifice NG (#29C) / Orifice de brûleur GN (#29C) 582-829

19 Burner Orifice LP (#48C) / Orifice de brûleur PL (#48C) 582-848

20 inch Wire Harness / Harnais de fil 107-559A

Pilot Support / Piloter le Soutien 385-120

13

19

7

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

Appliance Certification

TheHeat & Glo fireplacemodel discussed in thisInstallers

Guidehasbeen tested tocertificationstandards and listed

bytheapplicable laboratories.

Certification

MODEL: GEM42

LABORATORY: UnderwritersLaboratories

TYPE: Direct Vent Gas Fireplace Heater

STANDARD:

ANSI Z21.88-2000•CSA2.33-M98•UL307B

Installation Codes

Thefireplaceinstallationmustconformtolocalcodes. Before

installing the fireplace, consult the local building code

agency to ensure that you are in compliance with all

applicable codes, including permits and inspections.

Inthe absenceoflocalcodes,the fireplaceinstallation must

conform to the National Fuel Gas Code ANSI Z223.1 (in

theUnitedStates)or theCAN/CGA-B149InstallationCodes

(in Canada). The appliance must be electrically grounded

in accordance with local codes or, in the absence of local

codes with the National Electric CodeANSI/NFPANo. 70

(intheUnitedStates),ortothe CSAC22.1CanadianElectric

Code(in Canada).

Thesemodels may beinstalled in abedroom or bed-sitting

room in the U.S.A. and Canada.

1Approvals and

Codes

HighAltitude Installations

U.L. Listed gas appliances are tested and approved with-

outrequiring changes for elevations from0 to 2,000 feetin

the U. S.A. and in Canada.

Wheninstalling this appliance atanelevation above 2,000

feet, it may be necessary to decrease the input rating by

changingthe existing burner orificetoa smaller size. Input

rate should be reduced by 4% for each 1000 feet above a

2000 foot elevation in the U.S.A. or 10% for elevations

between2000and4500feet inCanada.Iftheheating value

of the gas has been reduced, these rules do not apply. To

identify the proper orifice size, check with the local gas

utility.

Ifinstallingthis appliance at an elevation above4,500feet

(in Canada), check with local authorities.

Heat & Glo Quality Systems

registeredbySGS ICS

8Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

2Getting Started

Introducing the Heat & Glo Gas Fireplaces

Heat& Glo directvent gas fireplacesaredesigned tooper-

ate with all combustion air siphoned from outside of the

building and all exhaust gases expelled to the outside.

The information contained in this Installers Guide, unless

noted otherwise, applies to all models and gas control

systems.Gasfireplace diagrams,including thedimensions,

are shown in this section.

Pre-install Preparation

Thisgasfireplace and its components are tested andsafe

when installed in accordance with this Installers Guide.

Report to your dealer any parts damaged in shipment,

particularly the condition of the glass. Do not install any

unit with damaged, incomplete, or substitute parts.

The vent system components and trim doors are shipped

in separate packages. The gas logs may be packaged

separately and must be field installed.

Read all of the instructions before starting the

installation. Follow these instructions carefully during

the installation to ensure maximum safety and benefit.

Failure to follow these instructions will void the

owner’s warranty and may present a fire hazard.

TheHeat & Glo Warranty will be voidedby, andHeat& Glo

disclaims any responsibility for, the following actions:

• Installation of any damaged fireplace or vent system

component.

• Modification of the fireplace or direct vent system.

• Installation other than as instructed by Heat & Glo.

• Improper positioning of the gas logs or the glass door.

• Installationand/or useof anycomponentpart notmanu-

factured and approved by Heat & Glo, not withstanding

anyindependenttestinglaboratoryor otherpartyapproval

of such component part or accessory.

ANY SUCH ACTION MAY POSSIBLY CAUSE A FIRE

HAZARD.

When planning a fireplace installation, it’s necessary to

determine:

•Where the unit is to be installed.

•Theventsystem configuration to be used.

•Gas supply piping.

•Electricalwiring.

•Framingandfinishing details.

•Whether optional accessories—devices such as a fan,

wallswitch,or remote control—are desired.

If the fireplace is to be installed on carpeting or tile, or on

any combustible material other than wood flooring, the

fireplaceshouldbe installed on a metal orwood panel that

extends the full width and depth of the fireplace.

9

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

Figure 1. Diagram of the GEM42

TOP STANDOFFS

TOP VENT

COLLARS

TRIM DOOR

RATNG PLATES

AND LABELS

GAS

CONTROLS

GAS LINE

ACCESS ELECTRICAL

ACCESS

HEAT-ZONE

KNOCKOUTS

HEAT-OUT

KNOCKOUT

ORIFICE

ACCESS PANEL

3”

(76.2mm)

47-9/16”

(1208.1mm)

40-17/32”

(1029.5mm) 35-9/32”

(896.2mm) 2”

(50.8mm)

4-1/2”

(114.3mm)

Ø8” (203mm)

8-3/32”

(205.6mm)

41-3/4” (1060.4mm)

20-29/32”

(531mm)

17-1/2” (443mm)

46” (1168.4mm)

5-7/32”

(132.9mm)

46-3/4” (1187.4mm)

10 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

3Installing the Fireplace

Step 1. Locating the Fireplace

Thefollowingdiagramshowsspace andclearance require-

ments for locating a fireplace within a room.

ABCD E

47-1/2” 18” 39” 55.25” 78-1/2”

Minimum Clearances

from the Fireplace to Combustible Materials

Inches mm

Glass Front........................ 36 .................... 914

Floor ................................... 0 ....................... 0

Rear ...................................1/2 ..................... 13

Sides .................................1/2 ..................... 13

SurroundSides*.................1/2 ..................... 13

Top...................................... 7 ..................... 178

Ceiling**............................. 31 .................... 787

Figure 2. Fireplace Dimensions, Locations,

and Space Requirements

Minimum Clearances

from the Vent Pipe to Combustible Materials

Inches mm

Vertical Sections. ............. 1 ................ 25

Horizontal Sections

Top..................................... 3 ................ 75

Bottom ............................... 1 ................ 25

Sides ................................. 1 ................ 25

At Wall Firestops

Top..................................... 3 ................ 75

Bottom ............................... 1 ................ 25

Sides ................................. 1 ................ 25

* See Figure 3.

**The clearanceto theceilingis measuredfrom the

topof the unit, excludingthestandoffs.

Thedistance from theunit to combustibleconstruction

is to be measured from the unit outer wrap surface to

thecombustibleconstruction,NOTfromthescrewheads

that secure the unit together.

For minimum clearances, see the direct vent termination

clearance diagrams on pages 20 and 21 in this manual.

1/2” MIN. (13mm)

D

C

E

B

12” MIN. (304.8mm)

A

Clearance Requirements

The top, back, and sides of the fireplace are defined by

stand-offs.The minimum clearanceto aperpendicular wall

extending past the face of the fireplace is 12” (304.8 mm).

Thebackofthefireplacemayberecessed171/2”(437.5mm)

into combustible construction.

Constructing the Fireplace Chase

A chase is a vertical box-like structure built to enclose the

gasfireplace and/or itsventsystem.Vertical ventsthat run

onthe outside of abuilding may be, butare not requiredto

be, installed inside a chase.

CAUTION: TREATMENTOF FIRESTOPSPACERSAND

CONSTRUCTIONOFTHECHASE MAYVARYWITHTHE

TYPEOF BUILDING.THESE INSTRUCTIONSARE NOT

SUBSTITUTES FOR THE REQUIREMENTS OF LOCAL

BUILDINGCODES.THEREFORE,YOURLOCAL BUILD-

INGCODES MUST BE CHECKED TODETERMINE THE

REQUIREMENTSFOR THESE STEPS.

Factory-builtfireplace chasesshould beconstructed in the

manner of all outside walls of the home to prevent cold air

draftingproblems. The chaseshould notbreakthe outside

buildingenvelopeinanymanner.

This means that the walls, ceiling, base plate and cantile-

ver floor of the chase should be insulated. Vapor and air

infiltration barriers should be installed in the chase as per

regionalcodes forthe restof thehome.Additionally,Heat &

Glo recommends that the inside surfaces be sheetrocked

and taped for maximum air tightness.

To furtherprevent drafts,the firestopsshould becaulked to

seal gaps. Gas line holes and other openings should be

caulked or stuffed with insulation. If the unit is being in-

stalled on a cement slab, we recommend that a layer of

plywoodbe placed underneath toprevent conducting cold

up into the room. Be sure to include spark arrestors for

woodburningunits ifthey arerequired.

THECHASESHOULDBECONSTRUCTEDSOTHATALL

CLEARANCES TO THE FIREPLACEARE MAINTAINED

AS SPECIFIED WITHIN THIS INSTALLERS GUIDE.

11

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

Framing should be

constructed of 2 X 4

lumber or heavier.

A. ................. 47-1/2”

B. ................. 47-3/4”

C. ................. 17-1/2”

D. ........................ 65”

E**. .......... 22-15/16”

F.* ................ 55-1/2”

Figure 3. Framing Dimensions

Step 2. Framing the Fireplace

Fireplaceframing canbe builtbefore orafter thefireplace is

set in place. Framing should be positioned to accommo-

date wall coverings and fireplace facing material. The dia-

grambelow showsframing referencedimensions.

CAUTION: MEASURE FIREPLACE DIMENSIONS AND

VERIFY FRAMING METHODS AND WALL COVERING

DETAILS BEFOREFRAMING.

Shows center of 10” x 12” vent framing

holes for top and rear venting. The center

of the hole is one (1) inch (25.4mm) above

the center of the horizontal vent pipe.

F

A

CB

1/2” CLEARANCE TO

FRAMING MEMBER

1/2” CLEARANCE

FRAMING

MEMBER

1/2” CLEARANCE

FROM BOTH SIDES

OF FIREPLACE

TO COMBUSTIBLE

1/2” CLEARANCE FROM BACK OF FIREPLACE TO COMBUSTIBLE

Note: Remove cover

plate (if present).

D

E

HEAT-OUT

*Studs labeled “F” are necessary if installing the optional

Arched Gem Stone Kits (BKMS6052, BEMS6052, GRS6052).

**Heat-Out framing is 12 inches wide by 10 inches tall, opposite

of vent framing. Center of Heat-Out framing is 1-1/16 inch

LOWER than the center of the Heat-Out pipe.

12 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

NOTE: PIPES OVERLAP 1-1/4 INCHES

AT EACH JOINT.

Figure 4. DVP-Series Direct Vent Component Specifications (5-inch inner pipe / 8-inch outer pipe)

DVP90ST

12-9/16

11-1/4

7-1/4

1-1/4 TYP

1/2 TYP

8-9/16

DVP36

DVP48

48

24

36

4

6

DVP4

DVP6

12

DVP12

2

MIN.

DVP12A

12-3/16

MAX.

DVP24

9-7/8

45.0

O

10-1/4

DVP45

14-1/4

13

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

Figure 5. Vent System Components and Termination Kits

Step 3. Installing the Vent System

A. Vent System Approvals

Thesemodels are approved touseDVP-series direct vent

pipe components and terminations (see Figures 4 and 5).

Approvedvent system componentsare labeled foridentifi-

cation. This pipe is tested and listed as an approved com-

ponent of the fireplace. The pipe is tested to be run inside

an enclosed wall. There is no requirement for inspection

openingsateach joint within thewall.There is no required

pitch forhorizontal vent runs. NO OTHER VENTING SYS-

TEMS OR COMPONENTS MAY BE USED.

Detailedinstallationinstructions areincludedwith eachvent

termination kit and should be used in conjunction with this

InstallersGuide.

Theflameandemberappearancemayvarybasedonthetype

offuelburnedandtheventingconfigurationused.

Identifying Vent Components

The vent systems installed on this gas fireplace may in-

clude one, two, or three 90°elbow assemblies. The rela-

tionshipsof vertical rise tohorizontalrun in vent configura-

tions using 90° elbows MUST BE strictly adhered to. The

risetorun relationships are showninthe venting drawings

andtables.Refertothediagramson thenextseveralpages.

NOTE: Two 45° elbows may be used in place of one

90° elbow. Rise to run ratios in the vent system must

be followed if 45° elbows are used.

Terminations Kits

HORIZONTAL

TERMINATION

WALLFIRESTOP

90 DEGREE

ELBOW

PIPE LENGTH

CEILING

FIRESTOP

VERTICAL

TERMINATION STORM COLLAR

ROOF FLASHING

SERIES

Î

PVK-80 DVP-TVHW DVP-TRAP

14 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

FLUE

RESTRICTOR

Figure 9

PILOT SHIELD

PILOT

BRACKET

PILOT SHIELD SHOULD BE

CLOSED AND TOUCHING

THE PILOT BRACKET

Figure 10

PILOT SHIELD

BEND PILOT SHIELD UP 3/8”

TO ALLOW AIR FLOW TO

FEED THE PILOT FLAME

Flue Restrictor Instructions

1. Locate the flue restrictors inside the unit to the left of the

controlpanel.There is one each of the 1-1/2” diameter,

1-3/4” diameter and 2” diameter. Use the following table

todeterminewhichrestrictorto usefor theventrun. Place

one restrictor into either the left or right 3” diameter ex-

haust collar as shown.

2. SeeFigure 8for restrictorinstallation.Inserteachrestric-

tor in one of the 3” exhaust collars as shown.

Figure 8. Flue Restrictor

1-3/4”& 2” & 1-1/2”

DIAMETER

Figure 7

FLUE

RESTRICTOR

15’-30’ 30’-40’

NG 1-3/4” 1-1/2”

LP 2” 1-3/4”

VentRun

Vertical

Figure 6.

Straight Up Vertical Venting

STRAIGHT UP

VERTICALVENTING

V (FT.)

40' MAX. (12.4 M)

NOTE: Onvertical venting

configurations install the

verticalbafflefoundinyour

manual bag per the flue

restrictor instructions in

this section.

CAP

V

Pilot Shield Adjustment

When venting this unit with high vertical (8feet ormore)

with very little horizontal the pilot shield will need to be

bent down in the closed position as shown in Figure 9.

Í

Note: When venting this unit with long horizontal runs

and/or multiple elbows, the pilot shield will need to be in

the opened position as in Figure 10.

Í

15

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

VENTING WITH ONE (1) 90° ELBOW

V (FT.) H (FT.)

2' MIN. (.609m) 3' MAX. (.912m)

2.5' MIN. (.762m) 6' MAX. (1.82m)

3.5' MIN. (1.06m) 9' MAX. (2.73m)

4.5' MIN. (1.37m) 12' MAX. (3.64m)

5.5' MIN. (1.67m) 15' MAX. (4.55m)

6.5' MIN. (1.98m) 18' MAX. (5.46m)

7.5' MIN. (2.28m) 21' MAX. (6.37m)

8.5' MIN. (2.59m) 24' MAX. (7.28m)

V = 40’ MAX. (12.2m)

V+H = 64’ MAX. (19.5m) H = 24' MAX. (7.28m)

Figure 11.

Venting with One 90° Elbow

NOTE: Musthave an18”

minimumverticalvent

beforeattaching a90o

elbow to the unit.

H

V

Figure 12. Venting with Two 90° Elbows

VFT. H + H1(FT.)

2' MIN. (.609m) 3´ MAX. (.912m)

2.5' MIN. (.762m) 6´ MAX. (1.82m)

3.5' MIN. (1.06m) 9’ MAX. (2.73m)

4.5' MIN. (1.37m) 12´MAX.(3.64m)

V+H+H1=64' MAX.(19.5m)

H+H

1

= 24´MAX.(7.3m)

V+V1+H=64'MAX.(19.5m)

VENTING WITH

TWO (2) 90o

ELBOWS

H

V

V

V

1

H

H

1

H

V

16 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

VENTING WITH THREE (3) 90° ELBOWS

V (FT.) H (FT.)

2' MIN. (.609m) 3' MAX. (.912m)

2.5' MIN. (.762m) 6' MAX. (1.82m)

3.5' MIN. (1.06m) 9' MAX. (2.73m)

4.5' MIN. (1.37m) 12'MAX.(3.64m)

NOTE: H + H1= 24' MAX. (7.28m)

V + V1 + H + H1= 64' MAX. (19.5m)

V (FT.) H + H1 (FT.)

2' MIN. (.609m) 3' MAX.(.912m)

2.5' MIN.(.762m) 6' MAX.(1.82m)

3.5' MIN.(1.06m) 9' MAX.(2.73m)

4.5' MIN.(1.37m) 12' MAX.(3.64m)

H+H1= 20' MAX. (6.2m)

NOTE:V+V1+H+H1=64'MAX.(19.5m)

Figure 13. Venting with three 90° elbows

V

H

H

1

V

1

V

H

H

1

V

1

17

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

B. Installing Vent Components

Venting Out the Top Vent

The glass must be taken off again for positioning the logs

whentheunit isfinally installedinplace andfinishedaround

it. Re-install the glass door.Attach vent system to the top

starting collars.

1. Attach the First Vent Component to the

Starting Collars

To attach the first vent component to the starting collars of

thefireplace:

• Make sure that the fiberglass rope ring supplied in the

manualbag seals betweenthe first 8inch (203mm) vent

componentand theouter fireplacewrap(see Figure14).

Referto CinchPipe (DVP)andTerminationCap installation

instructions.

Figure 14. Fiberglass Rope Ring

FIBERGLASS ROPE

RING

FIRST VENT COMPONENT

OUTER

WRAP

2. ContinueAdding Vent Components

• Continueadding ventcomponents snap-locking,locking

eachsucceedingcomponent into place.

• Ensurethat eachsucceeding ventcomponent issecure-

ly fitted and locked into the preceding component in the

ventsystem.Securing pipe sections witha maximum of

two screws is recommended.

• 90° elbows may be installed and rotated to any point

aroundthe preceding component’svertical axis. Ifan el-

bow does not end up in a locked position with the pre-

ceding component, attach with a minimum of two (2)

sheet metal screws.

3. Install Support Brackets

Refer to Cinch Pipe and Termination Cap installation

instructions.

!

WARNING: ENSURE THATTHE FIBERGLASS

GASKET SUPPLIED WITH THE FIREPLACE

SEALSBETWEEN THE FIRSTVENT COMPONENT

ANDTHE OUTERFIREPLACE WRAP.

18 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

4. Install Firestops

For Horizontal Runs - Firestops are REQUIRED on both

sidesof a combustiblewall through whichthe vent passes.

NOTE: Model DVP-TRAP does not need an exterior fir-

estop on an exterior combustible wall.

To install firestops for horizontal runs that pass through

eitherinterioror exterior walls:

• Cuta10-inchby12-inch (254mmX305mm)holethrough

the wall.

NOTE: The center of the hole is one (1) inch (25.4mm)

above the center of the horizontal vent pipe.

• Position the firestops on both sides of the hole previ-

ously cut and secure the firestops with nails or screws.

• The heat shields of the firestops MUST BE placed to-

wards the top of the hole.

• Continuethe vent run throughthefirestops.

Figure 15. 10" x 12" Hole and Vent Pipe

Figure 16. Heat Shield, Interior & Exterior Firestops

TRIM HEAT

SHIELD IF TOO

LONG, ADD TO

SHIELD IF TOO

SHORT

EXTERIOR

FIRESTOP

INTERIOR

FIRESTOP

HEAT SHIELD

NOTE: There must be NO INSULATION or other

combustibles inside the framed firestop opening.

10"

12"

INTERIOR

WALL SHIELD

For Vertical Runs - One ceiling firestop is REQUIRED at

the hole in each ceiling through which the vent passes.

Toinstallfirestopsforvertical runsthatpassthroughceilings:

• Positiona plumb bob directlyover the center ofthe verti-

calvent component.

• Mark the ceiling to establish the centerpoint of the vent.

• Drill a hole or drive a nail through this centerpoint.

• Check the floor above for any obstructions, such as wir-

ingor plumbing runs.

• Reposition the fireplace and vent system, if necessary,

to accommodate the ceiling joists and/or obstructions.

• Cutan10-inch X10-inch(254mmX254mm)holethrough

theceiling,using the centerpoint previously marked.

• Framethe hole withframing lumber thesame sizeasthe

ceiling joists.

Figure 18. Ceiling Firestop (Ceiling Side)

If the area above the ceiling is NOT an attic, position and

securetheceilingfirestopon theceilingsideofthepreviously

cutandframed hole.

Figure 17. 10" x 10" Hole & New Framing Members

JOIST

CEILING FIRESTOP

CEILING

NAILS (4 REQUIRED)

CEILING

NEW

FRAMING

MEMBERS

EXISTING CEILING

JOISTS

CHIMNEY

HOLE

10" (254mm)

10" (254mm)

NOTE: There must be NO INSULATION or other

combustibles inside the framed firestop opening.

19

Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

!

C. Vent Termination

For Horizontal Terminations - To attach and secure the

terminationto the last sectionof horizontal ventrefer to the

Cinch Pipe andTermination Cap installation instructions.

• Pushandsnap-lock the ends asdescribed at the begin-

ning of the Installing Vent Components section.

• Thetermination kitshouldpassthroughthe wallfirestops

fromtheexterior of the building.

• Adjustthe termination cap toits final exteriorpositionon

thebuilding.

WARNING: THETERMINATIONCAPMUSTBE

POSITIONEDSOTHAT THEARROW IS POINT-

ING UP.

For trapezoidal cap termination kits:

• Usingscrews secure thecapto the exteriorwall through

the flanges in the cap.

Figure 20. Trapezoid Termination Cap

!

WARNING: VENTING TERMINALS SHALL

NOT BE RECESSED INTO AWALL OR SID-

ING. VENT TERMINATION CLEARANCES MUST

BE FOLLOWED TO AVOID FIRE DANGER. SEE

VENTTERMINATION MINIMUM CLEARANCES DI-

AGRAM ON THE FOLLOWING PAGE.

7 1/4”

(184mm)

Ifthe areaabovethe ceilingIS an attic,position and secure

thefirestopon top of thepreviouslyframed hole.

NOTE: Keep insulation away from the vent pipe at least

1 inch (25mm).

Figure 19. Attic Firestop

CEILING

CEILING FIRESTOP

RAFTER

NAILS (4 REQUIRED)

20 Heat & Glo • GEM42 • 371-900 Rev. N • 2/05

V=VENT TERMINAL X=AIR SUPPLYINLET =AREAWHERETERMINALISNOTPERMITTED

Figure 21. Vent Termination Minimum Clearances

A = 12" ....................... clearances above grade, veran-

da, porch, deck or balcony

B = 12" ....................... clearances to window or door

that may be opened, or to per-

manently closed window.

D* = 18" ....................... vertical clearance to unventilat-

ed soffit or to ventilated soffit lo-

cated above the terminal

*30” ...................... for vinyl clad soffits and below

electrical service

F = 9" ........................ clearance to outside corner

G = 6" ......................... clearance to inside corner

H = 3 ft. (Canada) ...... not to be installed above a gas

meter/regulator assembly within

3feet(90cm)horizontally from the

center-line of the regulator

I = 3ft.(U.S.A.)

6 ft. (Canada) ...... clearance to gas service regu-

lator vent outlet

J = 9"(U.S.A.)

12" (Canada) ........ clearance to non-mechanical air

supply inlet to building or the

combustion air inlet to any other

appliance

K = 3ft.(U.S.A.)

6 ft. (Canada) ......... clearance to a mechanical

air supply inlet

L** = 7 ft.......................... clearance above paved

sidewalk or a paved driveway

located on public property

M*** = 18" ......................... clearance under veranda,

porch, dec, balcony or over-

hang

42” ......................... vinyl

N = 6” ........................... non-vinyl sidewalls

12” ......................... vinyl sidewalls

P = 8ft.

CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE

INSTALLED.

** a vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings

and serves both dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on

a minimum of 2 sides beneath the floor, meets Note 2.

NOTE 1: On private property where termination is less than 7 feet

above a sidewalk, driveway, deck, porch, veranda or balcony, use of

a listed cap shield is suggested.

NOTE 2: Termination in an alcove space (spaces open only on one side

and with an overhang) are permitted with the dimensions specified for

vinyl or non-vinyl siding and soffits. 1. There must be 3 feet minimum

between termination caps. 2. All mechanical air intakes within 10 feet

of a termination cap must be a minimum of 3 feet below the termination

cap. 3. All gravity air intakes within 3 feet of a termination cap must be

a minimum of 1 foot below the termination cap.

(See Note 1)

(See Note 1)

(See Note 2)

S = 6" .......................... clearance from sides of elec-

trical service

T = 12"......................... clearance above electrical

service

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

QMIN RMAX

1 cap 3 feet 2 x Q ACTUAL

2 caps 6 feet 1 x Q ACTUAL

3 caps 9 feet 2/3 x Q ACTUAL

4 caps 12 feet 1/2 x Q ACTUAL

QMIN = # termination caps x 3 RMAX = (2 / # termination caps) x QACTUAL

(See Note 5)

(See Note 5)

Electrical

Service

V

S

VS

V

T

D*

V

NOTE 3: Local codes or regulations may require different

clearances.

NOTE 4: Termination caps may be hot. Consider their proximity to

doors or other traffic areas.

NOTE 5: Location of the vent termination must not interfere with

access to the electrical service.

WARNING: In the U.S: Vent system termination is NOT permitted

in screened porches. You must follow side wall, overhang and

ground clearances as stated in the instructions.

In Canada: Vent system termination is NOT permitted in screened

porches. Vent system termination is permitted in porch areas

with two or more sides open. You must follow all side walls,

overhang and ground clearances as stated in the instructions.

Heat & Glo assumes no responsibility for the improper perfor-

mance of the fireplace when the venting system does not meet

these requirements.

DE

B

L

v

v

v

v

v

v

v

v

BB

AH

M

X

J or K

I

A

G

F

U.S.

(3 FT)

B

MN

P

R

Q

Table of contents

Other Heat & Glo LifeStyle Gas Heater manuals

Popular Gas Heater manuals by other brands

Desa

Desa Amity OWNER'S OPERATION AND INSTALLATION MANUAL

Powerfix Profi

Powerfix Profi PGH 17 A1 Operation and safety notes

Comfort Glow

Comfort Glow CGS155 manual

Majestic

Majestic 18VL Installation and operating instructions

Pakole

Pakole ZENIT 80+ Series user manual

Strend Pro

Strend Pro BGA1401-50T instruction manual

L.B. White

L.B. White AD100 owner's manual

Vermont Castings

Vermont Castings INDVRCBSB Installation and operating instructions

Desa

Desa 30 OWNER'S OPERATION AND INSTALLATION MANUAL

Aletra

Aletra ATLX 55 Installation and maintenance manual

Travis Industries

Travis Industries Avalon 700 NG troubleshooting guide

Hearth & Home

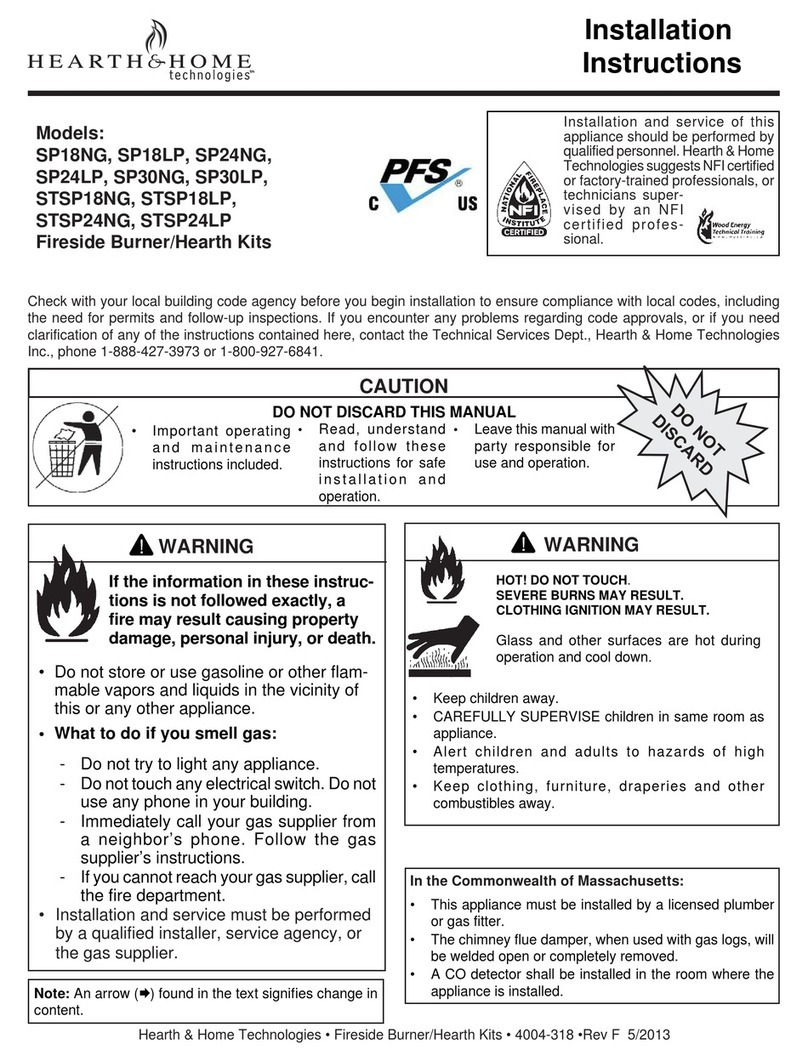

Hearth & Home SP18NG installation instructions